PCB (Printed Circuit Board) insulation resistance testing jig

An insulation resistance test and PCB board technology, applied in the field of test racks, can solve the problems of ink, substrate insulation performance degradation, encountering other metal objects, test results deviation, etc., to improve test efficiency, reduce the risk of electric shock, operation handy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

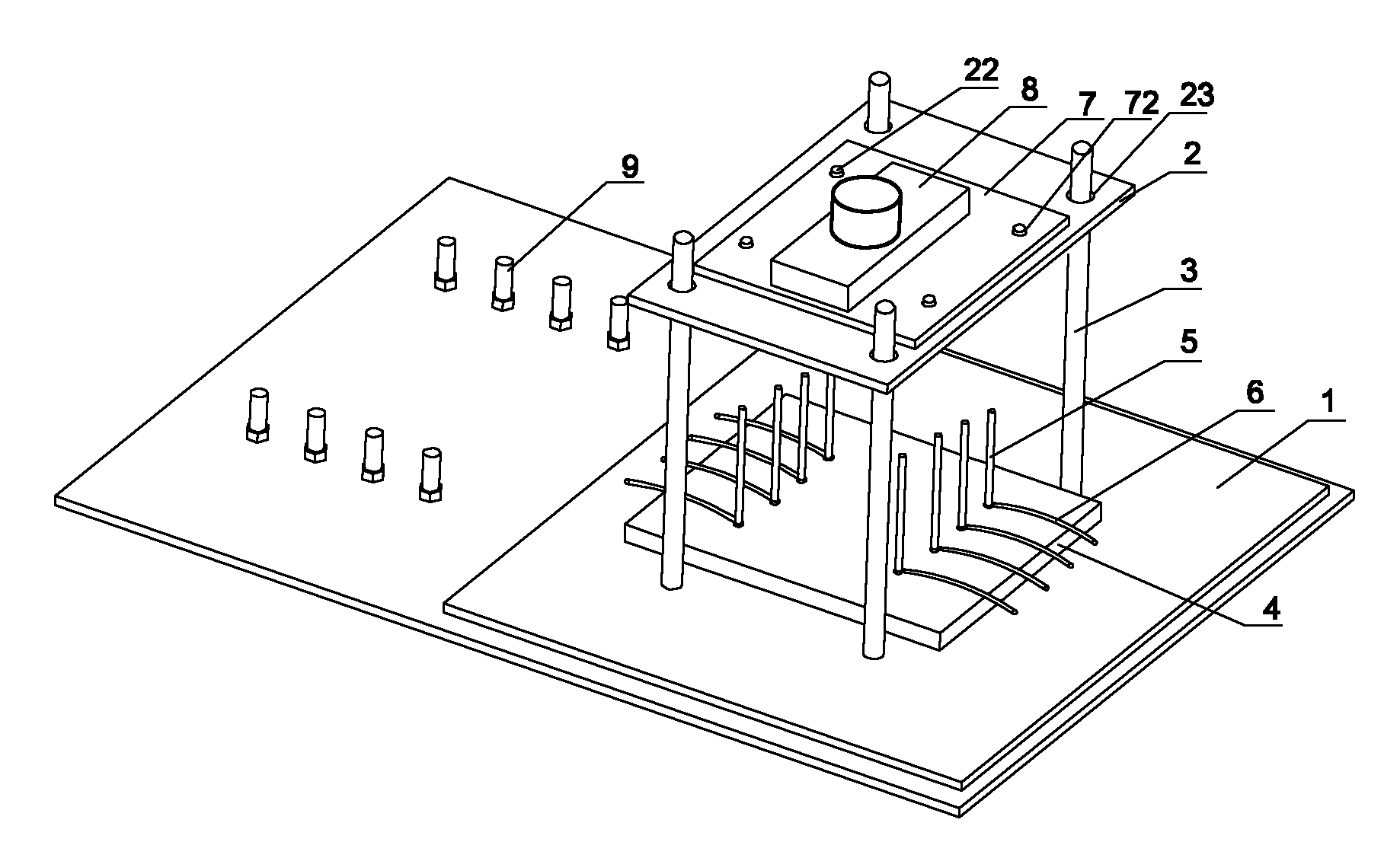

