Matte pencil lead and preparation method thereof

A pencil lead, matte technology, applied in pencil lead, home appliances, applications, etc., can solve problems such as reflection, affect the quality of the picture and the expression of artistic conception, achieve a clear sense of hierarchy, improve the artistic conception of painting, and ensure smoothness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

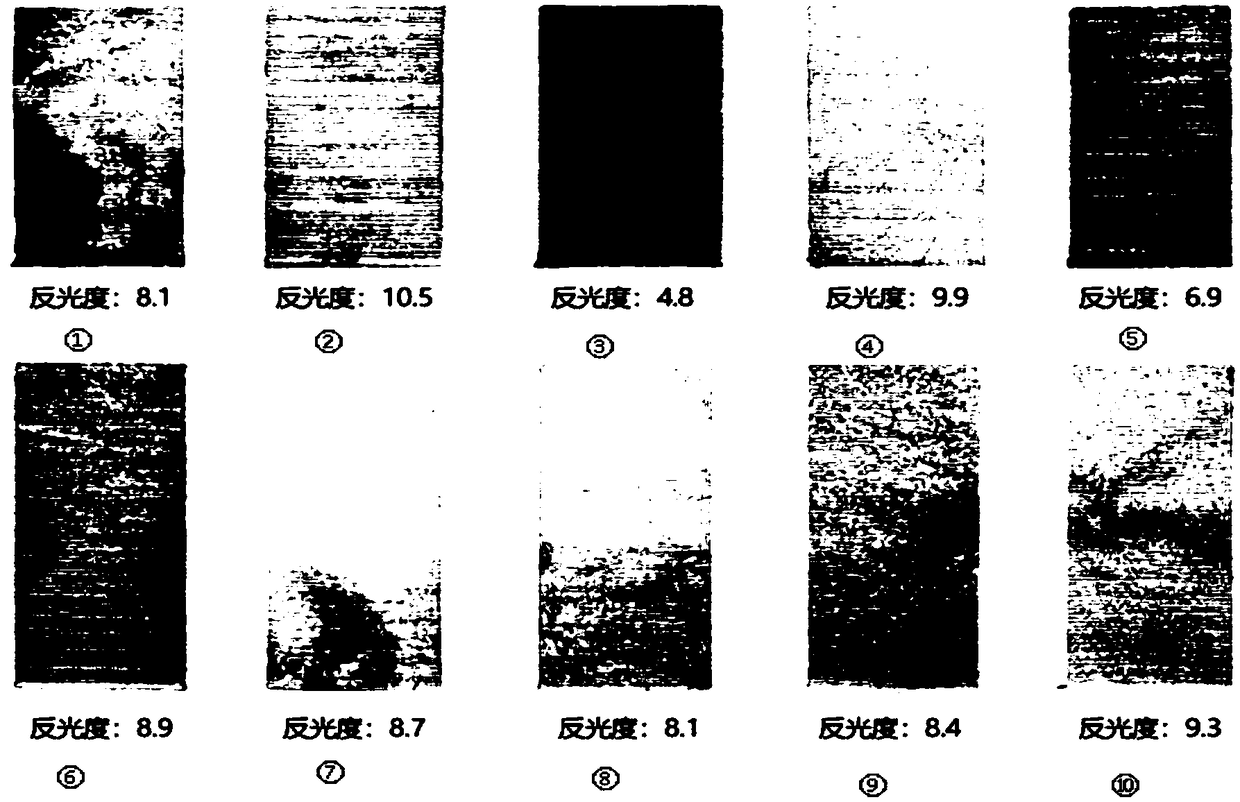

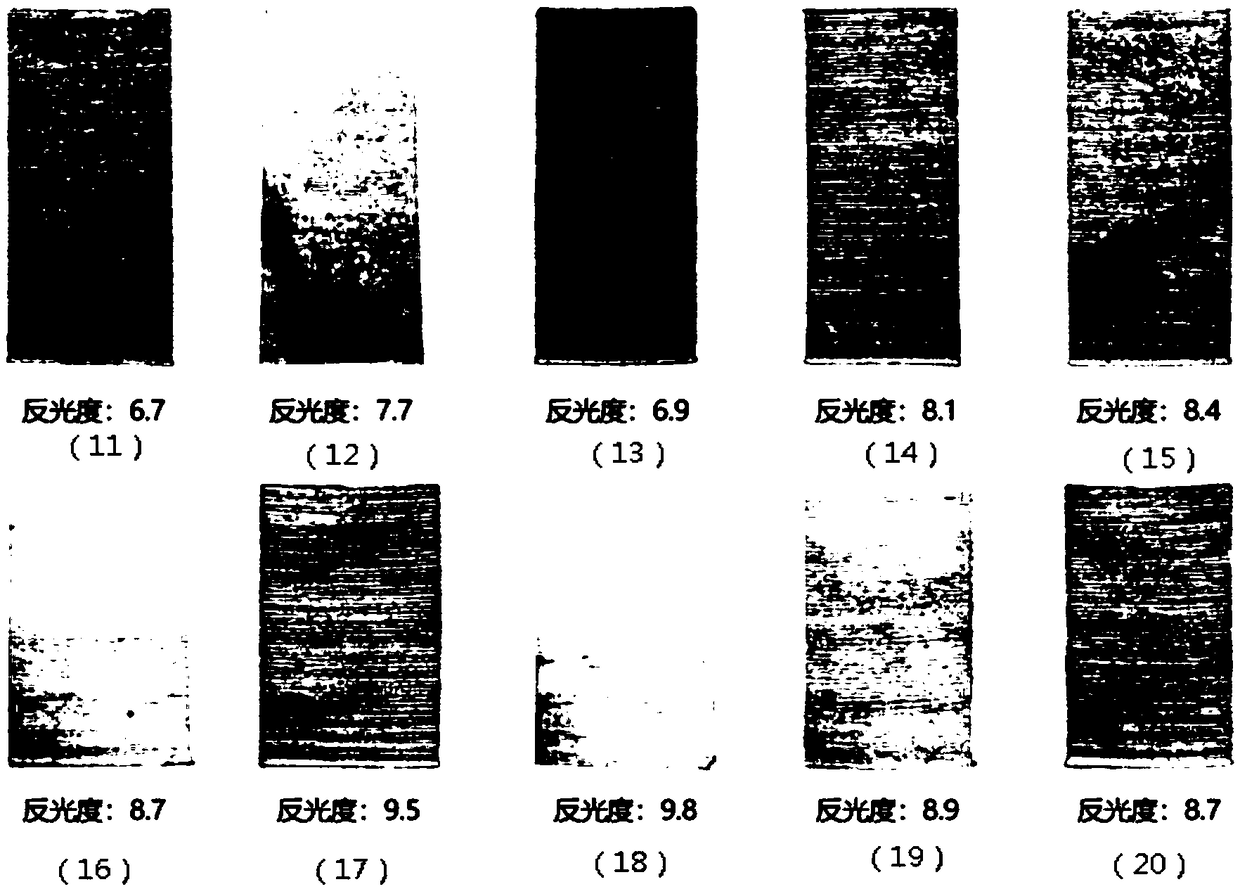

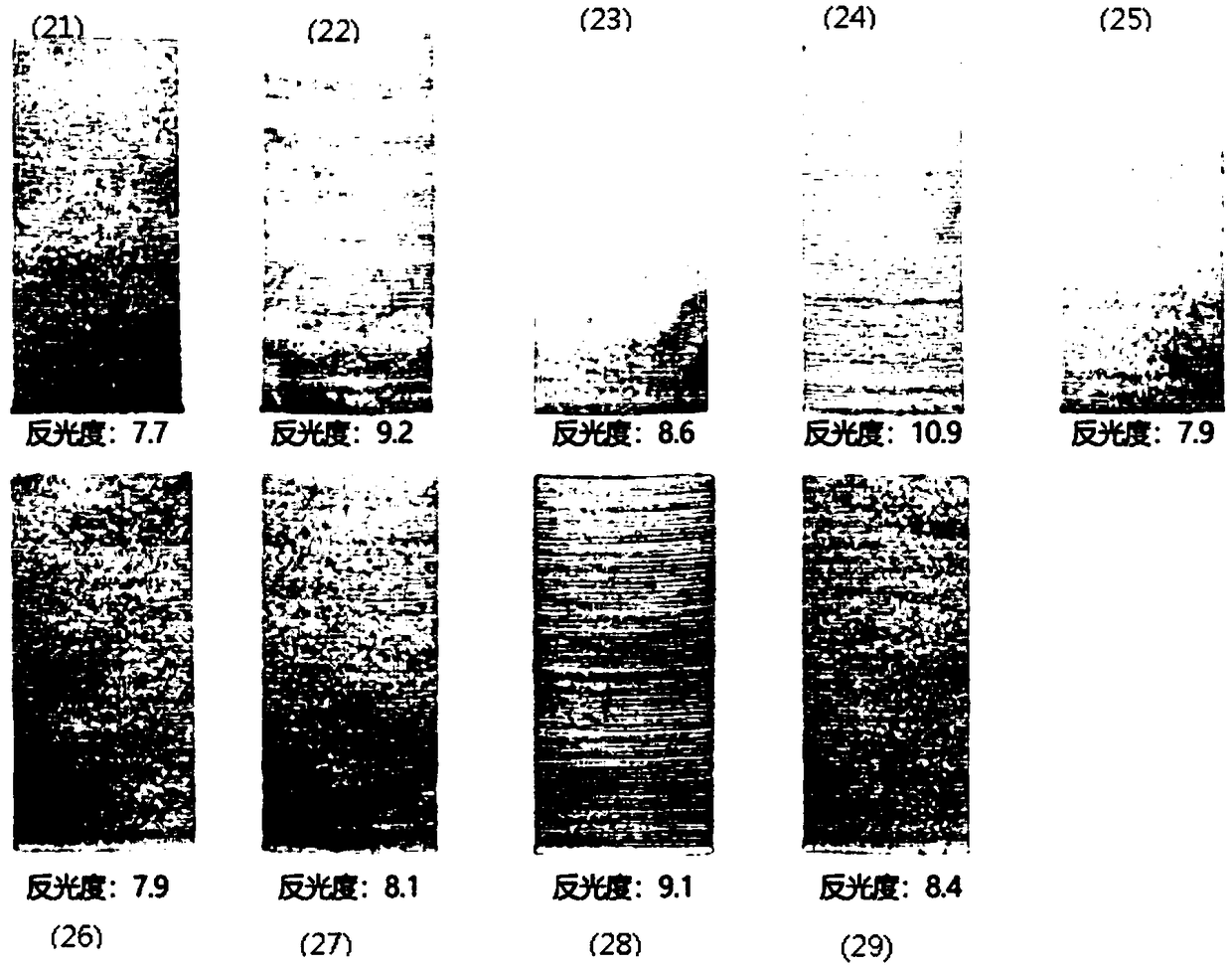

Image

Examples

Embodiment 1

[0022] The preparation of embodiment 1 matt pencil lead

[0023] The parts by weight of each component are: 10 parts of earthy graphite, 20 parts of clay, 20 parts of carbon black, 50 parts of talcum powder, 3 parts of xanthan gum and 120 parts of water.

