Patents

Literature

68 results about "Lead preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Homeopathic drug

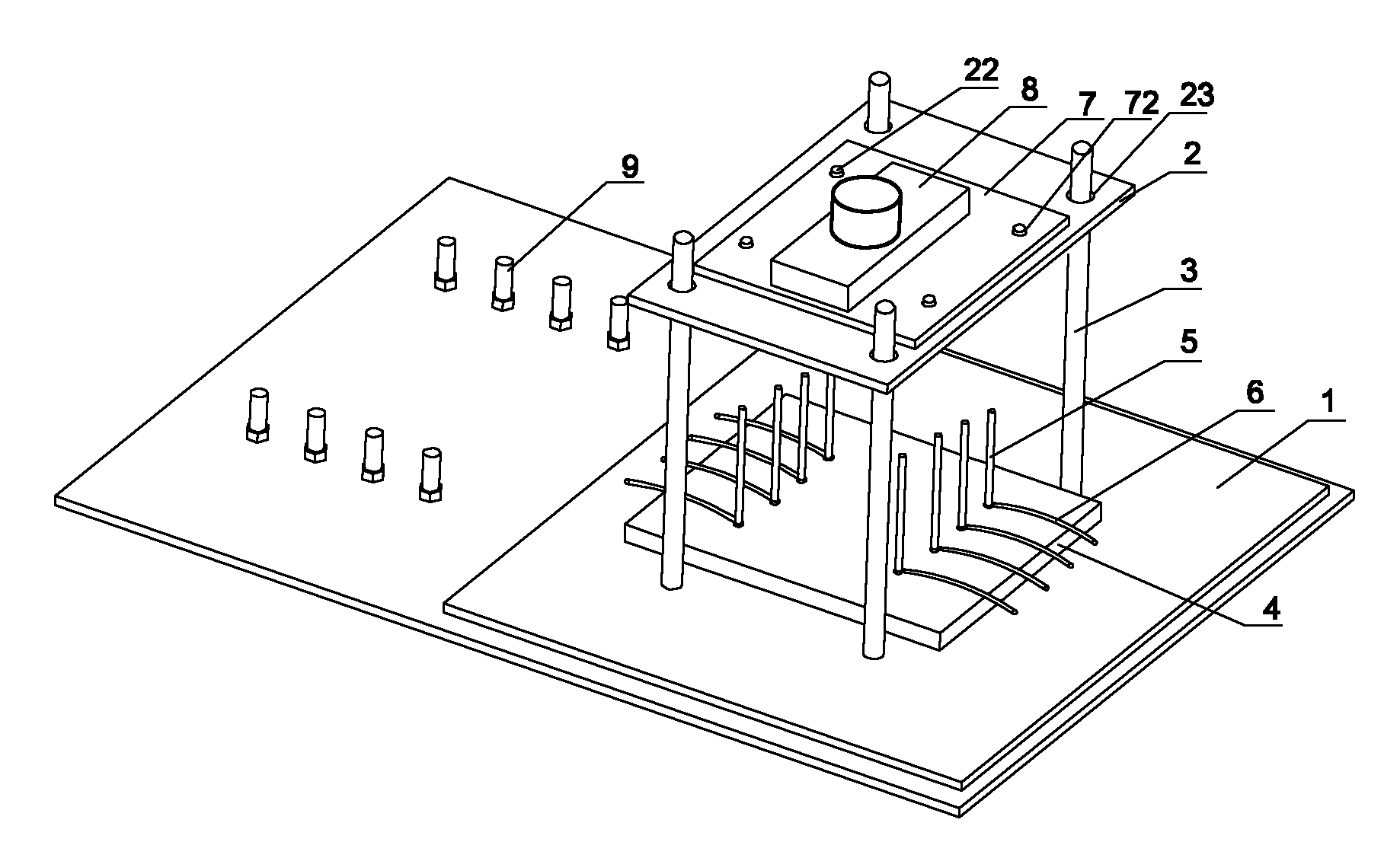

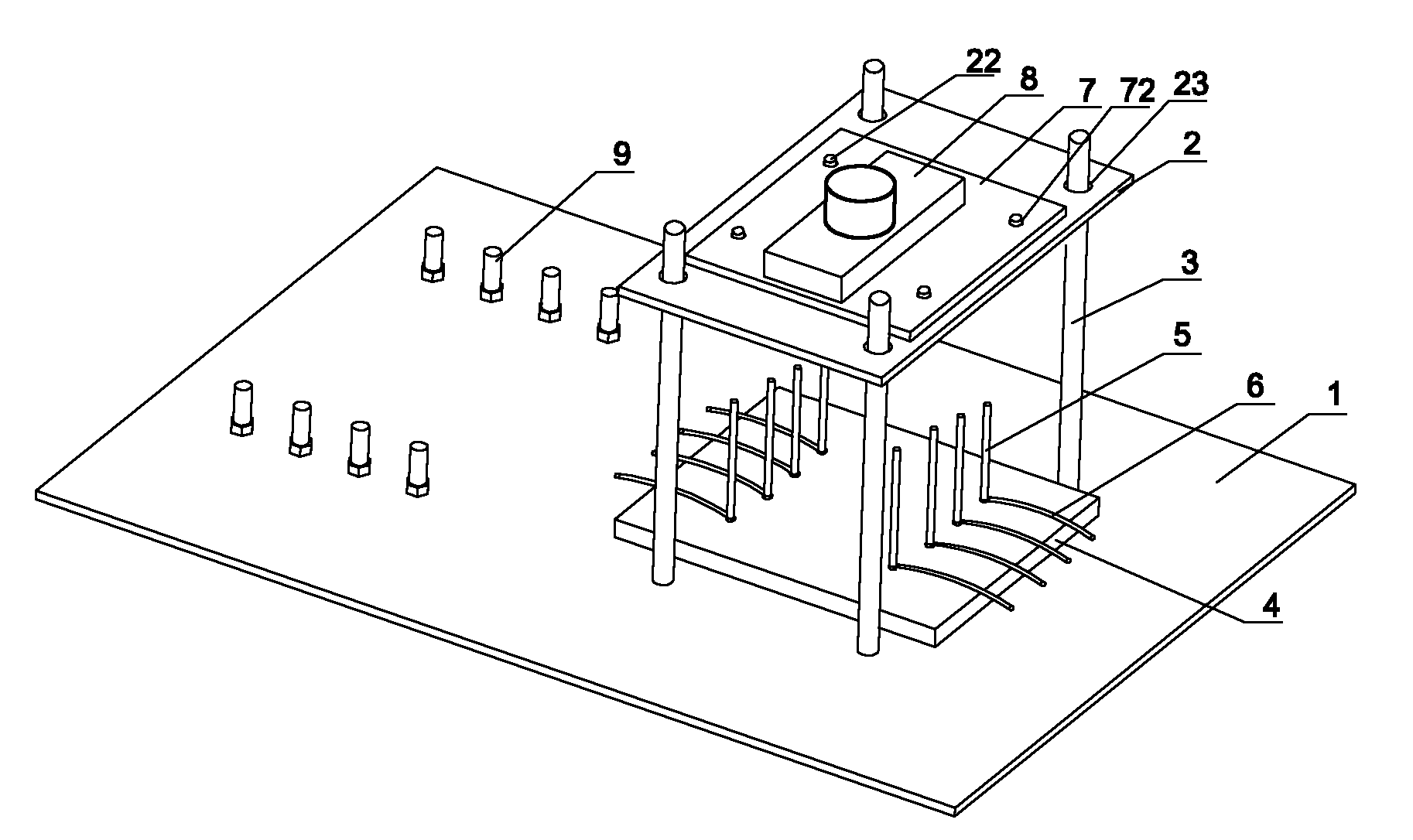

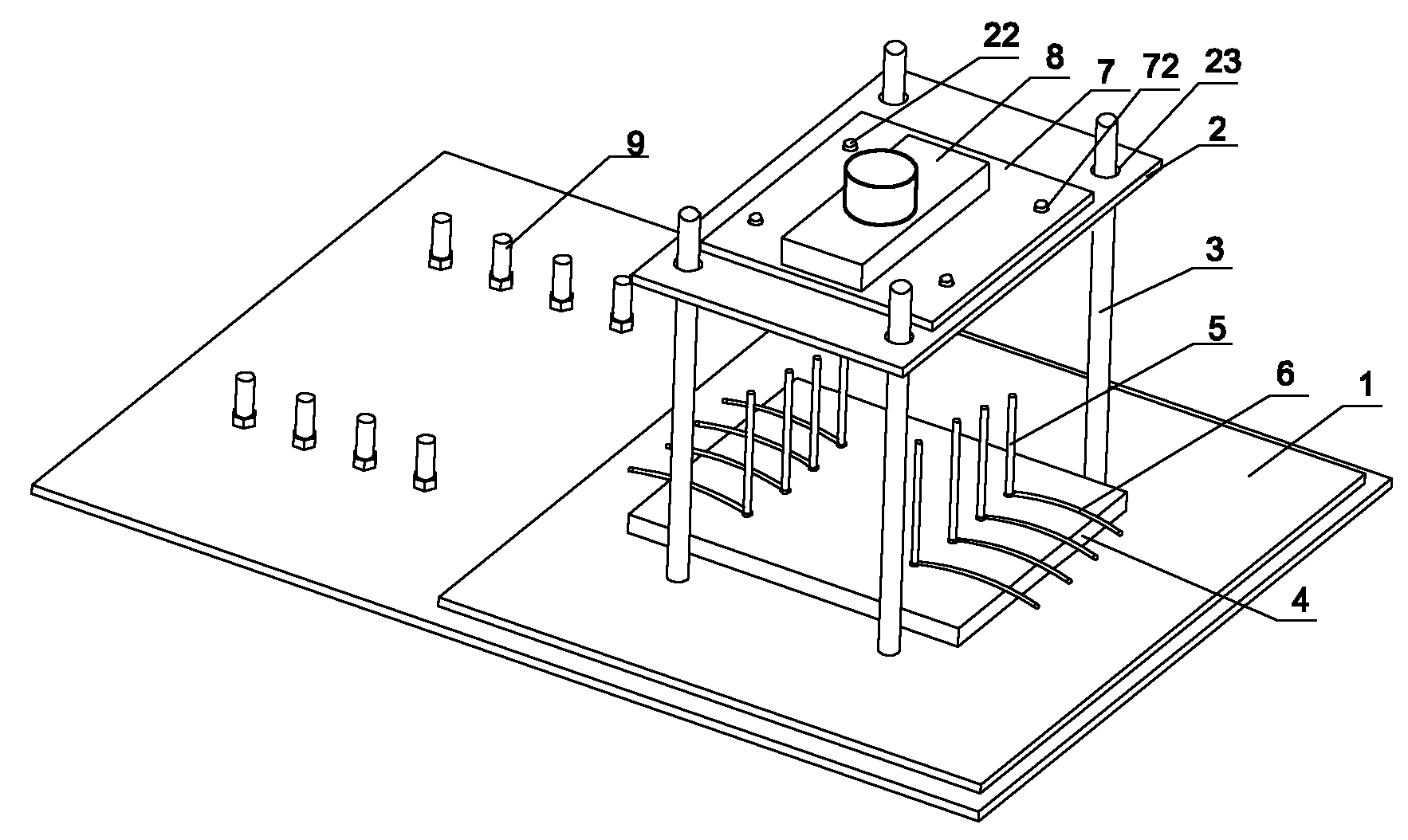

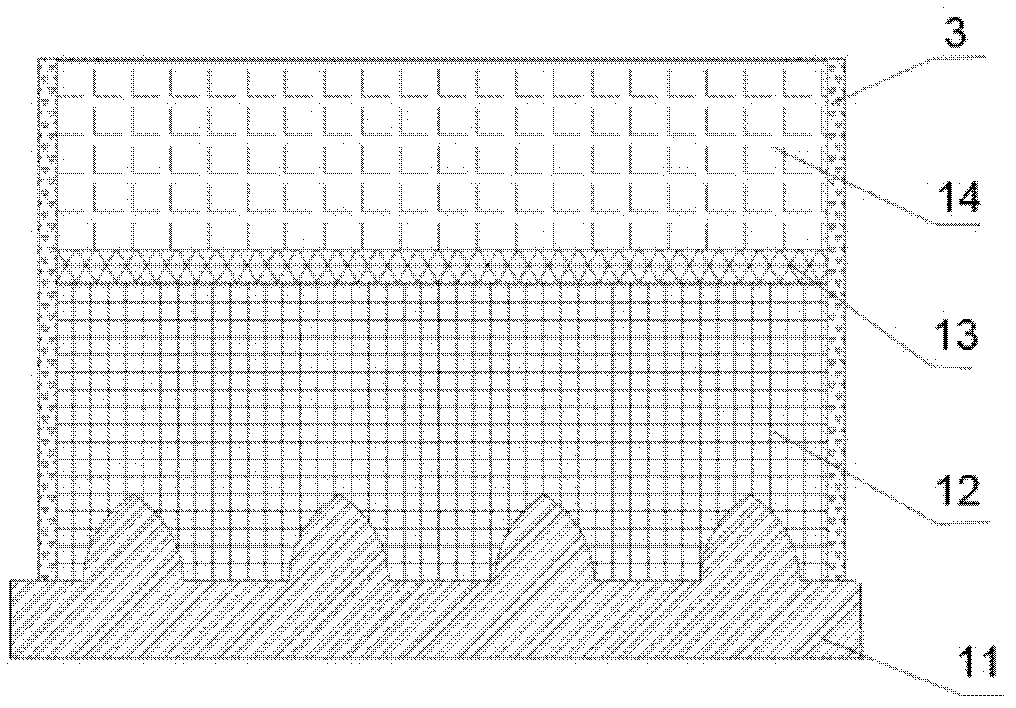

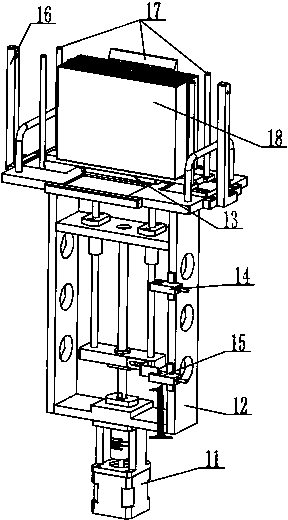

PCB (Printed Circuit Board) insulation resistance testing jig

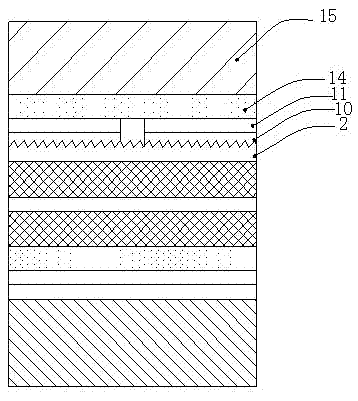

InactiveCN102062789ADoes not affect insulationAvoid high temperature shockResistance/reactance/impedenceMeasurement instrument housingTest efficiencyElectricity

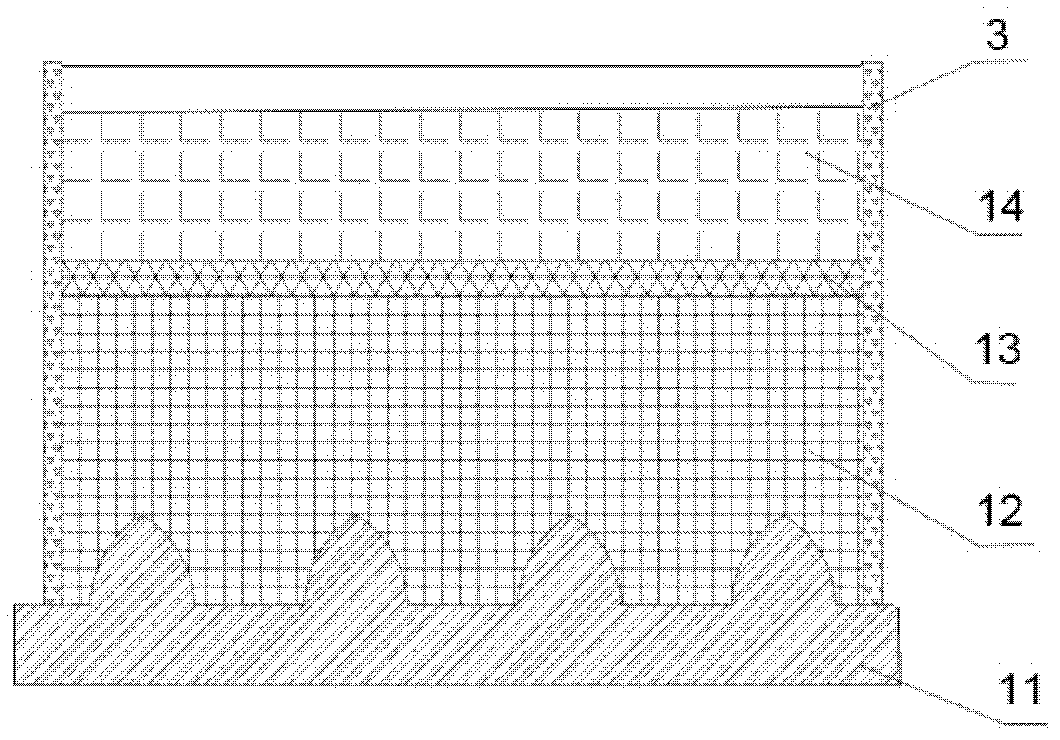

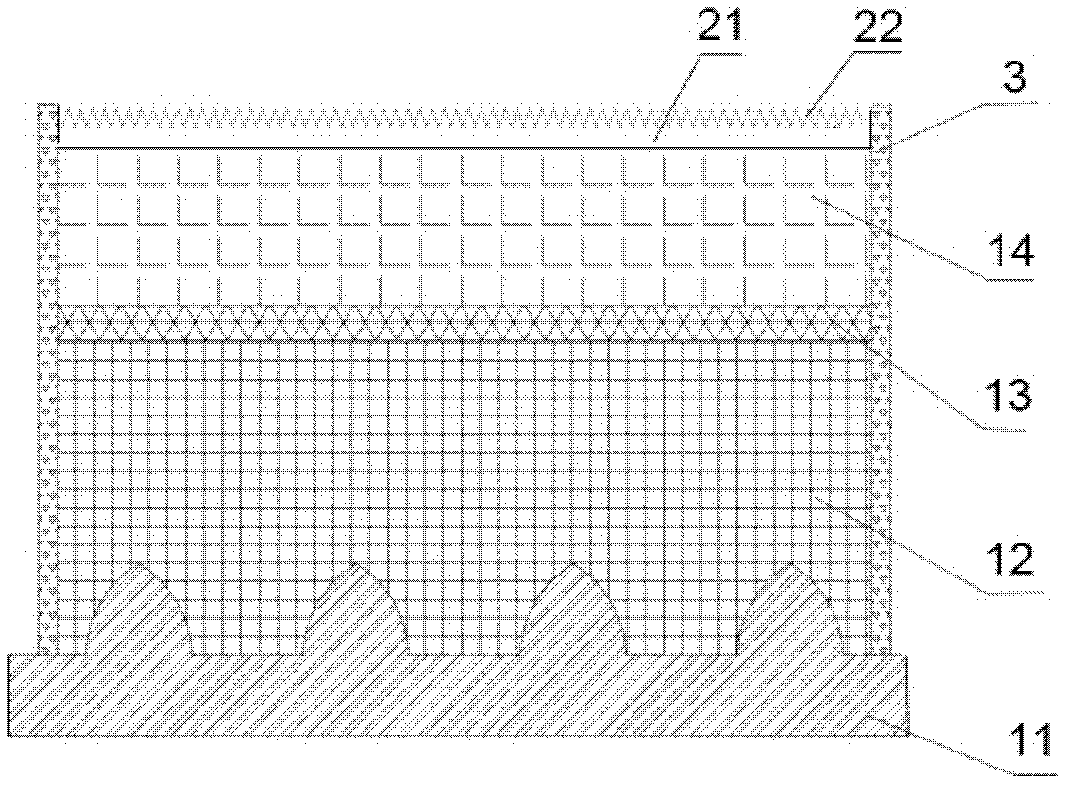

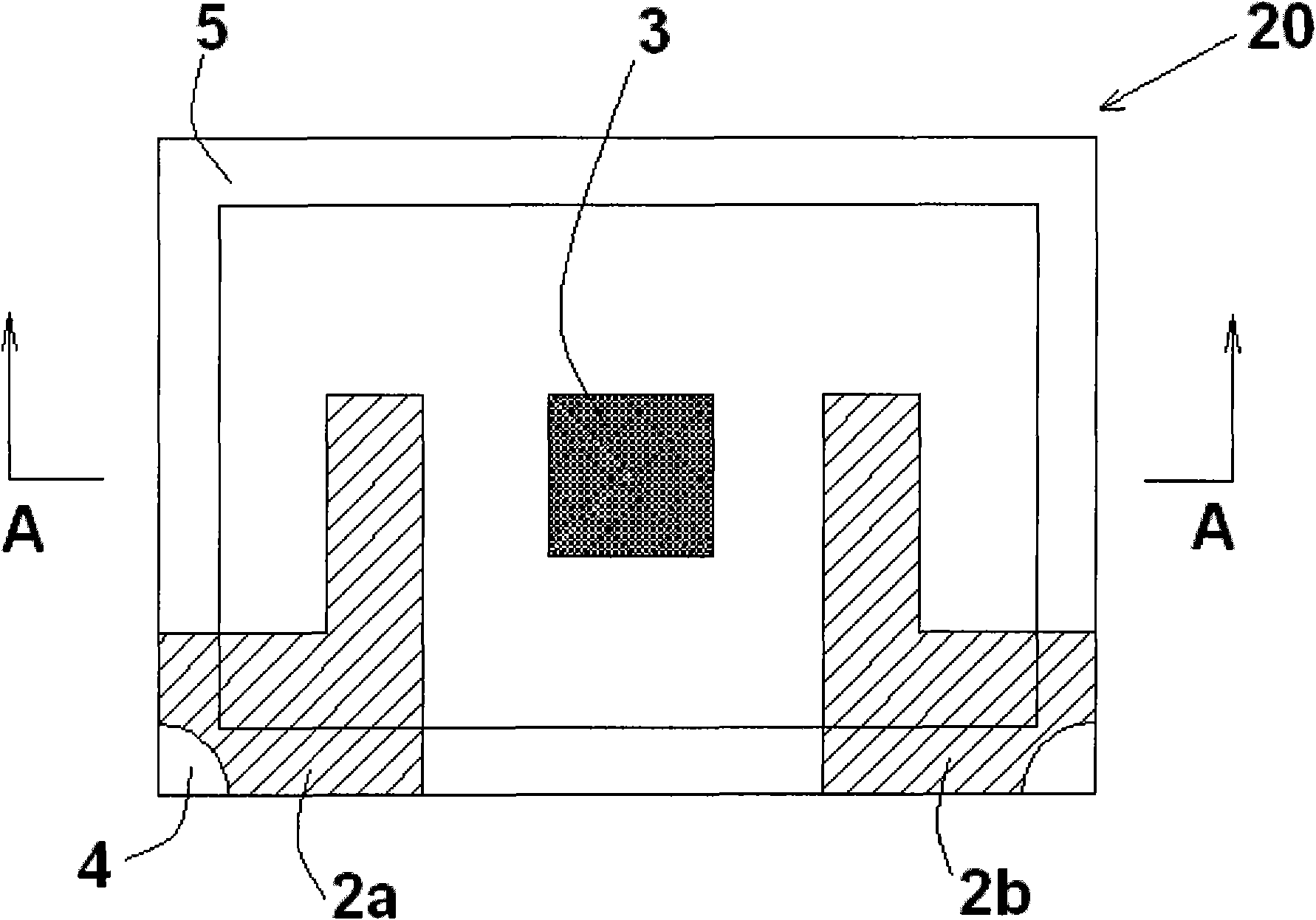

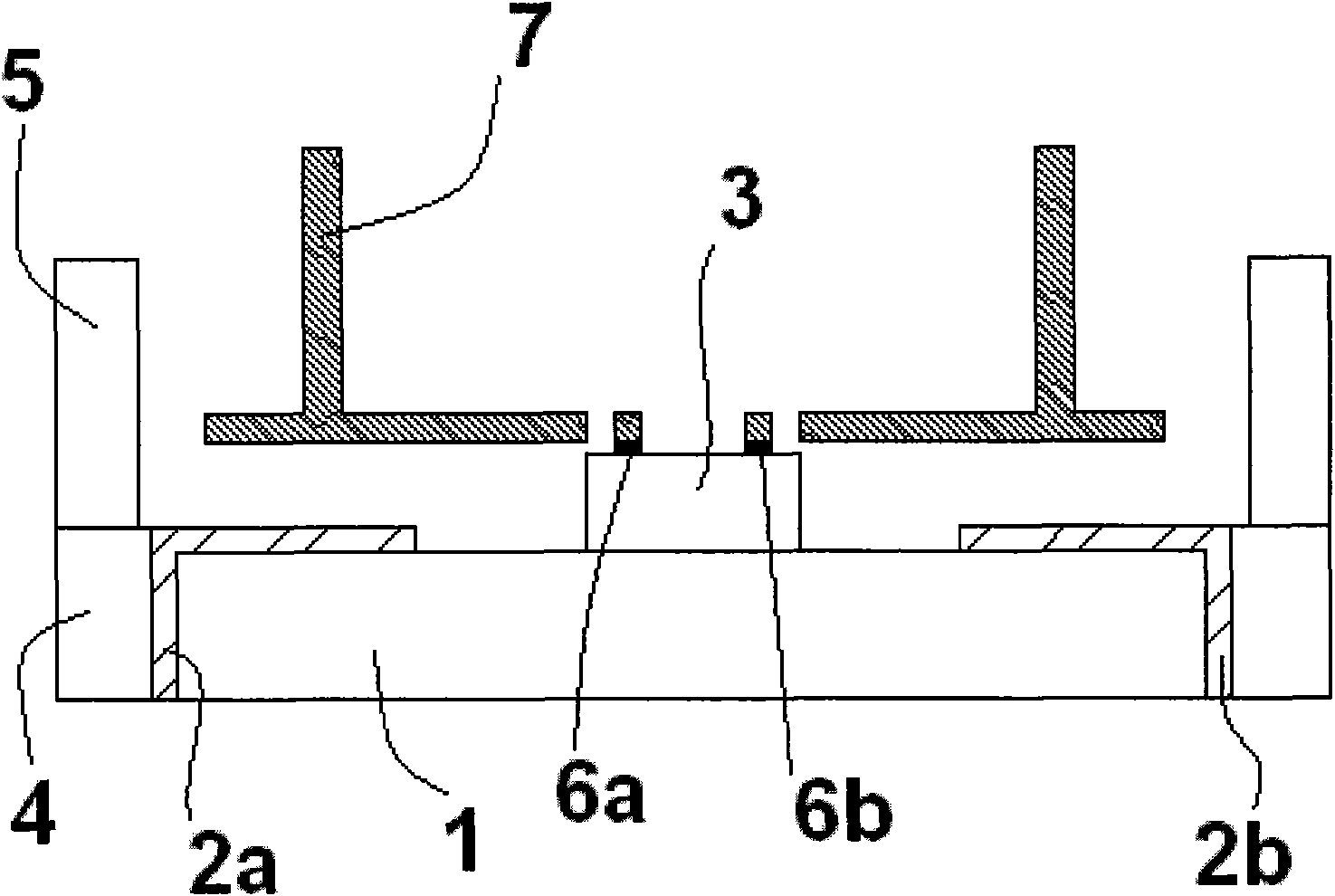

The invention relates to a testing jig, in particular to a PCB (Printed Circuit Board) insulation resistance testing jig, comprising a base, a PCB placing table, guide posts, test pins, a test pin table and test leads. The guide posts and the PCB placing table or the test pin table are fixed on the base, the PCB placing table is provided with a PCB locating structure, the test pins are arranged on the test pin table, the PCB placing table or the test pin table is provided with guiding holes matched with the guide posts, and the test leads electrically connect the guide posts and the test pins. In the invention, the PCB insulation resistance testing jig is a special jig, which avoids the steps of lead preparation, lead welding, soldering flux cleaning and the like in the prior art, improves the test efficiency, and prevents the high-temperature impingement on the PCB and the poor influence of the soldering flux on the tested results in the test lead welding process.