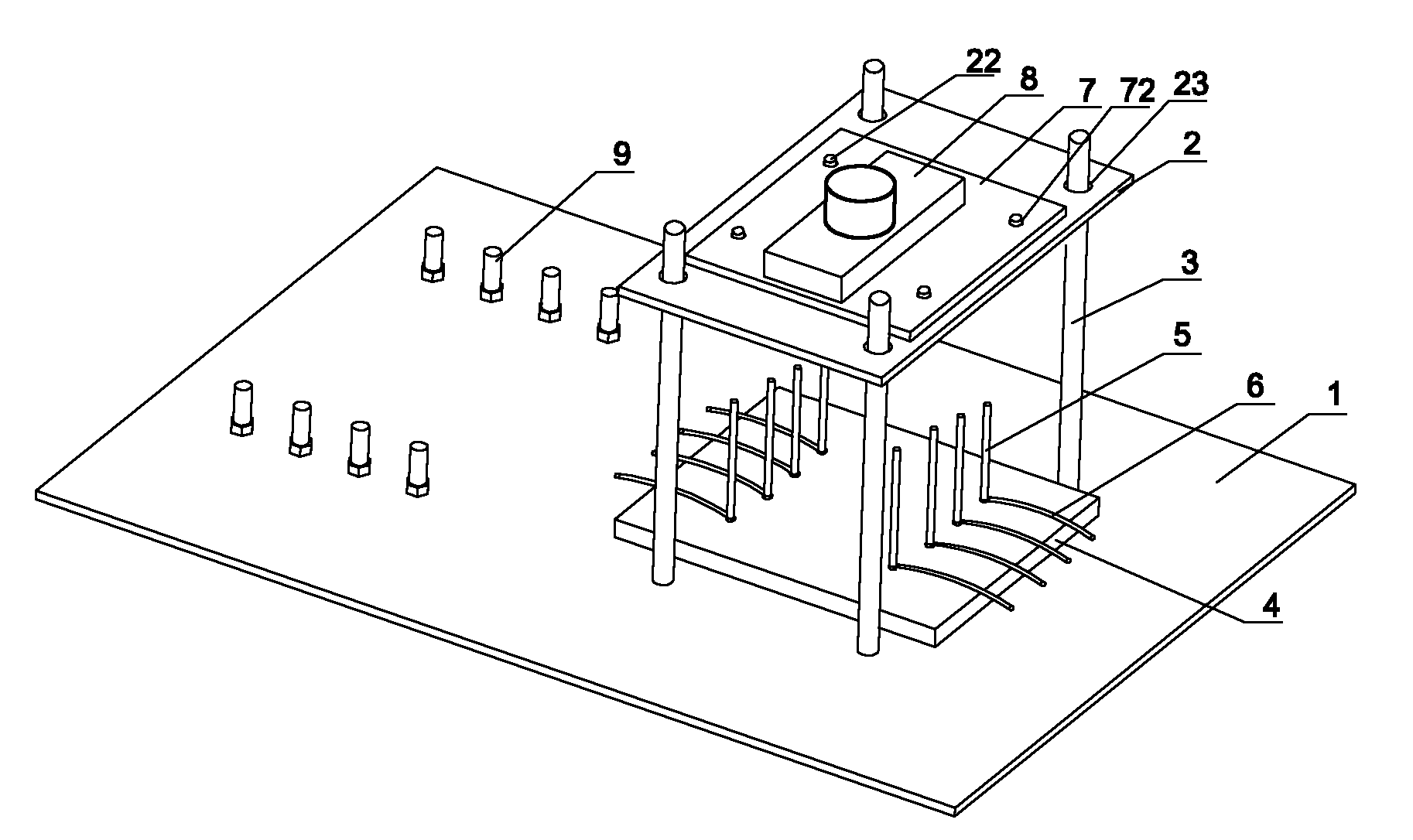

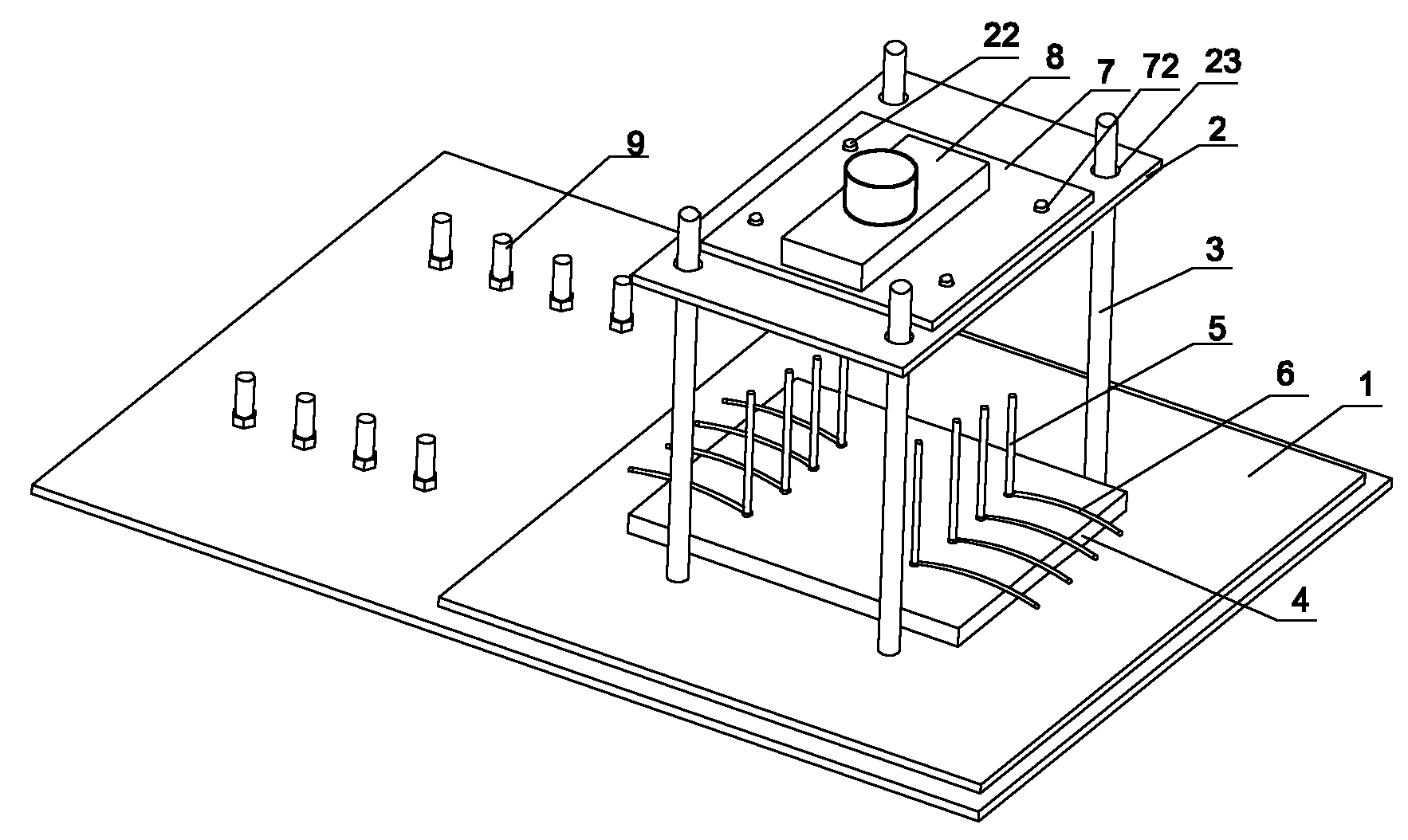

[0028] As the first embodiment of the PCB insulation resistance test frame of the present invention, please refer to figure 1 , including a base 1, a PCB board placement platform 2, a guide post 3, a test pin 5, a test pin stand 4, a test lead 6, a terminal post 9 and a counterweight 8, the guide post 3 is four in number, and is fixedly arranged on The four corners of the base 1, the PCB board placement platform 2 is fixedly arranged on the base 1, the test needle platform 4 is located above the PCB board placement platform 2, and corresponds to the position of the PCB board placement platform 2 up and down, and the test needle platform 4 is A guide hole 41 matched with the guide column 3 is provided, the test needle platform 4 slides up a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com