High-pressure splitting extrusion powder-mixing permeation-assisting in-situ remediation method for low-permeability polluted soil

A technology for in-situ remediation and contaminated soil, applied in the field of contaminated soil remediation, can solve the problems of long remediation period, difficult injection, and small remediation soil range, and achieves the improvement of remediation range increase, diffusion area, and pollution soil toxicity reduction. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

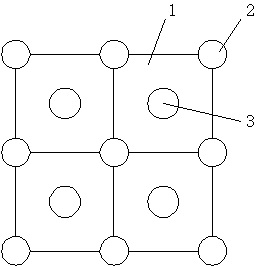

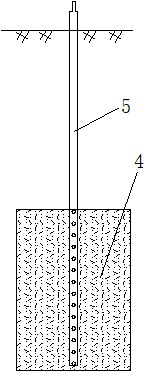

[0040] The present invention will now be described in further detail in conjunction with the accompanying drawings and preferred embodiments. These drawings are all simplified schematic diagrams, which only illustrate the basic structure of the present invention in a schematic manner, so they only show the configurations related to the present invention.

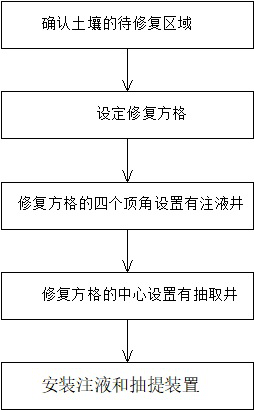

[0041] Such as Figure 1-4 A high-pressure splitting extrusion method for in-situ restoration of low-permeability polluted soil with powder mixing and infiltration aiding includes the following steps:

[0042] (1) Confirm the soil area to be repaired;

[0043] (2) According to the size of the soil area to be repaired, set four continuous distribution repair grids 1,

[0044] (3) The four corners of the repaired square 1 are provided with injection wells 2, and the construction method of the injection well 2 includes the following steps:

[0045] (31) The high-pressure rotary grouting pile is drilled longitudinally. When t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com