White LED preparation method and LED

A technology of light-emitting diodes and diodes, applied in the field of diodes, can solve the problems of difficult to ensure product quality in mass production, low color rendering index of white lights, cumbersome manufacturing process, etc., and achieve simple structure, improved concentration, and reasonable ratio Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

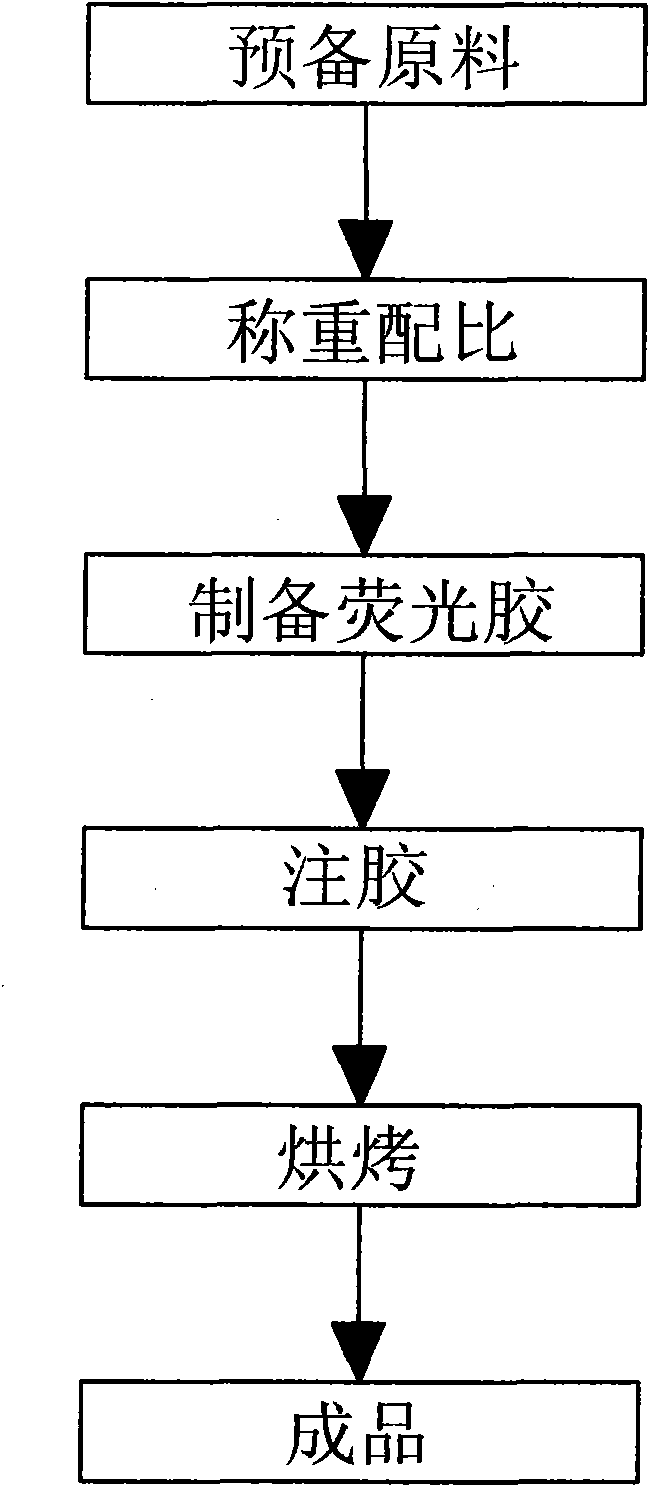

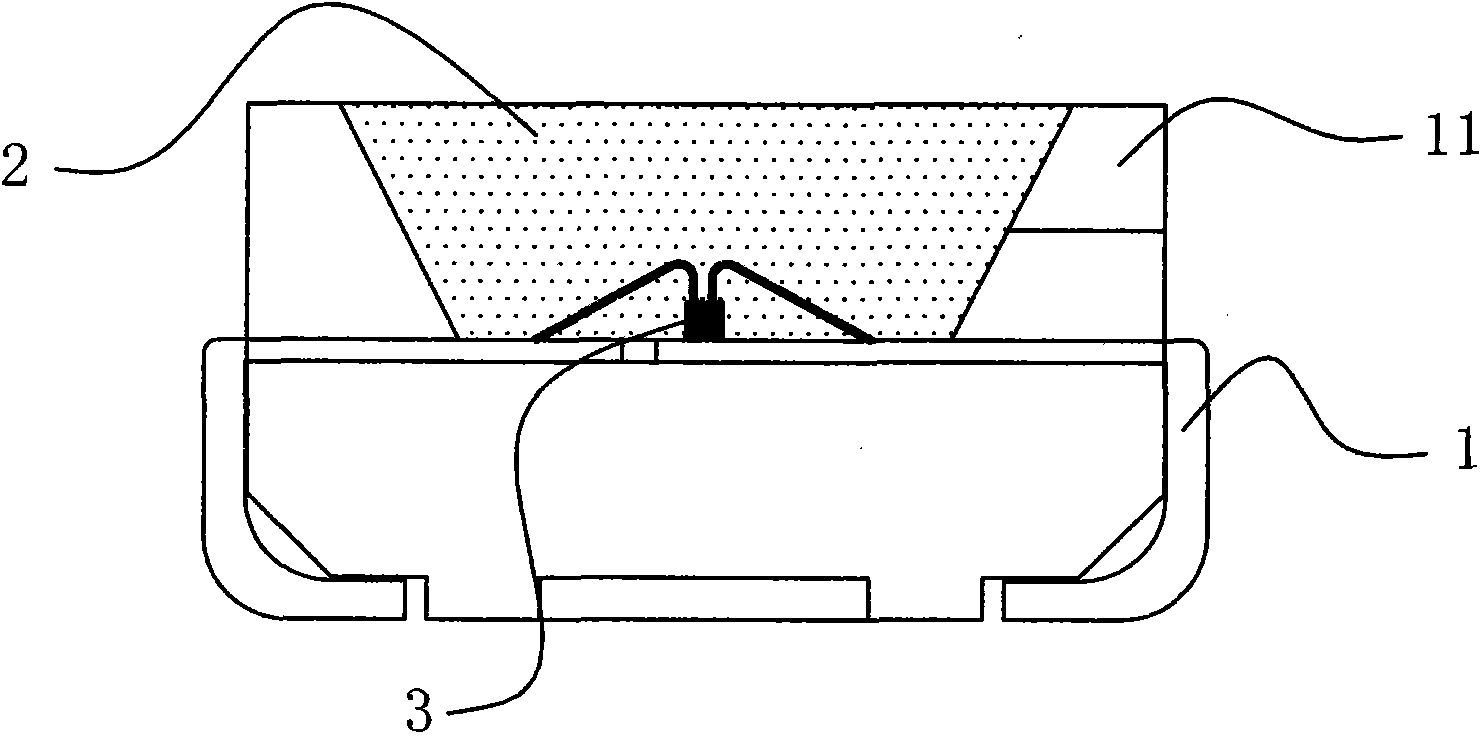

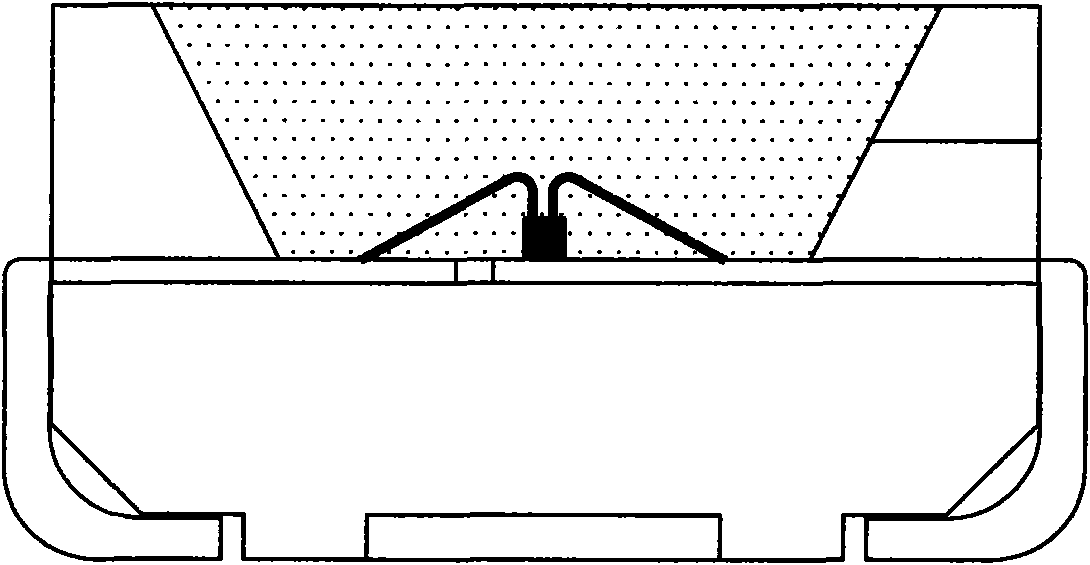

[0041] Example: see figure 1 and figure 2 , the present embodiment provides a method for preparing a white light emitting diode, which includes the following steps:

[0042] (1) Prepare raw materials: raw materials include two-component silica gel A, two-component silica gel B, fluorescent powder and red powder;

[0043] (2) Weight ratio: The weight ratio of the two-component silica gel A, the two-component silica gel B, the fluorescent powder and the red powder is:

[0044] 1:4:X:Y

[0045] Among them, X is 0.15-0.20, and Y is 0.003-0.006;

[0046] (3) Prepare fluorescent glue 2: uniformly mix the raw materials of two-component silica gel A, two-component silica gel B, fluorescent powder, and red powder with a good weight ratio to prepare fluorescent glue 2;

[0047] (4) Glue injection: prepare a diode bracket 1 with a cup body 11 on the top and a blue chip 3 at the bottom of the cup body 11, inject the fluorescent glue 2 into the cup body 11 of the diode bracket 1 ;

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com