ZnO-based white light LED and preparing method thereof

A zinc oxide-based, white light technology, which is applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of difficult control and complex white light LED preparation process, and achieve the effect of simplifying the preparation process and not requiring high requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

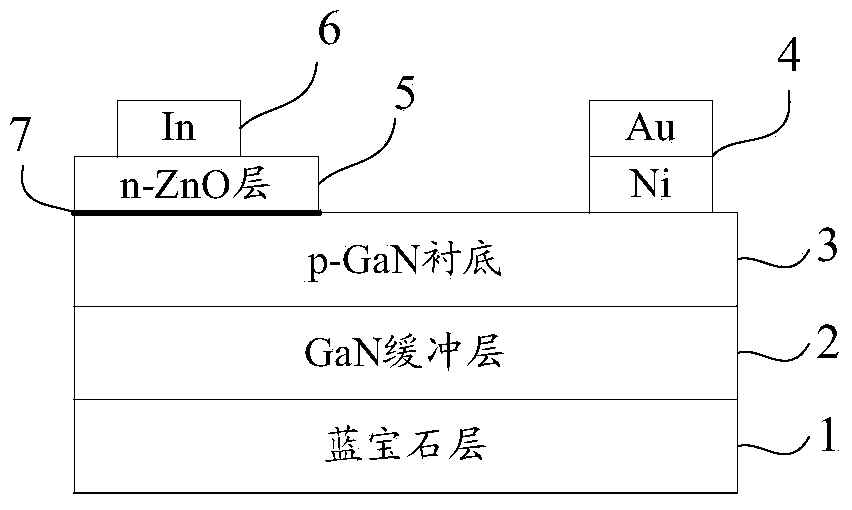

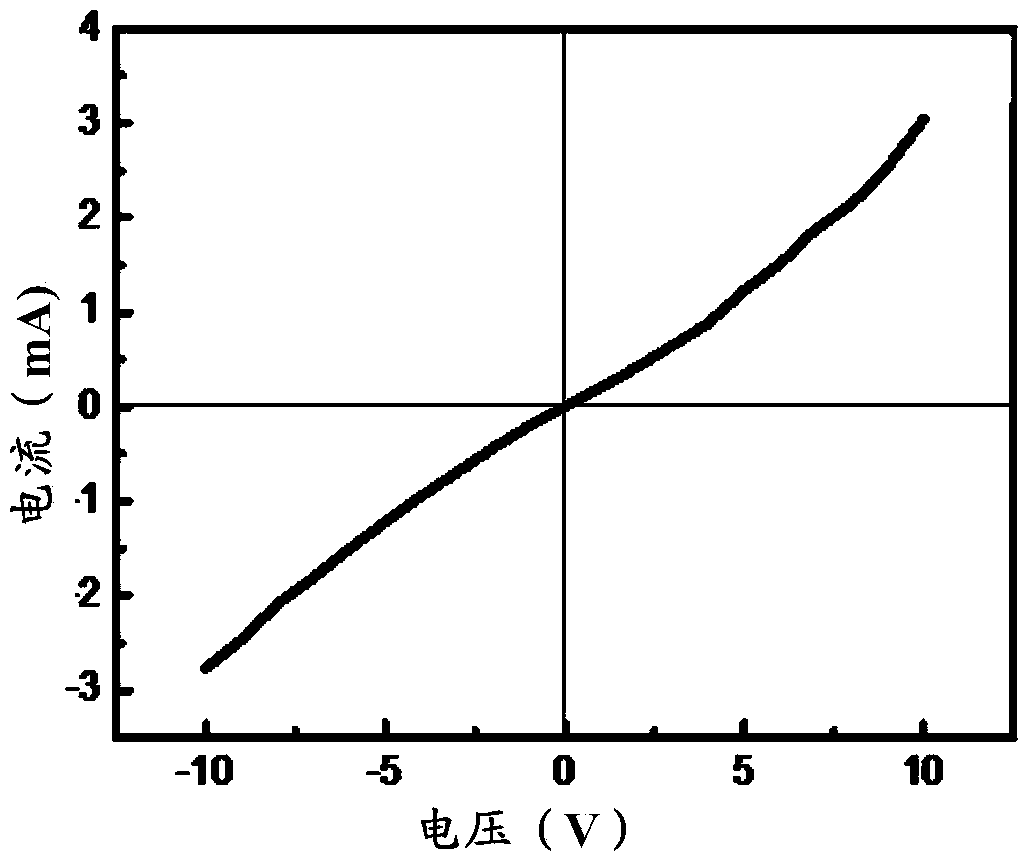

[0036] Embodiment 1: The oxygen pressure was adjusted to 0.6 Pa, and another n-ZnO layer sample was prepared according to the same method as above with other conditions. After the preparation is completed, the thickness of the sample is about 425nm, and then the electrodes are prepared on the p-GaN substrate and the n-ZnO layer by the same method as above. After the preparation is completed, the electrical properties of the two n-ZnO layers are compared and measured. The measurement results are as follows: the resistivity of the n-ZnO layer prepared under the condition of oxygen pressure of 2Pa is 1.3Ωcm, and the carrier concentration is 1.5x10 18 cm -3 , with a mobility of 3.7cm 2 / Vs, the resistivity of the n-ZnO layer prepared under the condition of oxygen pressure of 0.6Pa is 1.6Ωcm, and the carrier concentration is 5.0x10 17 cm -3 , with a mobility of 7.7cm 2 / Vs. The resistivity of the p-GaN substrate under both conditions is 3.7Ωcm, and the carrier concentration i...