Owner:SHENNAN CIRCUITS

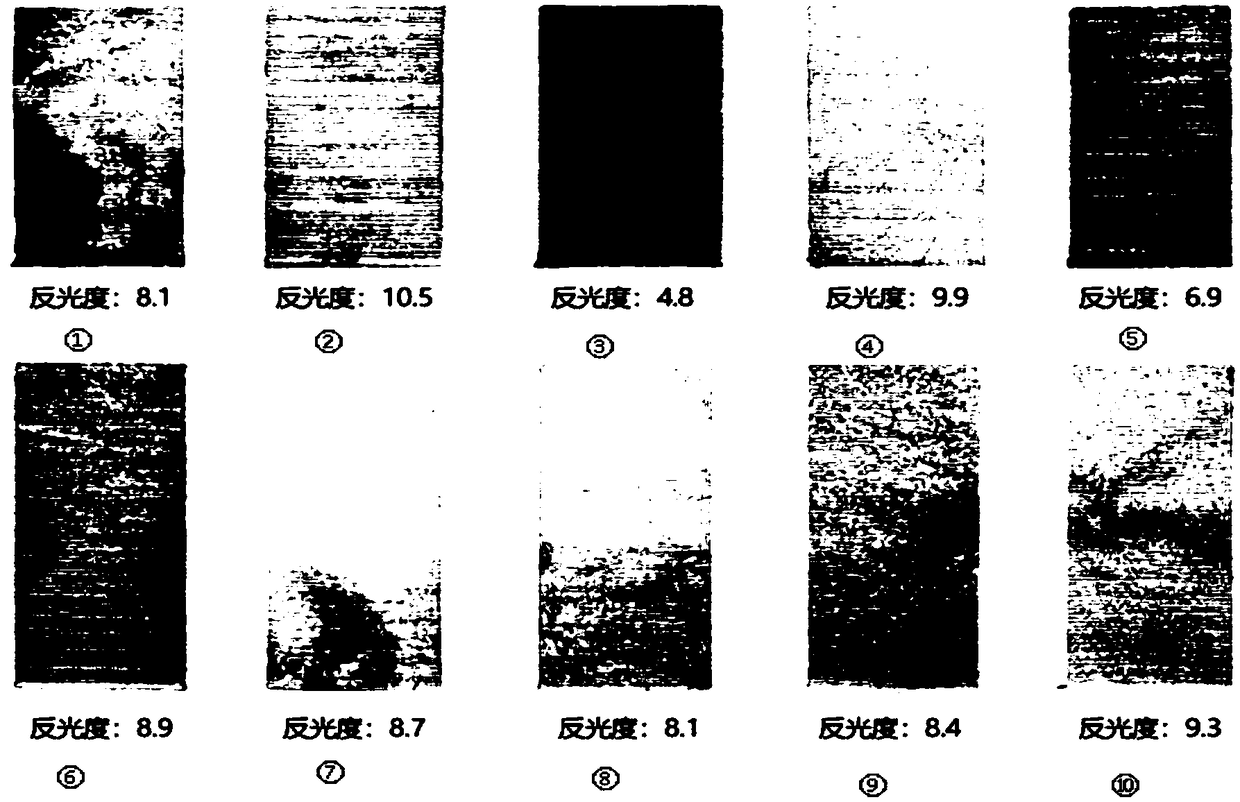

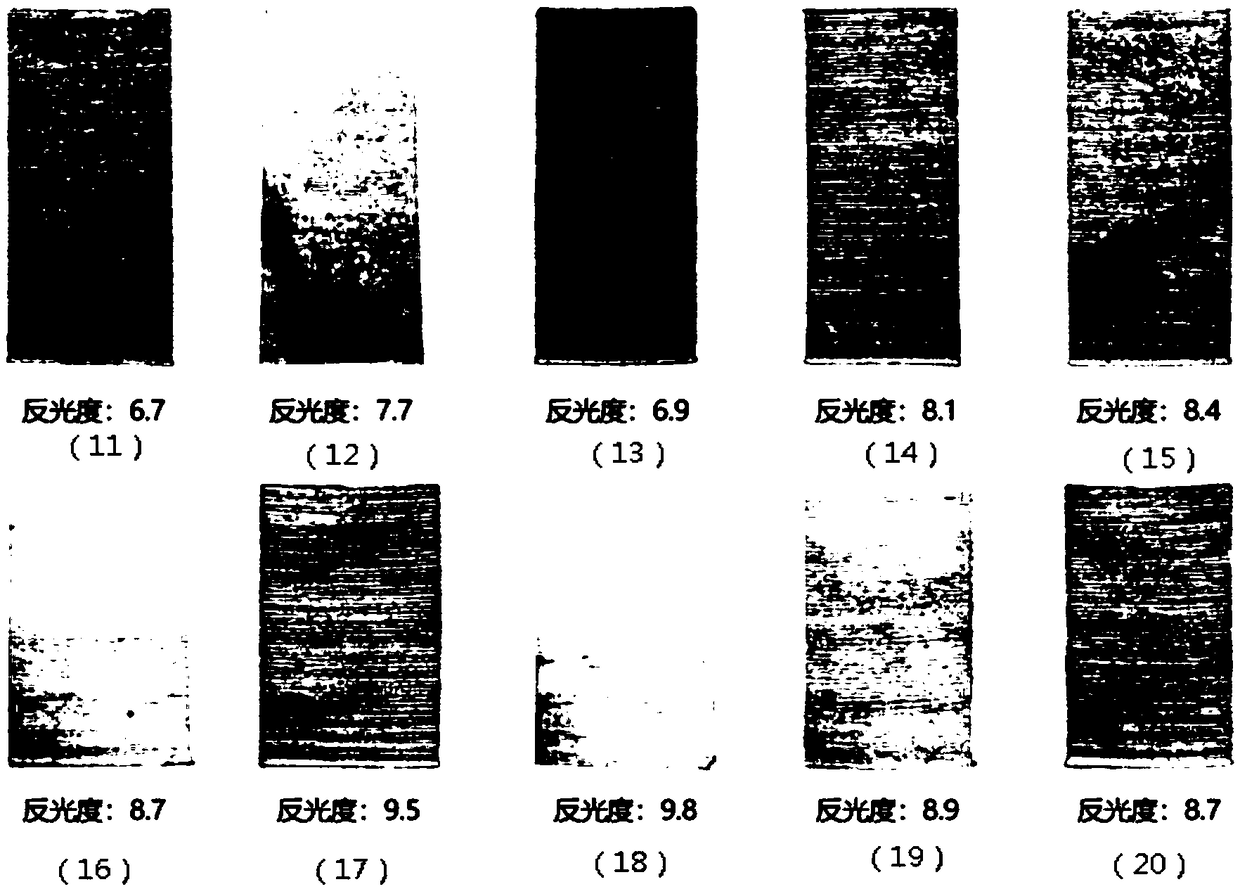

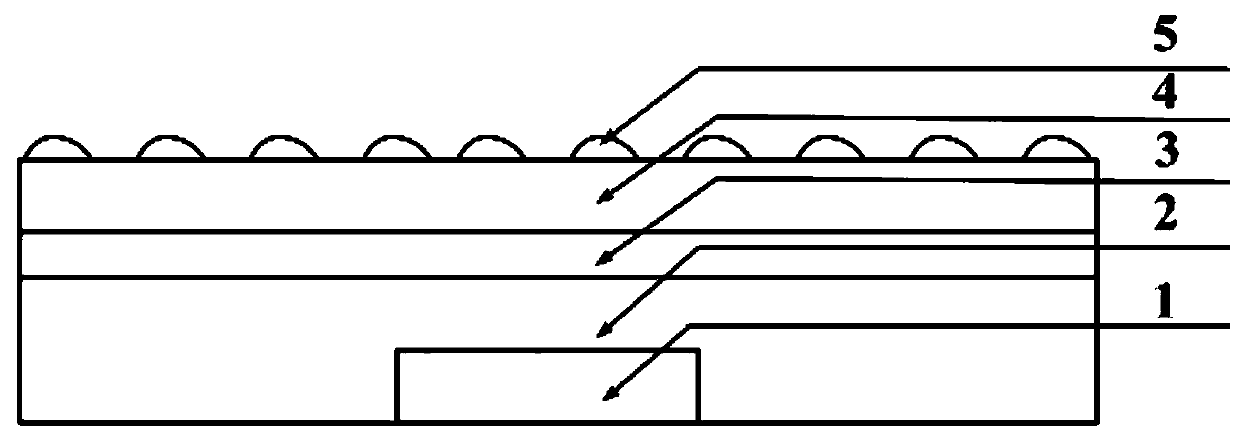

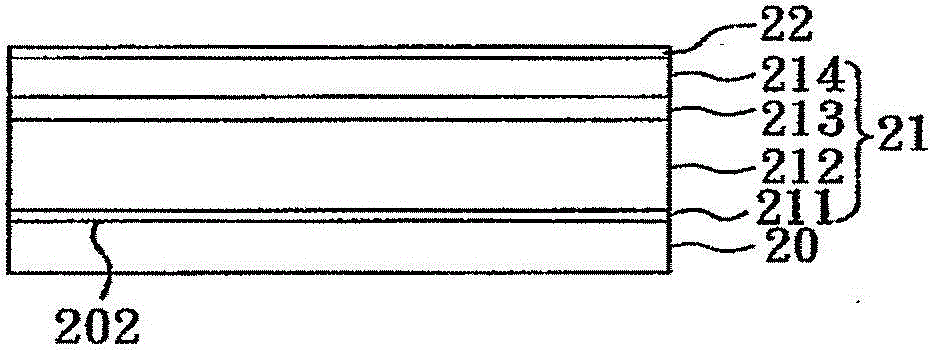

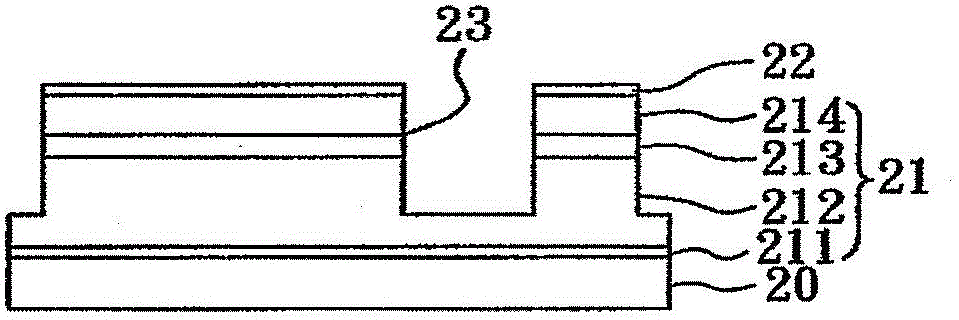

High-power GaN-based vertical structure LED with light extraction microstructure and preparation method thereof

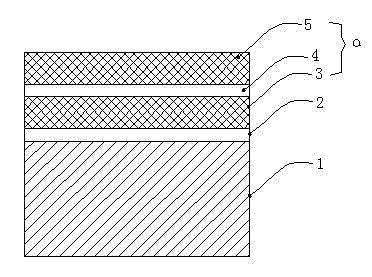

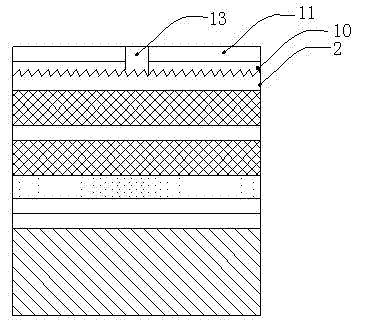

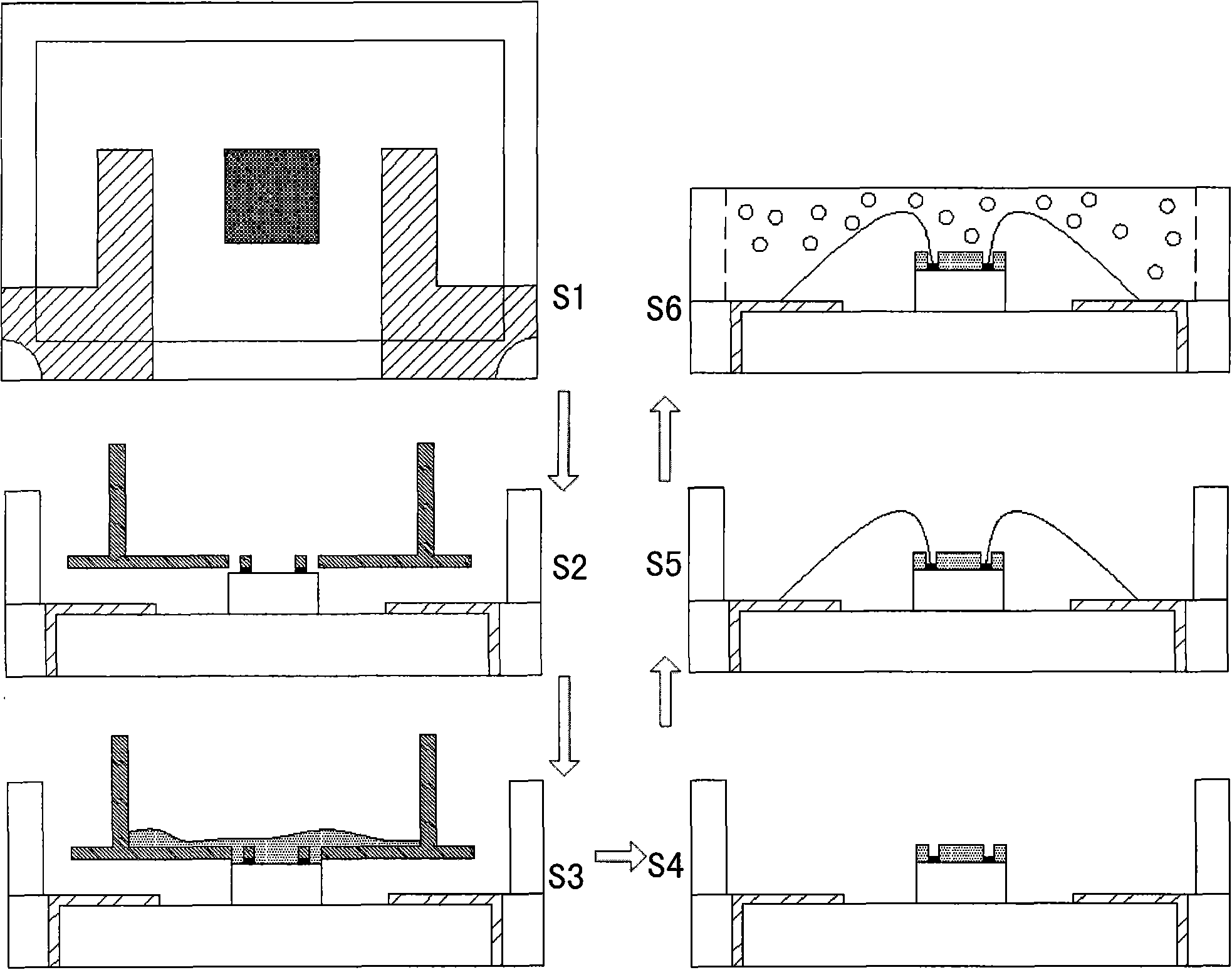

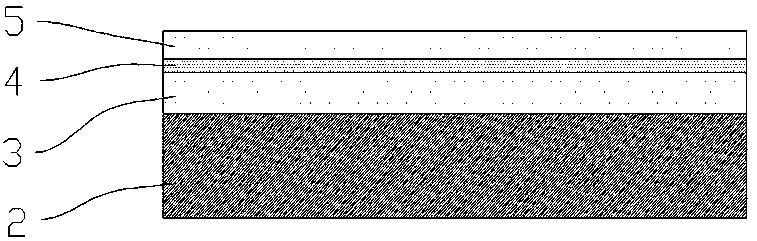

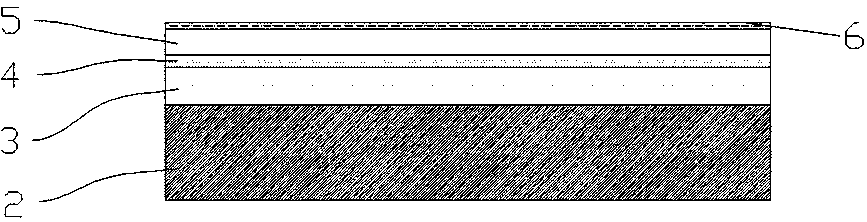

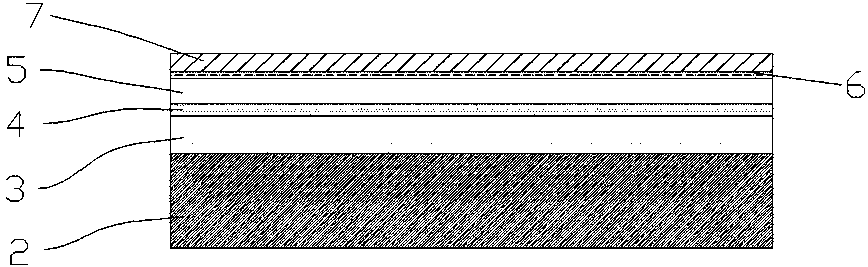

The invention discloses a high-power GaN-based vertical structure LED with a light extraction microstructure and a preparation method thereof. According to the invention, the LED prepared through the preparation method is provided with a light-emitting surface microstructure transferred through a laser-stripping sapphire pattern substrate and complemented with patterns positioned on the surface of the laser-stripping sapphire pattern substrate; a means which has great high repetitiveness and controls the light-emitting surface microstructure is provided because the morphology of the light-emitting surface microstructure of the laser-stripping sapphire pattern substrate can be controlled through a process means; besides, nanometer-level coarsing is additionally carried out on the local area of a light-emitting surface, therefore the morphology of the light-emitting surface is further optimized; a mirror surface metallic reflection layer is changed into a nanometer-level rough grain metallic diffuse reflection layer during the LED preparation of the traditional process, so that the diffuse reflection and scattering effect is enhanced, the collocation of the reflection layer and the light-emitting surface microstructure is optimized, and the extraction efficiency of light inside the LED is furthest increased. The preparation method disclosed by the invention is simple in process and high in repeatability and can be used for large-scale industrial production.

Owner:EPILIGHT TECH

LED preparation method for improving light-emitting efficiency

The invention relates to a light-emitting diode (LED) preparation method for improving light-emitting efficiency and relates to a preparation process for a semiconductor luminescent device. The method aims to improve the light-emitting efficiency and the yield of products. In the technical scheme, the preparation method comprises the following steps of: allowing an epitaxy membrane to grow on a sapphire substrate, and performing vapor deposition and alloying on a transparent conducting layer to grow a SiO2 protective layer; coating mucilage glue on the SiO2 protective layer, and curing with a temporary support baseplate; stripping the sapphire substrate by laser; coarsening the N surface of the stripped epitaxy membrane; manufacturing a transparent bonding material layer capable of being cured on the N surface of the stripped epitaxy membrane, and curing the bonding material layer; preparing a reflective layer, and curing with the bonding material layer at high temperature; manufacturing an N electrode in a groove formed on a layer on the coarsened surface; evaporating a bonding metal layer, and performing eutectic bonding with a conducting and heat-conducting perpetual baseplate; and removing the temporary support baseplate and the SiO2 protective layer, and manufacturing a P electrode on the transparent conducting layer.