[0024] Preparation process: batching each component according to the stated weight parts, kneading in a kneader (kneader ZC-500L heating type; manufactured by Rugao Zhongchen Kneading Machinery Manufacturing Co., Ltd.), and then kneading in a three-roll mill (enhanced three Roll grinding SQ16-400; manufactured by Changzhou Longxin Chemical Machinery Co., Ltd.) for grinding, and in a secondary kneader (secondary kneader ZZ-NH-200L; manufactured by Shangzhi Pearl Pen Industry Co., Ltd.) After kneading, squeeze the core in a hydraulic press (hydraulic press YQ32-100; manufactured by Nantong Forging Equipment Co., Ltd.) and bake in a core drying furnace (core drying furnace ZZ-HX-500; manufactured by Shangzhi Pearl Pen Industry ...

Embodiment 2

[0025] The preparation of embodiment 2 matt pencil lead

[0026] The parts by weight of each component are: 10 parts of earthy graphite, 20 parts of clay, 0 parts of carbon black, 20 parts of talcum powder, 3 parts of binder and 120 parts of water.

[0027] The preparation process is the same as in Example 1.

Embodiment 3

[0028] Example 3 matt pencil lead

[0029] The parts by weight of each component are: 60 parts of earthy graphite, 20 parts of clay, 20 parts of carbon black, 50 parts of talcum powder, 3 parts of binder and 120 parts of water.

[0030] The preparation process is the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com