A kind of separation and purification method of liraglutide

A technology for separation and purification of liraglutide, which is applied in the field of separation and purification, can solve the problems of low yield, difficult desalination, and low purity of liraglutide, and achieve high yield, good packing separation, and remarkable desalination effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

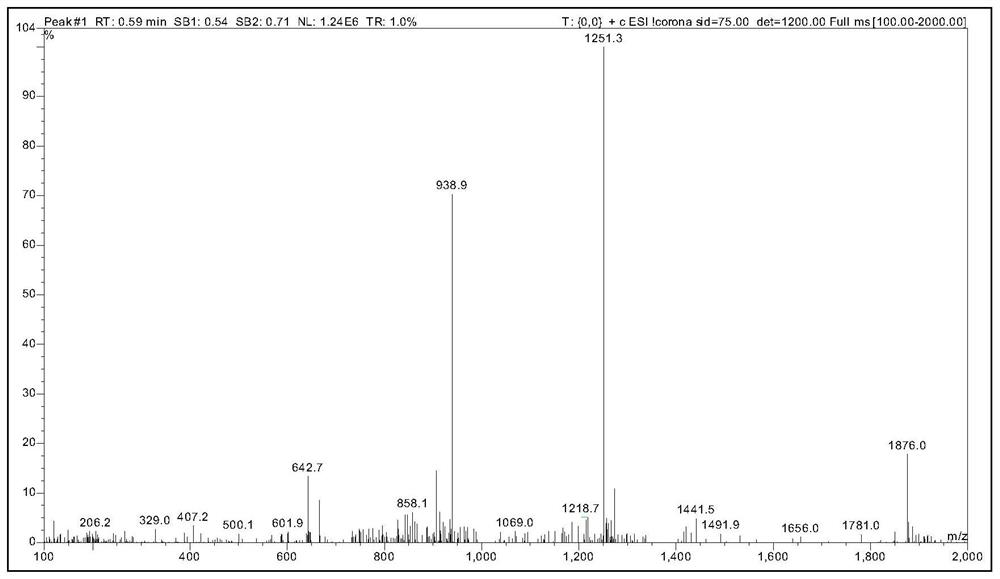

[0027] Example 1: Separation and purification of liraglutide

[0028] The separation and purification method of liraglutide of the present invention comprises the following steps:

[0029] 1. Sample dissolution: Dissolve 10 grams of crude product (the target peptide is 4 grams of liraglutide, which also contains impurities and some solvents, which are not shown in the HPLC test results) with dilute ammonia water with a pH of 9 and 5% methanol. , and filtered through a 0.22um organic membrane to obtain a crude product solution.

