Electronic pouring sealant and preparation method thereof

A potting and electronic technology, used in the field of sealants, can solve the problems of low requirements for equipment and reaction conditions, poor flame retardancy and bonding performance, low thermal conductivity, etc., and does not meet the requirements of equipment and reaction conditions. , excellent thermal conductivity and flame retardant performance, excellent comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

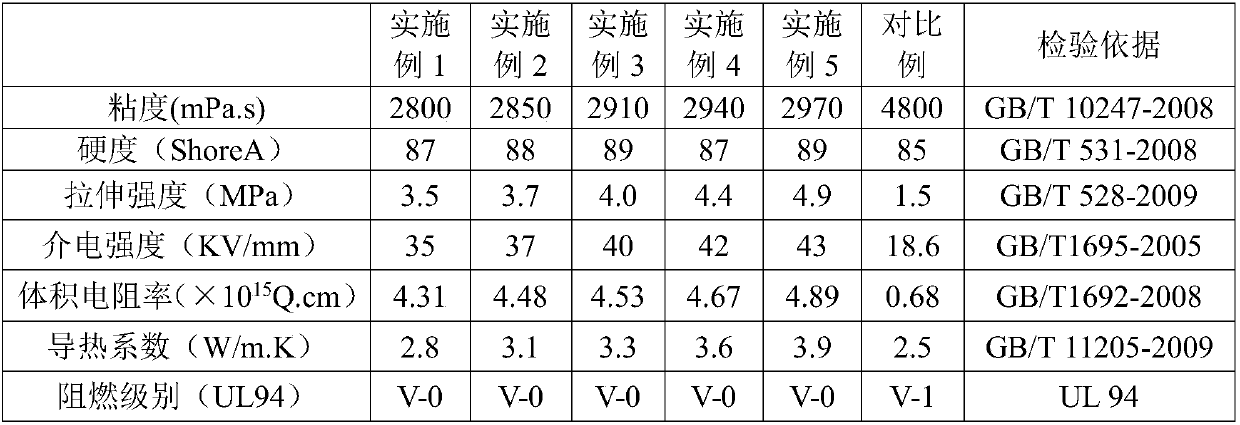

Examples

Embodiment 1

[0029] An electronic potting glue, which is composed of component A and component B in a weight ratio of 100:90, and the component A includes raw materials in the following weight ratio: 50 parts of modified vinyl silicone oil, silicon dioxide modified Cu - 5 parts of Al-O-B, 1 part of γ-aminopropyltriethoxysilane; the B component includes the following raw materials in weight ratio: 45 parts of dibromoneopentyl glycol diglycidyl ether, silica modified 5 parts of Cu-Al-O-B, 1 part of γ-(2,3-glycidoxy)propyltrimethoxysilane.

[0030] The preparation method of the modified vinyl silicone oil comprises the following steps: under a nitrogen atmosphere, mix 20 g of vinyl silicone oil with 1,1-dicyano-2-methoxy-4-dimethylamino-1,3 - Add 10g of butadiene into a three-neck flask equipped with a reflux condenser and an electric stirrer, then add 50g of isopropanol into the bottle, and reflux and stir the reaction at 125°C for 2 hours, then spin evaporate to remove the solvent, and obta...

Embodiment 2

[0037]An electronic potting glue, which is composed of component A and component B in a weight ratio of 100:95, and the component A includes raw materials in the following weight ratio: 53 parts of modified vinyl silicone oil, silicon dioxide modified Cu -6 parts of Al-O-B, 2 parts of γ-(methacryloyloxy)propyltrimethoxysilane; the B component includes raw materials in the following weight ratio: 47 parts of dibromoneopentyl glycol diglycidyl ether, Silica-modified Cu-Al-O-B 7 parts, γ-aminopropyltriethoxysilane 2 parts.

[0038] The preparation method of the modified vinyl silicone oil comprises the following steps: under a helium atmosphere, mix 23 g of vinyl silicone oil with 1,1-dicyano-2-methoxy-4-dimethylamino-1, Add 10 g of 3-butadiene into a three-necked flask equipped with a reflux condenser and an electric stirrer, then add 60 g of acetone into the bottle, and reflux and stir the reaction at 128°C for 2.3 hours, then remove the solvent by rotary evaporation to obtain ...

Embodiment 3

[0045] An electronic potting glue, which is composed of component A and component B in a weight ratio of 100:100; the component A includes raw materials in the following weight ratio: 56 parts of modified vinyl silicone oil, silicon dioxide modified Cu - 8 parts of Al-O-B, 3 parts of γ-(2,3-glycidyloxy) propyltrimethoxysilane; the B component includes raw materials in the following weight ratio: dibromoneopentyl glycol diglycidyl ether 51 parts, 8 parts of silica-modified Cu-Al-O-B, 2 parts of γ-aminopropyltriethoxysilane;

[0046] The preparation method of the modified vinyl silicone oil comprises the following steps: under a neon gas atmosphere, mix 26 g of vinyl silicone oil with 1,1-dicyano-2-methoxy-4-dimethylamino-1, Add 10 g of 3-butadiene into a three-necked flask equipped with a reflux condenser and an electric stirrer, then add 70 g of dichloromethane into the bottle, reflux and stir the reaction at 130 ° C for 2.6 hours, and then spin evaporate to remove the solvent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com