Owner:LATTICE POWER (JIANGXI) CORP

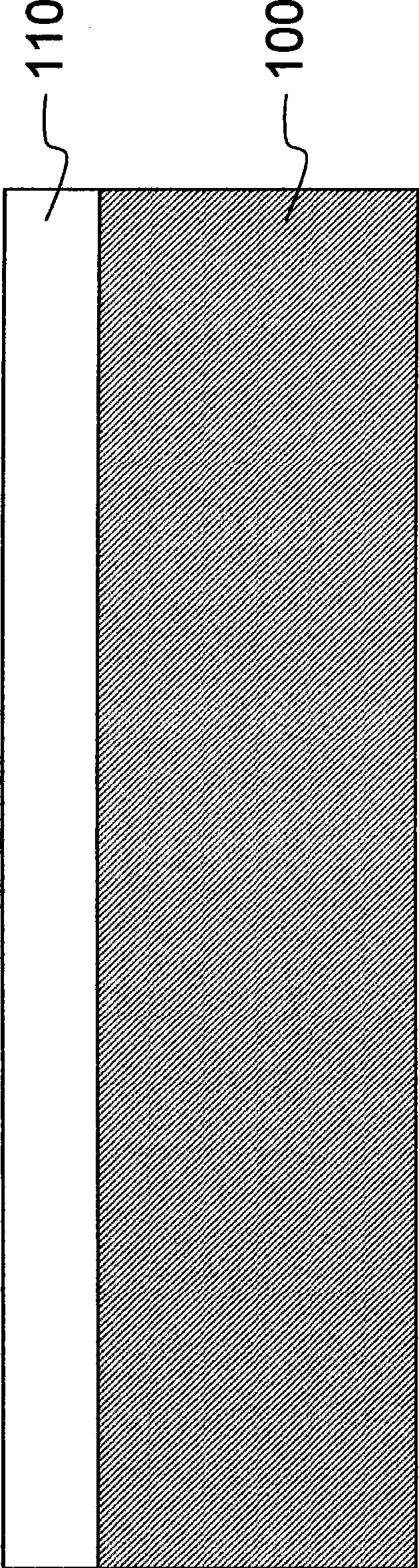

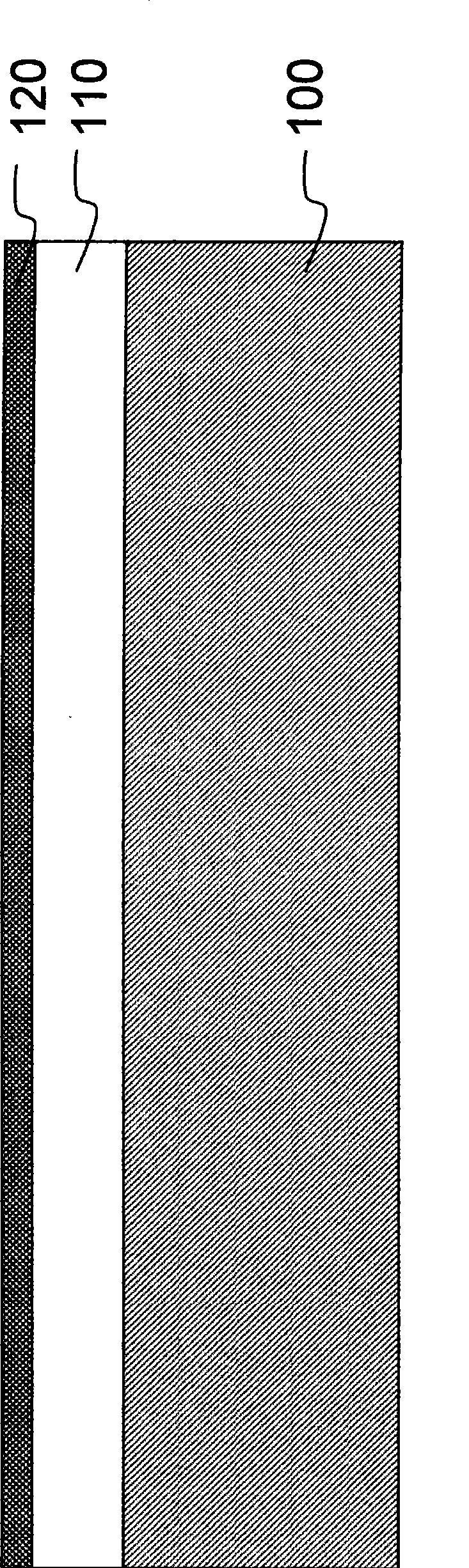

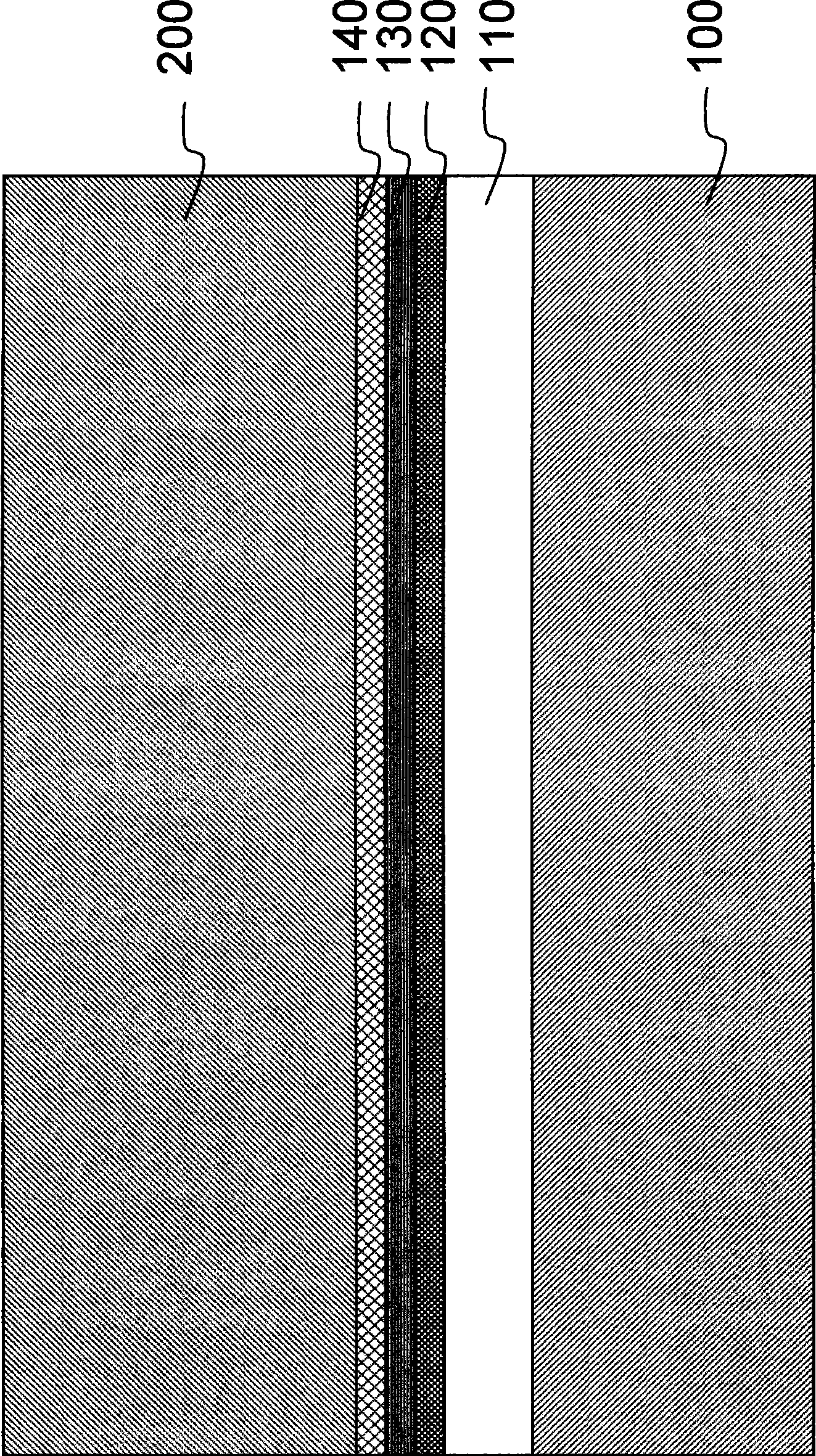

Method for preparing film GaN LED based on plane bonding and temporality substrate transfer technology

ActiveCN101465401AAchieve absolute separationReduce generationSemiconductor devicesOptoelectronicsLead preparation

The invention discloses a film GaN LED preparation method based on the plane bonding and temporary substrate transfer technology. In the method, a plane is firstly bonded on a support substrate and then unit devices are separated, so that the gapless seaming between the GaN LED and the support substrate can be realized; then the absolute separation among all the GaN LED devices is achieved so as to reduce the production and extension of the cracks in the laser stripping process; through the temporary substrate, chip manufacturing is carried out after the laser stripping to ensure high yield rate of GaN LED film production when the sapphire substrate is removed after large-area laser stripping.

Owner:XIAMEN SANAN OPTOELECTRONICS TECH CO LTD

Fully-inorganic quantum dot backlight LED preparation method

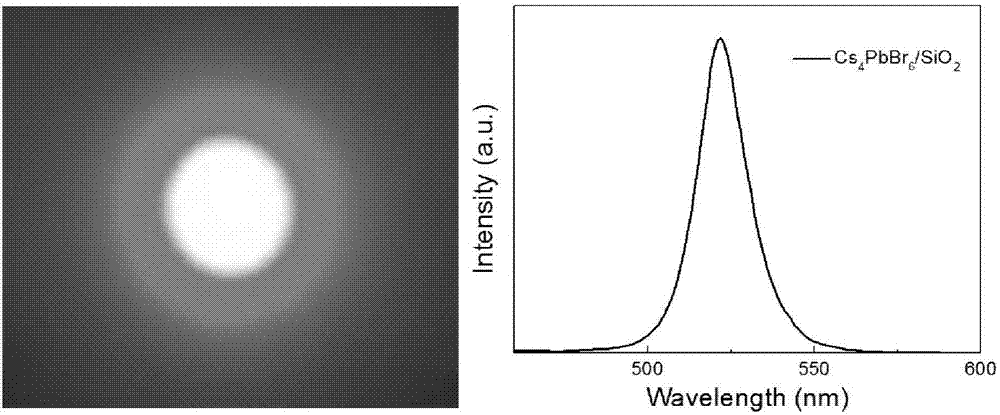

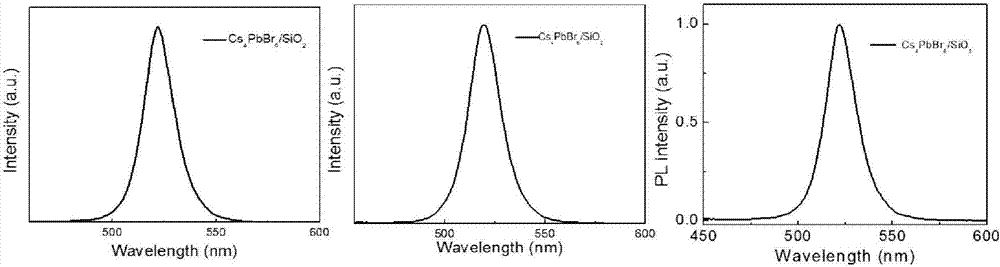

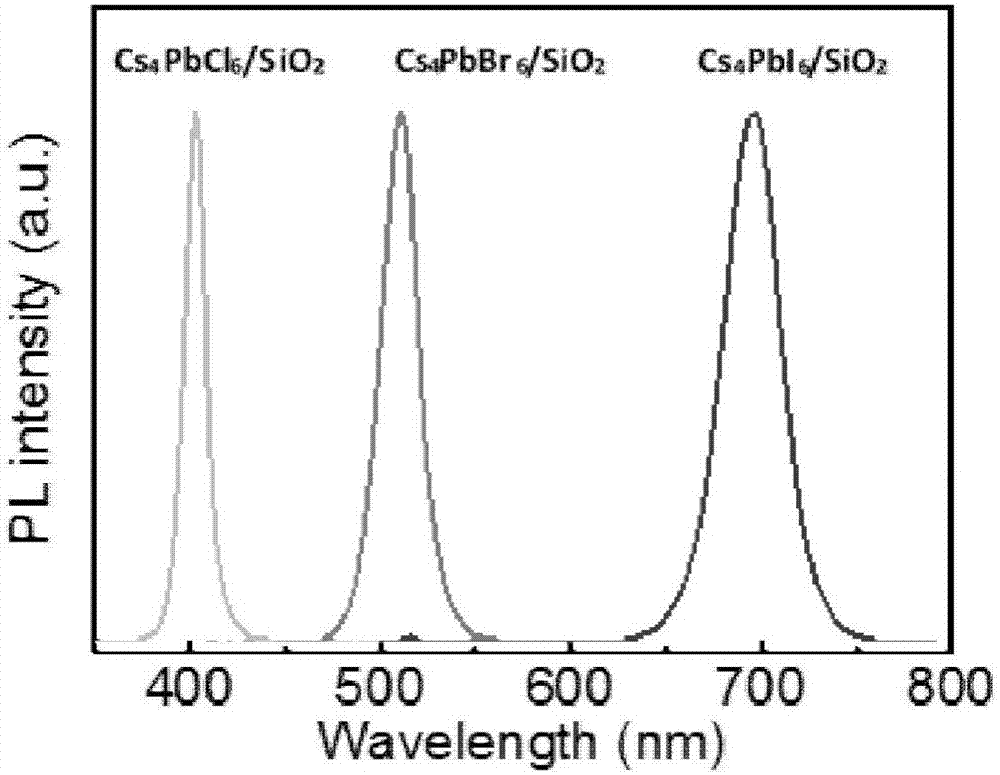

InactiveCN107195741AImprove stabilityNovel materialSolid-state devicesSemiconductor devicesQuantum dotRoom temperature

The invention discloses a fully-inorganic quantum dot backlight LED preparation method. A prepared quantum dot backlight LED adopts inorganic perovskite quantum dots, and is novel in material and excellent in performance; and the quantum dot backlight LED adopts a fully-inorganic device structure, and light-emitting material thereof is formed through room temperature crystallization and is wrapped by SiO2 on the surface thereof, thereby helping to improve device stability.

Owner:NANJING UNIV OF SCI & TECH

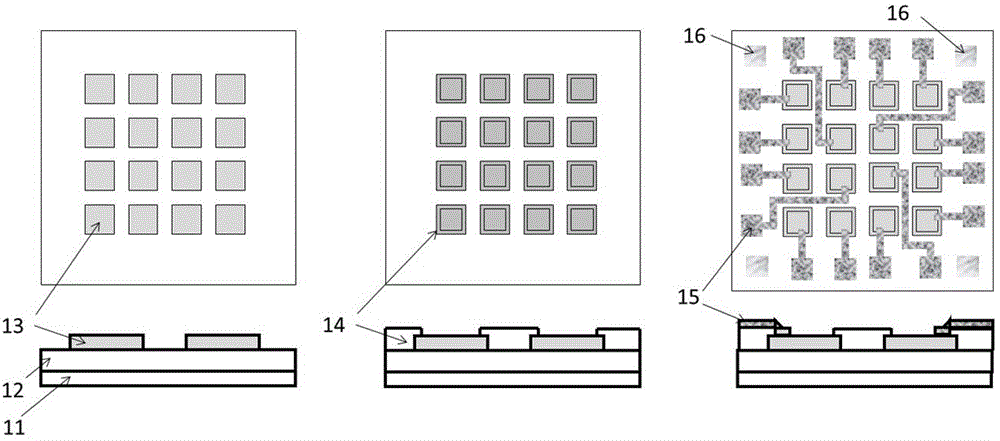

Micron LED array based visible light communication system and construction method thereof

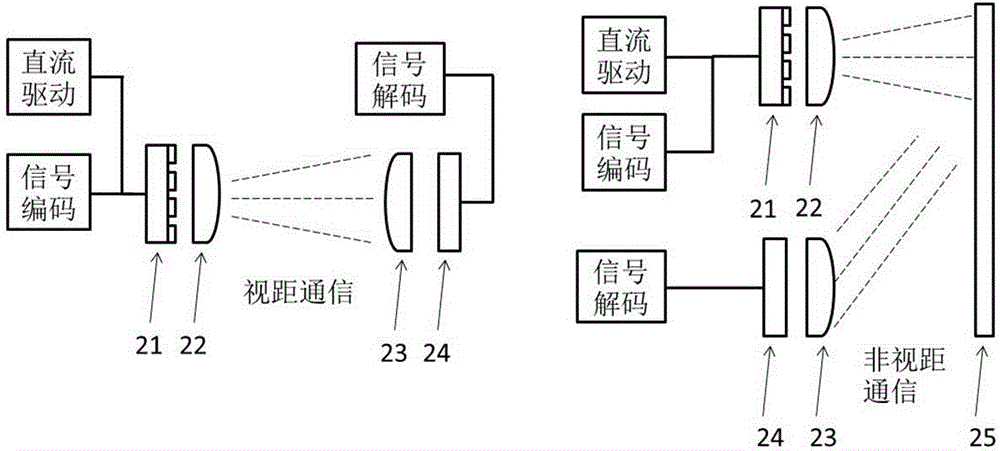

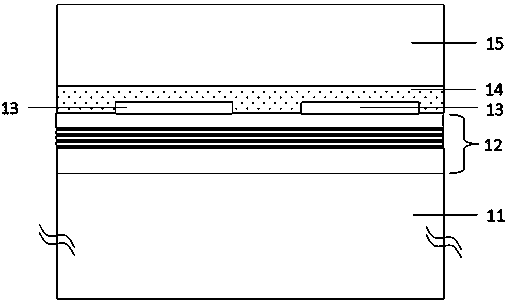

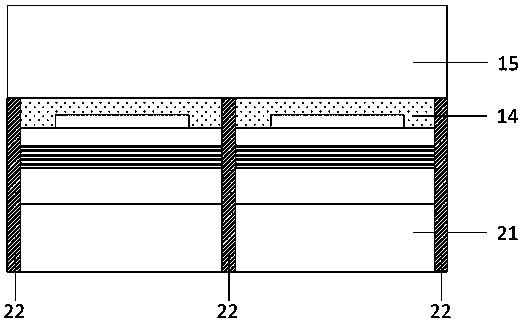

ActiveCN105897337AAchieve line of sightRealize non-line-of-sight communicationClose-range type systemsModulation bandwidthLed array

The invention belongs to the technical field of wireless communication, and specifically discloses a micron LED array based visible light communication system and a construction method thereof. The method comprises the following steps: etching through reactive ions to obtain a p type micron LED mesa array, wherein a size of a mesa is less than 100 microns; depositing an insulated passivation layer; forming holes in the insulated layer under an area where electrodes are to be constructed; preparing p type and n type electrodes to control each LED unit of a micron LED array; integrating the micron LED array and an optical collimating lens; integrating a receiving end high-speed photoelectric detector and a focusing lens through an OFDM modulation technology so as to achieve line-of-sight communication and non-line-of-sight communication and meet indoor communication distance demand. According to the method, the LED preparation and the visible light communication system are provided, and the prepared micron LED array is high in photoelectric modulation bandwidth and can perform communication; the prepared micron LED array is high in communication speed, has the micro-displaying and lighting functions, can perform line-of-sight communication and non-line-of-sight communication, and is high in practicality.

Owner:FUDAN UNIV

GaN-based LED preparation method based on regional laser lift-off and chemical corrosion

The invention discloses a GaN-based LED preparation method based on regional laser lift-off and chemical corrosion. The method includes the following steps: manufacturing an ohmic contact layer and a metal layer sequentially on a p-type GaN and manufacturing a new support substrate; carrying out laser groove cutting on a polished sapphire surface according to the size of an LED chip, wherein the groove depth reaches the new support substrate; carrying out regional laser lift-off on a sapphire sample on which a mask plate is placed; placing the sample in a corrosion solution which enters the GaN layer, which bounders with the sapphire substrate, through cut grooves and corrodes the GaN layer in a side direction so that the sapphire substrate is removed completely finally, and coarsening the surface of the GaN; manufacturing an n-type electrode and a passivation layer on the surface of the GaN, the substrate of which is removed, so that an LED chip of a vertical structure is formed. The method prevents damages on a GaN epitaxial wafer because of unevenness of laser spots and overlapping of the laser spots during traditional laser lift-off and prevents a defect that a traditional corrosion technology requires a thicker GaN thickness at the same time.

Owner:SOUTH CHINA UNIV OF TECH

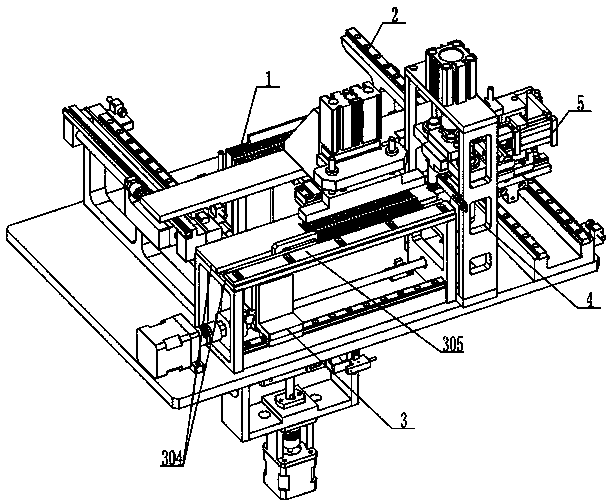

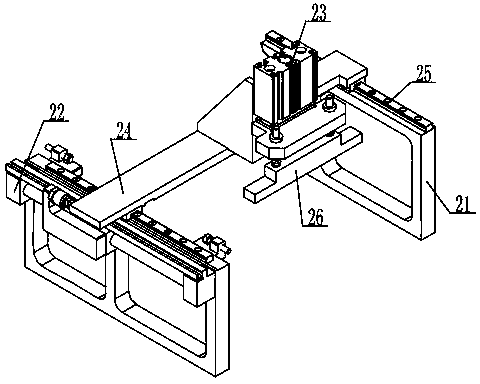

Electrode lead preparation device and batter cell coiling device comprising same

ActiveCN103427107AEfficient preparationReliable preparationFinal product manufactureSmall-sized cells cases/jacketsMechanical engineeringSingle electrode

The invention discloses an electrode lead preparation device which comprises a material box, a transport mechanism, a feeding mechanism, a shearing mechanism and a material conveying mechanism, wherein the material box is used for storing plate type electrode leads, the transport mechanism is used for transporting the electrode leads to the feeding mechanism which is used for feeding the plate type electrode leads to the shearing mechanism continuously, the shearing mechanism is used for shearing the plate type electrode leads into single electrode leads, and the material conveying mechanism is used for conveying the single electrode leads to a welding process. The electrode lead preparation device achieves efficient and reliable battery cell electrode lead preparation, production efficiency is improved, and production cost is lowered.

Owner:SHENZHEN YINGHE TECH

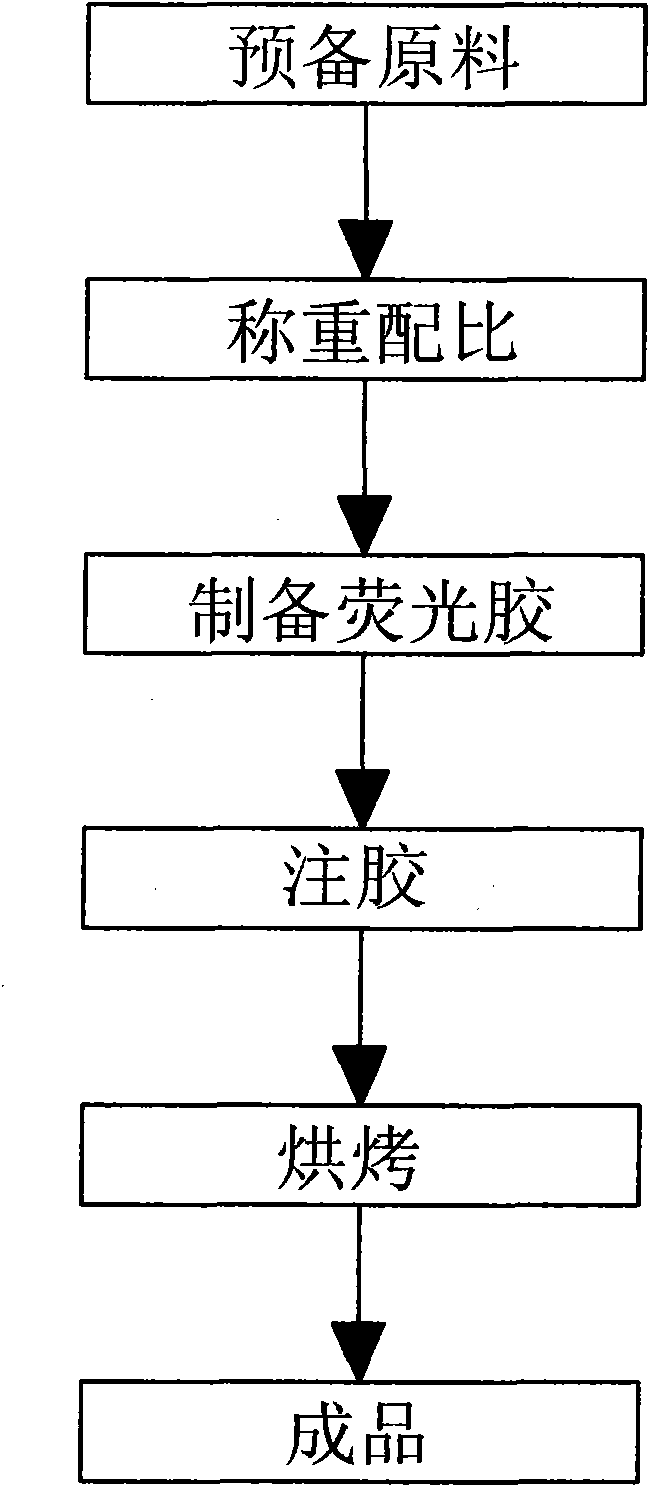

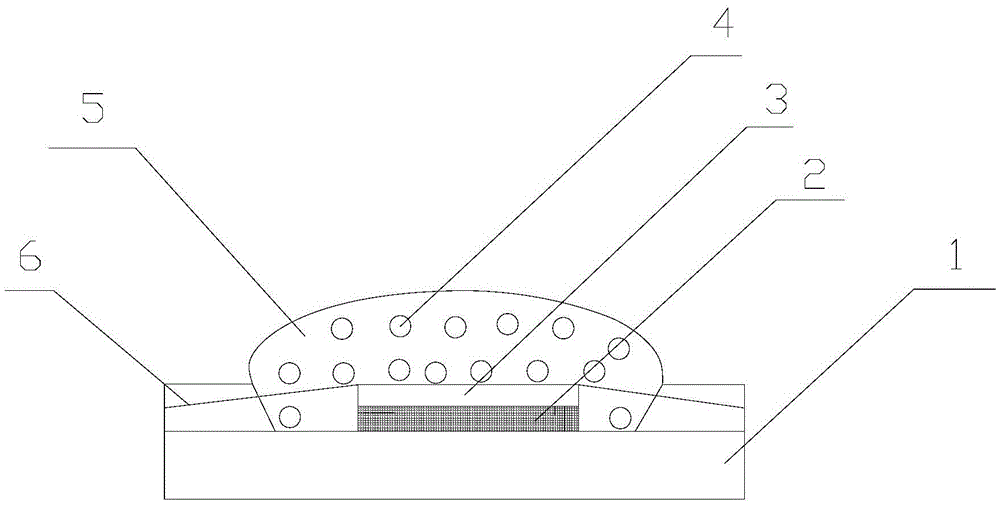

White LED preparation method and LED

InactiveCN101958384ASimple structureReasonable ratioSemiconductor devicesFluorescenceColor rendering index

The invention discloses a white LED preparation method which comprises the following steps of: (1) preparing raw materials; (2) weighing and proportioning; (3) preparing fluorescent gel; (4) injecting the gel; (5) roasting; and (6) obtaining the finished product. After the roasting step is completed, the finished product of the white LED is prepared. The invention also discloses an LED prepared by using the LED preparation method. The method provided by the invention has simple manufacturing process, low cost and high product quality, and the requirement of large-scale production is satisfied. According to the LED provided by the invention, the structure is simple, the fluorescent gel has reasonable proportioning, not only the concentricity, the color rendering index and the luminous flux of a white color region is improved and discreteness is reduced, but also the service life is greatly prolonged.

