A kind of flip-chip LED chip and preparation method thereof

A LED chip and flip-chip technology, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of complicated packaging process and high cost, and achieve the effect of reducing production cost and simplifying the packaging process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

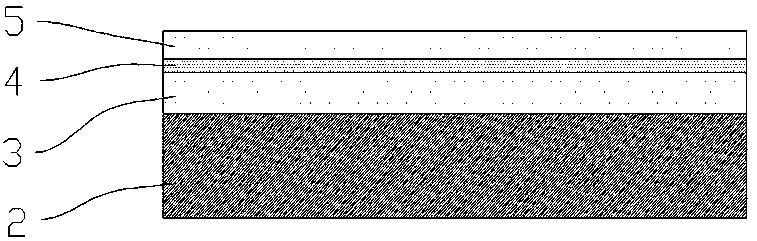

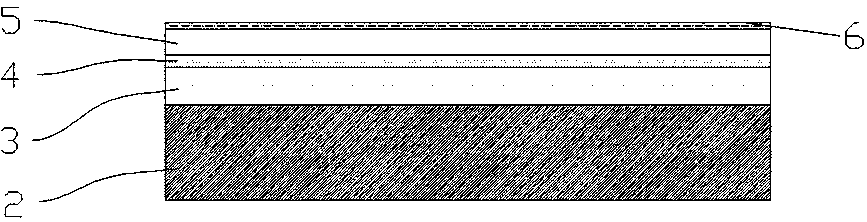

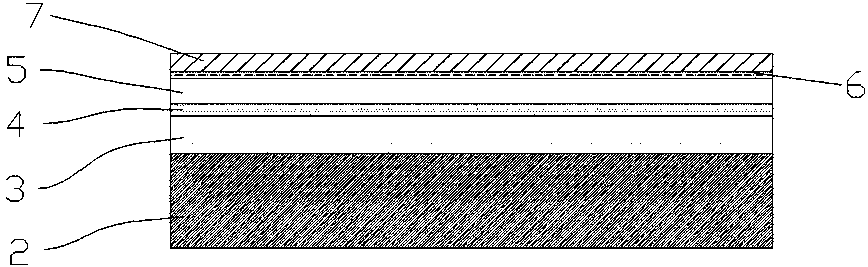

[0020] The present invention proposes a flip-chip LED chip, including a sapphire substrate, an InGaAlN multilayer structure formed on the sapphire substrate, and the InGaAlN multilayer structure includes an N-type GaN layer, a multi-quantum well layer and a P type GaN layer, a reflective layer formed on the P-type GaN layer, a metal protective layer deposited on the surface of the reflective layer, etched in a part of the metal protective layer to expose the N electrode hole formed by the N-type GaN layer. The passivation layer formed by the partial area of the surface of the protective layer and the side wall of the N electrode hole, the N electrode formed by depositing metal in the N electrode hole and connecting multiple N electrode holes, the metal protection not covered by the passivation layer The P electrode formed on the layer also includes a solder paste layer formed on the N electrode and the P electrode, and a metal barrier layer is formed around the solder paste l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com