Purple LED (light-emitting diode) preparation method, purple LED and chip

A purple light and crystal nucleus technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of purple light LEDs such as poor antistatic performance, easy to generate dislocations, and poor luminous efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

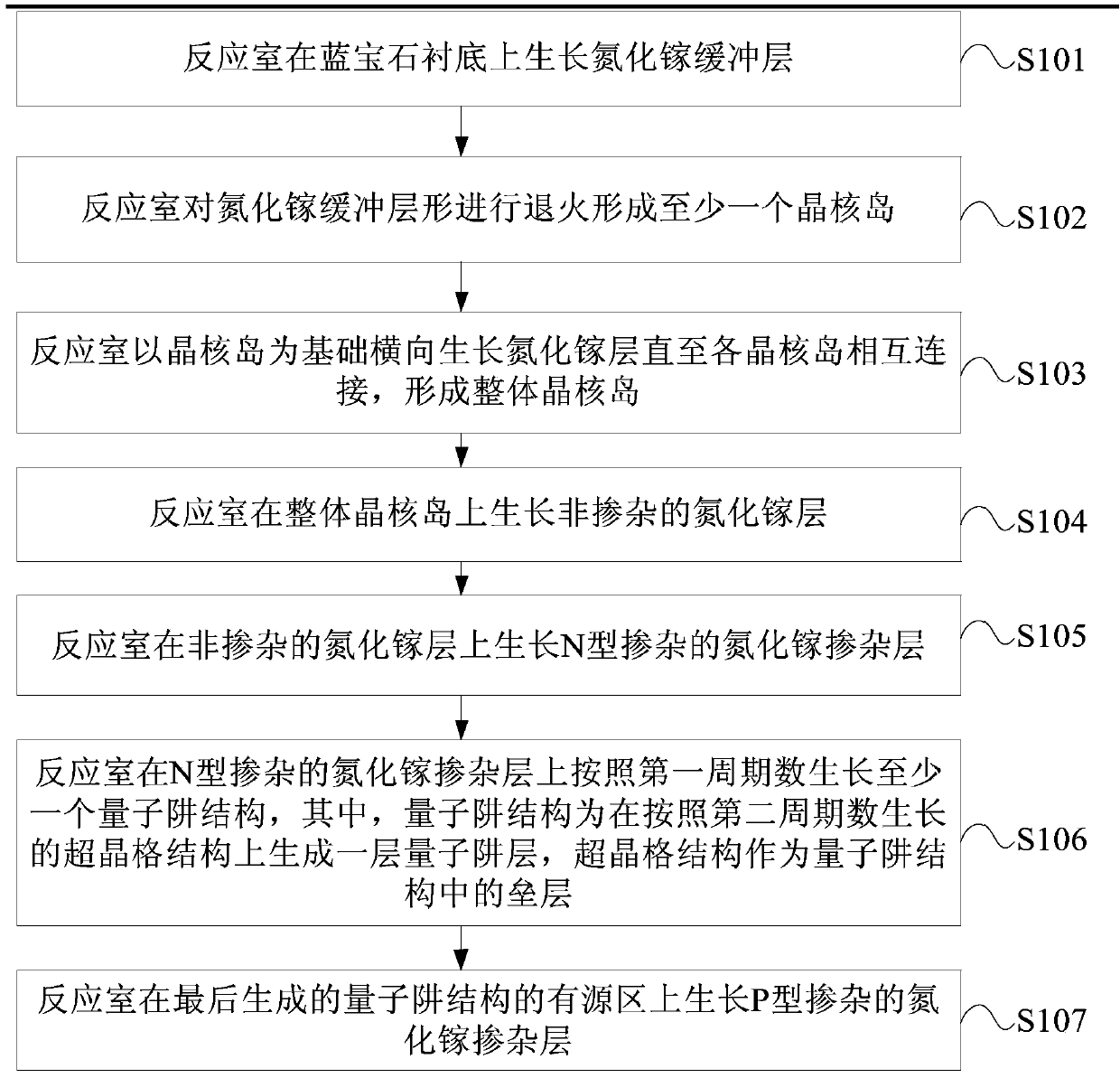

[0023] figure 1 The flow chart of the preparation method of purple light LED provided by the present invention, such as figure 1 As shown, the method includes:

[0024] It should be noted that this method can be implemented in growth equipment, which can be metal-organic chemical vapor deposition equipment (Metal-organic Chemical Vapor Deposition, MOCVD), molecular beam epitaxy equipment (Molecular Beam Epitaxy, MBE) or hydride vapor phase epitaxy equipment (Hydride Vapor Phase Epitaxy, HVPE).

[0025] S101. A reaction chamber grows a gallium nitride buffer layer on a sapphire substrate.

[0026] For example, when the temperature is 530°C and the pressure is 500torr, the reaction chamber is fed with trimethylgallium and NH3 for about 3.5 minutes at the same time, and at least one gallium nitride GaN buffer layer with a thickness of 5nm-60nm is grown on the sapphire substrate , wherein the feed rate of trimethylgallium is 150ml / min. Preferably, the thickness of the grown ga...