Owner:东莞市勤望达光电科技有限公司

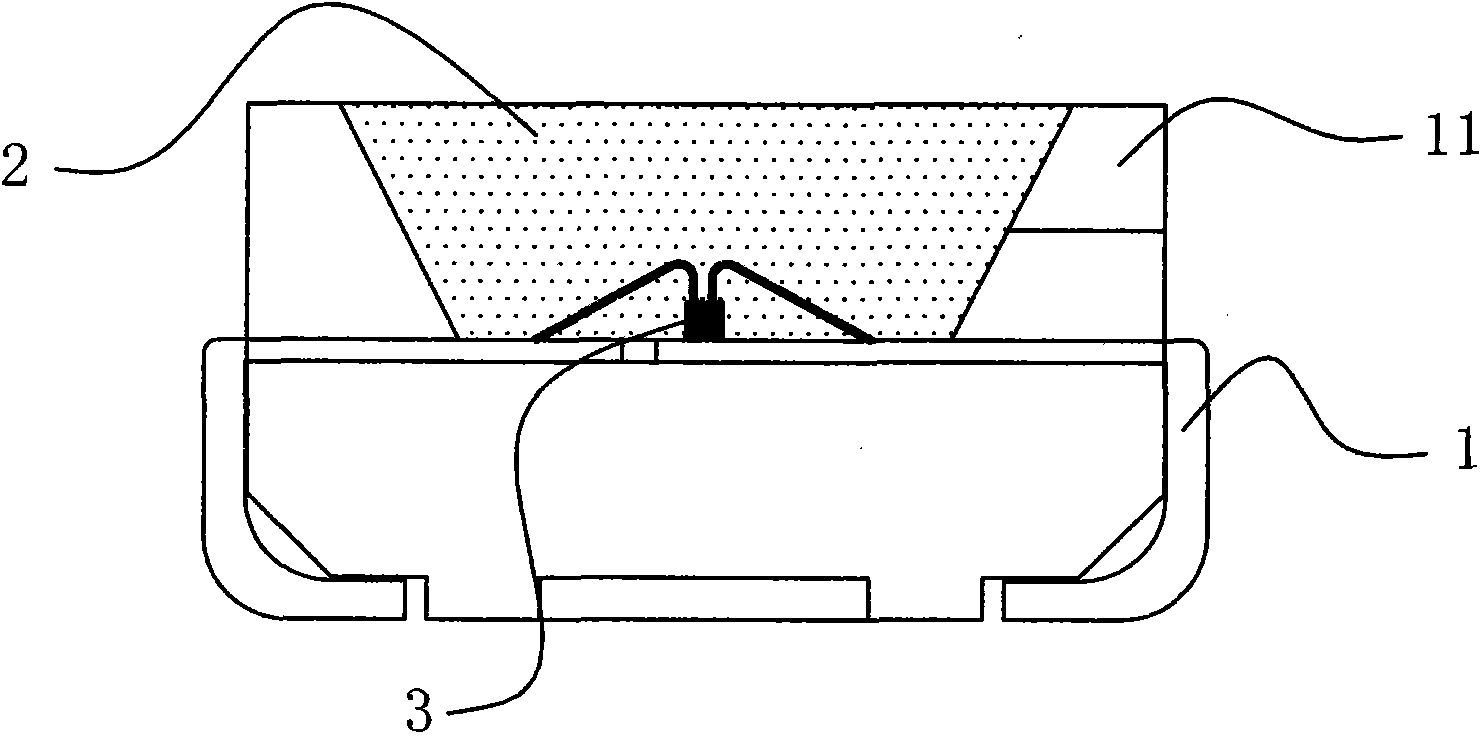

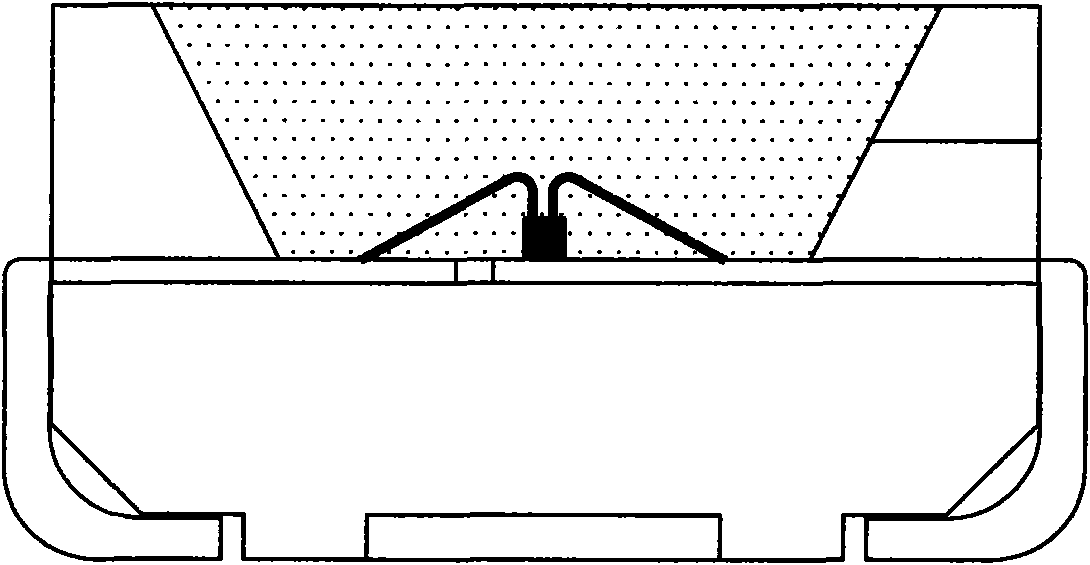

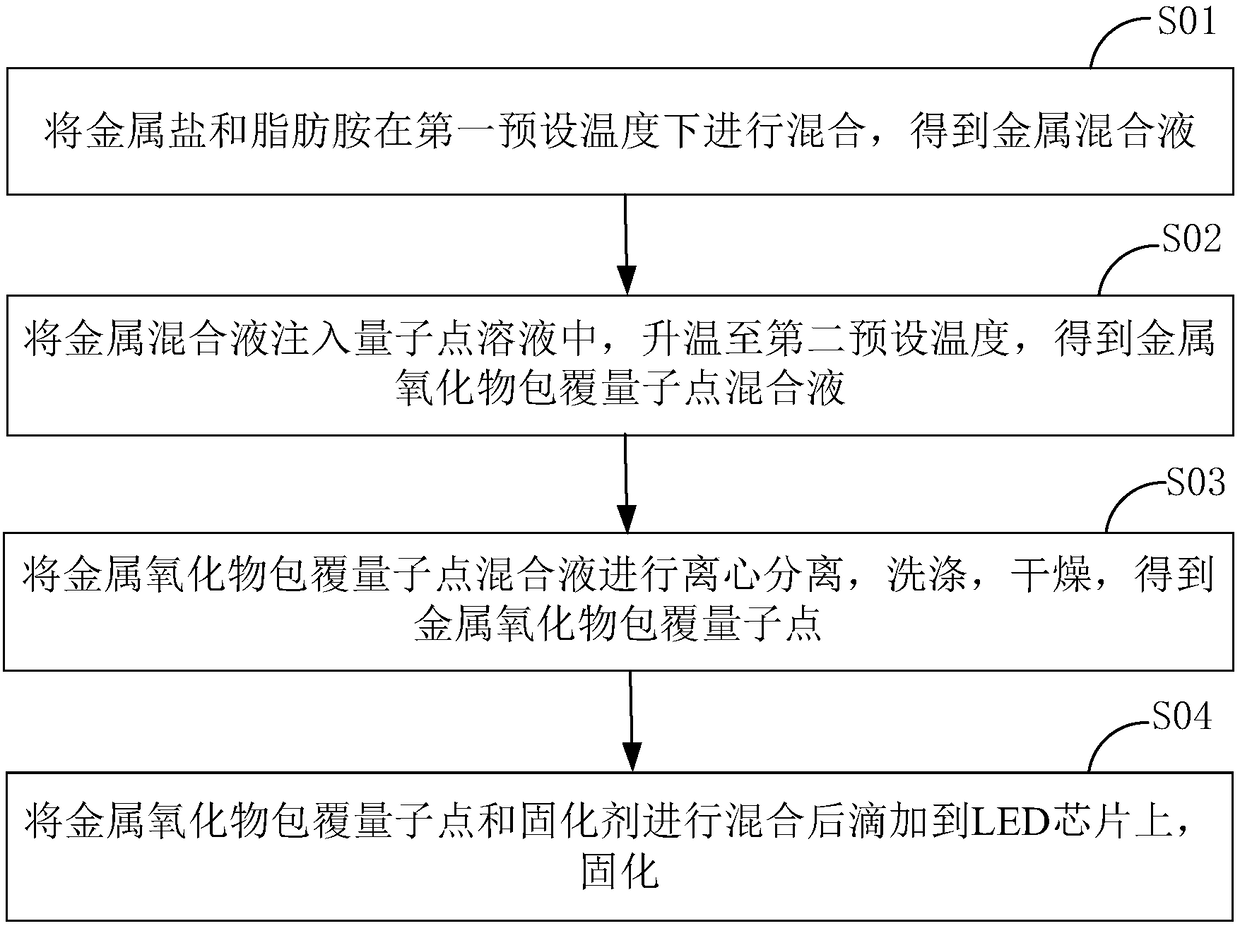

Oxide-coated quantum dot LED preparation method

ActiveCN108807608AImprove thermal stabilityImprove thermal efficiencySemiconductor devicesElectricityQuantum dot

The invention belongs to the illumination and display technical field, and provides an oxide-coated quantum dot LED preparation method; the method coats a metal oxide on quantum dots so as to obtain the metal oxide-coated quantum dot LED, thus effectively separating quantum dots of the LED from the outer side, preventing quantum dot oxidation, improving quantum dot thermal stability and light / electroluminescent efficiency, and improving the LED reliability and service life. The preparation method is simple in process, low in cost, and can easily realize large scale production.

Owner:TCL CORPORATION

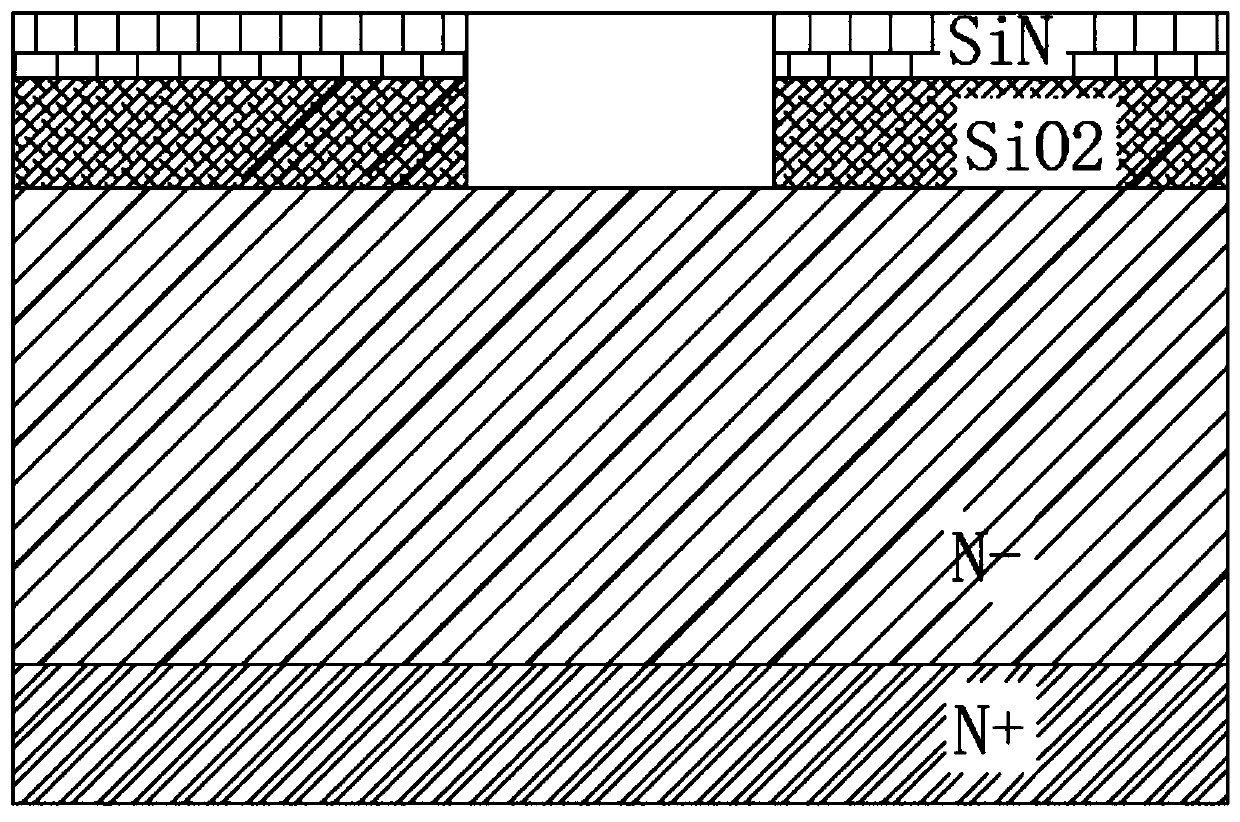

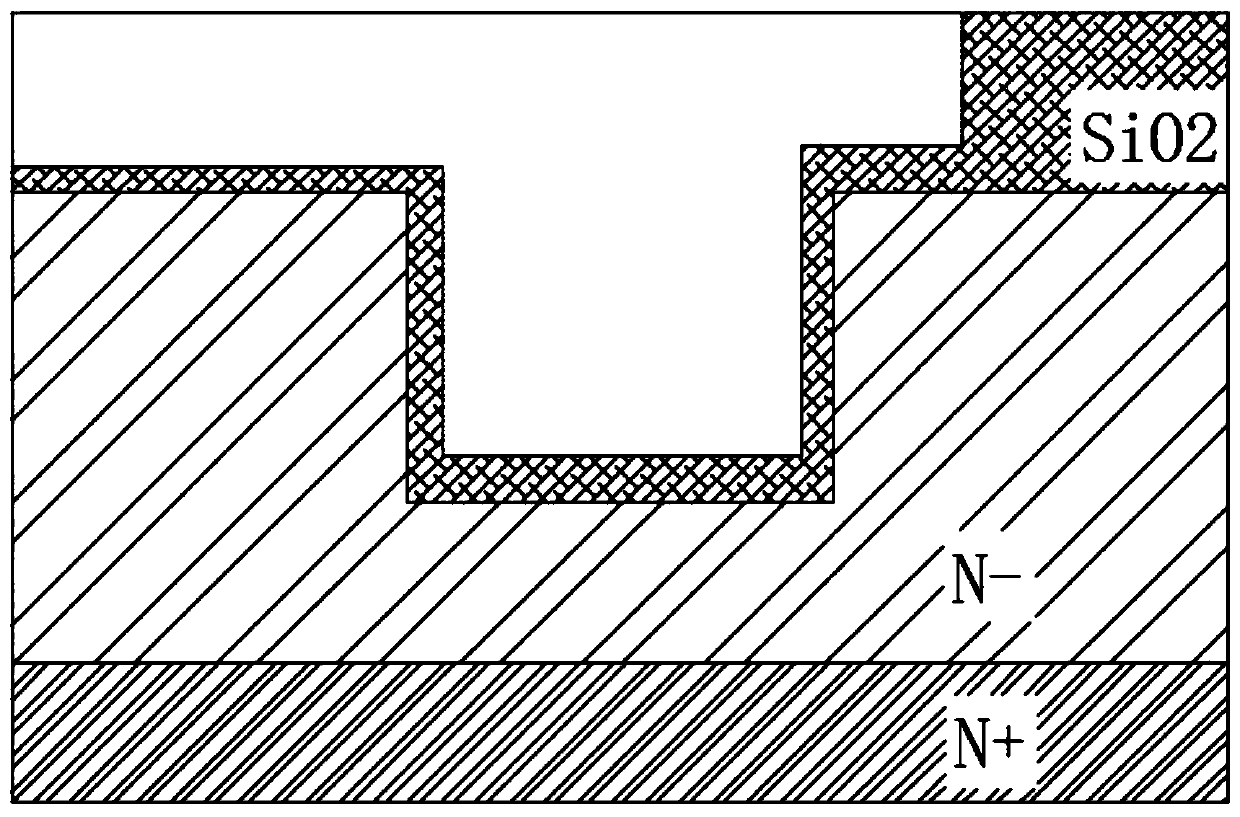

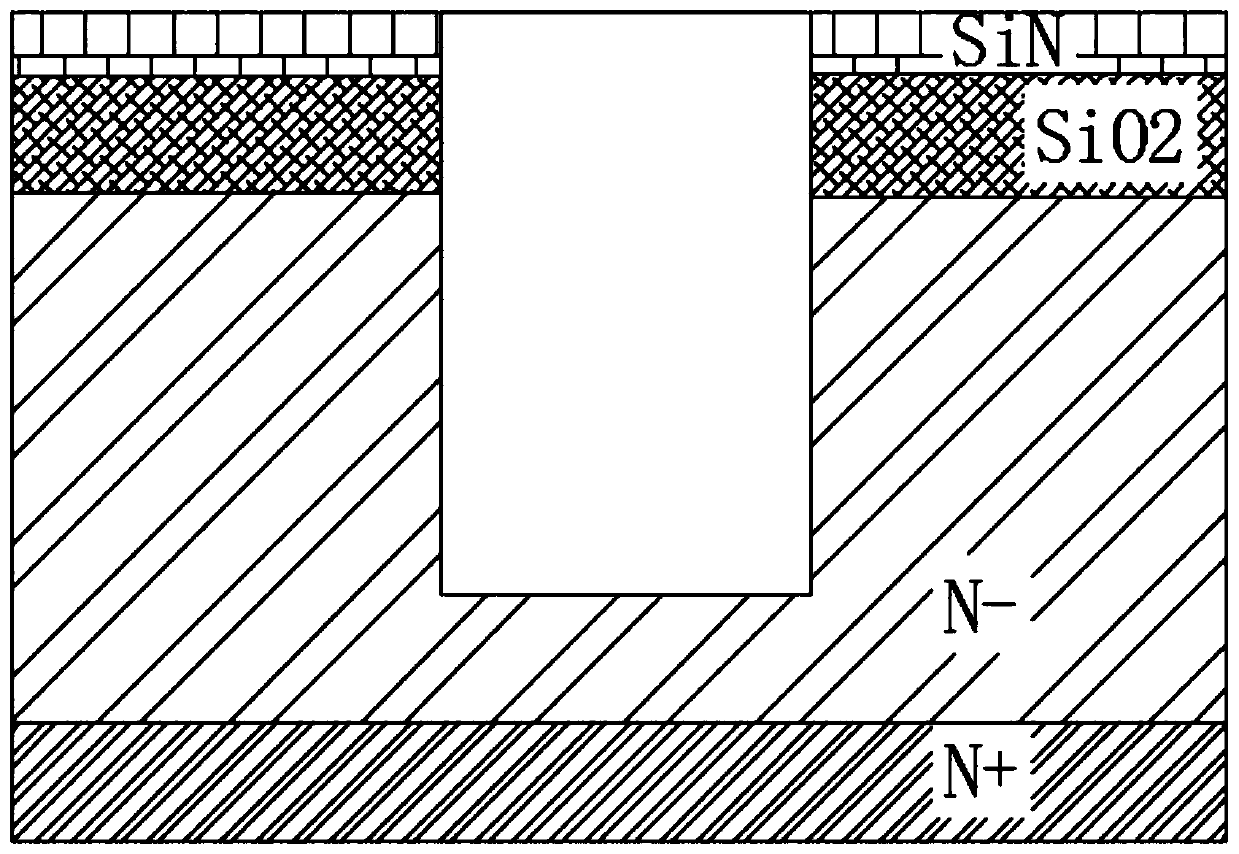

Preparation method of trench MOSFET integrating Schottky diode

InactiveCN109904152AImprove yield levelImprove performanceSolid-state devicesSemiconductor devicesTrench mosfetEngineering

The invention discloses a preparation method of a trench MOSFET integrating a Schottky diode. The method comprises the steps of first, trench construction; second, conductive region preparation; third, conductive trench arrangement; fourth, Schottky structure activation; and fifth, conductive lead preparation. According to the embodiment, the structure of a power MOSFET device integrating the Schottky diode function is provided; and even though the Schottky diode is integrated in the MOSFET structure, through optimization of structural design and layout design, the manufacturing difficulty inpractical production is lowered, the yield of the device is improved, cost is lowered, and device performance is improved.

Owner:JIANGSU HAIDONG SEMICON TECH CO LTD

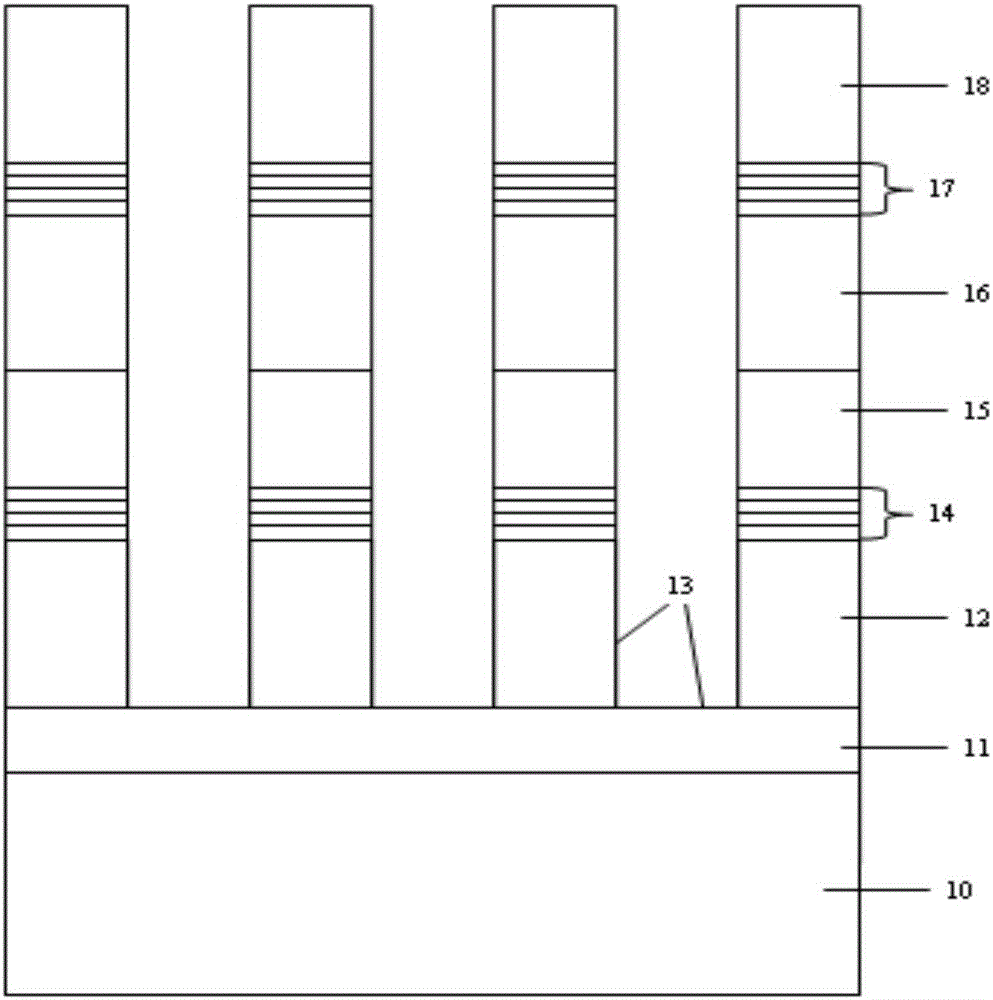

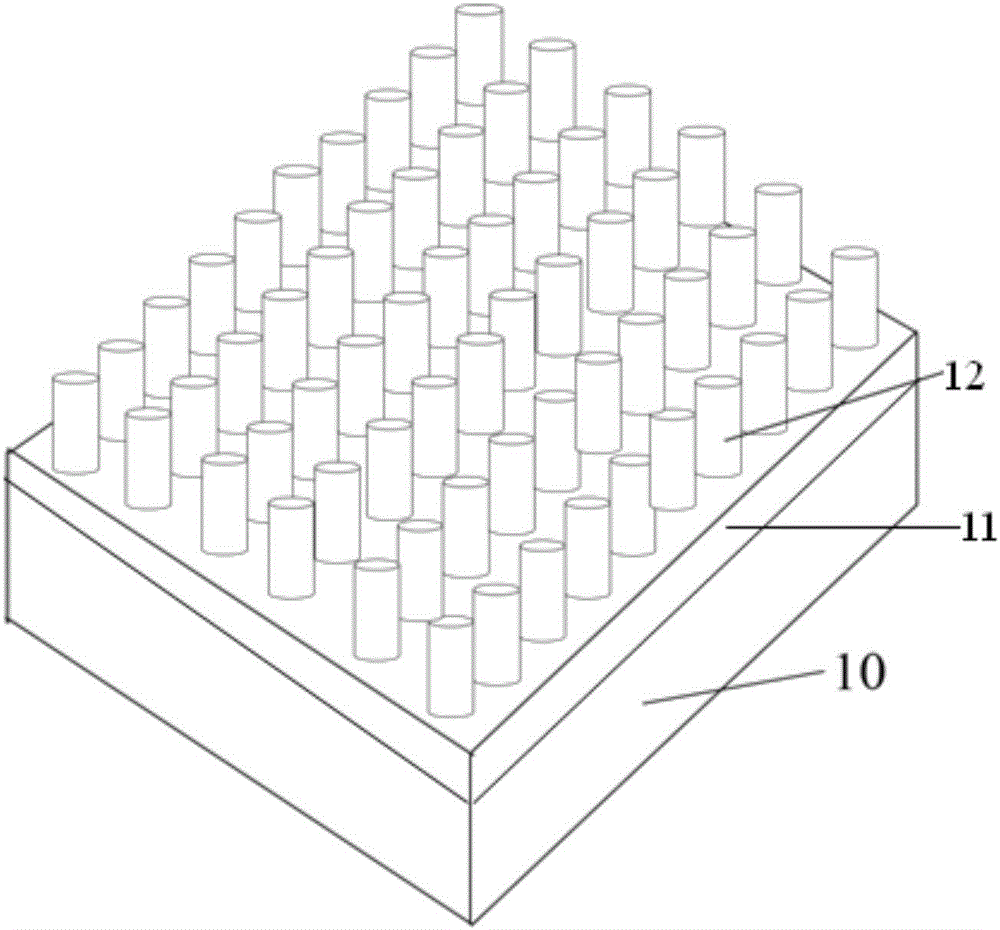

Nano-pillar LED grown on strontium tantalum lanthanum aluminate substrate and preparation method thereof

The invention belongs to the technical field of nano-pillar LED preparation, and discloses a nano-pillar LED grown on a strontium tantalum lanthanum aluminate substrate and a preparation method thereof. The nano-pillar LED grown on a strontium tantalum lanthanum aluminate substrate comprises a strontium tantalum lanthanum aluminate substrate, an AlN nucleation layer grown on the strontium tantalum lanthanum aluminate substrate, a GaN nano-pillar template grown on the AlN nucleation layer, an AlN / GaN super lattice layer grown on the GaN nano-pillar template, a non-doped GaN layer grown on the AlN / GaN super lattice layer, an n-type doped GaN layer grown on the non-doped GaN layer, an InGaN / GaN quantum well grown on the n-type doped GaN layer, and a p-type doped GaN layer grown on the InGaN / GaN quantum well. The substrate material is of low cost. A nano-pillar array prepared is size-controllable and of uniform orientation. The obtained nano-pillar LED has low defect density and excellent electrical and optical properties.

