High-efficiency energy-saving LED preparation technology

A preparation process, high-efficiency and energy-saving technology, applied in the field of lighting, can solve the problems of commercial production, high preparation cost, complicated process, etc., and achieve reduction of production cost and process complexity, easy controllable wavelength, and indium component content stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

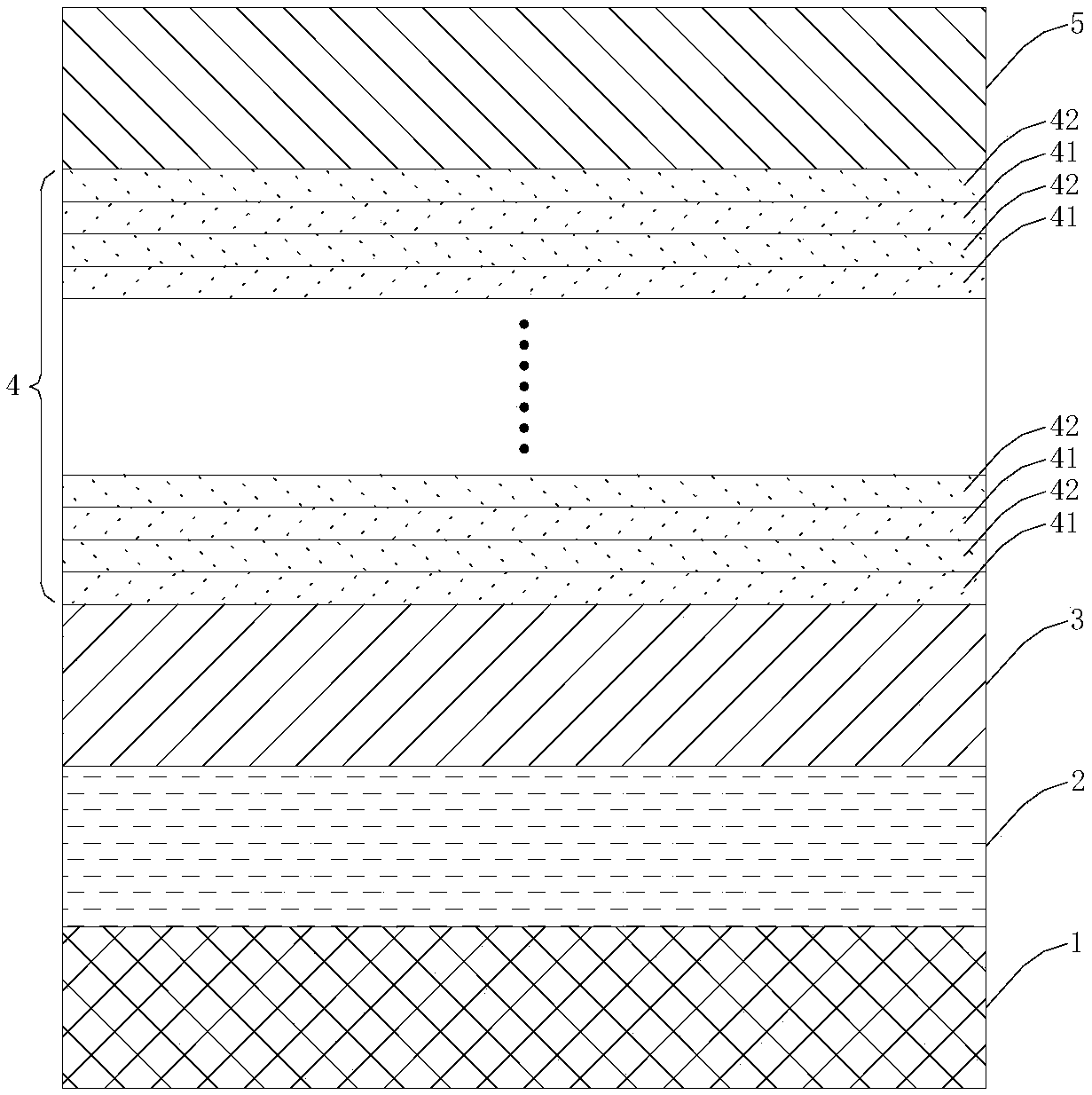

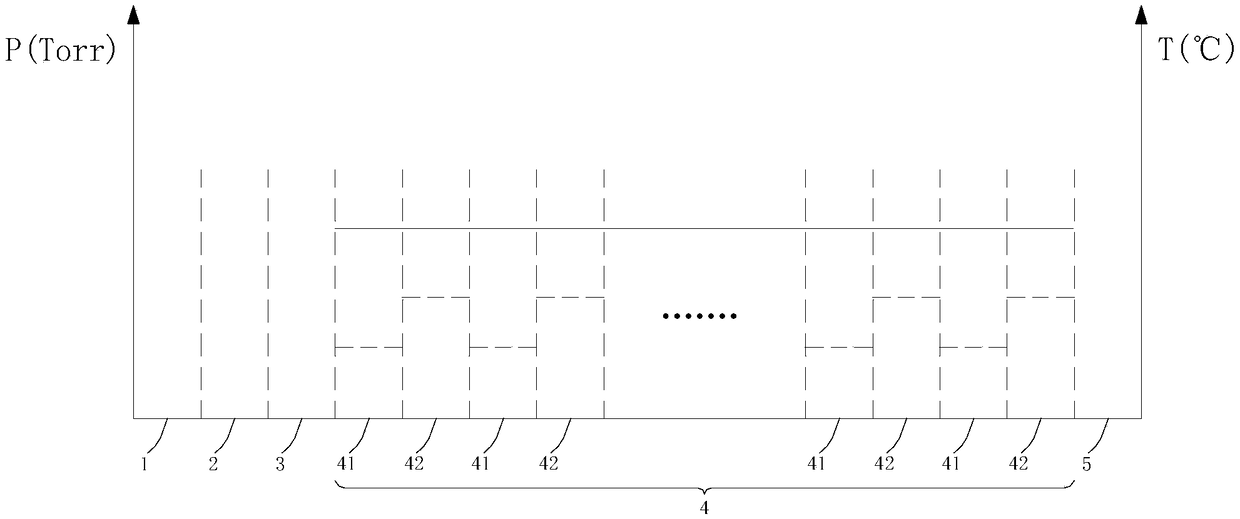

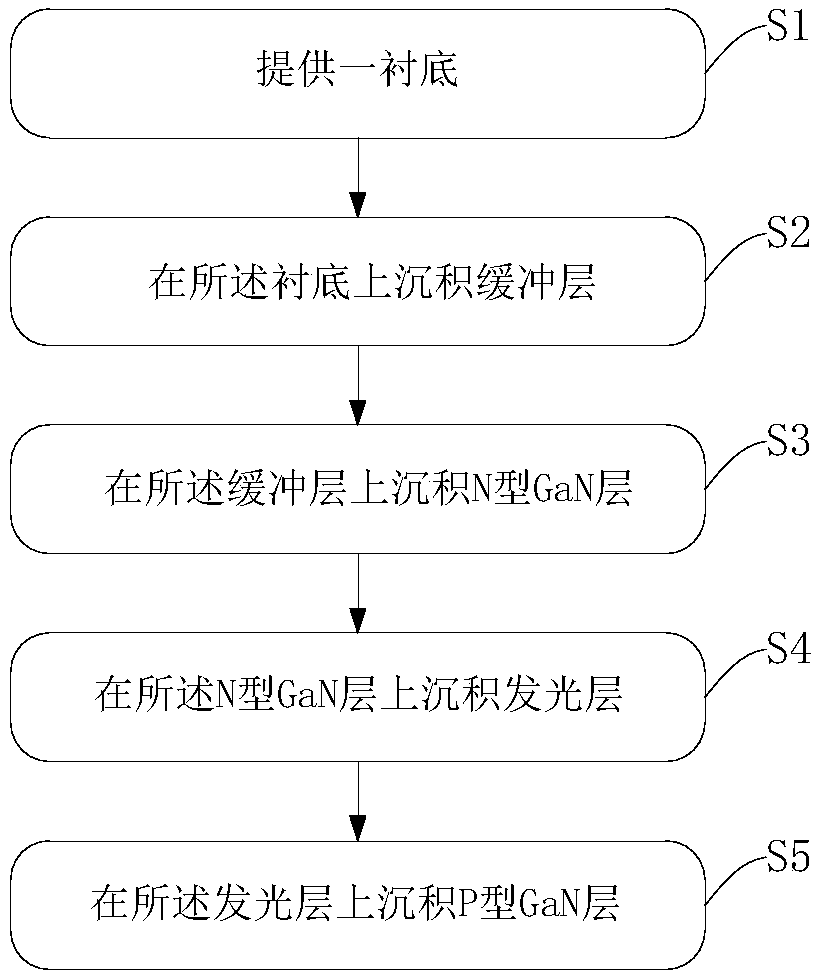

[0027] In the prior art, LED structures such as figure 1 As shown, it includes a buffer layer 2, an N-type GaN layer 3, a light-emitting layer 4, and a P-type GaN layer 5 sequentially deposited on a substrate 1 by a metal-organic chemical vapor deposition process; the light-emitting layer 4 includes periodically stacked quantum well layers 41 and quantum barrier layer 42, the pressure and temperature when forming quantum well layer 41 and quantum barrier layer 42 are as figure 2 As shown (the horizontal solid line above the coordinate system in the figure represents the pressure, and the horizontal dotted line below represents the temperature, and the expressions in the subsequent corresponding figures are consistent and will not be repeated), in the prior art, when forming the quantum well layer 41 and the quantum well layer 41 The pressure of the barrier layer 42 is equal, and the temperature for forming the quantum well layer 41 is lower than the temperature for forming th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com