Flip Chip Light Emitting Diode and Its Manufacturing Method and Application

A light-emitting diode and flip-chip technology, applied in the field of chip board packaging structure, can solve the problems of inability to achieve light output rate, influence luminous intensity, thermal expansion of materials, etc. The effect of degree and longevity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

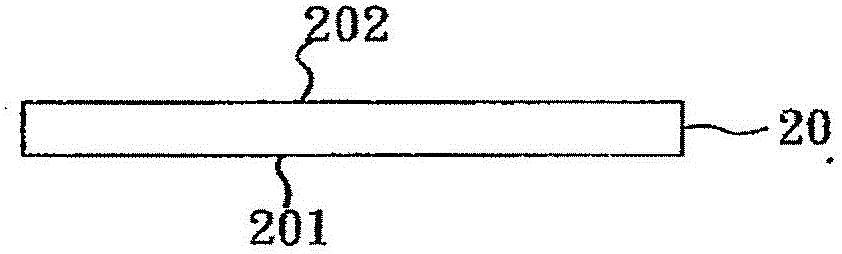

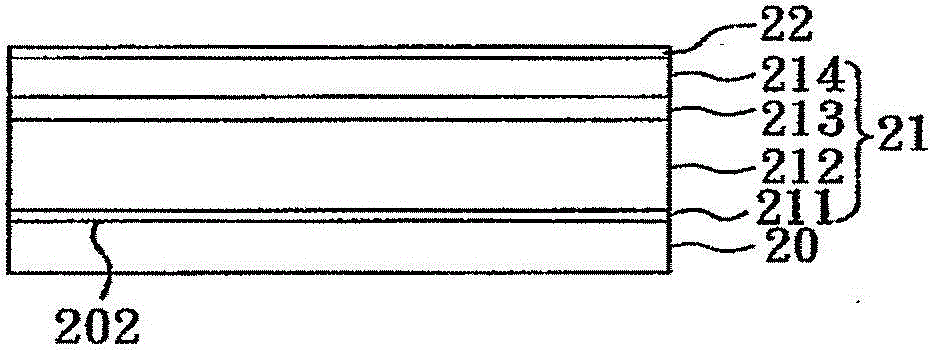

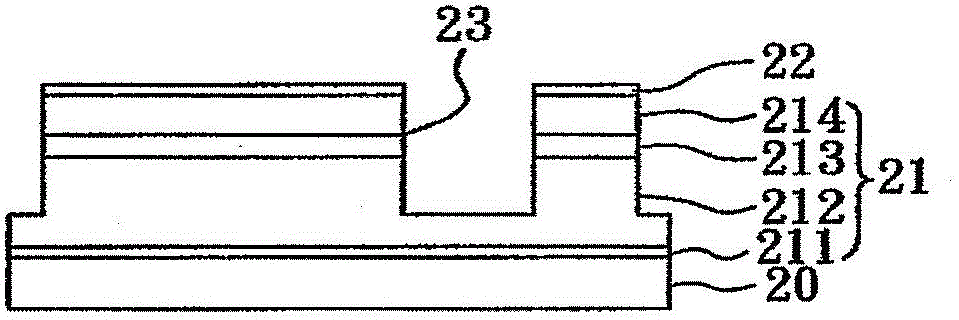

[0075] refer to Figures 1A to 1H It is a schematic flow diagram of the manufacturing method of the flip-chip light emitting diode according to the first embodiment of the present invention. First, if Figure 1A As shown, a substrate 20 is provided, which has a first surface 201 and a second surface 202 opposite to the first surface 201 . Next, if Figure 2B As shown, a semiconductor epitaxial multilayer composite structure 21 is formed above the second surface 202 of the substrate 20, wherein the semiconductor epitaxial multilayer composite structure 21 includes an undoped semiconductor epitaxial layer 211, a first Semiconductor epitaxial layer 212, an active intermediate layer 213, and a second semiconductor epitaxial layer 214, wherein the undoped semiconductor epitaxial layer 211, the first semiconductor epitaxial layer 212, the active intermediate layer 213 and the The second semiconductor epitaxial layer 214 is stacked, the undoped semiconductor epitaxial layer 211 is ...

Embodiment 2

[0085] Please refer to image 3 , a schematic diagram of the structure of the flip-chip light emitting diode according to the second embodiment of the present invention. like image 3 As shown, the structure of the flip-chip light emitting diode of this embodiment is substantially the same as that of the first embodiment, including: a substrate 40 having a first surface 401 and a second surface 402 opposite to the first surface 401; A semiconductor epitaxial multilayer composite structure 41 located on the second surface 402 of the substrate 40 and the semiconductor epitaxial multilayer composite structure 41 includes an undoped semiconductor epitaxial layer 411 and a first semiconductor epitaxial layer 412 , an active intermediate layer 413, and a second semiconductor epitaxial layer 414, wherein the undoped semiconductor epitaxial layer 411, the first semiconductor epitaxial layer 412, the active intermediate layer 413, and the second semiconductor epitaxial layer 414 The ...

Embodiment 3

[0087] refer to Figure 4 , which is a schematic structural diagram of the chip-on-board packaging structure of this embodiment. like Figure 4 As shown, the package structure on the chip includes: a circuit carrier board 6; The circuit carrier board 6 is electrically connected, wherein the circuit carrier board 6 includes an insulating layer 61, a circuit substrate 60, and an electrical connection pad 63, and the material of the insulating layer 61 can be selected from diamond-like carbon, alumina, ceramics, Diamond-containing epoxy resin, or a mixture of the above materials, the circuit substrate 60 is a metal plate, a ceramic plate or a silicon substrate.

[0088] In the chip-on-chip package structure, the solder 62 formed on the surface of the electrical connection pad 63 can be used to connect the first metal bonding layer 29 and the second metal bonding layer 28 to the circuit board through flip chip. The electrical connection pads 63 of 6 are electrically connected. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com