Owner:SOUTH CHINA UNIV OF TECH

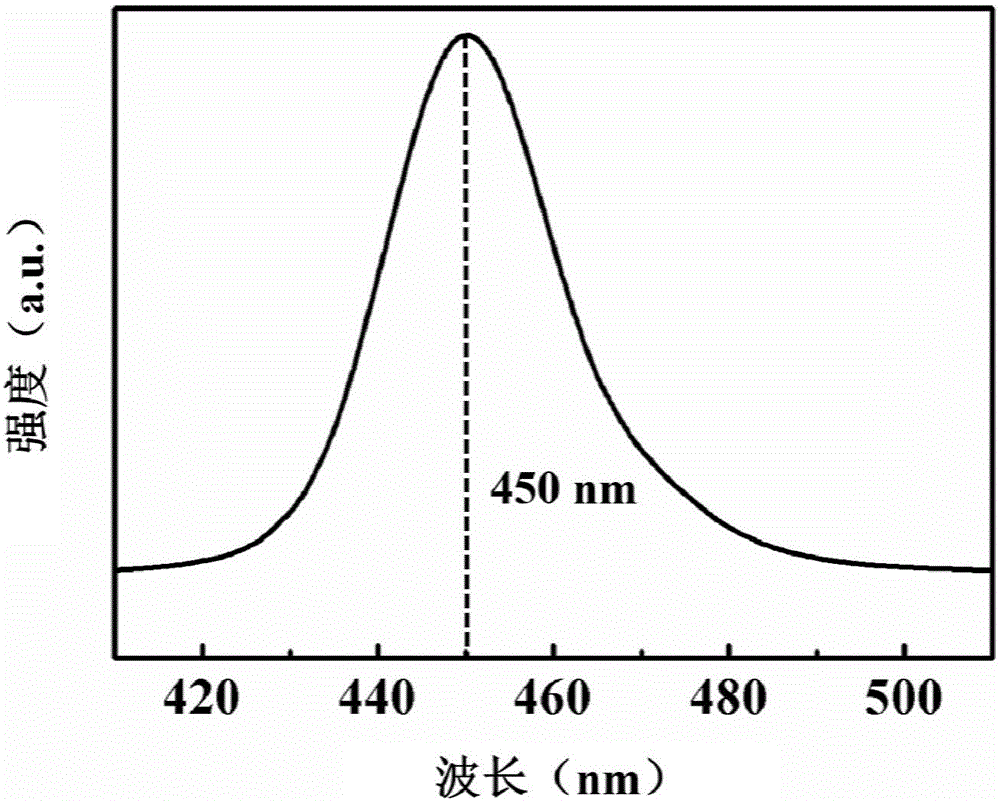

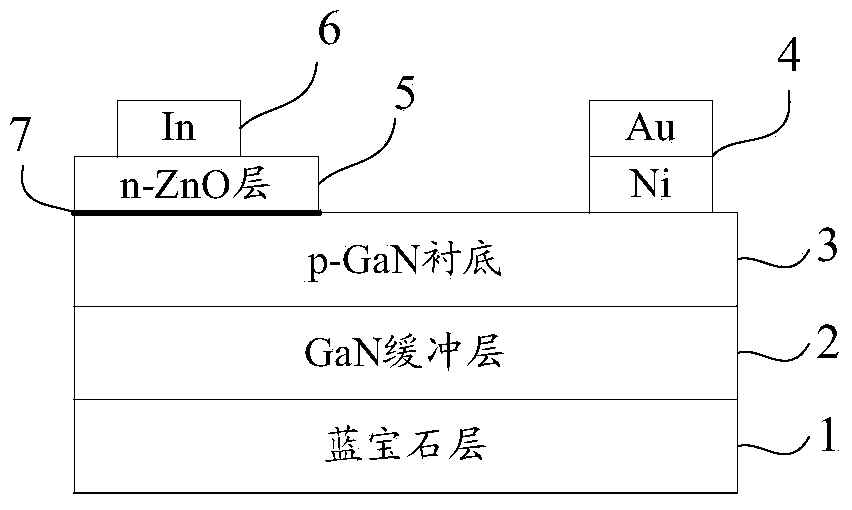

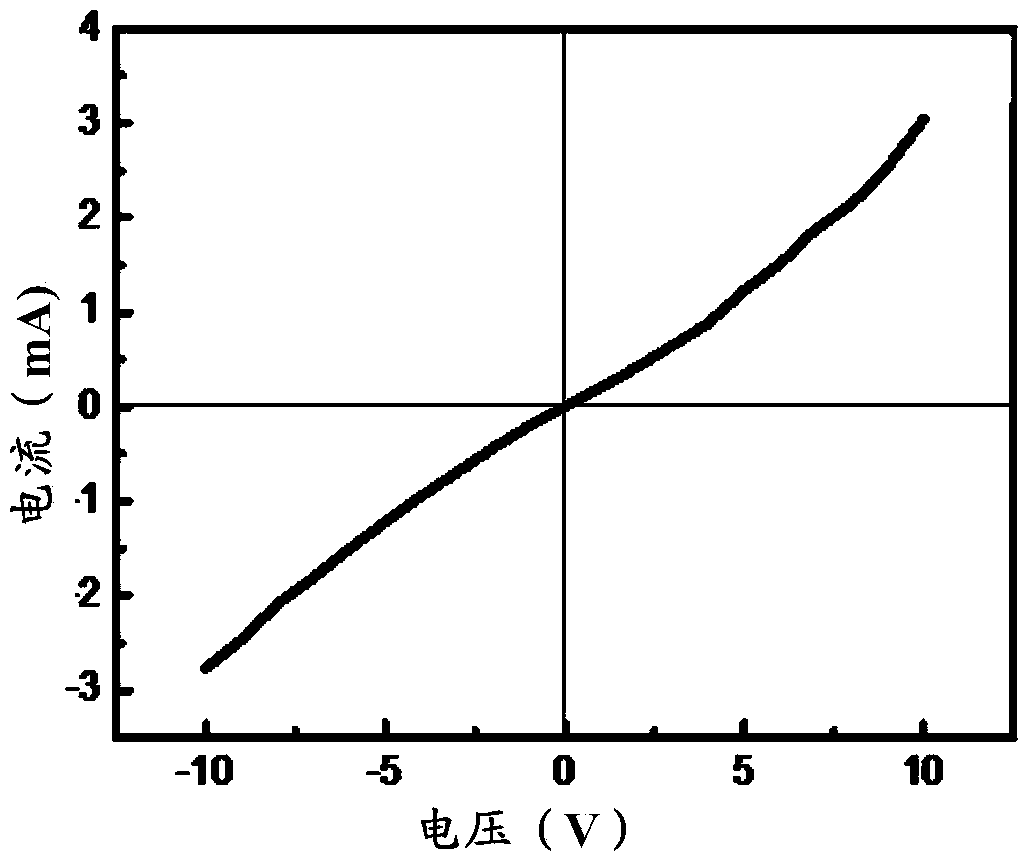

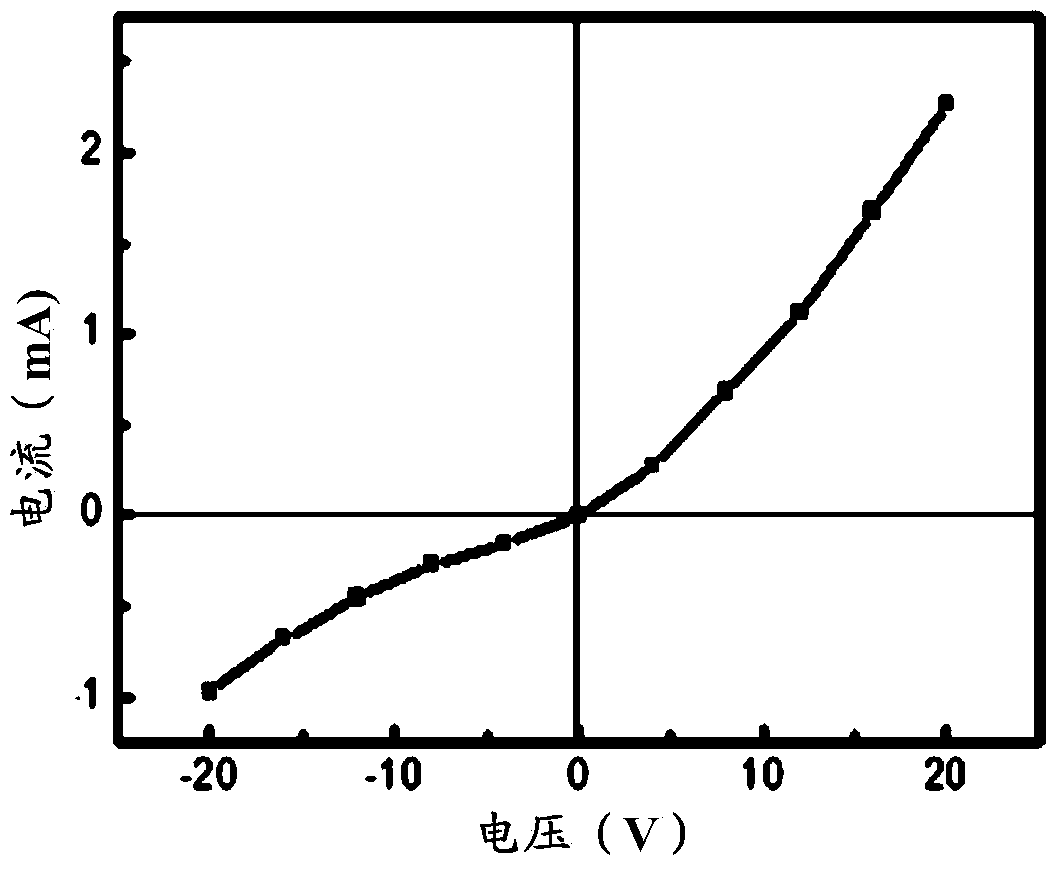

ZnO-based white light LED and preparing method thereof

InactiveCN103956416ASimple manufacturing processLower requirementSemiconductor devicesHeterojunctionInterface layer

The invention relates to the technical field of LEDs, in particular to a ZnO-based white light LED and a preparing method thereof. The method comprises the steps that high-purity oxygen is used as growth gas, an n-ZnO layer grows on a p-GaN substrate which has the characteristic of blue electroluminescence, and a p-GaN / n-ZnO heterojunction is formed; in the preparing process of the heterojunction, by controlling the pressure intensity of the high-purity oxygen and the growth temperature, a Ga, Zn and O mixed interface layer is formed on the interface of the heterojunction, the interface layer obtains the characteristic of yellow electroluminescence, and light from the interface layer and light emitted by the p-GaN substrate can be mixed to generate white light; electrodes are prepared on the p-GaN substrate and the n-ZnO layer respectively, and the preparation of the ZnO-based white light LED is achieved. Compared with the prior art, the LED preparation is achieved in one time in the growing process, the preparing process of the LED is effectively simplified, the requirement for growing materials is not high, and the method is a practicable method for preparing the ZnO-based heterojunction white light LED, and meets the development direction of the semiconductor illumination light source technology.

Owner:SHENZHEN UNIV

Purple LED (light-emitting diode) preparation method, purple LED and chip

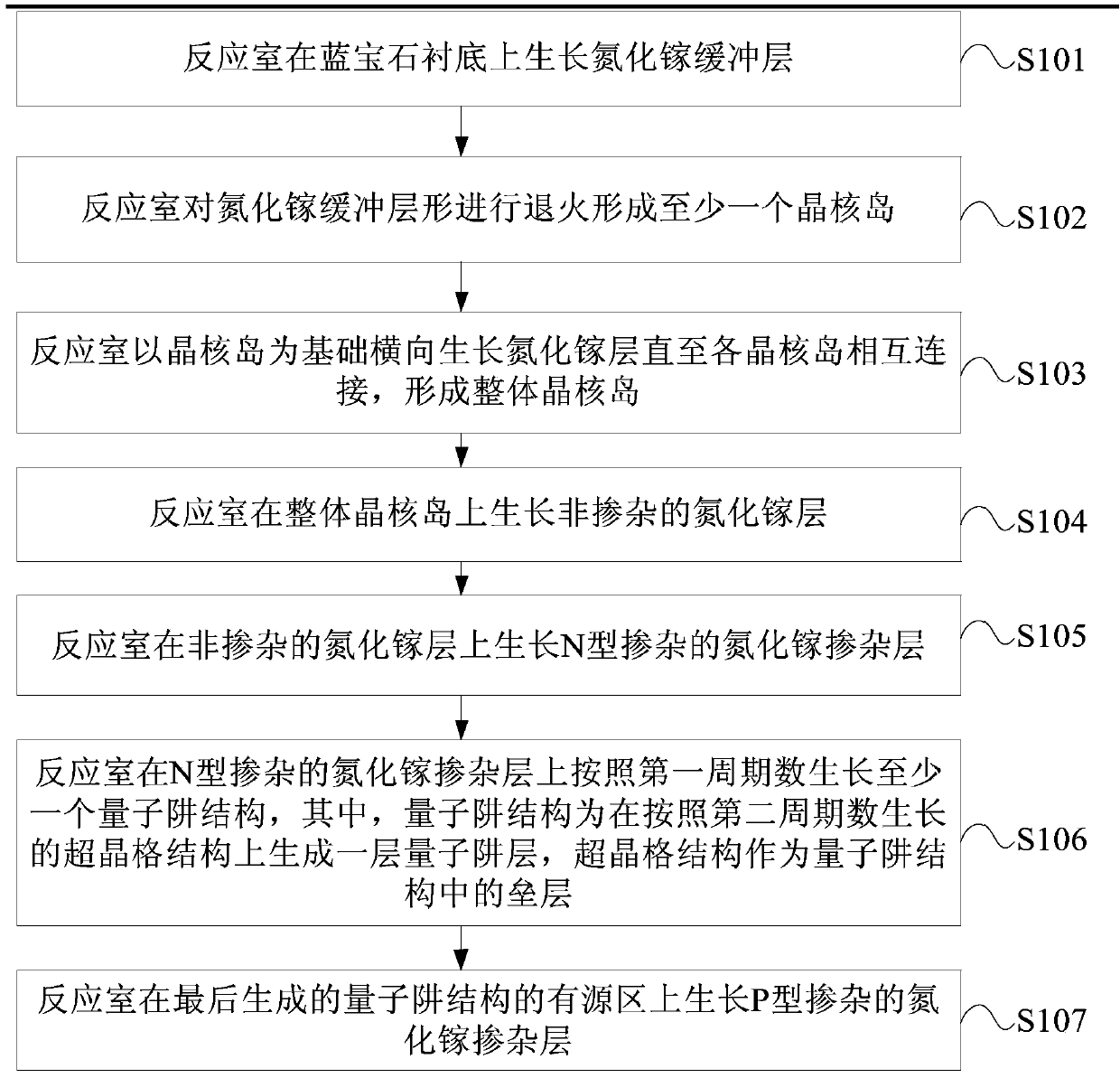

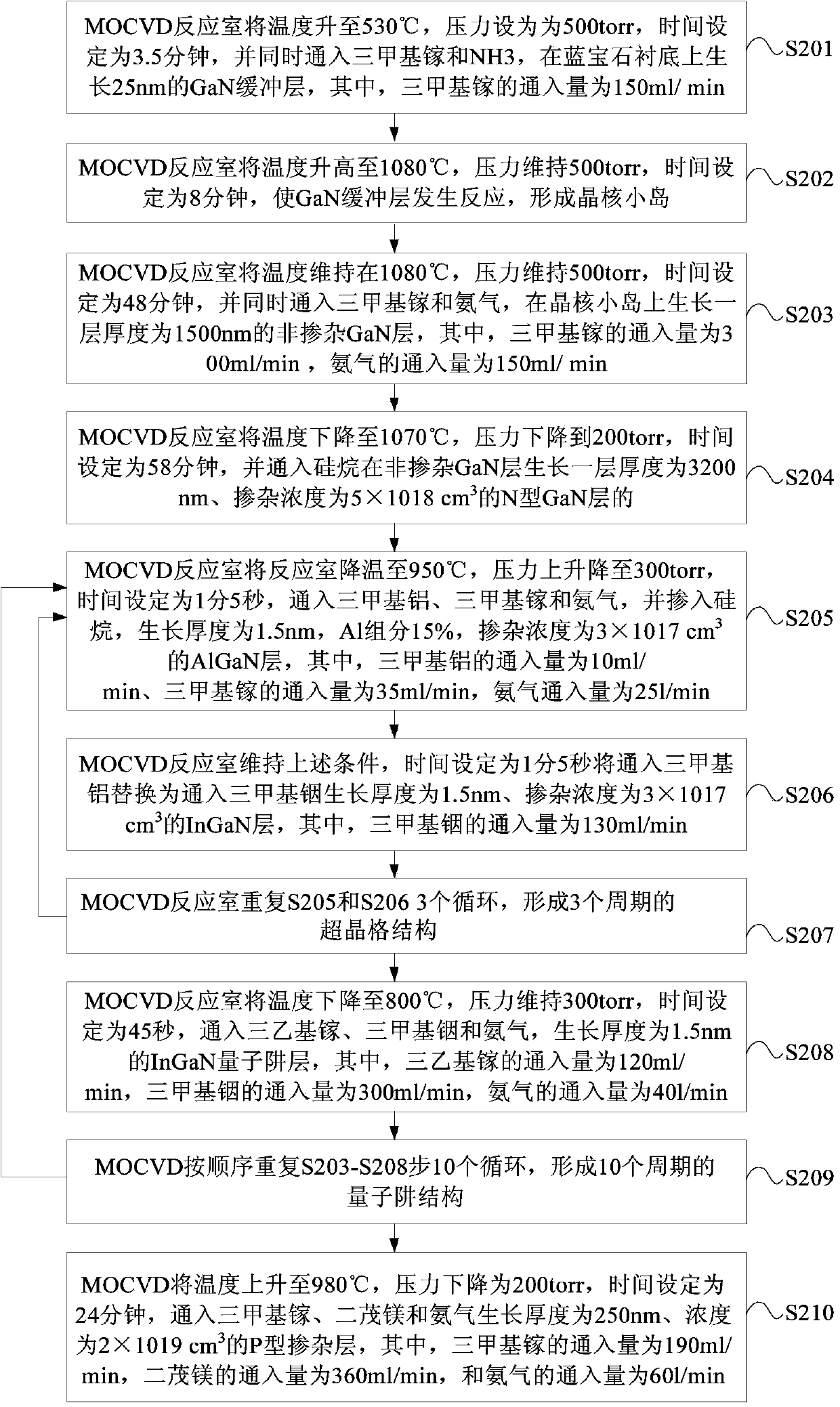

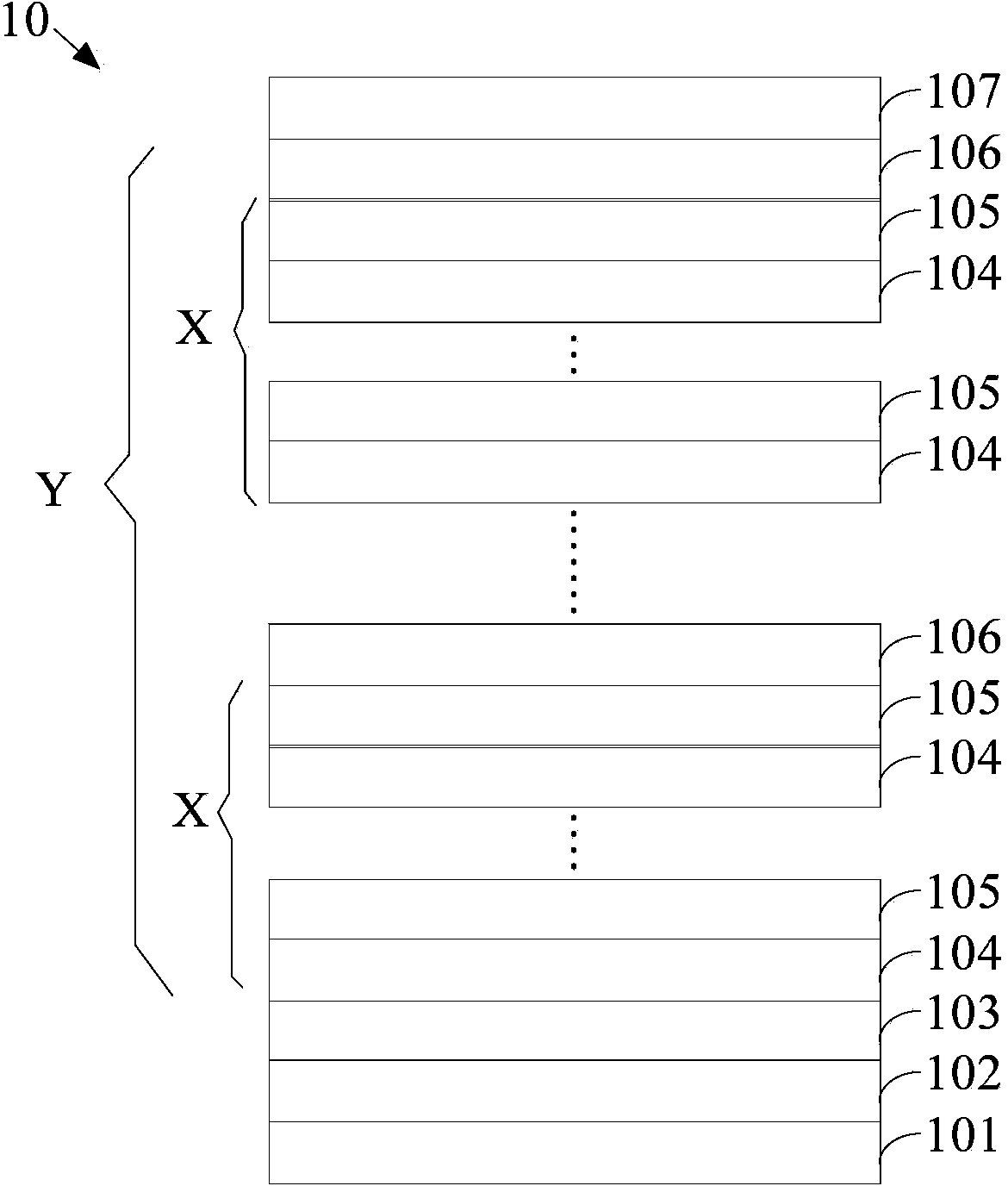

ActiveCN103746053AIncrease the restrictive effectIncrease chance of compoundingSemiconductor devicesCharge carrierQuantum well

The embodiment of the invention provides a purple LED (light-emitting diode) preparation method, a purple LED and a chip. The method comprises the following steps of growing a gallium nitride buffer layer on a sapphire substrate; annealing the gallium nitride buffer layer to form at least one crystal nucleus island; transversely growing a gallium nitride layer based on the crystal nucleus islands until the crystal nucleus islands are connected with one another to form an integrated crystal nucleus island; growing an undoped gallium nitride layer on the integrated crystal nucleus island; growing an N-type doped gallium nitride layer on the undoped gallium nitride layer; growing at least one quantum well structure on the N-type doped gallium nitride layer according to a first cycle number, wherein each quantum well structure is formed by generating a quantum well layer on a superlattice structure grown according to a second cycle number, and the superlattice structures are used as barrier layers of the quantum well structures; growing a P-type doped gallium nitride layer on an active area of a finally generated quantum well structure. According to the purple LED preparation method, the purple LED and the chip, the charge-carrier recombination probability, the luminous efficiency and the antistatic performance of the purple LED can be improved.

Owner:EPITOP PHOTOELECTRIC TECH

Method for preparing white light LED

InactiveCN101894889AThe printing process is simple and matureIncrease productivitySemiconductor devicesScreen printingCooking & baking

The invention discloses a method for preparing a white light LED, which is suitable for preparing the white light LED connected with a lead frame in batch. The invention adopts the technical scheme that: the method comprises the following steps of: fixation: fixing a blue light LED chip on a chip area, providing two through holes corresponding to positive and negative electrodes of a substrate on the lateral surface of the substrate, and arranging a resin frame on the substrate; silk screen arrangement: forming the positive and negative electrodes of the substrate on the upper surface, extending the positive and negative electrodes to the inner surfaces of the through holes respectively, placing a silk screen at a position parallel to the surface of a chip, and making reserved holes of the silk screen correspond to patterns of the positive and negative electrodes of the chip; printing of fluorescent powder: printing the fluorescent powder on the surface of the chip by using a silk-screen printing process; removal of the silk screen and baking of the fluorescent powder: removing the silk screen, baking and curing the fluorescent powder, making the cured fluorescent powder coated on the surface of the chip, and exposing the positive and negative electrodes of the chip; lead bonding: connecting the positive electrodes of the chip and the substrate, and connecting the negative electrodes of the chip and the substrate; silica gel filling: filling silica gel into the resin frame, and baking and curing the silica gel to finish the preparation. The method is applied to the field of LED preparation.

