Electrode lead preparation device and batter cell coiling device comprising same

A pole ear and cylinder technology, applied in the field of cell winding equipment, can solve problems affecting battery production efficiency, safety, poor consistency, lack of automatic material preparation, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be emphasized that the following description is only exemplary and not intended to limit the scope of the invention and its application.

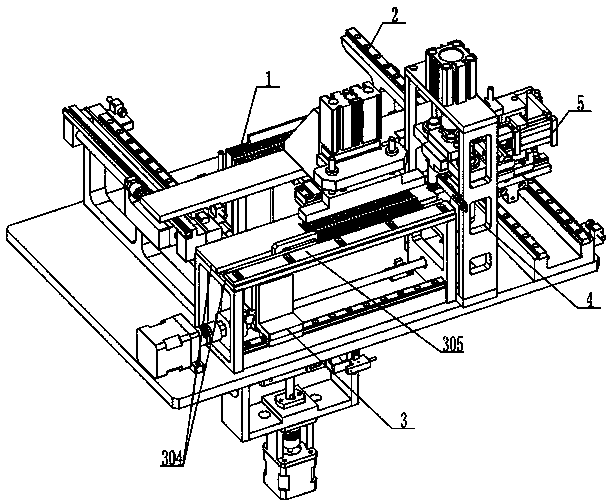

[0025] refer to figure 1 , in some embodiments, a device for preparing tabs includes a material box 1 for containing plate-type tabs, a transport mechanism 2 for transporting the tabs to the feeding mechanism, and a feeding mechanism 3 for continuously feeding the plate-type tabs into the shearing mechanism , the shearing mechanism 4 for separating the plate-type tab into a single tab, and the feeding mechanism 5 for sending a single tab into the welding process.

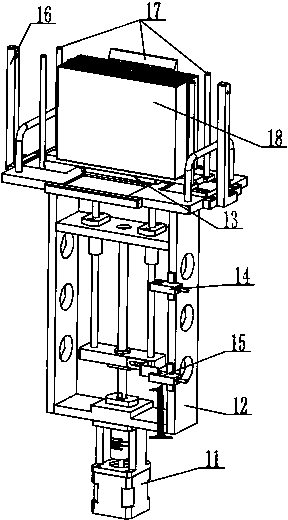

[0026] refer to figure 2 , preferably, the magazine 1 includes a drive assembly 11, a drive support assembly 12, a lifting plate 13, a first detection assembly 14, a second detection assembly 15, a third detection assembly 16, and a material st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com