Method for preparing white light LED

A preparation process and LED chip technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of uneven coating of phosphor, expensive equipment, uneven light and color, etc., and achieve simple and mature screen printing process, improve Product consistency, the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The technical solutions of the present invention will be further described below in conjunction with the drawings and embodiments.

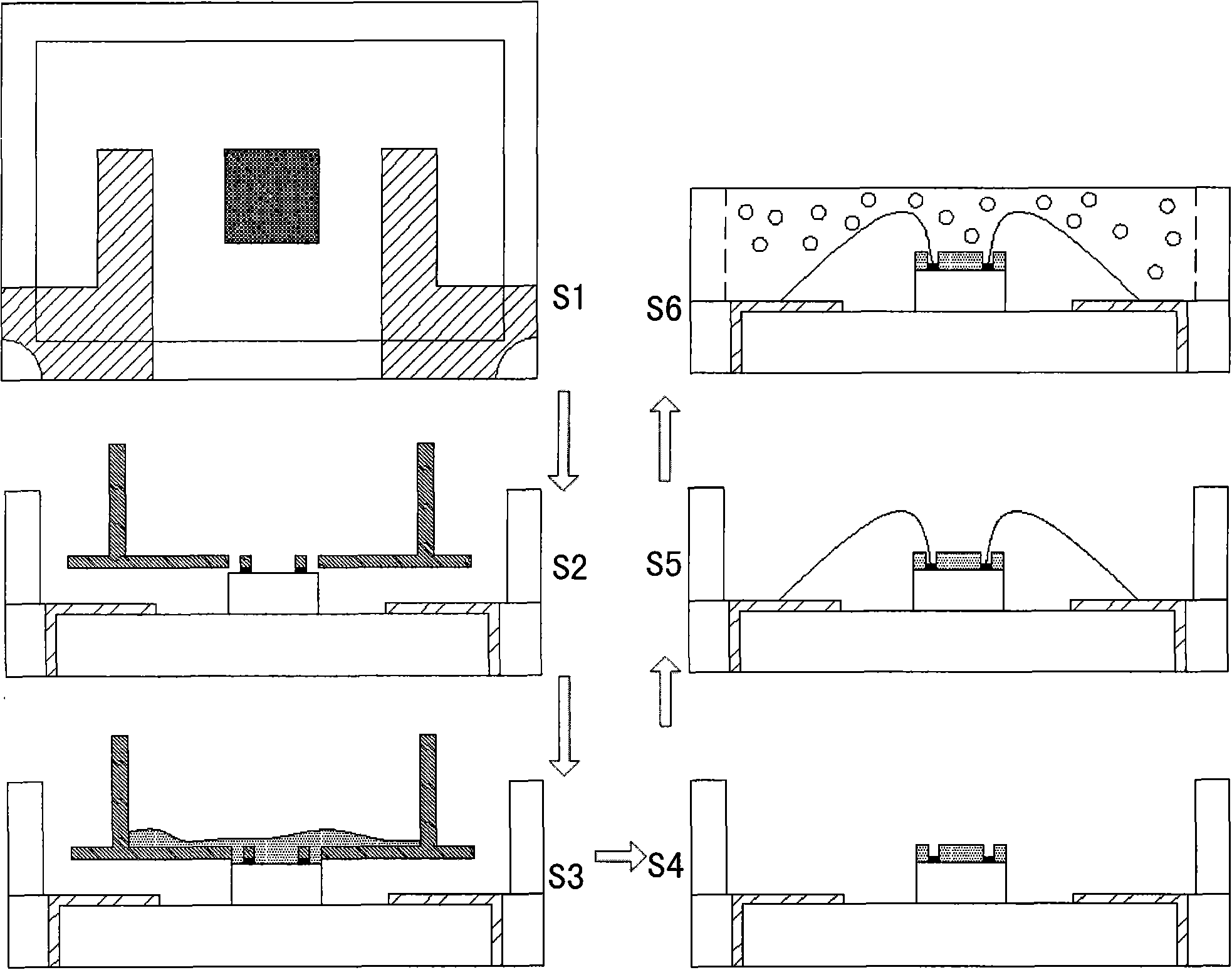

