Double-heterojunction gallium nitride based HEMT (High Electron Mobility Transistor) taking aluminum-gallium-nitrogen as high-resistance layer and manufacturing method thereof

A double-heterojunction, GaN-based technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problem of AlGaN barrier layer crystal quality, surface and interface quality deterioration, mobility reduction, and impact on Device reliability and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

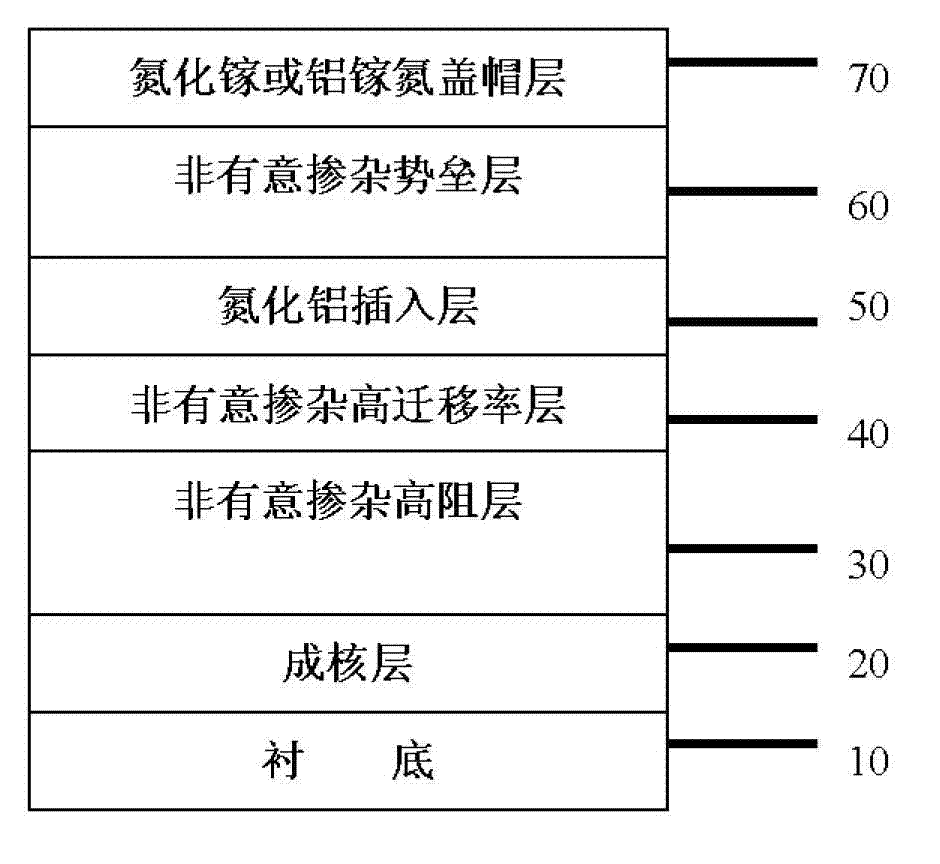

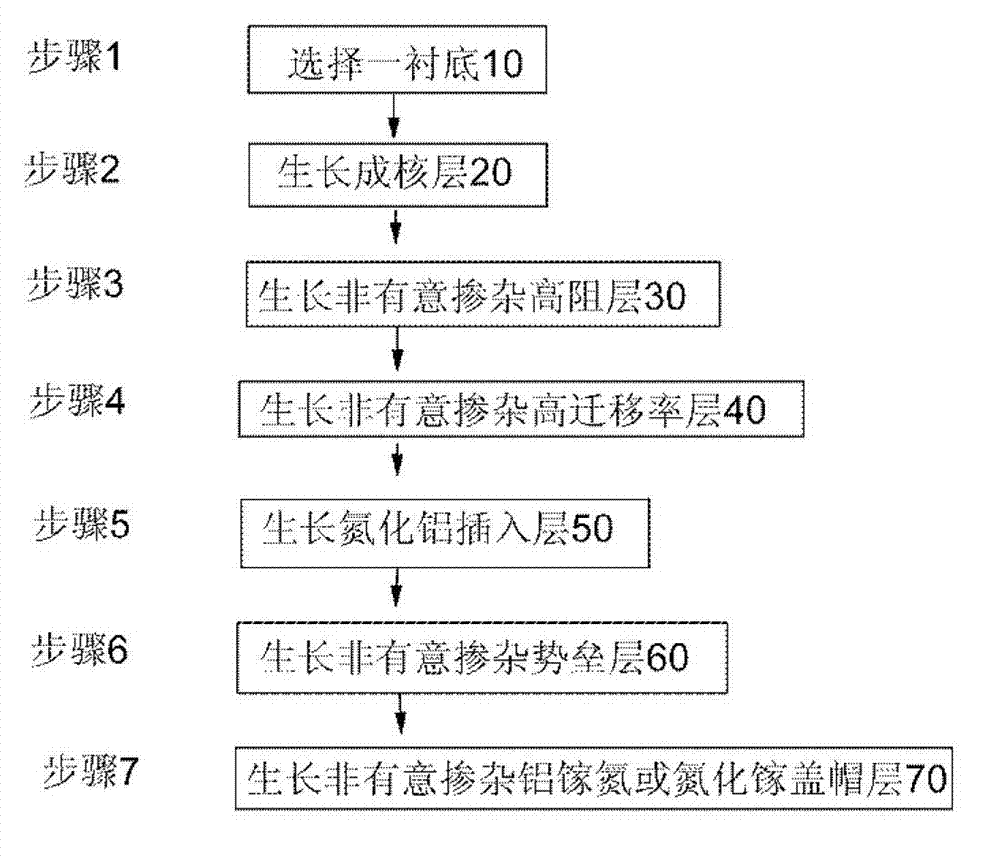

[0050] The invention provides a double-heterojunction GaN-based HEMT with AlGaN as a high-resistance layer, including:

[0051] A substrate 10, the material of the substrate 10 is sapphire;

[0052] A nucleation layer 20, the nucleation layer 20 is made on the substrate 10, the material of the nucleation layer 20 is low-temperature gallium nitride, and the thickness is 100nm;

[0053] An unintentionally doped high-resistance layer 30, the unintentionally doped high-resistance layer 30 is fabricated on the nucleation layer 20, and the material of the unintentionally doped high-resistance layer 30 is Al 0.05 Ga 0.95 N, with a thickness of 1.5 μm;

[0054] An unintentionally doped high-mobility layer 40, the unintentionally doped high-mobility layer 40 is fabricated on the unintentionally doped high-resistance layer 30, and the material of the unintentionally doped high-mobility layer 40 is gallium nitride , with a thickness of 30nm;

[0055] An aluminum nitride insertion lay...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com