Owner:上海科学院 +1

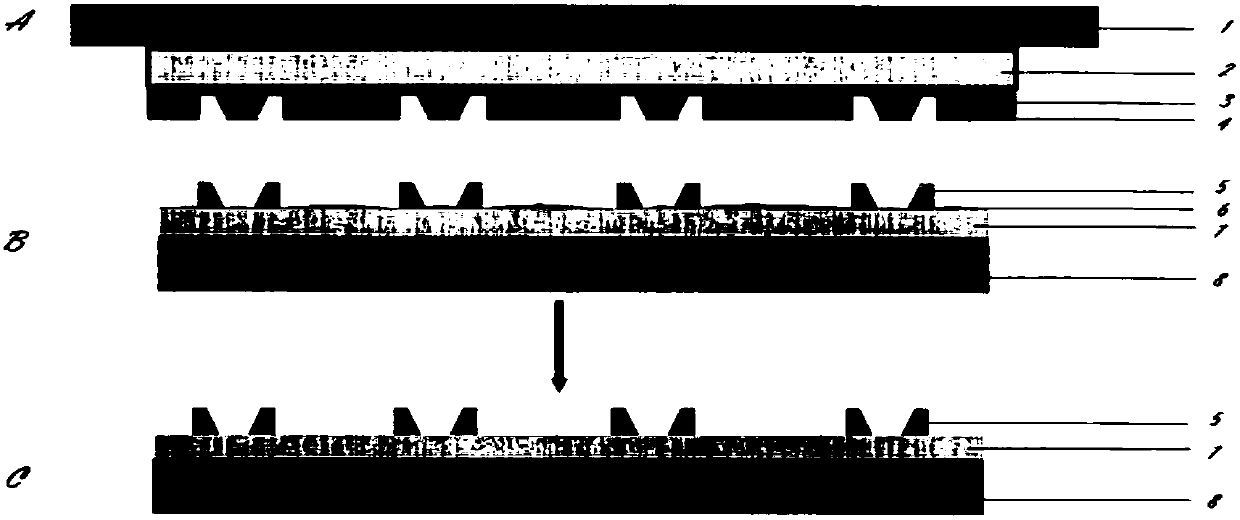

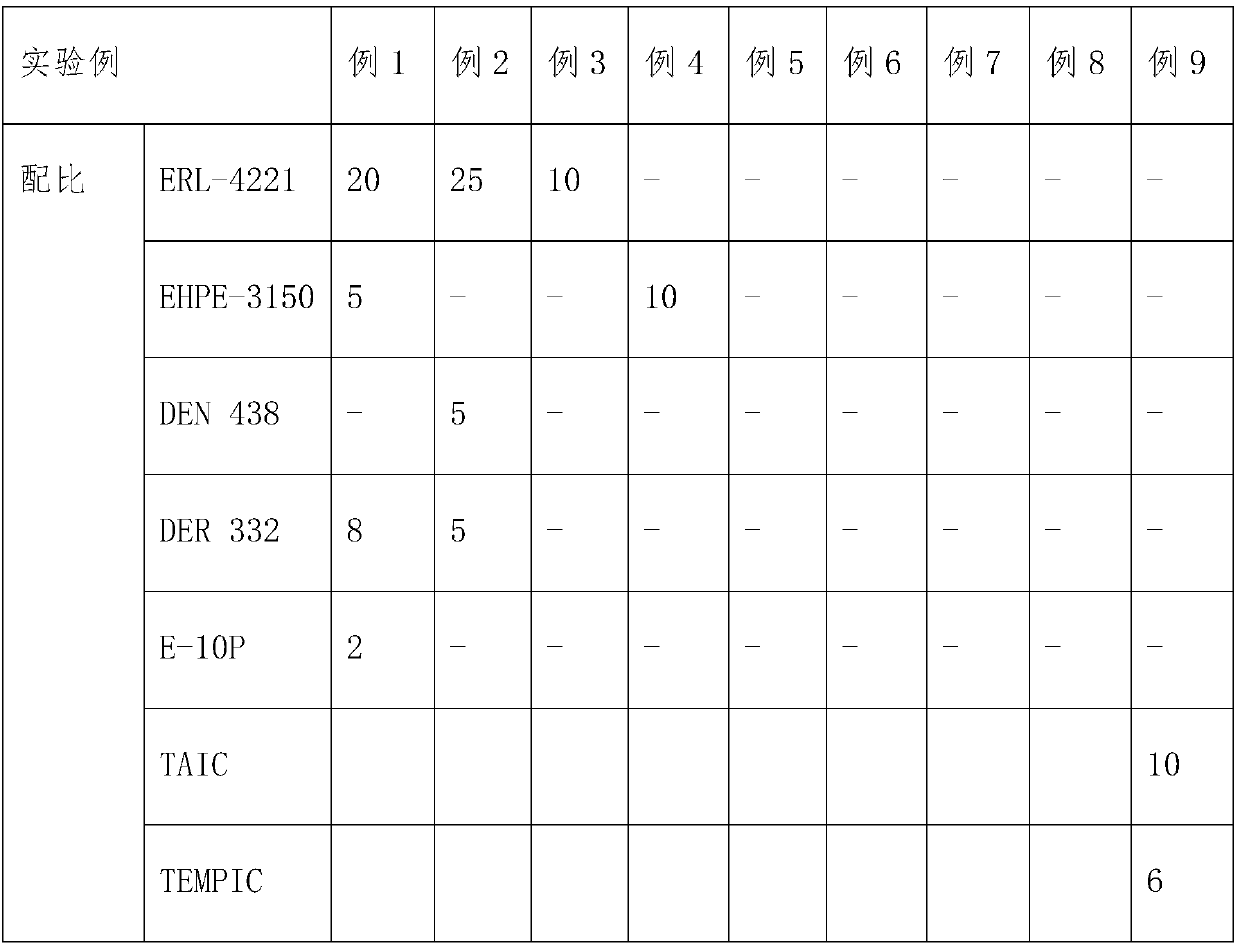

Material and method for preparing LED bracket through imprint lithography technology

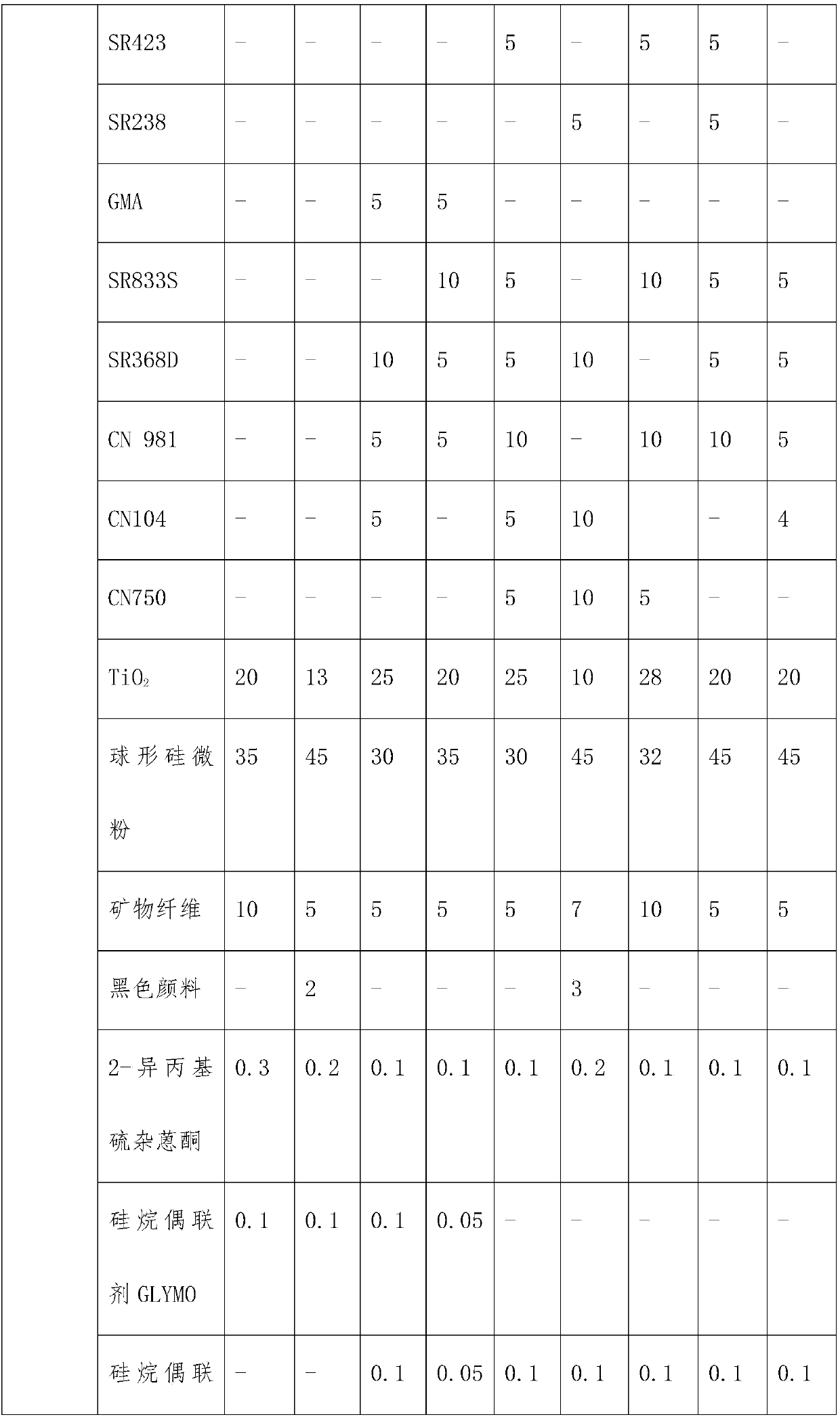

ActiveCN107910421ASolve the problem of energy consumptionAddress reliabilityPhotomechanical apparatusSemiconductor devicesEpoxyLithographic artist

The invention discloses LED bracket preparation technology, and particularly relates to a preparation process and related material technology. The LED preparation technology according to the inventioncomprises the steps of applying liquid imprint glue on a printed circuit board (PCB) with arranged circuit or a pin, and obtaining a large-area manufactured LED bracket at an original position through an imprint template. The imprint template is a flexible composite die. Through function of an external electric field or vacuum, a template contacts with a substrate, thereby realizing patterning ofliquid imprint glue. After illumination, the liquid imprint glue is solidified, and furthermore demolding developing is performed. The liquid imprint glue is composed of epoxy resin, acrylic acid ester, a filling material, a pigment, a photoinitiator, a curing agent, etc. The obtained LED bracket can be further cut for use or directly used in a large-area manner.

Owner:南通康池新材料有限公司

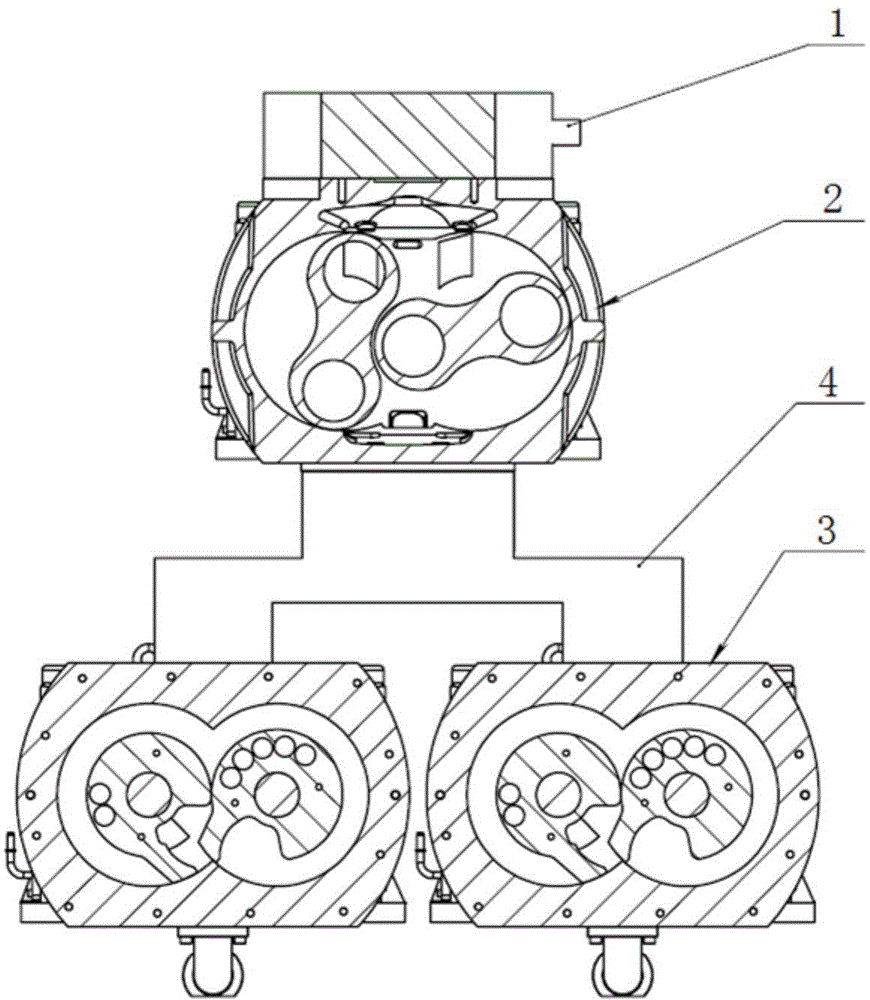

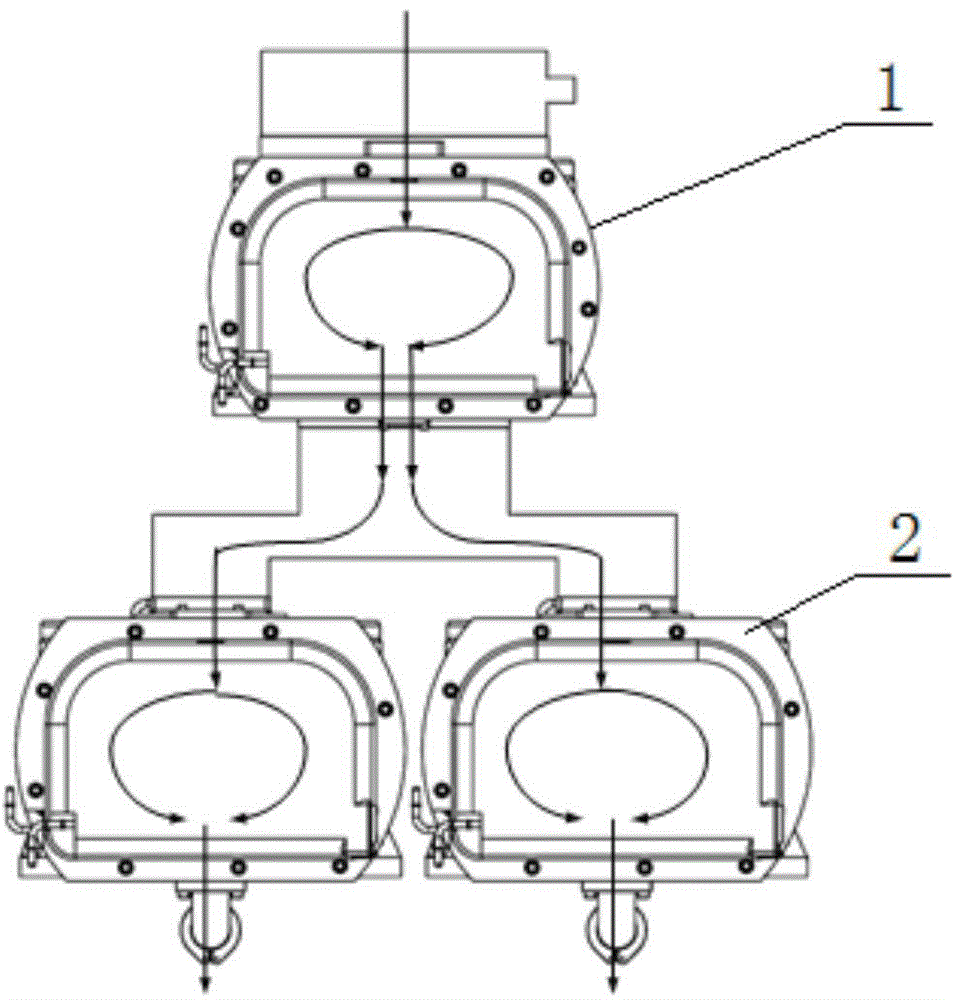

Vacuum system for efficiently pumping gases with small molecular weights

InactiveCN104632629AIncrease pumping speedEffective pumping speedRotary/oscillating piston combinations for elastic fluidsMachines/enginesPulp and paper industryVacuum chamber

The invention relates to a vacuum system used in semiconductor and LED preparation processes and particularly relates to a vacuum system for efficiently pumping gases with small molecular weights. The vacuum system comprises a controller, a first-grade vacuum pump and a plurality of second-grade vacuum pumps, wherein the first-stage vacuum pump is connected with the second-stage vacuum pumps; both the first-stage vacuum pump and the second-stage vacuum pumps are connected with the controller; and the first-stage vacuum pump is connected with a process vacuum chamber. The plurality of second-stage vacuum pumps are connected with the first-stage vacuum pump after being connected in parallel. By using the vacuum system, more gases with low molecular weights can be carried within unit time, and the backflow of the gases with low molecular weights can be reduced, so that the gases with low molecular weights are efficiently pumped.

Owner:SHENYANG SCI INSTR RES CENT CHINESE ACAD OF SCI

Method of preparing gold-silver alloy with precious antimony

The invention discloses a method of preparing gold-silver alloy with precious antimony. The method comprises the following steps of sequentially adding a precious antimony raw material in a reverberatory furnace, a lead smelting furnace and a vacuum furnace, and performing the steps of precious antimony smelting, precious antimony impurity removal, precious antimony cupellating, lead adding, continuous cupellating, copper removal with sulphur addition, coarse lead preparation with condensation and the like to prepare the gold-silver alloy. By directly preparing high-value gold-silver alloy with the precious antimony, the method provided by the invention is short in technological process and relatively low in cost, is efficient and environmentally friendly, saves the energy, is the first invention in the antimony industry, has better application value and is worthy of large-scale popularization and use.

Owner:广西万仕智稀贵金属科技有限公司

Performance enhancing LED (light emitting diode) preparation method and LED chip

ActiveCN107863432AReduce thicknessReduce reflective effectSemiconductor devicesOhmic contactTransmittance

The invention provides a performance enhancing LED preparation method and an LED chip. The performance enhancing LED preparation method comprises providing a semiconductor substrate, forming a patterned Ohmic contact layer which is made of Ga<x>In<(1-x)>N; forming a current expanding layer on the patterned Ohmic contact layer and a second type semiconductor layer, wherein the total thickness of the current expanding layer and the Ohmic contact layer is smaller than or equal to 1100A. By controlling the composition of In and Ga in the Ohmic contact layer, the patterned Ohmic contact layer can achieve the characteristics of higher transverse conductivity compared with the current expanding layer, good Ohmic contact features with the second type semiconductor layer, an appropriate refractiveindex, and good transmittance effects within the visible spectrum, thereby being capable of replacing a certain thickness of the current expanding layer to achieve a current expanding function and further to improve the light emitting efficiency of the LED chip.

Owner:XIAMEN CHANGELIGHT CO LTD

Matte pencil lead and preparation method thereof

The invention discloses a matte pencil lead and a preparation method thereof and belongs to the field of matte pencil lead preparation. The invention discloses the matte pencil lead for a first time,and the matte pencil lead comprises the following components: flake graphite, amorphous graphite, clay, carbon black, talcum powder, an adhesive and water. The invention further discloses a method forpreparing the matte pencil lead. The method comprises the following steps: mixing and blending the components, kneading the mixture, grinding with three rollers, kneading the ground material for a second time, carrying out lead extrusion, drying, sintering, and soaking into oil, thereby obtaining the matte pencil lead. On the basis of a conventional graphite pencil lead, the amount of graphite isreduced, and proper amounts of carbon black and talcum powder are added, so that a glare phenomenon is effectively reduced, and the matte pencil lead has the smoothness and concentration of the conventional graphite pencil lead, and meanwhile has a color overlapping effect without glare. When a picture is drawn with the matte pencil lead, the drawing smoothness is ensured, the glare phenomenon iseffectively reduced, the picture has remarkable layering, and the picture quality and the drawing artistic conception can be improved.

Owner:哈尔滨隆之道科技有限公司

High-efficiency energy-saving LED preparation technology

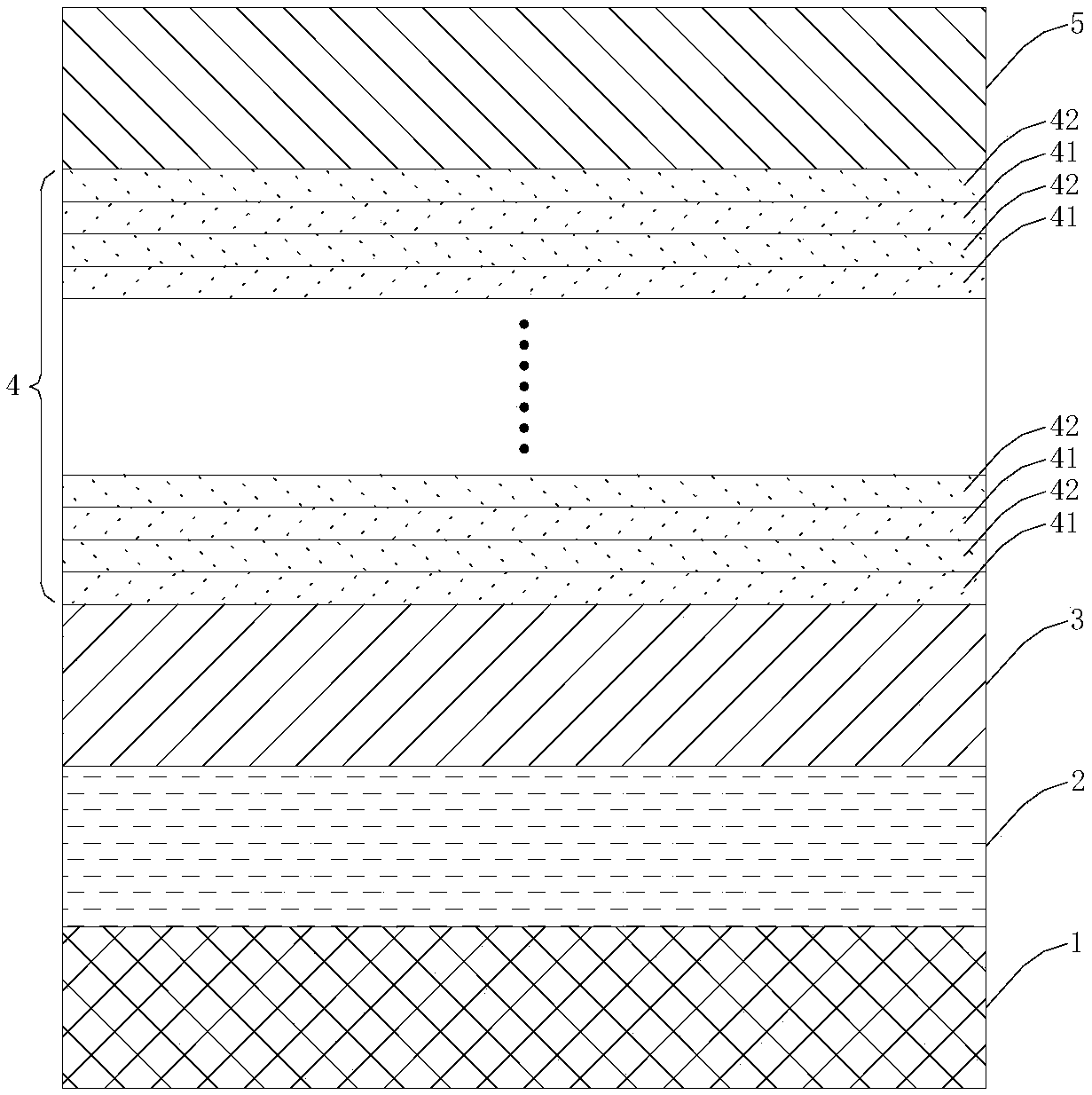

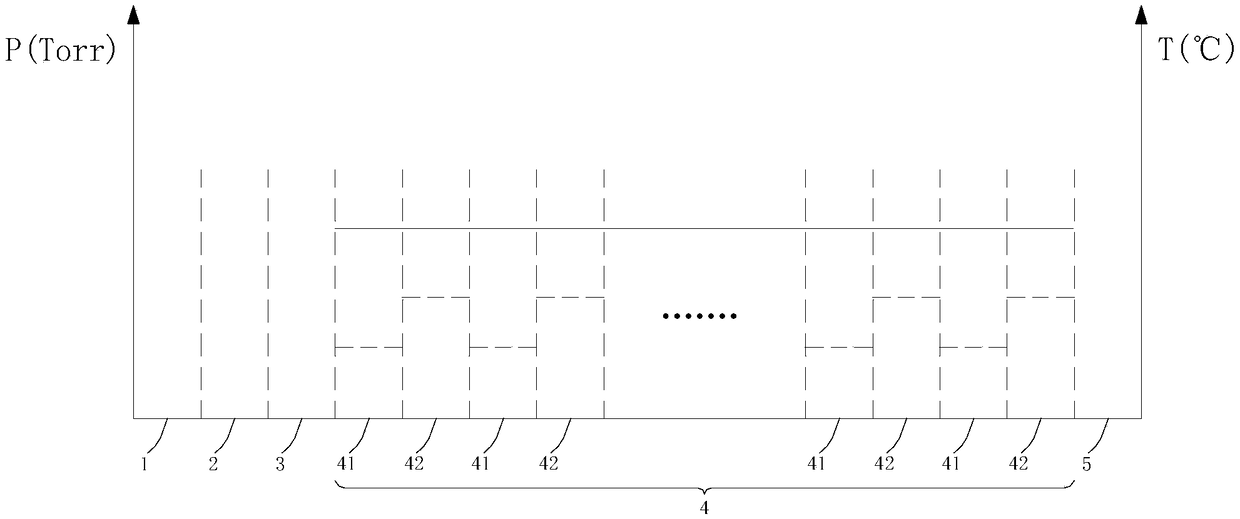

InactiveCN108258087AImprove crystal qualityComponent content is stableSemiconductor devicesIndiumGas phase

The invention provides a high-efficiency energy-saving LED preparation technology. A buffer layer, an N type GaN layer, a luminescent layer and a P type GaN layer successively deposed on a substrate in a vapor deposition technology of metal organic chemistry are included; and the luminescent layer comprises quantum well and barrier layers stacked periodically, at least one quantum well layer is ahigh-pressure quantum well layer, at least one quantum barrier layer is a low-pressure quantum barrier layer, and the pressure formed in the high-pressure quantum well layer is higher than that formedin the low-pressure quantum barrier layer. Indium is doped into gallium nitride via high pressure, the doping amount of indium is not improved by reducing the growth temperature, the quantum well layers can be deposed at a higher temperature, and the crystallization quality of the obtained quantum well layers is higher; and the cost is low, and realization is easy.

