Oxide-coated quantum dot LED preparation method

A technology of oxides and quantum dots, applied in electrical components, circuits, semiconductor devices, etc., can solve problems such as unstable work, poor thermal stability, and low luminous efficiency, and achieve improved reliability and service life, low cost, and easy preparation The effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

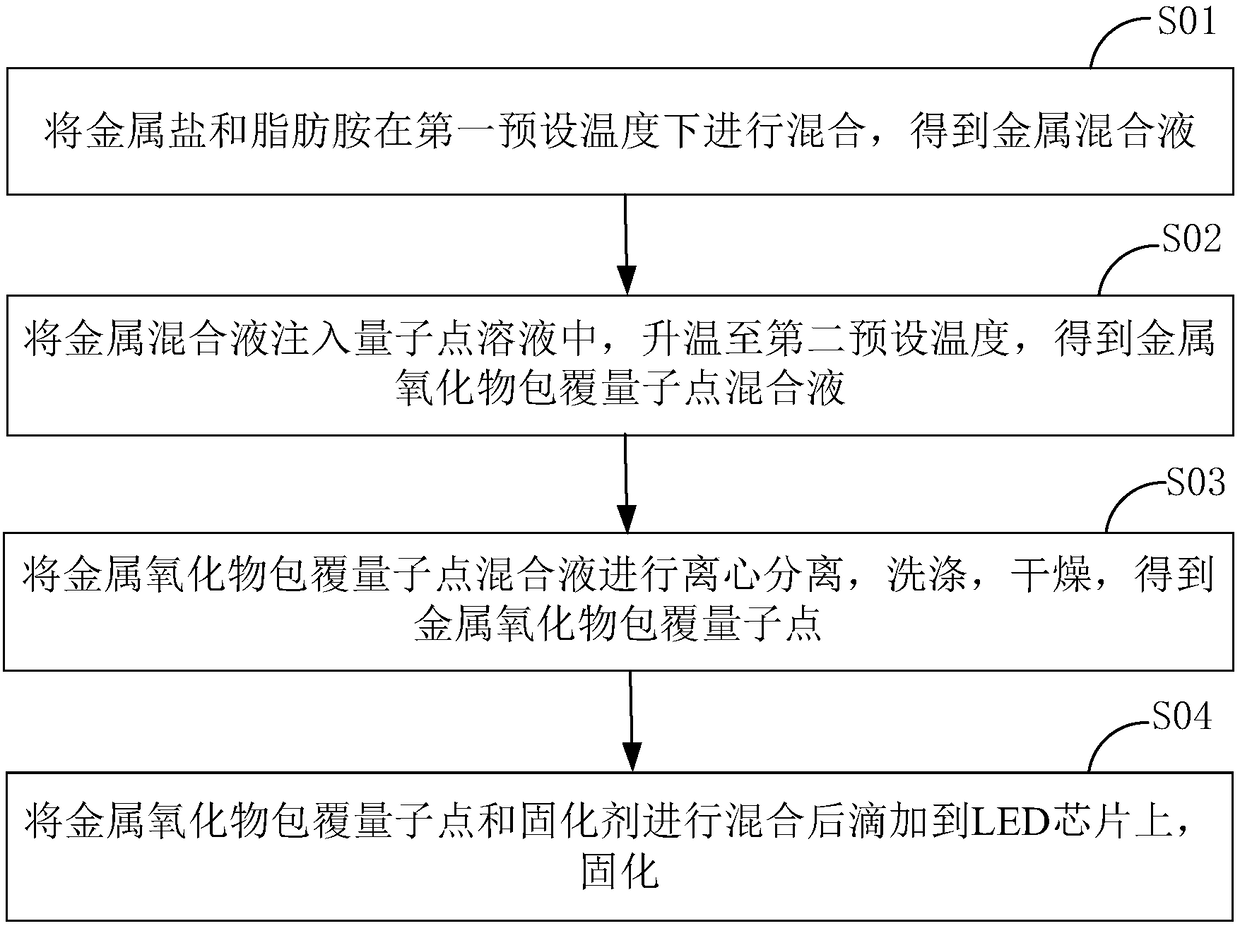

[0015] see figure 1 , figure 1 A schematic flow chart of a method for preparing an oxide-coated quantum dot LED provided by an embodiment of the present invention. A method for preparing an oxide-coated quantum dot LED according to an embodiment of the present invention includes the following steps:

[0016] Step S01: Mixing the metal salt and fatty amine at a first preset temperature to obtain a metal mixture.

[0017] In the embodiment of the present invention, at the first preset temperature, the metal salt and the fatty amine are mixed, the metal salt is dissolved in the fatty amine, and finally a metal mixed liquid is obtained. Among them, the metal salt can be at least one of acetate, halide salt, carbonate, stearate, but not limited to the aforementioned materials; the fatty amine is preferably an unsaturated fatty primary amine, in order to stabilize the particles in the solution It is better to choose high-boiling point polar substance oleylamine and metal salt for...

Embodiment 1

[0043] This embodiment takes the red InP / ZnS core-shell quantum dot phosphor powder coated with indium oxide and the green InP / ZnSeS core-shell quantum dot phosphor powder coated with indium oxide as the fluorescent layer, and the preparation of a white LED with a blue LED chip as the light source as an example. , the method of the present invention is described, comprising the following steps:

[0044] 1. Preparation of red InP / ZnS core-shell quantum dots coated with indium oxide

[0045] 1) Preparation of indium precursor mixture

[0046] 5.81 mmol of indium acetate (Indium(III) acetate) was dissolved in 4 ml of oleylamine (Oleylamine) at 120° C. to obtain a mixed liquid of indium precursor.

[0047] 2) Preparation of indium oxide-coated red InP / ZnS core-shell quantum dot solution

[0048] At 210°C, the above-prepared indium precursor mixture was added to the red InP / ZnS quantum dot reaction system that had been reacted in a three-necked flask, and reacted at 180°C for 1 h...

Embodiment 2

[0061] This embodiment takes zinc oxide-coated red InP / ZnS core-shell quantum dot phosphor powder and zinc oxide-coated green core-shell quantum dot phosphor powder as the fluorescent layer, and the preparation of a white LED with a blue LED chip as the light source as an example. The method is described, including the following steps:

[0062] 1. Preparation of red InP / ZnS core-shell quantum dots coated with zinc oxide

[0063] 1) Preparation of zinc precursor mixture

[0064] 2.3 mmol of zinc acetate (Indium(III) acetate) was dissolved in 4 ml of oleylamine (Oleylamine) at 120° C. to obtain a zinc precursor mixture.

[0065] 2) Preparation of zinc oxide-coated red InP / ZnS core-shell quantum dot solution

[0066] At 210°C, the above-prepared zinc precursor mixture was added to the red InP / ZnS quantum dot reaction system that had been reacted in a three-necked flask, and reacted at 180°C for 1 h. Among them, the luminescence peak of the red InP / ZnS quantum dot is 630nm, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| emission peak | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com