Process and system for producing ammonium sulfate by deaminizing coke oven gas with ammonium sulfite method

The technology of ammonium sulfite and coke oven gas is applied in the field of coal chemical industry, which can solve the problems of long process, high operation cost and high investment, and achieve the effects of low energy consumption, low investment and simple process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

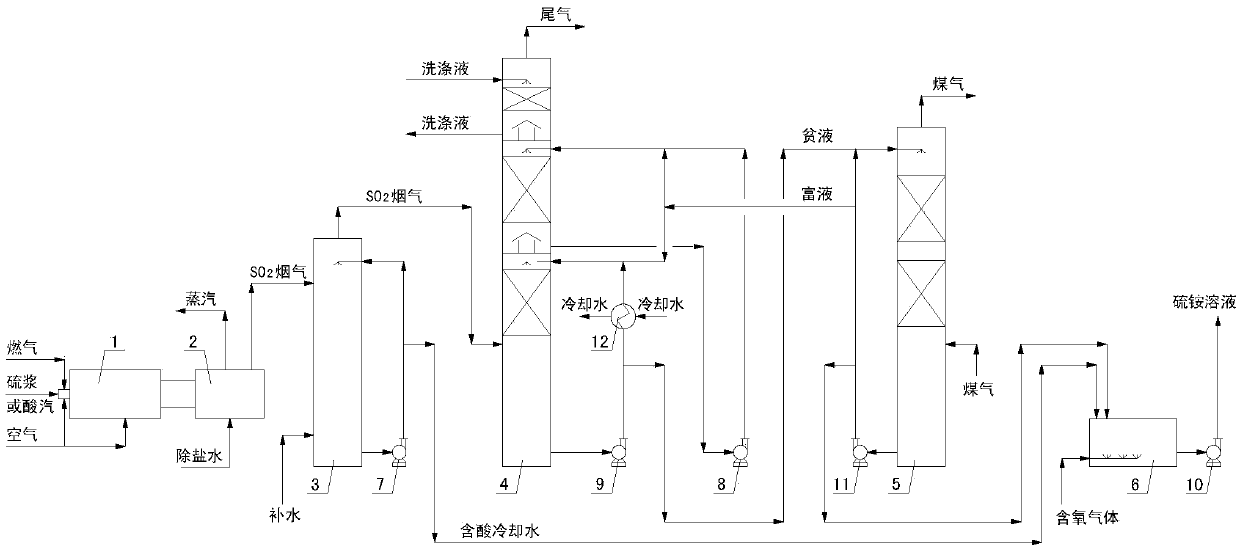

[0052] This embodiment discloses a coke oven gas ammonium sulfite method to produce ammonium sulfate system, its structure is as follows figure 1 As shown, it includes combustion furnace 1, waste heat boiler 2, cooling tower 3, desulfurization tower 4, ammonia washing tower 5, oxidation tank 6, cooling water pump 7, desulfurization upper circulation pump 8, desulfurization lower circulation pump 9, ammonium sulfate solution circulation pump 10. Ammonia washing circulating fluid pump 11. Desulfurization tower cooler 12:

[0053] The desulfurization tower 4 is a multi-stage packed tower.

[0054] The oxidation tank 6 has a built-in microporous air distribution pipe, and a cobalt sulfate fixed-bed catalyst is set.

[0055] The sulfur slurry or acid steam pipeline, fuel gas pipeline and air pipeline are connected to the inlet of the combustion furnace 1, and combustion generates flue gas containing sulfur dioxide;

[0056] The flue gas outlet of the combustion furnace 1 is conne...

Embodiment 2

[0085] This embodiment discloses a coke oven gas ammonium sulfite deamination process for producing ammonium sulphate, using the coke oven gas ammonium sulfite deamination system described in Example 1 to produce ammonium sulphate.

[0086] 1.1 million tons of coking plant gas treatment capacity of 55,000m 3 / h, the gas contains ammonia 6g / m 3 , containing hydrogen sulfide 4g / m 3 . Gas dehydrogen sulfide adopts vacuum carbonate desulfurization technology, and carbonate desulfurization rich liquid is vacuum desorbed to produce acid vapor containing hydrogen sulfide.

[0087] In the ammonia washing tower, the coal gas is in countercurrent contact with the ammonium sulfite lean solution sprayed on the top of the tower from bottom to top, the ammonia in it is absorbed, and the ammonia reacts with ammonium bisulfite to form ammonium sulfite, which forms ammonium sulfite at the bottom of the tower Rich liquid; the operating temperature of the ammonia washing tower is 30°C, and th...

Embodiment 3

[0091] This embodiment discloses a coke oven gas ammonium sulfite deamination process for producing ammonium sulphate, using the coke oven gas ammonium sulfite deamination system described in Example 1 to produce ammonium sulphate.

[0092] 1.1 million tons of coking plant gas treatment capacity of 55,000m 3 / h, the gas contains ammonia 7g / m 3 , containing hydrogen sulfide 5g / m 3 . Hydrogen sulfide removal from coal gas adopts ammonia wet oxidation technology to convert hydrogen sulfide removed from coal gas into sulfur slurry.

[0093] In the ammonia washing tower, the coal gas is in countercurrent contact with the ammonium sulfite lean solution sprayed on the top of the tower from bottom to top, the ammonia in it is absorbed, and the ammonia reacts with ammonium bisulfite to form ammonium sulfite, which forms ammonium sulfite at the bottom of the tower Rich liquid; the operating temperature of the ammonia washing tower is 30°C, and the pressure is 20kPa; the pH value of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com