Owner:李丹丹

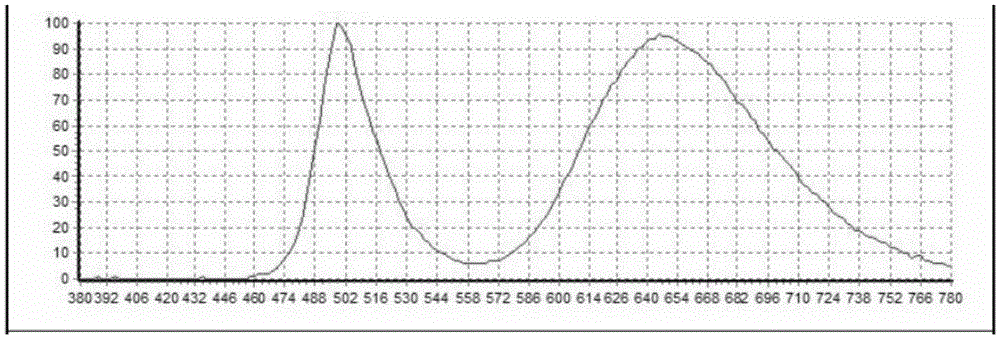

High-luminance LED preparation process

ActiveCN107799631AImprove crystal qualityHigh luminous intensitySemiconductor devicesLuminous intensityQuantum well

Disclosed is a high-luminance LED preparation process. The preparation process comprises the steps of performing epitaxial growth of a buffer layer, a non-doped GaN layer, an N type GaN layer, a stress release layer, a multi-quantum-well layer, a P type electron barrier layer and a P type GaN layer on a substrate in sequence, wherein the N type GaN layer is divided into a highly doped N type GaN layer and a lightly doped N type GaN layer; the Si concentration of the highly doped N type GaN layer is higher than the Si concentration of the lightly doped N type GaN layer; an AlGaN layer is inserted between the highly doped N type GaN layer and the lightly doped N type GaN layer; the highly doped N type GaN layer adopts a stacked structure which consists of a doped nGaN layer and a non-doped uGaN layer; the nGaN layer is in contact with the non-doped GaN layer; and the uGaN layer is in contact with the nGaN layer. By dividing the N type GaN layer into the highly doped N type GaN layer andthe lightly doped N type GaN layer, relatively high electron concentration can be accumulated in the highly doped N type GaN layer, so that ions can jump from the highly doped N type GaN layer to thelightly doped N type GaN layer, and then jump to the multi-quantum-well layer grown subsequently to be compounded with holes in the multi-quantum-well layer to give out light, so that the light emitting efficiency of the multi-quantum-well layer is improved, and the luminous intensity of the LED is further improved.

Owner:CHUZHOU HKC OPTOELECTRONICS TECH CO LTD

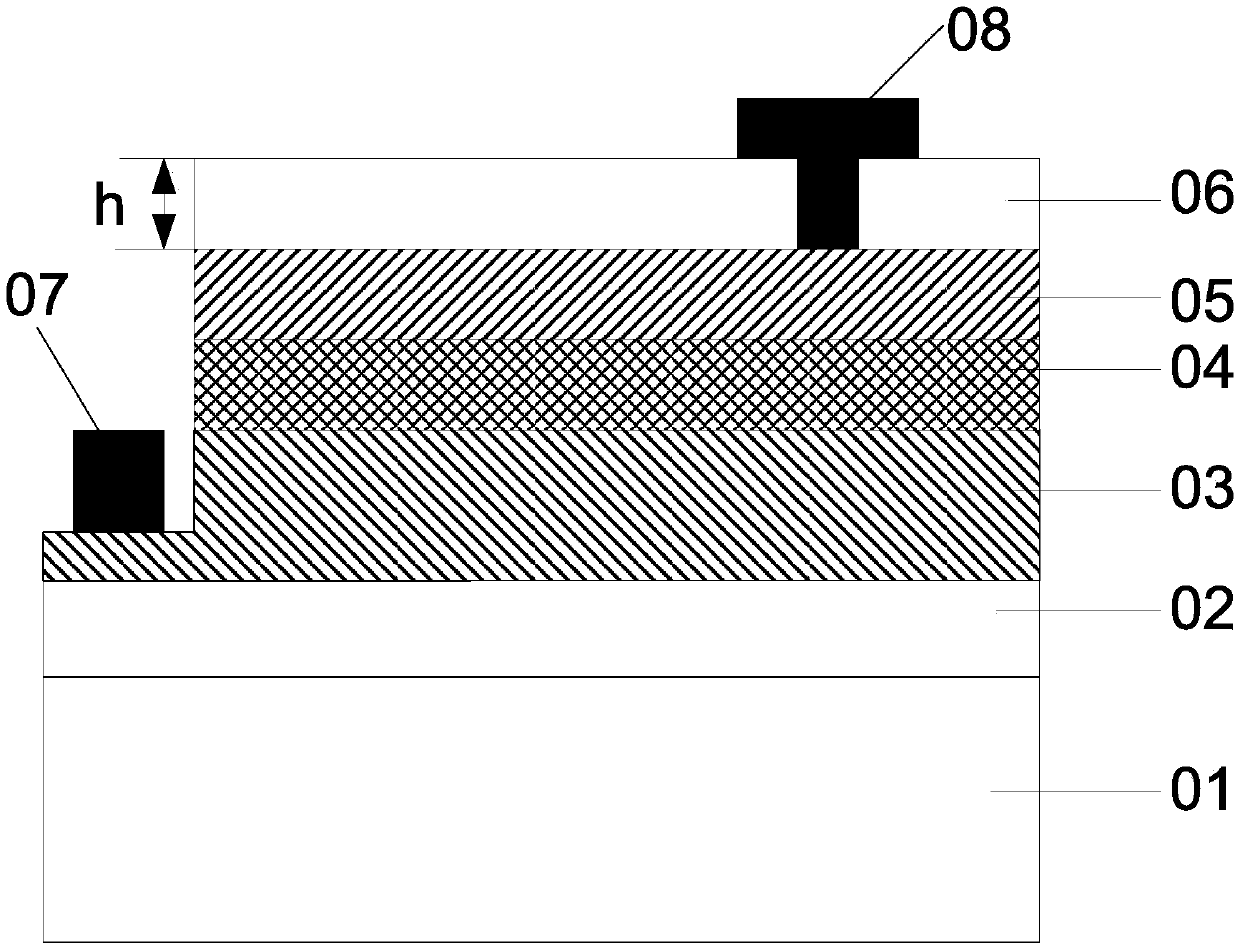

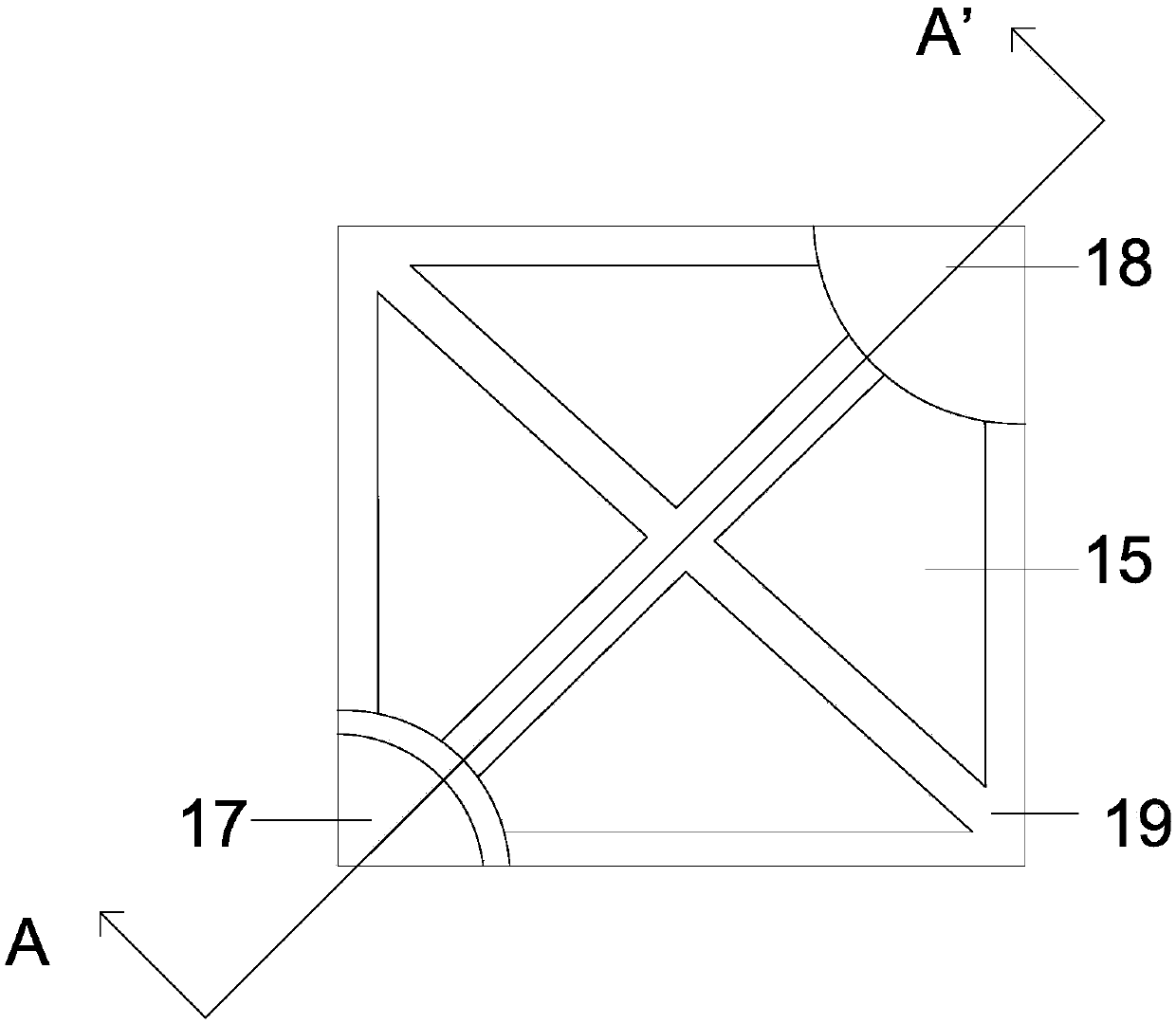

Light-emitting diode and manufacturing method thereof

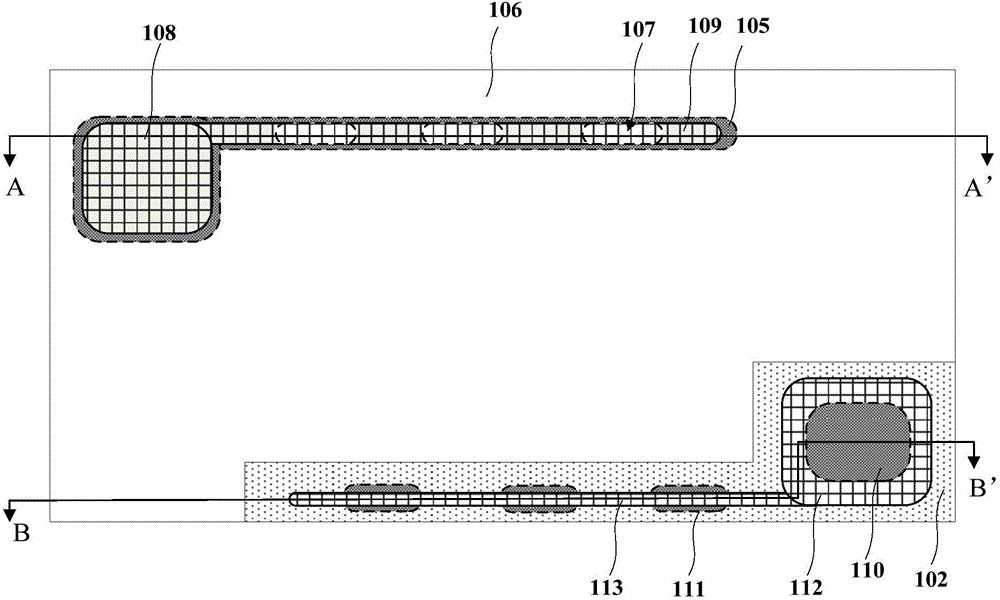

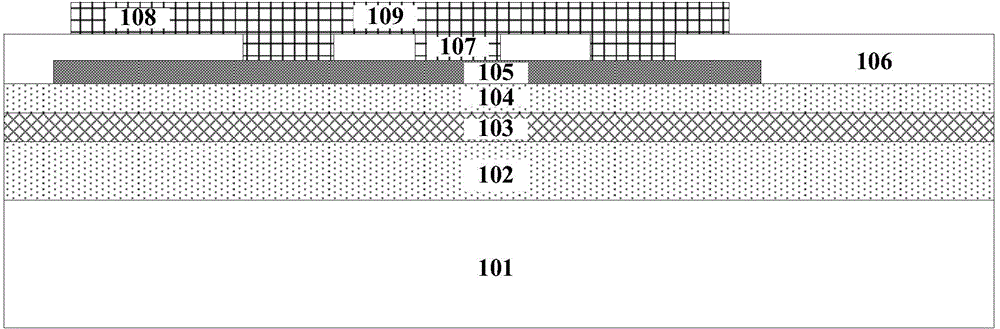

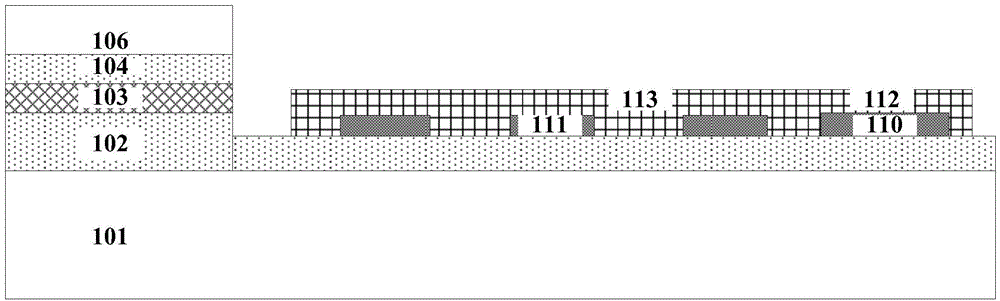

ActiveCN104465919AIncrease brightnessImprove light extraction efficiencySemiconductor devicesInsulation layerEngineering

The invention provides a light-emitting diode and a manufacturing method thereof. The light-emitting diode includes a growth substrate, a light-emitting epitaxy structure, a current spreading layer, an N electrode, a P electrode and a transparent insulation structure; an N electrode pad preparation area and an N electrode lead preparation area are formed on the light-emitting epitaxy structure; the current spreading layer is provided with a plurality of open holes which are distributed at intervals and are corresponding to the P electrode lead; the N electrode include an N electrode pad and an N electrode lead; the P electrode includes a P electrode pad and a P electrode lead; the transparent insulation structure includes a first insulation layer which is combined at a part of an interface between the N electrode pad preparation area and the N electrode lead preparation area, a second insulation layer which is combined between the N electrode lead and the N electrode lead preparation area in the form of a plurality of insulation layer segments, and a third insulation layer which is combined between a P type layer and the current spreading layer, and is located below the P electrode, and is shaped to be corresponding to the P electrode. With the light-emitting diode and the manufacturing method thereof, the current of the light-emitting diode can be distributed more uniformly, and luminous efficiency can be effectively improved, and brightness can be improved.

Owner:EPILIGHT TECH

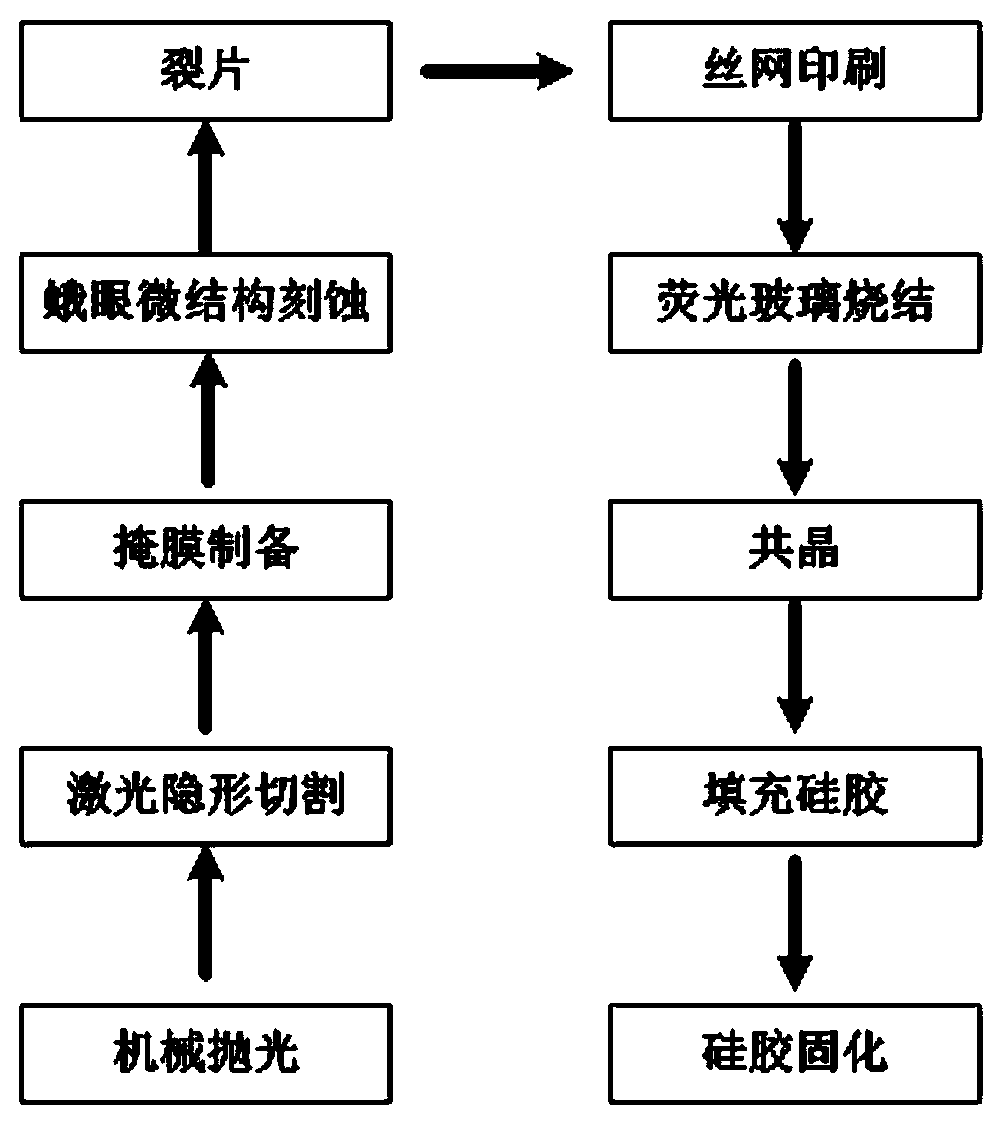

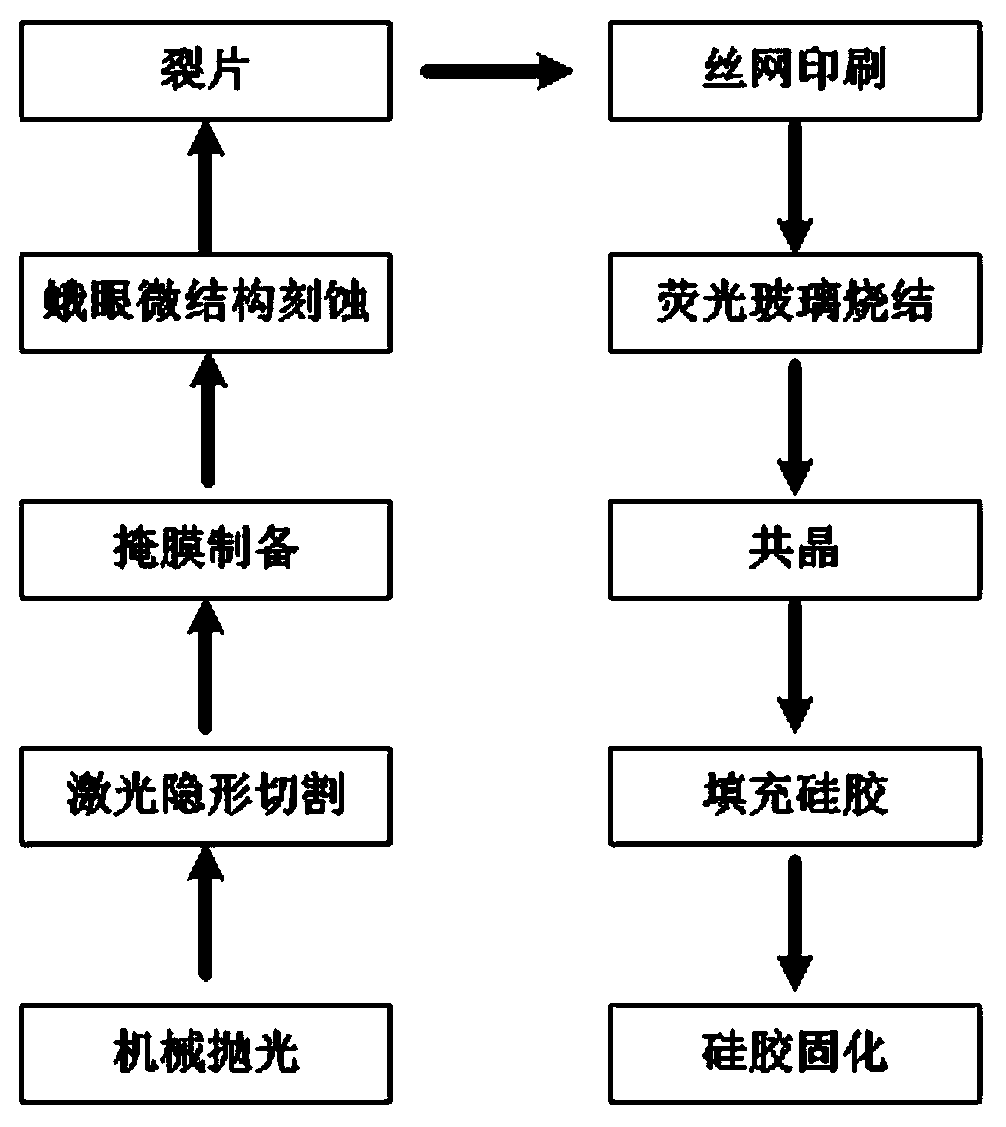

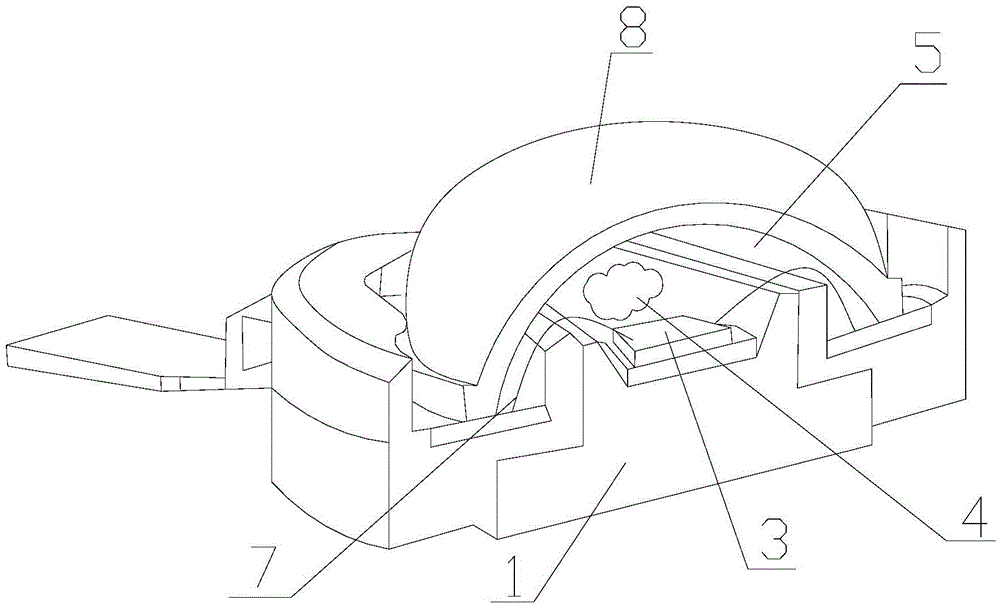

White light LED preparation method and white light LED device

InactiveCN109841720AReduced full launch effectEase of lightSemiconductor devicesFluorescenceSilica gel

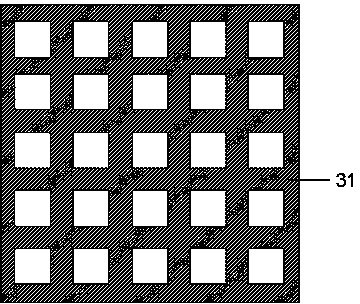

The invention provides a white light LED preparation method, which comprises the steps of: performing chemical-mechanical polishing to obtain a sapphire sheet, cutting the surface of the sapphire by using laser, and performing mask preparation, etching and sheet splitting to obtain a sapphire sheet having a moth-eye microstructure array on the upper surface; preparing a fluorescent powder layer, and sintering the fluorescent powder layer in an air furnace to obtain a fluorescent glass having a moth-eye microstructure array; coating a silica gel on a chip and a ceramic substrate; arranging thefluorescent glass having the moth-eye microstructure array on the silica gel; and curing the fluorescent glass and the silica gel to obtain a white light LED device. The invention further provides thewhite light LED device prepared by adopting the preparation method. Compared with the prior art, the white light LED device manufacturing method provided by the invention has simple process and is suitable for industrial production; and the white light LED device overcomes the problem of a material that the organic polymer turns yellow under ultraviolet irradiation, and improves the light extraction efficiency of the white light LED.