Embodiment 2

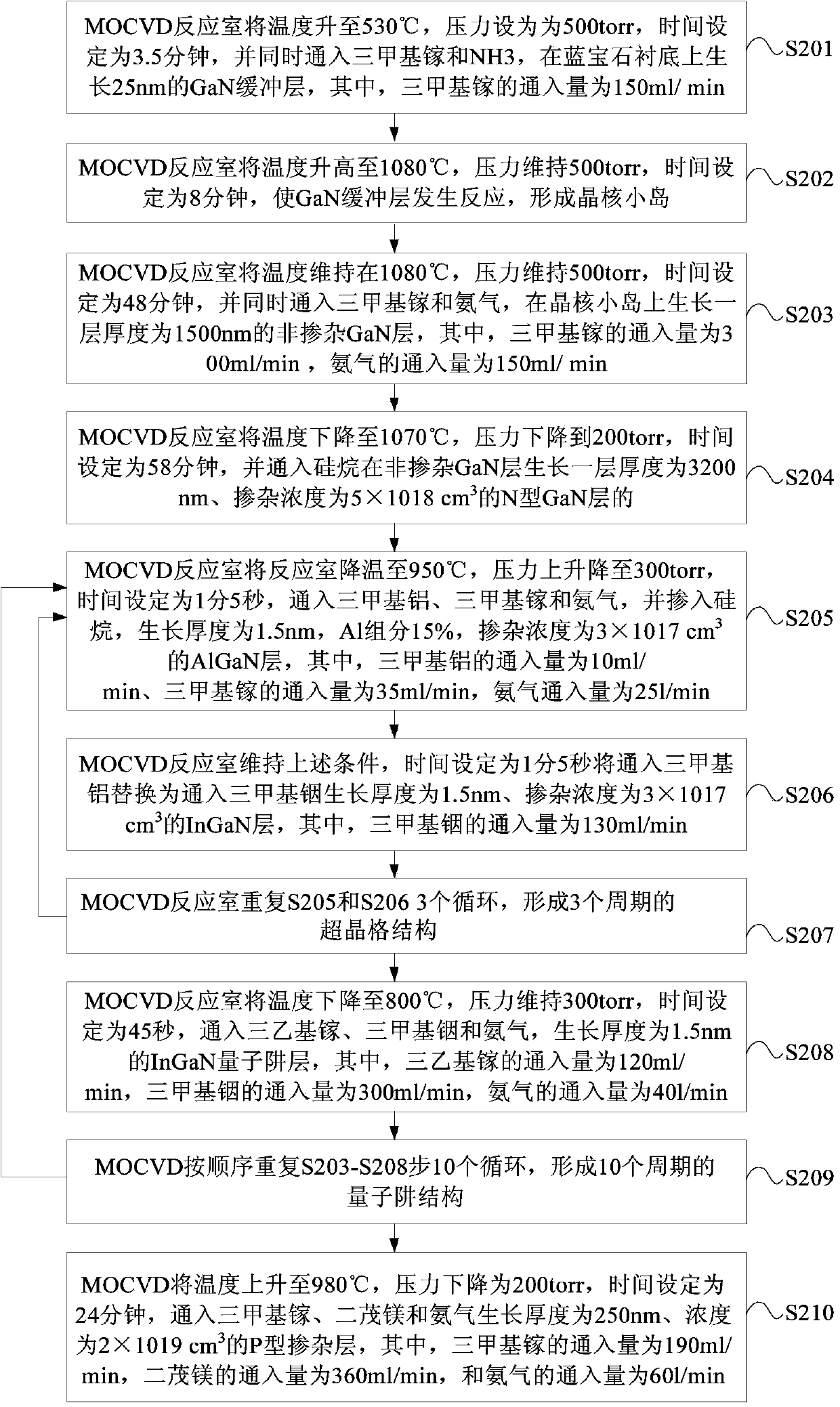

[0046] figure 2 The flowchart of another preparation method for purple LED provided by the present invention is illustrated by taking MOCVD reaction chamber such as purple LED with a growth wavelength of 390nm as an example, as figure 2 As shown, the method includes:

[0047] S201. The temperature of the MOCVD reaction chamber is raised to 530° C., the pressure is set to 500 torr, and the time is set to 3.5 minutes, and trimethylgallium and NH3 are simultaneously introduced to grow a 25 nm GaN buffer layer on the sapphire substrate, wherein, The feed rate of trimethylgallium is 150ml / min.

[0048] S202. The temperature of the MOCVD reaction chamber is raised to 1080° C., the pressure is maintained at 500 torr, and the time is set at 8 minutes, so that the GaN buffer layer reacts to form crystal nucleus islands.