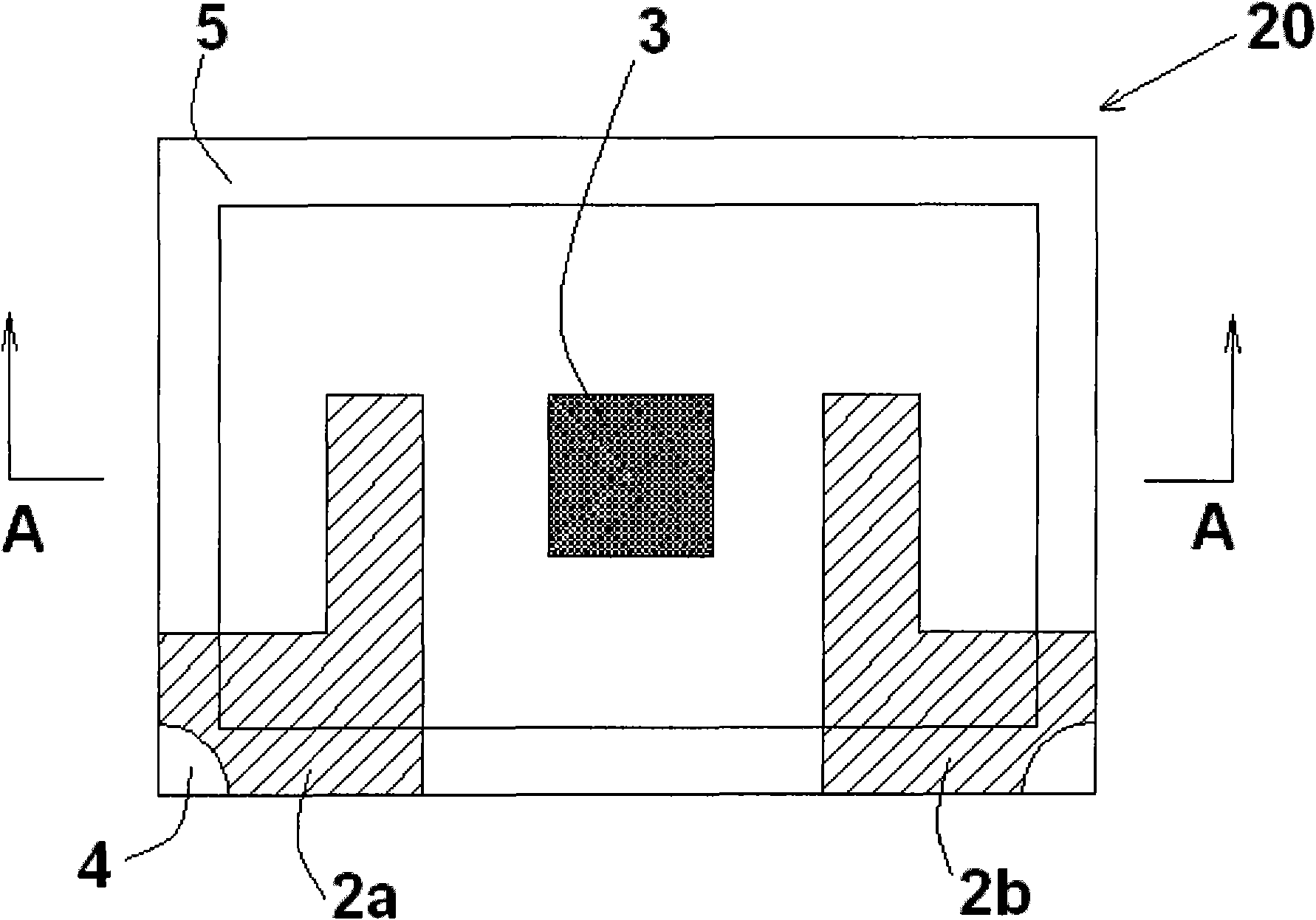

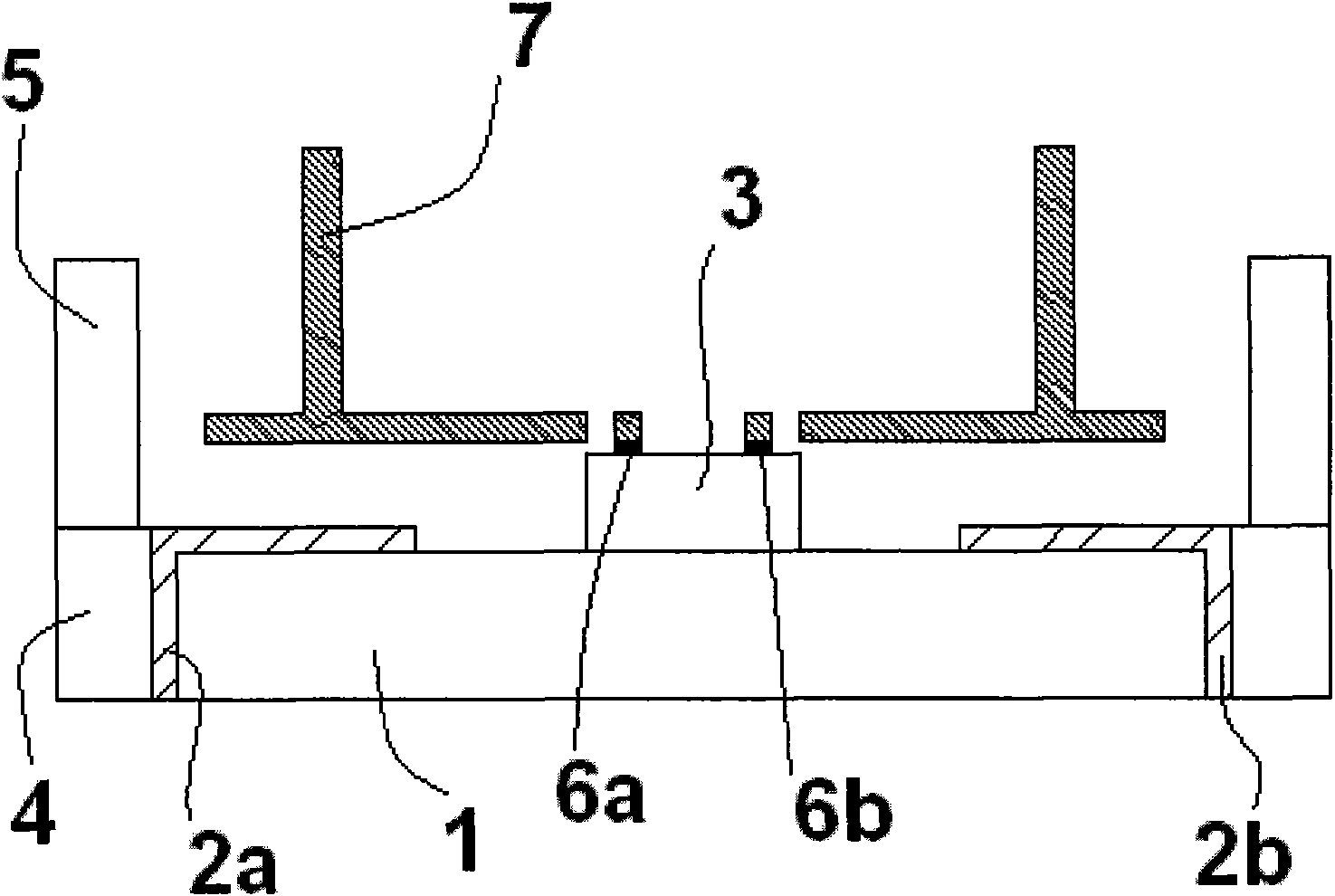

[0026] figure 1 The process flow of the embodiment of the manufacturing process method of the white light LED of the present invention is shown. See figure 1 , the preparation process of this embodiment is divided into 6 processes, which are crystal-bonding process S1, screen-on process S2, phosphor printing process S3, screen-removing and phosphor-baking process S4, and wire bonding process S5. And filling the silica gel step S6. Figure 2 to Figure 7 The six processes are shown respectively, and the six processes will be described below in conjunction with the accompanying drawings.

[0027] Die Bonding Process: Please refer to figure 2 , the blue LED chip 3 is fixed on the chip area by a chip bonding material, and two through holes 4 are provided on the side of the substrate, one of which corresponds to the positive electrode 2a of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Peak wavelength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com