Fully-inorganic quantum dot backlight LED preparation method

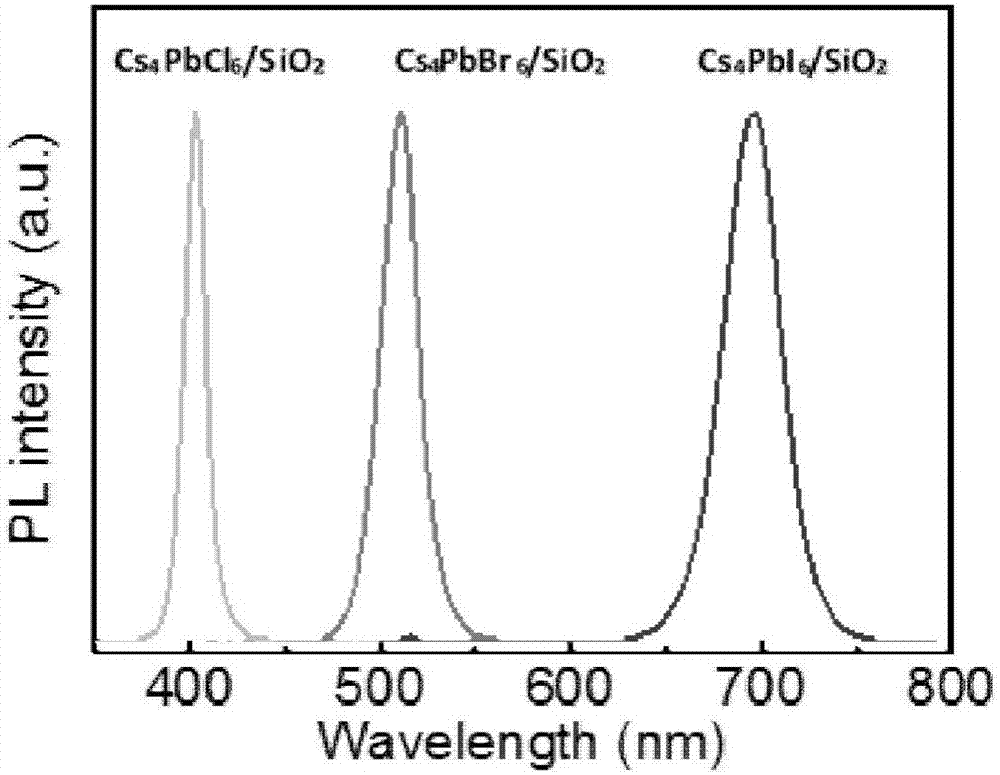

A quantum dot and inorganic technology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of lack of all-inorganic perovskite materials and poor stability of all-inorganic perovskite materials, achieve novel materials and improve device stability , excellent performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

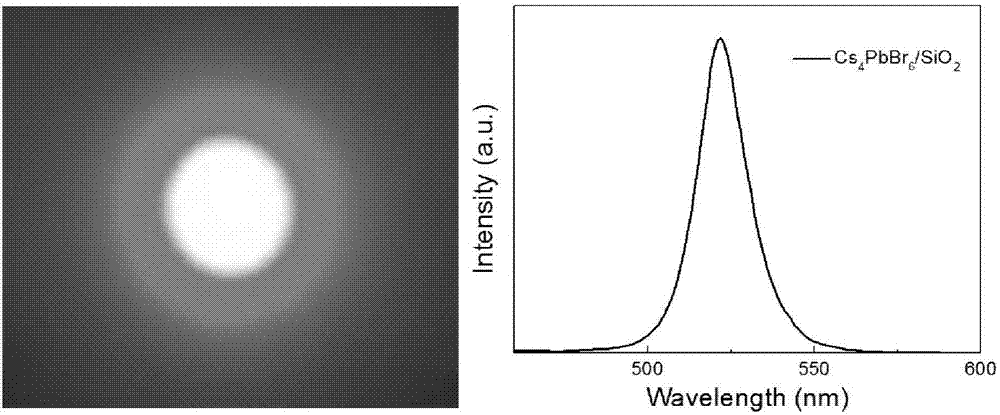

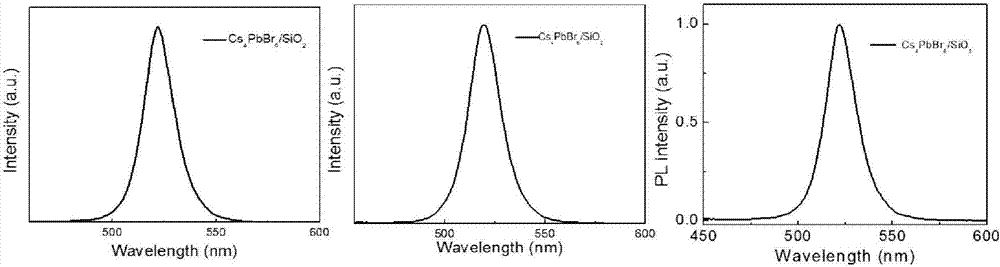

[0033] The ultra-stable Cs described in this example 4 PbX 6 / SiO 2 The all-inorganic quantum dot backlight LED of perovskite material, taking PDMS glue as an example, the specific steps are as follows:

[0034] 1) Add 20 mL of toluene, 1 mL of oleic acid, 1 mL of oleylamine, and 200 μL of triethoxysilane (APTES) into a 100 mL single-neck flask, and stir in room temperature air at a stirring speed of 800 r / min to obtain a reaction solvent. And the metal halide PbBr 2 Dissolve it in DMSO at a molar ratio of 1:1 to CsBr, and ultrasonically until it is completely dissolved to form a perovskite precursor solution.

[0035] 2) Take 1mL of the precursor solution and quickly inject it into the mixed solution, continue to stir and react for 12 hours, after the reaction is completed, the precipitate is purified by centrifugation and dried in vacuum to obtain a surface coated with SiO 2 Cs 4 PbBr 6 powder.

[0036] 3) Wrap the obtained surface with SiO 2 Cs 4 PbBr 6 Mix the powder with PDMS gl...

Embodiment 2

[0040] Similar to Example 1, the difference is that the PDMS glue in step 3) of Example 1 is changed to UV glue, and other conditions remain the same.

Embodiment 3

[0042] Similar to Example 1, the difference is that the PDMS glue in step 3) of Example 1 is changed to PS glue, and other conditions remain the same.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com