Combination structure of evaporation-boiling capillary core coupled with liquid replenishment capillary core

A combined structure and capillary core technology, which is applied in the construction of electrical equipment components, cooling/ventilation/heating transformation, lighting and heating equipment, etc., can solve the problems of unclear transformation mechanism, improve the liquid capillary pumping capacity, improve Phase-change heat capacity to achieve the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] Below in conjunction with accompanying drawing, the present invention is described in further detail:

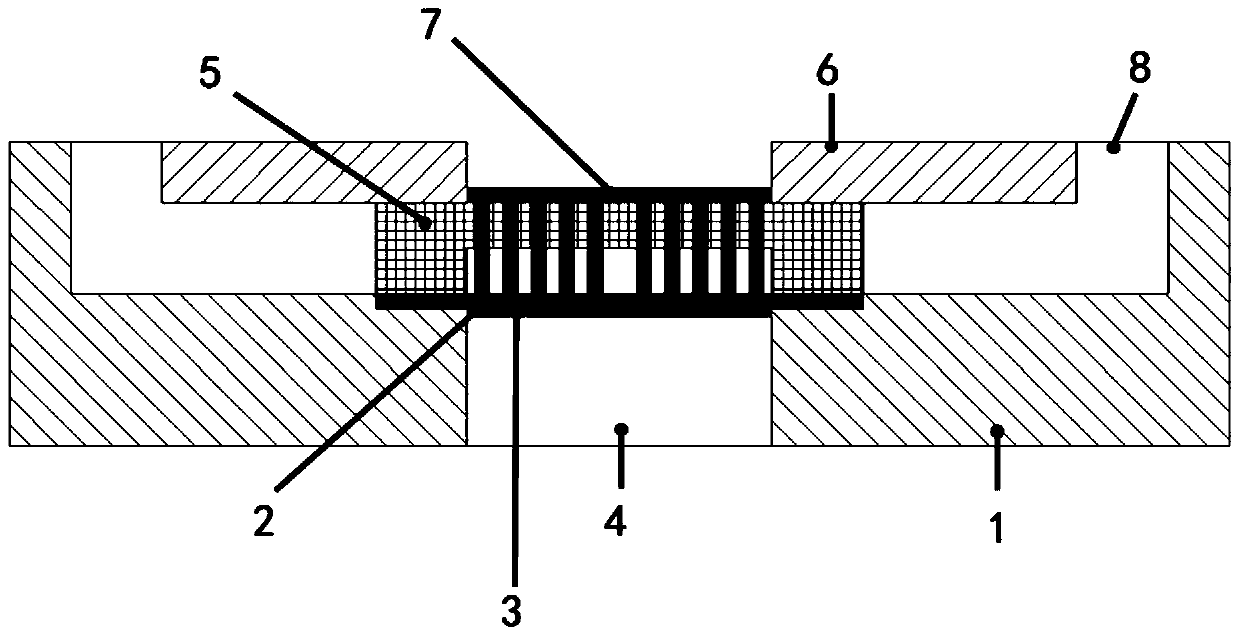

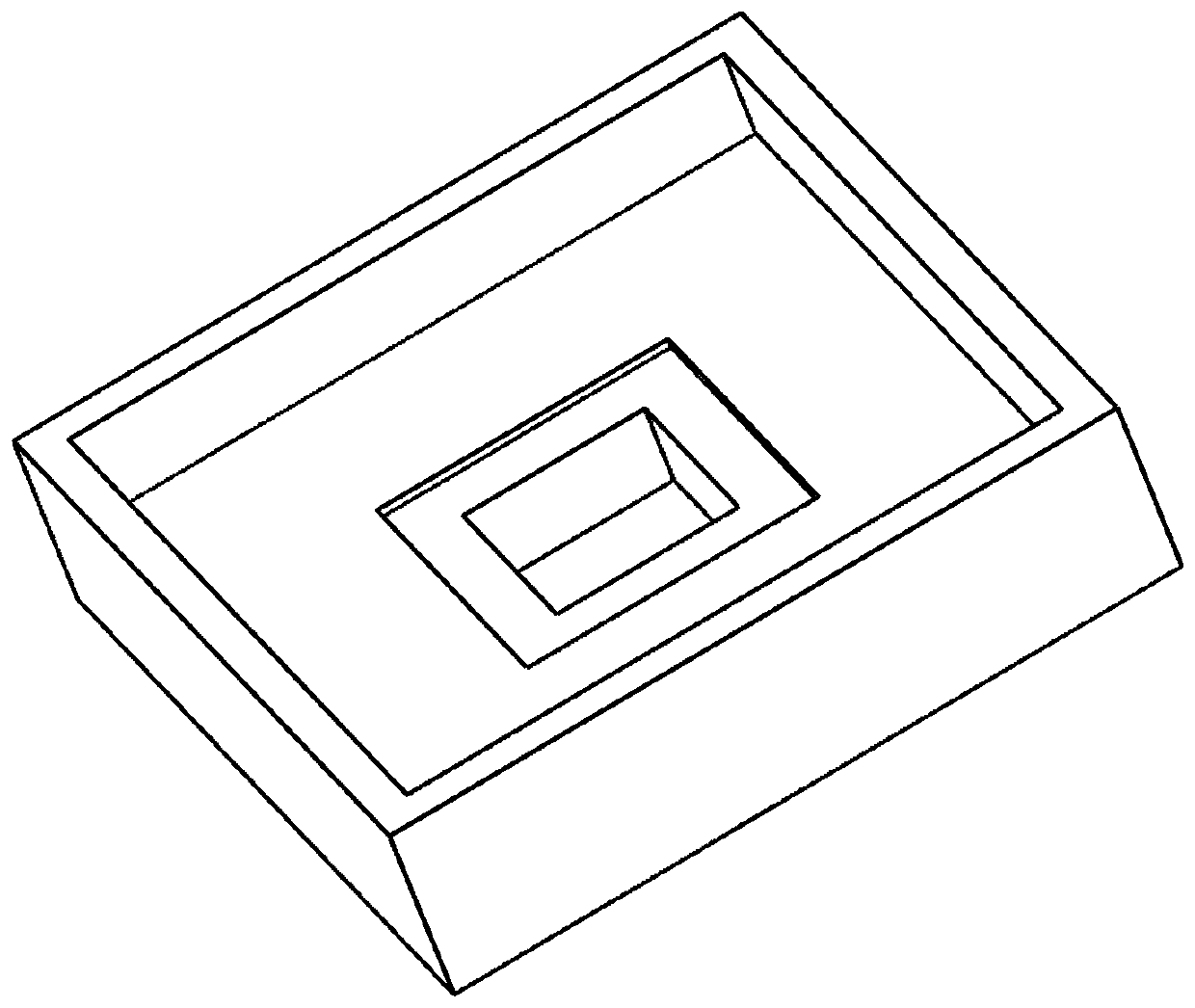

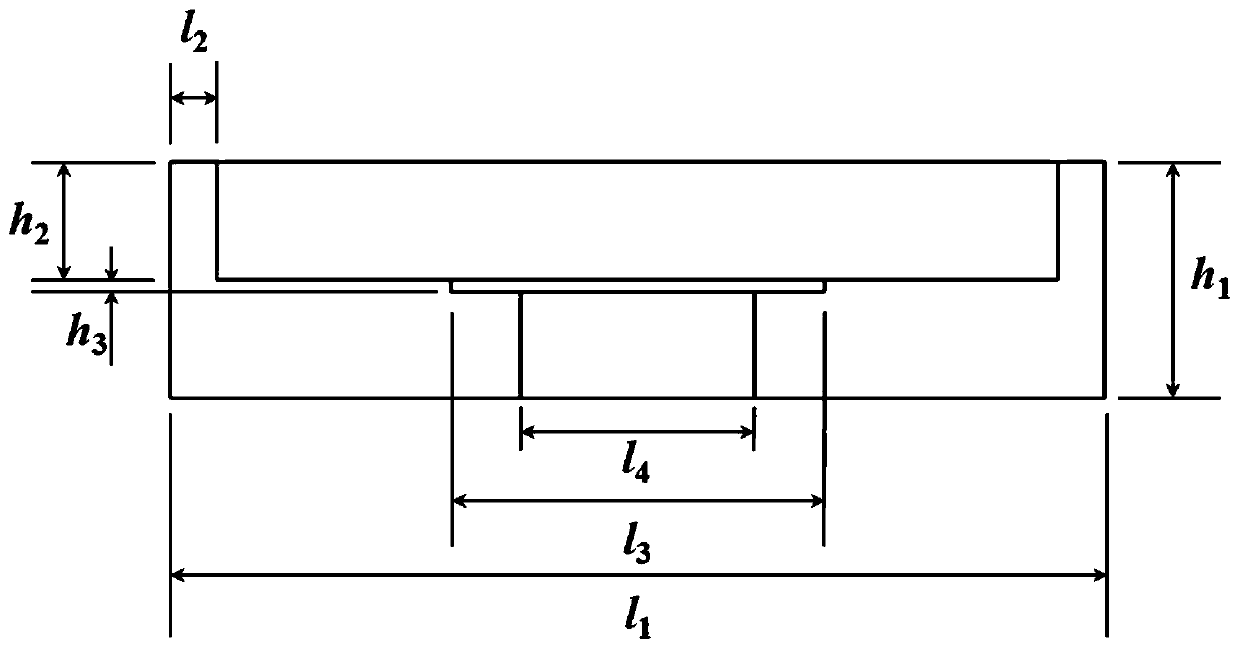

[0036] A combination structure of evaporation-boiling capillary core coupled with liquid replenishment capillary core, such as figure 1 As shown, it includes the lower substrate 1 of the rehydration channel, the evaporation-boiling capillary core 2, the ITO heating film 3, the heat insulating material 4, the rehydration capillary wick 5, the upper substrate 6 of the rehydration channel, the nano-evaporation film 7, the rehydration channel 8, and under the rehydration channel The evaporation-boiling capillary core 2 is arranged on the substrate 1, the ITO heating film 3 is sputtered at the bottom of the evaporation-boiling capillary core 2, the evaporation-boiling capillary core 2 is heated by the ITO heating film 3, and the heat insulating material 4 is arranged at the bottom of the ITO heating film 3 , to prevent the loss of heat; at the same time, the liquid repleni...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com