Performance enhancing LED (light emitting diode) preparation method and LED chip

A LED chip and performance technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of increasing the light output rate of LED chips, and achieve the effects of increasing light output rate, reducing thickness, and reducing light absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

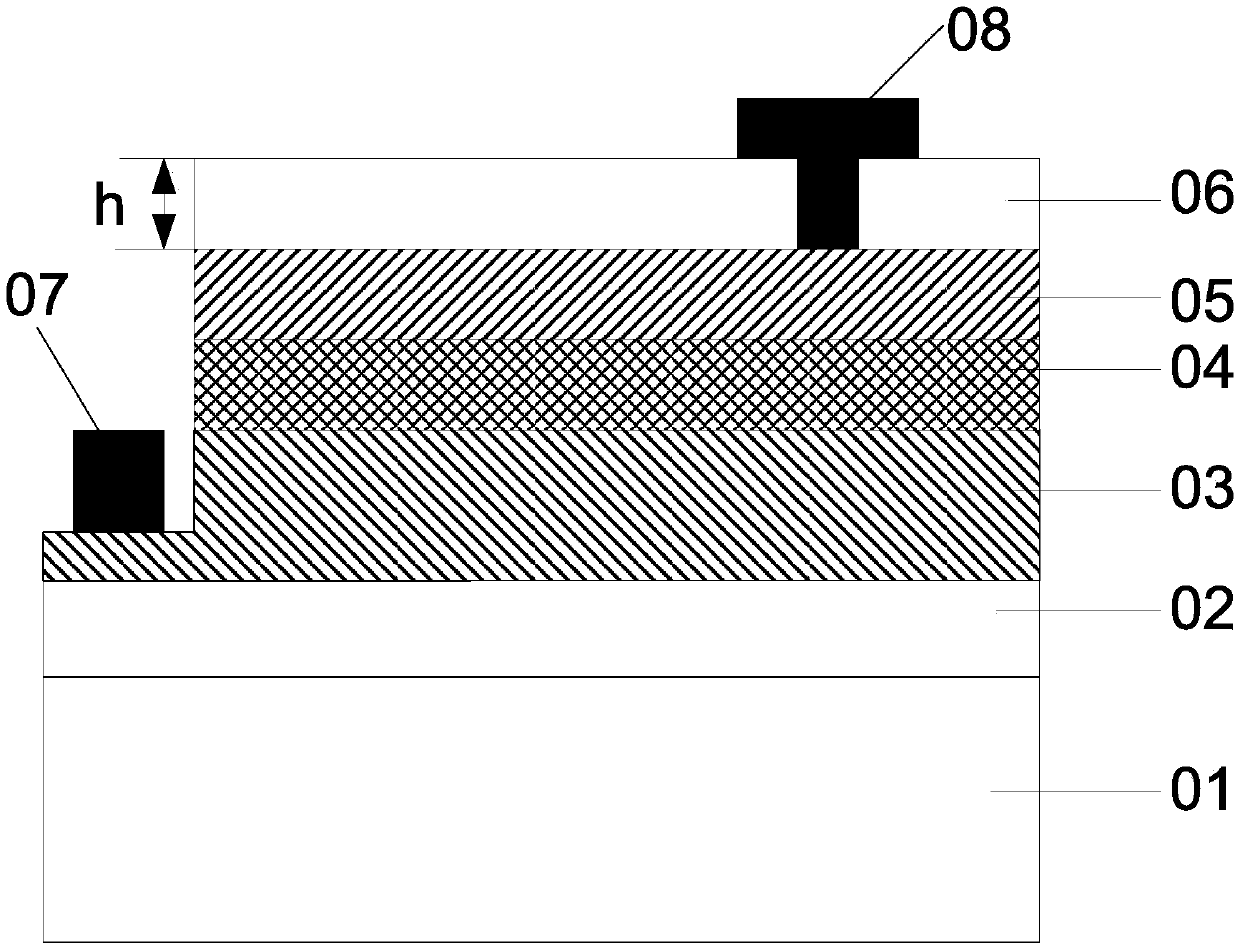

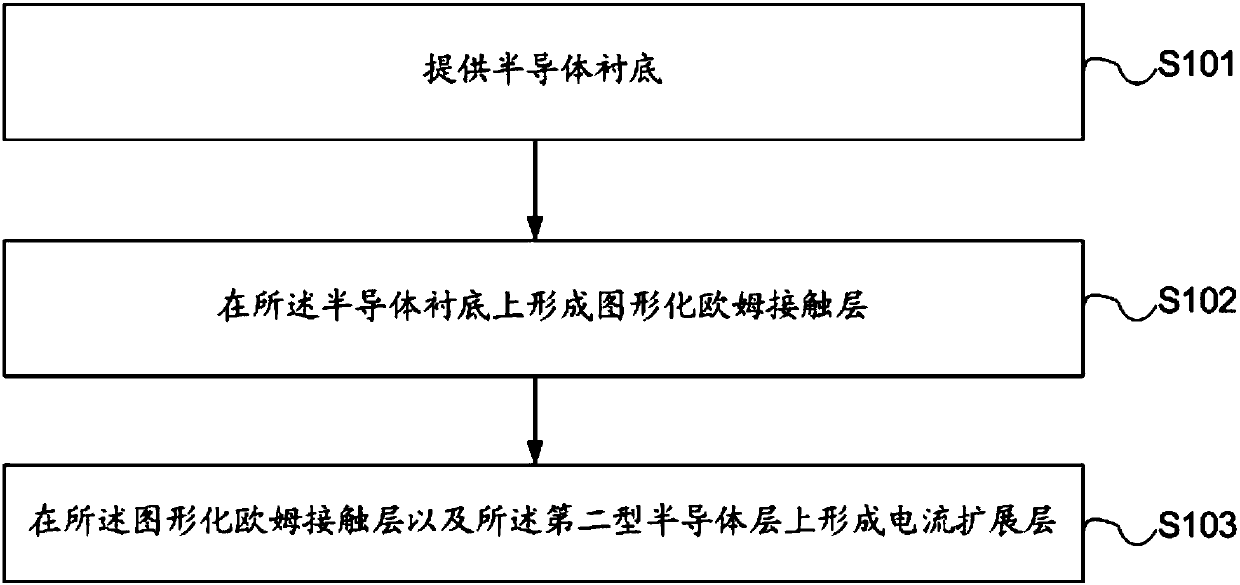

[0048]Based on this, the present invention provides a LED preparation method for improving LED performance, including:

[0049] A semiconductor substrate is provided, the semiconductor substrate at least includes a substrate, and a buffer layer, a first-type semiconductor layer, a multi-quantum well layer, and a second-type semiconductor layer;

