Rubber cable insulating material and preparation method thereof

A technology of rubber cables and insulating materials, applied in rubber insulators, organic insulators, etc., can solve problems such as surface damage of rubber cables, and achieve the effects of increasing applicability, increasing heat dissipation, and resisting odor and adapting to changes in cold and heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

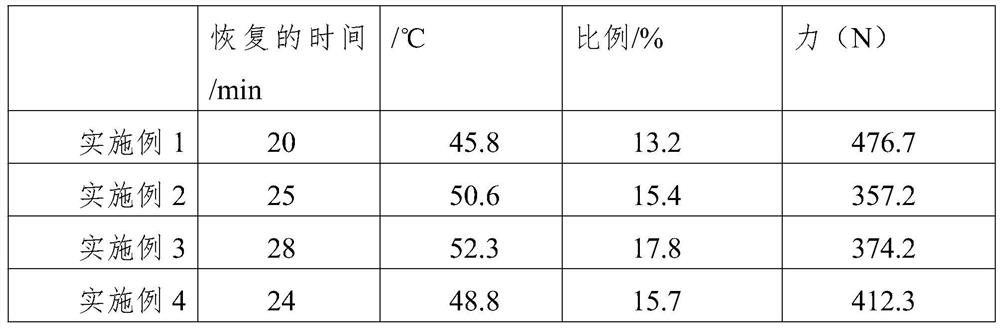

Embodiment 1

[0026] A kind of rubber cable insulation material of this embodiment, the main material used comprises the following and includes by weight: 12 parts of natural rubber; 18 parts of styrene-butadiene rubber; 12 parts of ethylene-propylene rubber; 12 parts of silicone rubber; aluminum oxide 8 parts of ceramics; 6 parts of coupling agent; 4 parts of plasticizer; 3 parts of antioxidant; 4 parts of water; 2 parts of organic solvent.

[0027] Further, the main specific components of the silicone glue are polydimethylsiloxane and silicon dioxide, and the weight ratio of polydimethylsiloxane to silicon dioxide is 5:3.

[0028] Further, the insulating layer and the sheath of the rubber cable are mainly composed of natural rubber, styrene-butadiene rubber and ethylene-propylene rubber, and the weight ratio of the natural rubber, styrene-butadiene rubber and ethylene-propylene rubber is 5:4:3.

[0029] Further, the specific components of the organic solvent are styrene, perchlorethylene,...

Embodiment 2

[0043] A rubber cable insulating material, the main materials used include the following in parts by weight: 15 parts of natural rubber; 20 parts of styrene-butadiene rubber; 13 parts of ethylene-propylene rubber; 13 parts of silicone rubber; 9 parts of alumina ceramics; 6 parts of coupling agent; 5 parts of plasticizer; 4 parts of antioxidant; 4 parts of water; 3 parts of organic solvent.

[0044] Further, the main specific components of the silicone glue are polydimethylsiloxane and silicon dioxide, and the weight ratio of polydimethylsiloxane to silicon dioxide is 5:3.

[0045] Further, the insulating layer and the sheath of the rubber cable are mainly composed of natural rubber, styrene-butadiene rubber and ethylene-propylene rubber, and the weight ratio of the natural rubber, styrene-butadiene rubber and ethylene-propylene rubber is 5:4:3.

[0046] Further, the specific components of the organic solvent are styrene, perchlorethylene, trichlorethylene, ethylene glycol ether ...

Embodiment 3

[0060] A rubber cable insulation material, the main materials used include the following in parts by weight: 20 parts of natural rubber; 20 parts of styrene-butadiene rubber; 14 parts of ethylene-propylene rubber; 13 parts of silicone rubber; 10 parts of alumina ceramics; 7 parts of coupling agent; 6 parts of plasticizer; 5 parts of antioxidant; 5 parts of water; 3 parts of organic solvent.

[0061] Further, the main specific components of the silicone glue are polydimethylsiloxane and silicon dioxide, and the weight ratio of polydimethylsiloxane to silicon dioxide is 5:3.

[0062] Further, the insulating layer and the sheath of the rubber cable are mainly composed of natural rubber, styrene-butadiene rubber and ethylene-propylene rubber, and the weight ratio of the natural rubber, styrene-butadiene rubber and ethylene-propylene rubber is 5:4:3.

[0063] Further, the specific components of the organic solvent are styrene, perchlorethylene, trichlorethylene, ethylene glycol eth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com