Embodiment 2

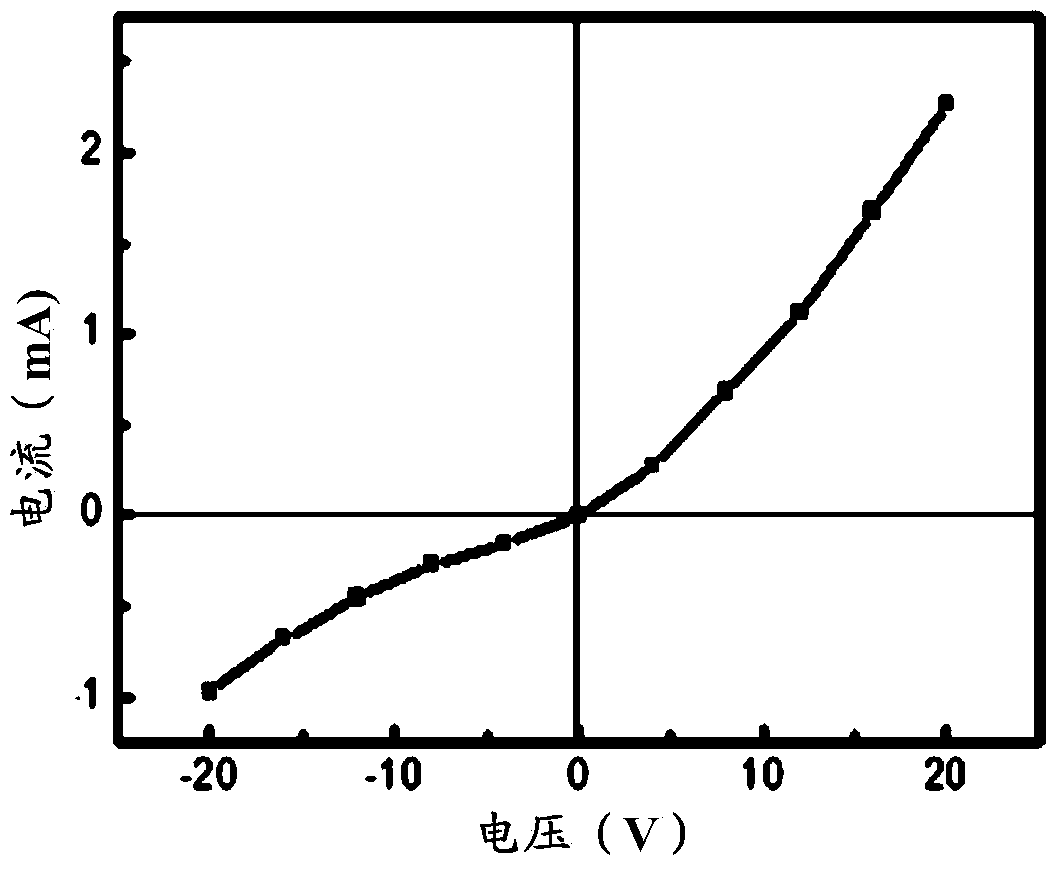

[0038] Example 2: Preparation of n-ZnO / i-ZnO / p-GaN heterojunction light-emitting LED. Before growth, the vacuum chamber was pumped to 6 × 10 -4 Below Pa. Put the cleaned p-GaN substrate into the sample holder, mask the position of the electrode to be prepared on the substrate, then place the substrate on the sample holder of the vacuum chamber, adjust the distance between the target and the substrate to 85mm, Lower the shield over the substrate. Oxygen with a purity of 99.9999% was used as the growth gas, the oxygen flow rate was set to 30 sccm, and the vacuum valve was adjusted to control the pressure of the growth chamber so that the oxygen pressure was 8Pa. Set the growth temperature to 300°C, adjust the laser pulse energy to 300mJ, pulse frequency to 5Hz, start the laser to pre-ablate the target, remove the substrate baffle after 10 minutes, and start growing the ZnO layer on the p-GaN substrate. After 10 minutes of growth, a high-resistance I-layer ZnO layer (i-ZnO) wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| carrier concentration | aaaaa | aaaaa |

| carrier mobility | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com