Vacuum system for efficiently pumping gases with small molecular weights

A small molecular weight, vacuum system technology, applied in the field of vacuum system, can solve the problems of large volume and low effective pumping speed, and achieve the effect of improving effective pumping speed and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be further described below in conjunction with the drawings.

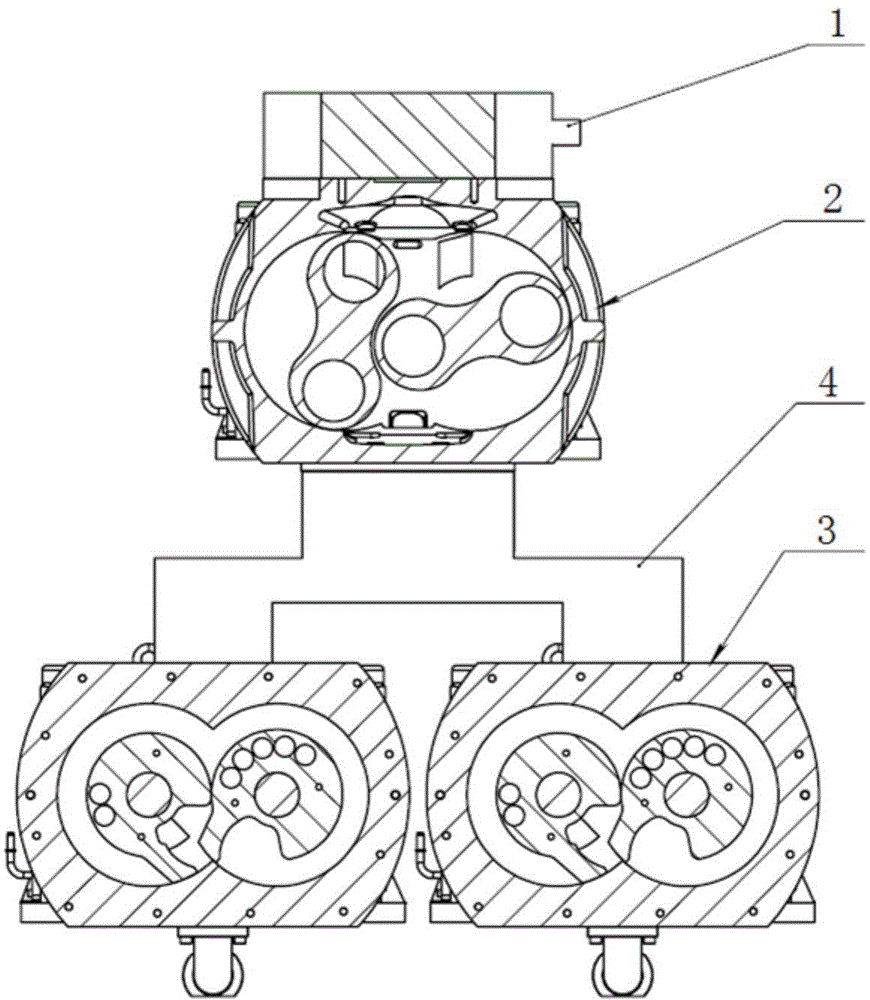

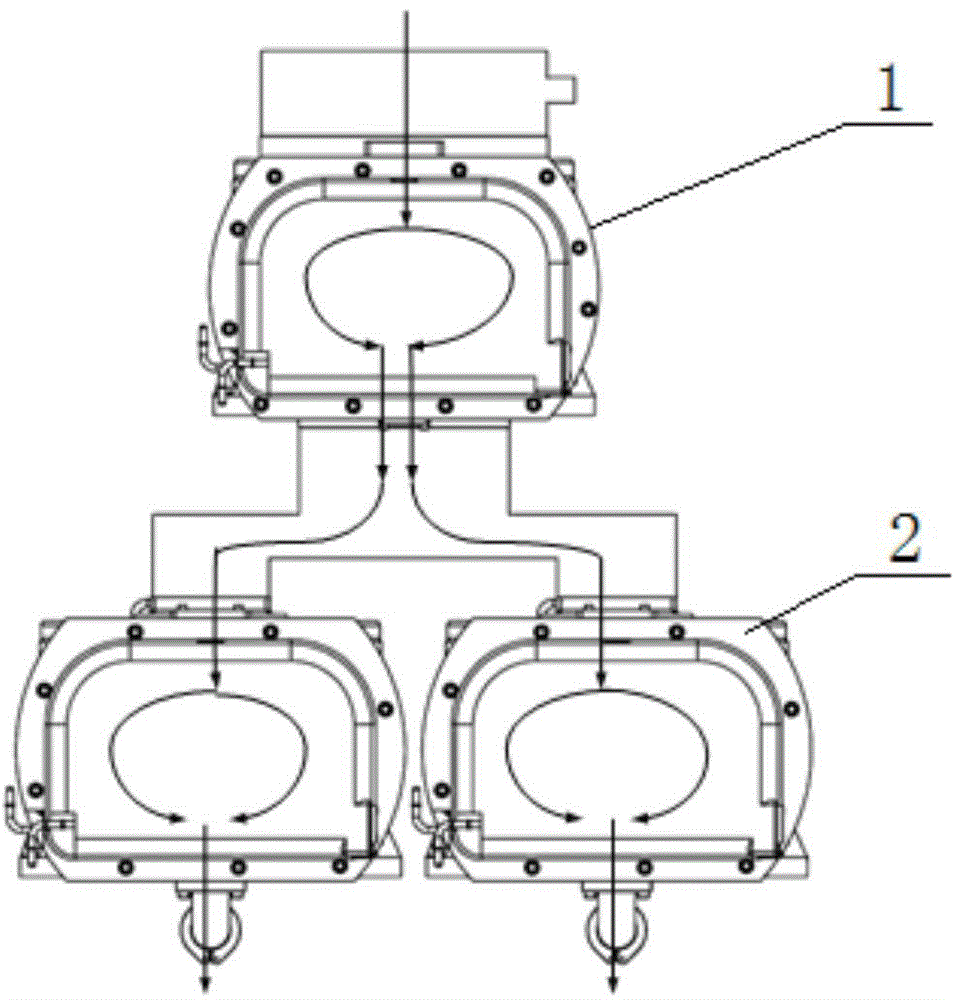

[0016] Such as figure 1 As shown, the present invention includes a controller, a primary vacuum pump 2 and a secondary vacuum pump 3, wherein there are multiple secondary vacuum pumps 3, and multiple secondary vacuum pumps 3 are connected in parallel to the primary vacuum pump 2. The primary vacuum pump 2 and each secondary vacuum pump 3 are both connected to the controller, and the primary vacuum pump 2 is connected to the process vacuum chamber.

[0017] The first-stage vacuum pump 2 is a Roots vacuum pump, the second-stage vacuum pump 3 is a multi-stage dry vacuum pump, and the multi-stage dry vacuum pump is a multi-stage pump with a combination of Roots and claw rotors, which can directly discharge gas to Outside of the pump, its special structure design can make it work stably at a speed above 3000 rpm (revolutions per minute). The high speed can improve the carrying capacity of sm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com