Attached insulator body cleaning device

A technology for cleaning devices and insulators, applied in cleaning methods and appliances, cleaning methods using tools, chemical instruments and methods, etc., can solve the problems of the insulation performance of the insulator body, the impact of power transmission safety, time-consuming and labor-intensive efficiency, etc., to improve Endurance, reduced replacement or charging times, and improved cleaning efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

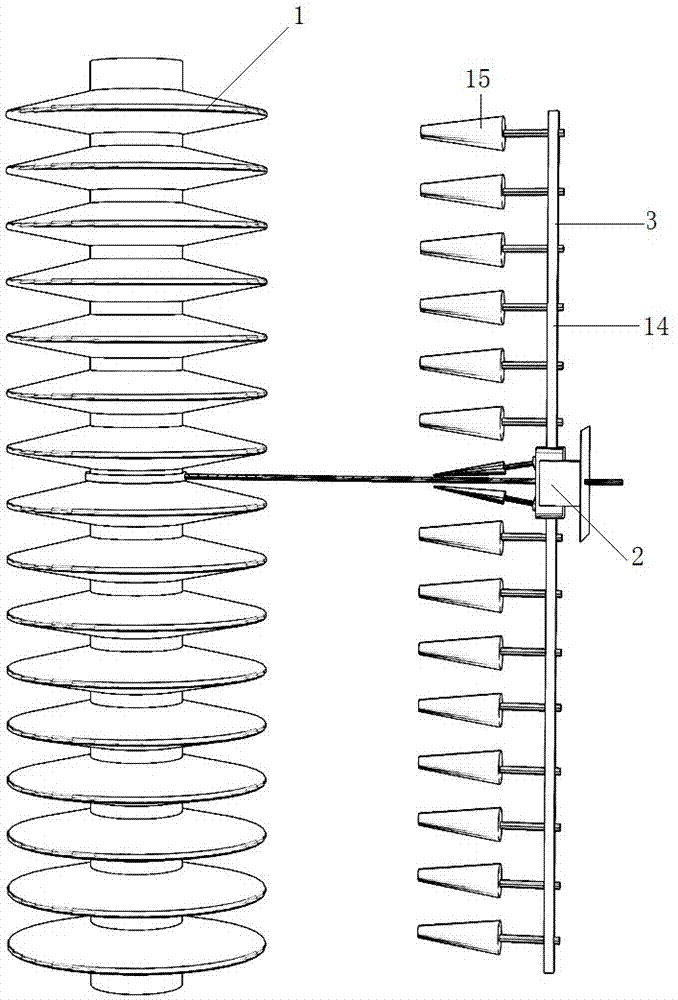

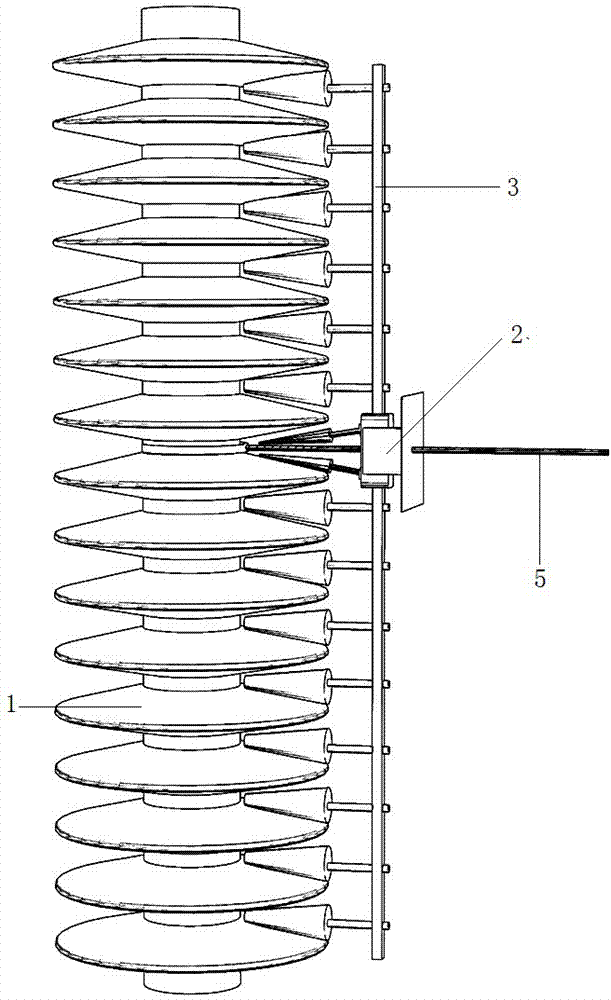

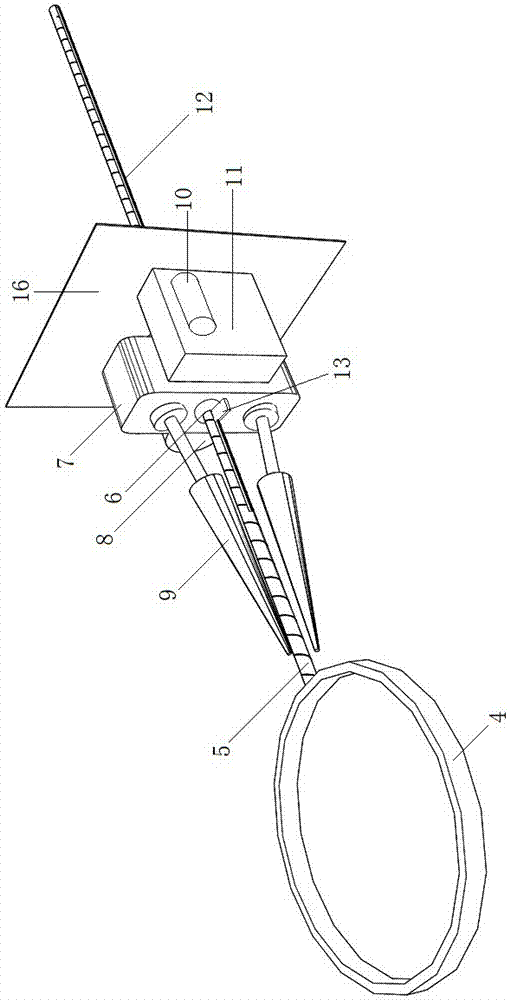

[0016] Such as Figure 1-3 As shown, the attached insulator body cleaning device includes an insulator body 1, an active cleaning unit 2, and a follower cleaning unit 3; the active cleaning unit 2 includes a support ring 4 that surrounds the middle of the insulator body 1 and is rotatably connected with the insulator body 1, a fixed On the outer surface of the support ring 4 and the threaded rod 5 arranged perpendicular to the axial direction of the insulator body 1, the screw sleeve 6 threadedly connected with the threaded rod 5; the screw sleeve 6 is rotatably mounted on the base 7; the base 7 is installed with Screw sleeve driving motor 8, two rollers 9 symmetrically arranged about the threaded rod 5, the roller driving motor 10, the gear box 11 connected with the output end of the roller driving motor 10; the output end of the scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com