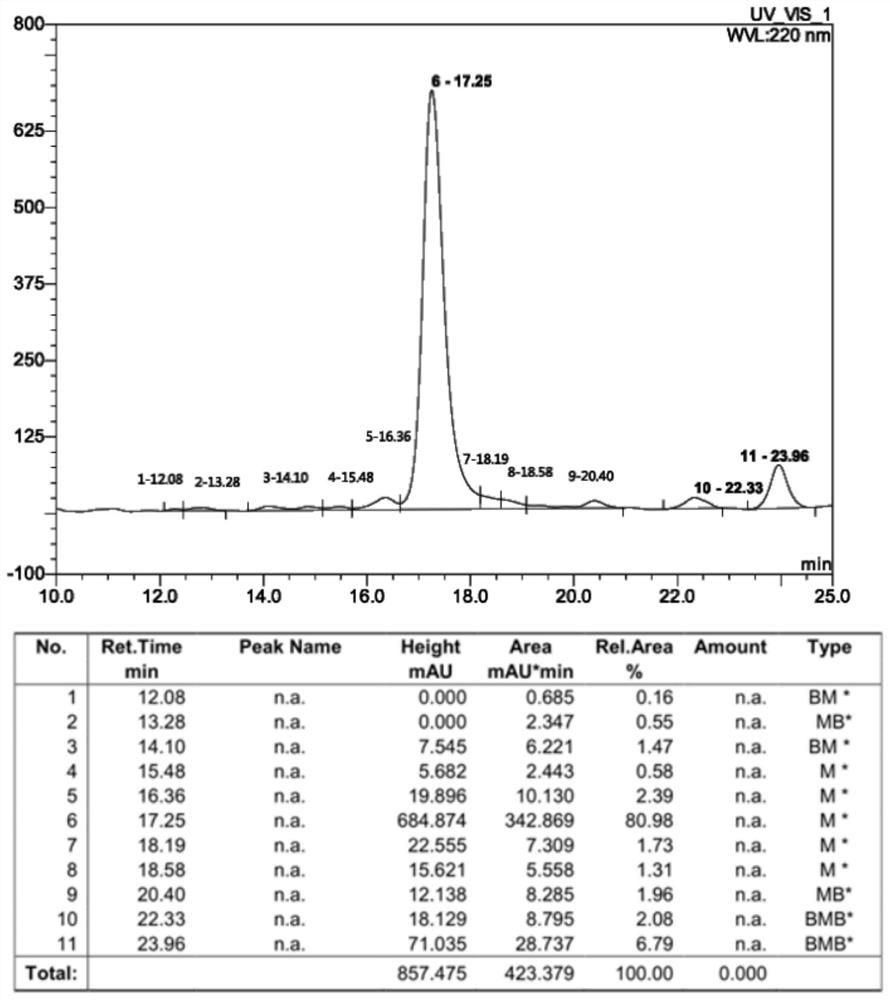

[0030] 2. Primary purification: the filtrate of step (1) is separated and purified through polymethacrylate polymer filler, phase A is: 20mmol / L sodium carbonate solution (pH is adjusted to 9 with phosphoric acid), phase B is: acetonitrile, gradient 30-45%, the gradient elution time is 40min, the detection wavelength is 220nm, the flow rate is 80ml / min, room temperature, and the sample is a crude product containing 4g of the target product.

[0031] ...

Embodiment 2

[0036] Example 2: Separation and purification of liraglutide

[0037] The separation and purification method of liraglutide of the present invention comprises the following steps:

[0038] 1. Sample dissolution: Dissolve 10 grams of the crude product (the target peptide is 4 grams of liraglutide, which also contains impurities and some solvents) with dilute ammonia water with a pH of 9 and 6% methanol and sonicate, and filter with a 0.22um organic filter membrane A crude solution was obtained.

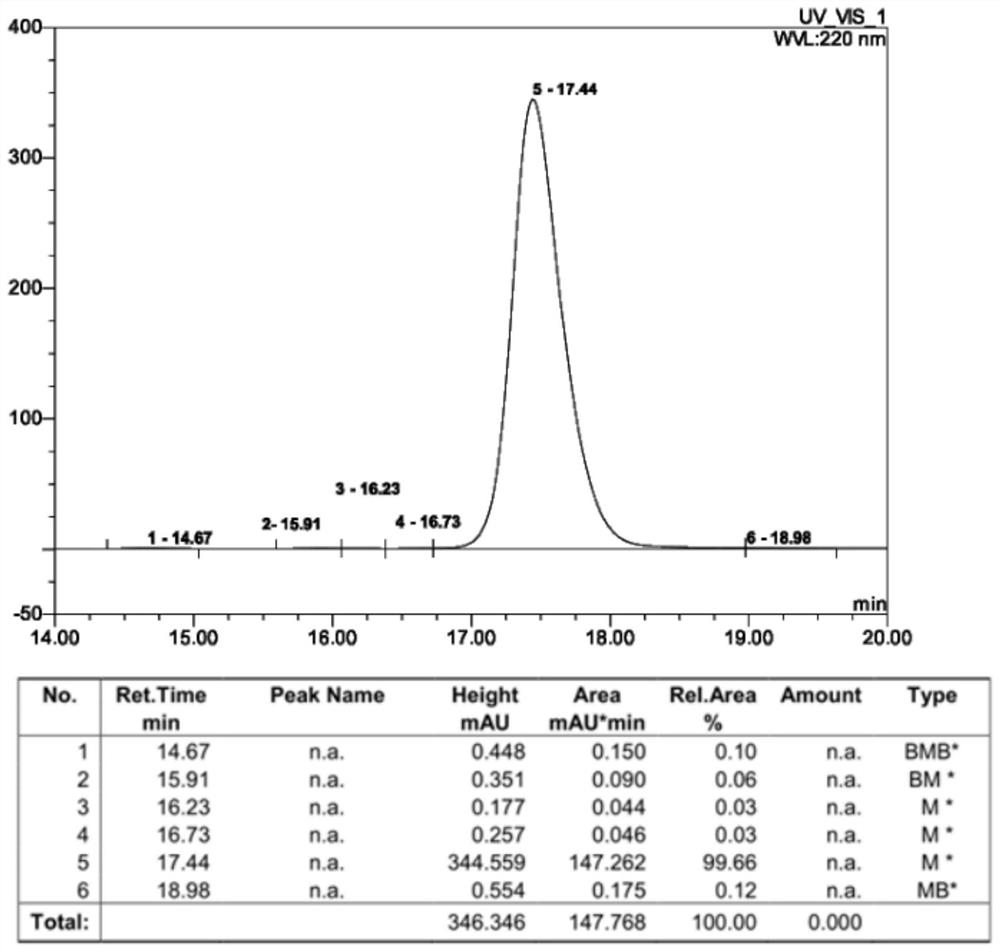

[0039] 2. Primary purification: the filtrate of step (1) is separated and purified through polymethacrylate polymer filler, phase A is: 30mmol / L sodium carbonate solution (pH is adjusted to 9 with phosphoric acid), phase B is: acetonitrile, gradient 30-45%, the gradient elution time is 40min, the detection wavelength is 220nm, the flow rate is 80ml / min, room temperature, and the sample is a crude product containing 4g of the target product.

[0040] Purification process: wash the chr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com