Method for preparing film GaN LED based on plane bonding and temporality substrate transfer technology

A temporary, substrate technology, applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve problems such as cracks, poor bonding force of support components, uneven surface of GaN epitaxial film, etc., achieve high yield, reduce cracks, The effect of reducing the propagation of cracks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as Figure 1a to Figure 1j A thin-film GaN LED preparation method based on planar bonding and temporary substrate transfer technology is shown, and its preparation steps are as follows:

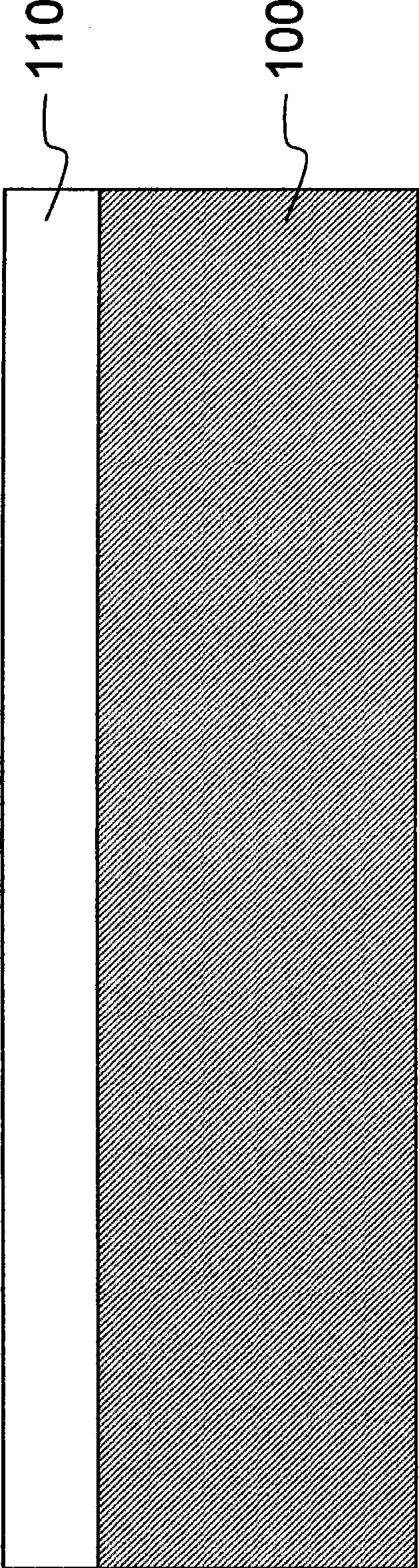

[0023] Step 1: If Figure 1a As shown, a GaN-based LED luminescent material 110 is epitaxially grown on a sapphire substrate 100 by metal-organic chemical vapor deposition (MOCVD);