[0049] S203. The MOCVD reaction chamber maintains the temperature at 1080°C, the pressure at 500 torr, the time is set at 48 minutes, and trimethylgallium and amm...

Embodiment 3

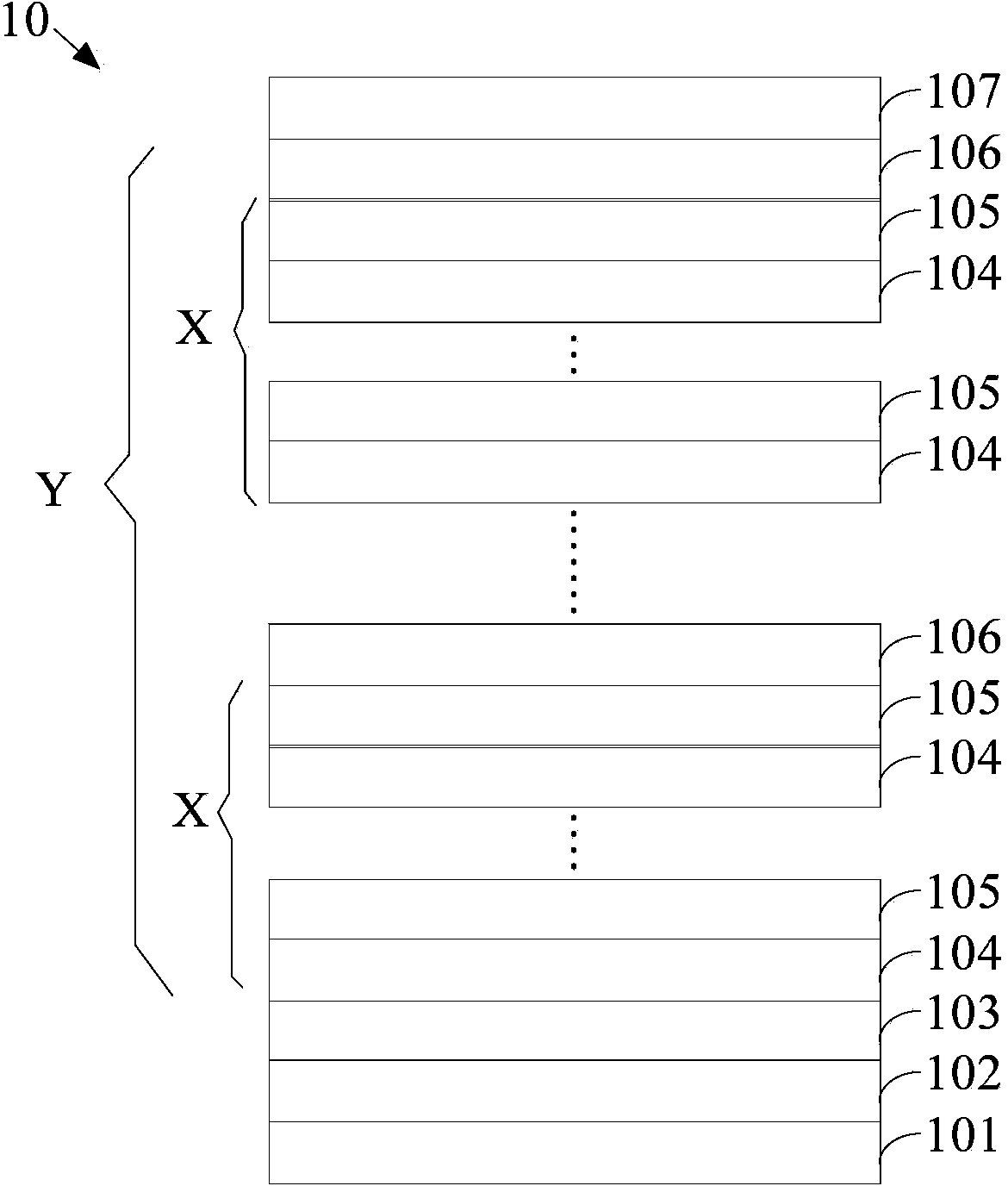

[0059] image 3 The structural representation of the purple LED provided by the present invention, such as image 3 As shown, the violet LED10 includes:

[0060] GaN buffer layer 101, undoped GaN cladding layer 102, N-type doped layer 103, AlGaN layer 104 in the superlattice, InGaN 105 in the superlattice, InGaN quantum well layer 106, P-type electron blocking layer 107 and P-type doped layer 108, and, image 3 The X in it is 2-20, and the Y is 2-20.

[0061] Further, the AlGaN layer 104 in the superlattice and the InGaN 105 in the superlattice constitute a superlattice structure as a quantum barrier layer in the quantum well structure.

[0062] It should be noted that the purple LED 10 can be based on the above-mentioned embodiments and figure 1 with figure 2 Prepared by the method shown, the structure is as image 3 shown.

[0063] The preparation method of the violet LED provided by the embodiment of the present invention includes: growing a gallium nitride buffer l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com