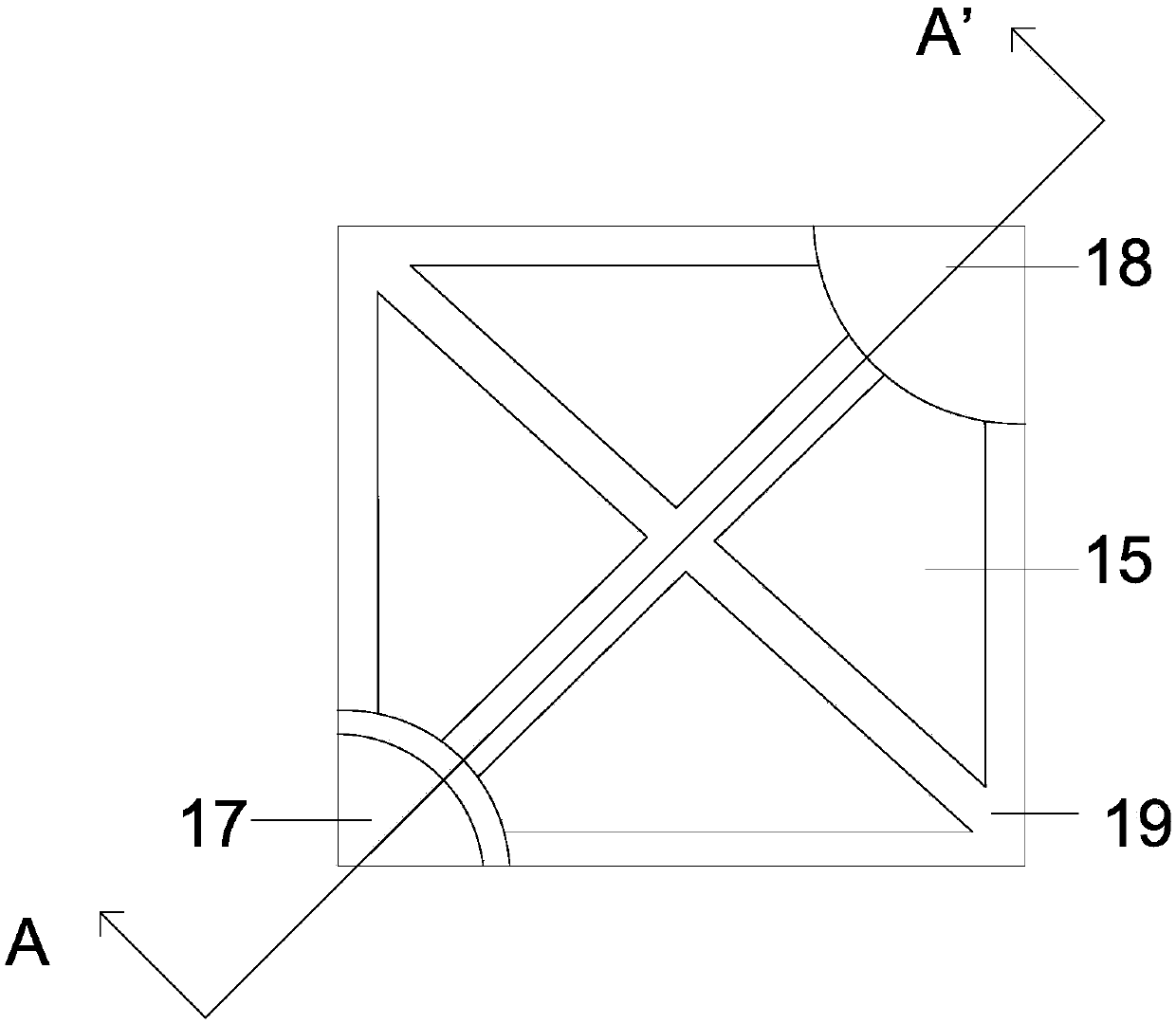

[0050] A patterned ohmic contact layer is formed on the semiconductor substrate, and the patterned ohmic contact layer is Ga x In (1-x) N material, where the value range of x is 0.5-1, including 0.5, excluding 1;

[0051] forming a current spreading layer on the patterned ohmic contact layer and the second type semiconductor layer, the current spreading layer comprising: ITO, IZO, IGO or ZnO;

[0052] Wherein, the sum of the thicknesses of the current spreading layer and the ohmic contact layer is less than or equal to

[0053] In the present invention, a patterned ohmic contact layer is used to replace the partial thickness of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com