Owner:EZHOU INST OF IND TECH HUAZHONG UNIV OF SCI & TECH +1

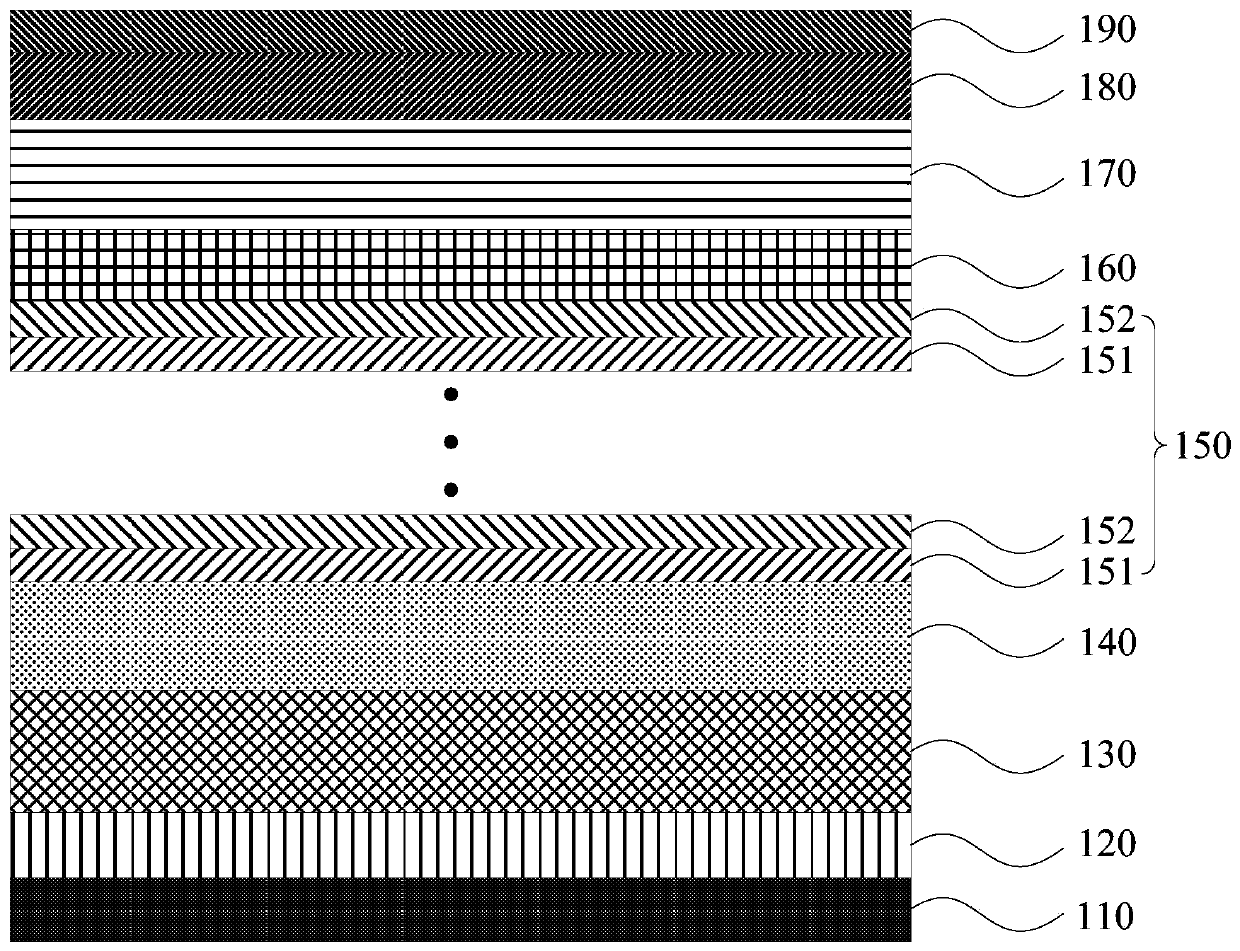

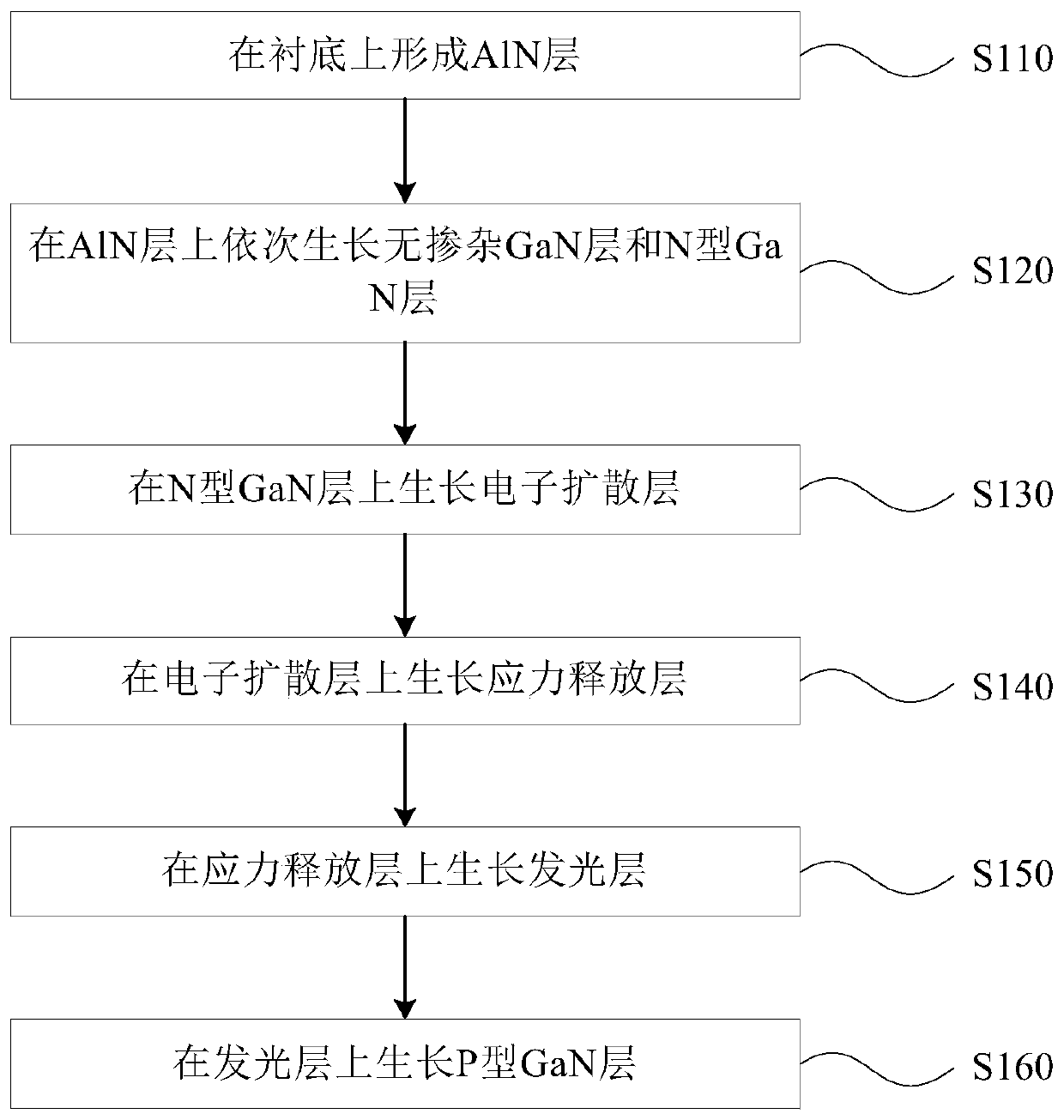

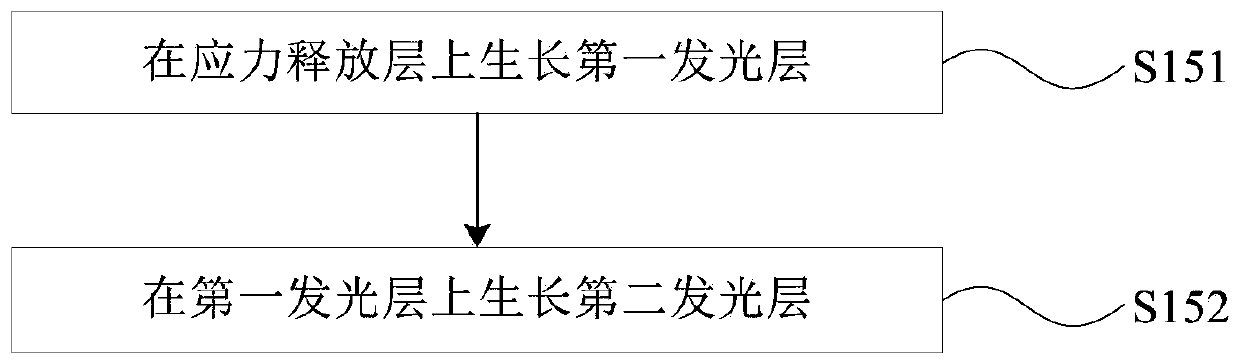

LED preparation method and LED

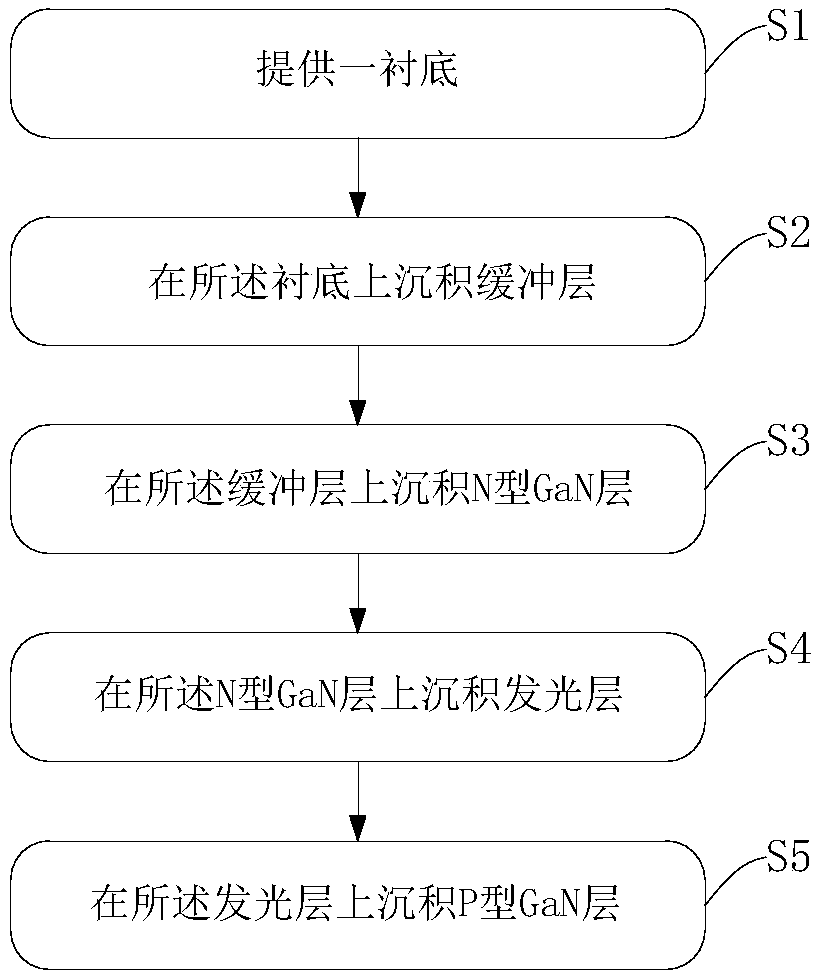

ActiveCN110061105AConcentrated glowImprove luminous efficiencySemiconductor devicesOptoelectronicsElectron

The invention provides an LED preparation method and an LED. The LED preparation method provided by the invention comprises the steps of forming an AlN layer on a substrate; growing an undoped GaN layer and an N-type GaN layer on the AlN layer in sequence; growing an electron diffusion layer on the N-type GaN layer; growing a stress release layer on the electron diffusion layer; growing a light-emitting layer on the stress release layer; and growing a P-type GaN layer on the light-emitting layer. According to the LED preparation method provided by the invention, the electron and hole recombination probability is relatively high; and the light-emitting efficiency of the LED is relatively high.

Owner:JIANGXI EPITOP OPTOELECTRONICS

A kind of flip-chip LED chip and preparation method thereof

ActiveCN104733600BSimple packaging processReduce manufacturing costSemiconductor devicesReflective layerProtection layer

The present invention is a flip-chip LED chip and its preparation method, comprising a sapphire substrate, an InGaAlN multilayer structure formed on the sapphire substrate, and the InGaAlN multilayer structure includes an N-type GaN layer and multiple quantum wells from bottom to top layer and a P-type GaN layer, a reflective layer formed on the P-type GaN layer, a metal protective layer deposited on the surface of the reflective layer, and a part of the metal protective layer is etched to expose the N formed by the N-type GaN layer. Electrode holes, the passivation layer formed on the part of the surface of the metal protective layer and the side walls of the N electrode holes, the N electrodes formed by depositing metal in the N electrode holes and connecting multiple N electrode holes, The P electrode formed on the metal protection layer covered by the passivation layer is characterized in that the flip-chip LED chip also includes a solder paste layer formed on the N electrode and the P electrode, and a metal barrier is formed around the solder paste layer. Floor.

Owner:LATTICE POWER (JIANGXI) CORP

Flip Chip Light Emitting Diode and Its Manufacturing Method and Application

ActiveCN103489983BImprove light outputImprove cooling effectSemiconductor devicesDiamond-like carbonRefractive index

A flip-chip light emitting diode is disclosed, and includes: a substrate, a semiconductor multilayer structure, first and second electrodes, first and second diamond-like-carbon / conductive-material composite structures, and a passivation layer, wherein, the passivation layer is a stacked structure possessing a material of different refractive index, and the first and second diamond-like-carbon / conductive-material can buffer thermal stress in the flip-chip light emitting diode. Therefore, the flip-chip light emitting diode can improve the whole photoelectric efficiency, and prevent the photoelectric characteristic of elements from being decreased, and accordingly its reliability and service life are improved. A method of manufacturing the abovementioned flip-chip light emitting diode and application thereof are also disclosed.

Owner:RITEDIA CORPORATION

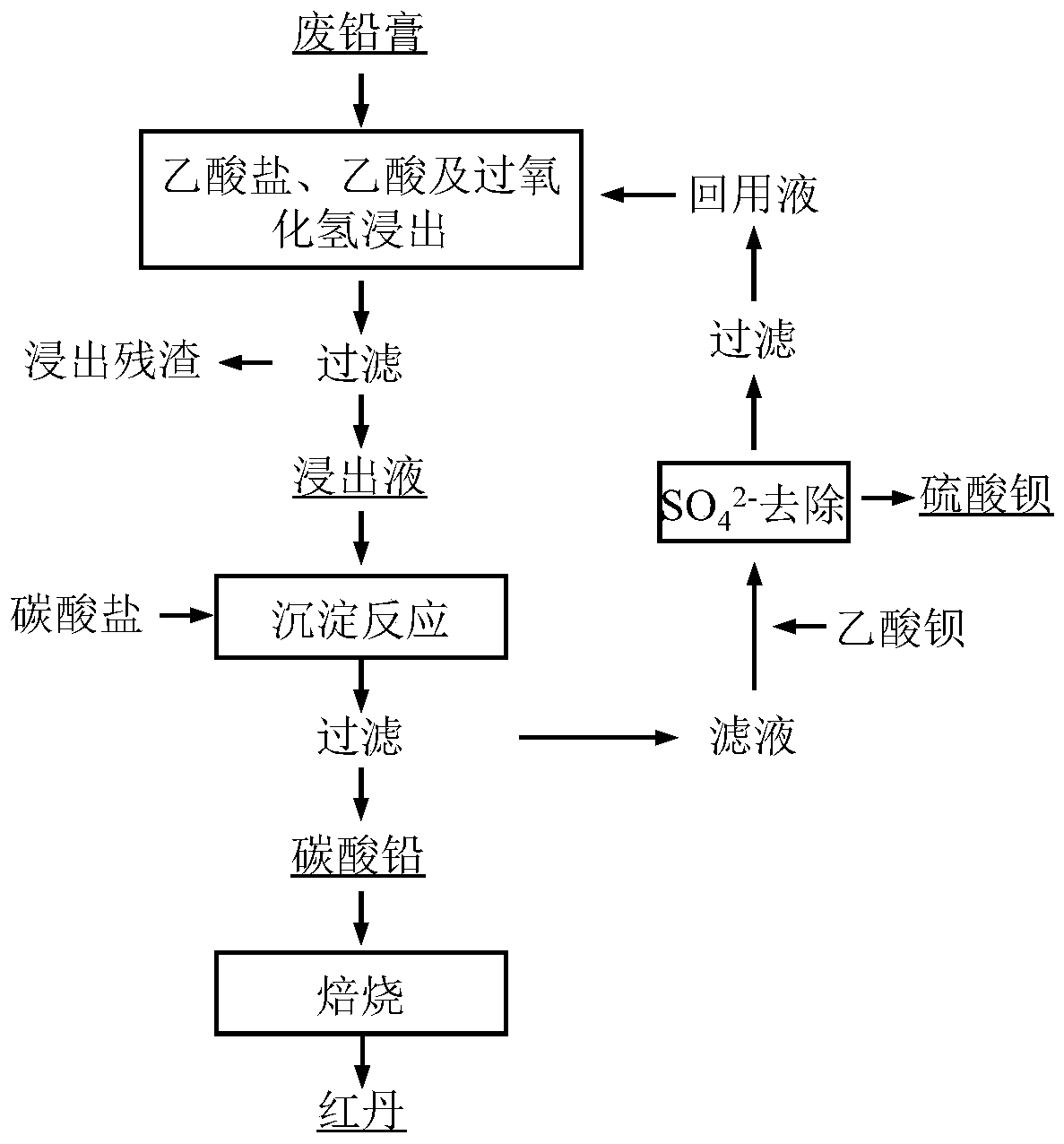

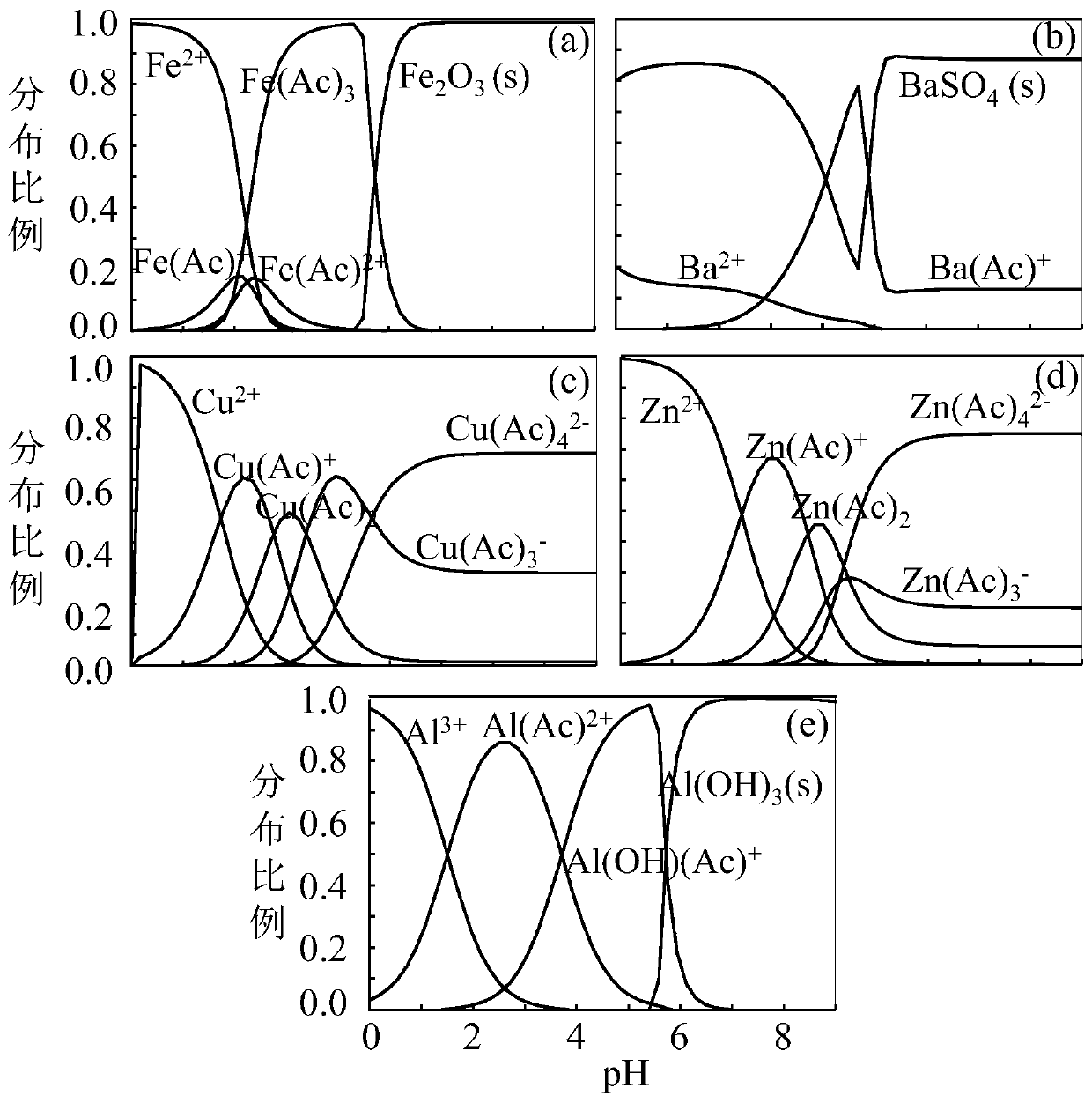

Method for achieving filter liquor circulation, recovering waste lead plaster through wet process and preparing high-purity red lead

ActiveCN109868366AClose the loopAchieve directional separationProcess efficiency improvementOrganic acidLead carbonate

The invention discloses a method for achieving filter liquor circulation, recovering waste lead plaster through a wet process and preparing high-purity red lead and relates to the technical field of waste lead-acid cell lead plaster wet process recovery and red lead preparation. The method comprises the following steps that 1, organic acid salt, organic acid and reducer mixed liquor are utilized for leaching out the waste lead plaster, and after solid and liquid are separated, lixivium is obtained; 2, a carbonate solution is added to the lixivium, the reaction pH is regulated, and solid and liquid separating is carried out to obtain lead carbonate sediment and filter liquor; and 3, lead carbonate is roasted in the aerobic atmosphere, and the high-purity red lead with low impurity content is prepared. The prepared red lead product is high in purity and low in impurity content, the content of main impurities Ba and Fe is smaller than 10 mg / kg, the content of Cu, Zn and Al impurity elements is smaller than 1 mg / kg, the filter liquor can achieve closed circulation of organic acid radical ligand in a leaching system, and the use efficiency of a leaching agent is improved remarkably.

Owner:HUAZHONG UNIV OF SCI & TECH

Method for preparing high-heat dissipation LED substrate through abandoned straight-chain silica gel modification

ActiveCN106098897AImprove cooling effectImprove performanceSemiconductor devicesPolymer sciencePolyvinyl alcohol

The invention relates to a method for preparing a high-heat dissipation LED substrate through abandoned straight-chain silica gel modification and belongs to the technical field of LED preparation. The method comprises the steps of crushing abandoned straight-chain silicone rubber and polyethylene plastic into mixed blocks; mixing the mixed blocks with a dissolved solution prepared from the substances of cyclohexane and the like to obtain mixed and modified sol for later use; carrying out ball-milling on the substances of Al2O3, brass powder and the like, mixing and stirring the product and polyvinyl alcohol, and carrying out dry pressing and drying to obtain a dried and dry-pressed blank; and coating the mixed and modified sol on the dried and dry-pressed blank and carrying out calcination to prepare the high-heat dissipation LED substrate. The prepared LED substrate is good in heat dissipation performance; the heat transfer coefficient is 2.0-3.0W / m.k; the thermal expansion coefficient is low; and the performance of a device is effectively improved.

Owner:PINGHU IENERGY LIGHTING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com