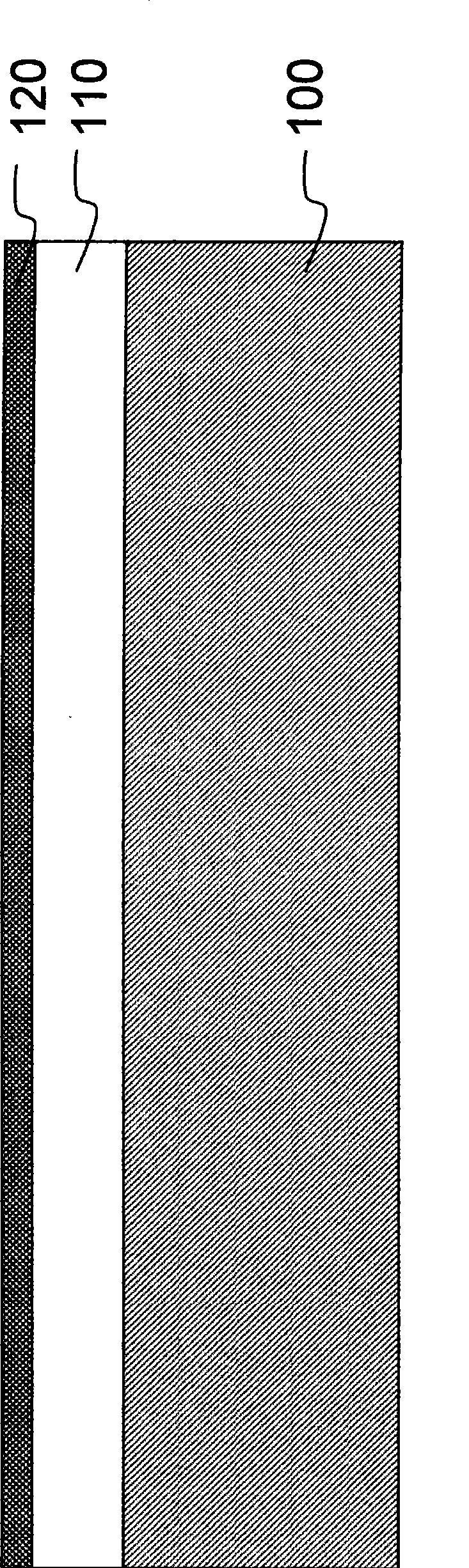

[0024] Step 2: If Figure 1b As shown, electron beam evaporation is used to deposit p metal and reflective metal film 120 on the surface of p-GaN. Ag is selected with a thickness of 100 nm. The ohmic contact and adhesion between metal film 120 and GaN-based semiconductor unit device 110 are improved by high temperature annealing. And form ohmic contact with p-GaN after high temperature annealing;

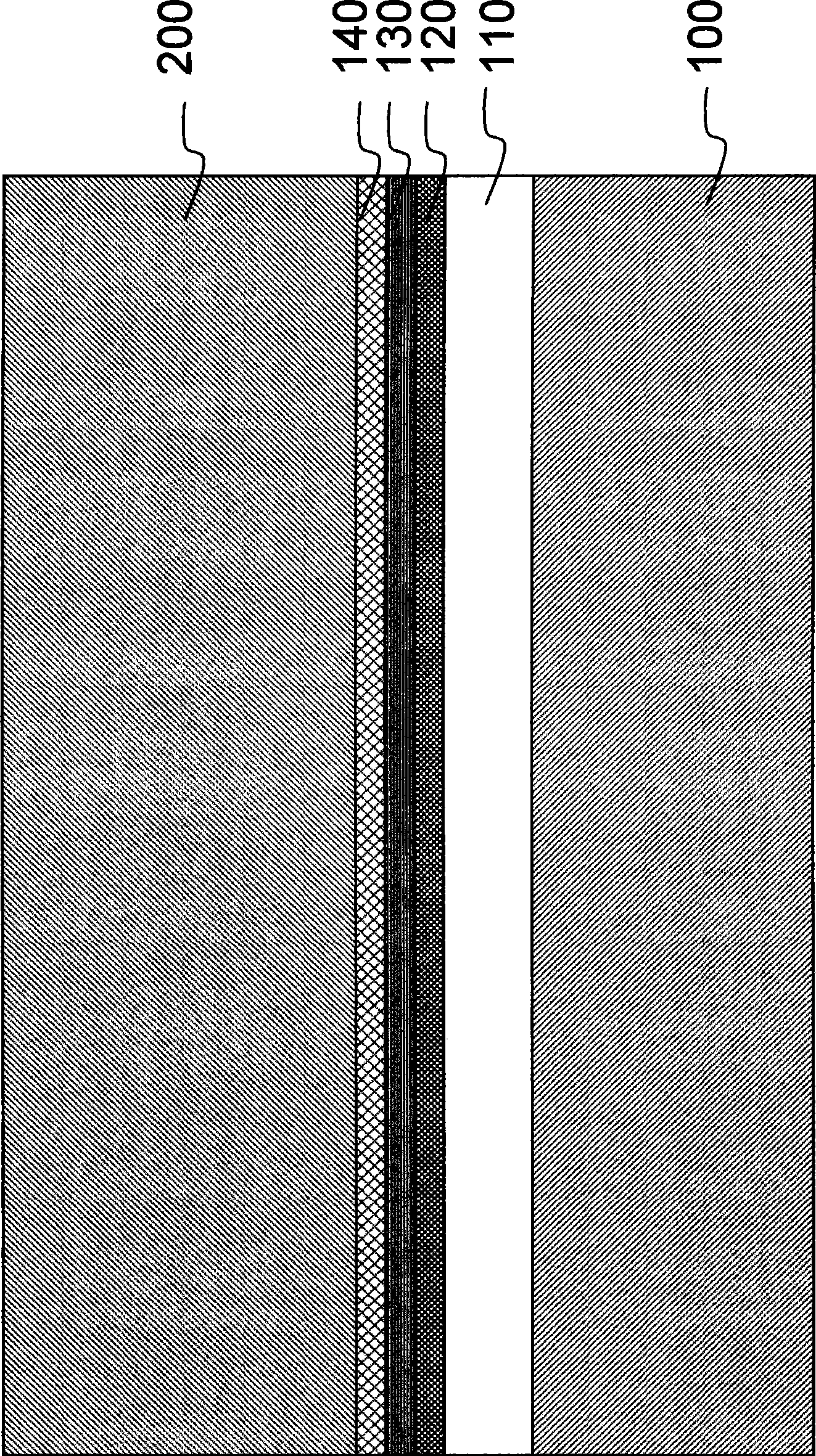

[0025] Step 3: If Figure 1c As shown, electron beam evaporation is used to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com