Chemical stripping solution and stripping method

A stripping solution and chemical technology, applied in the field of stripping, can solve the problems of substrate corrosion and environmental pollution, and achieve the effect of fast stripping speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

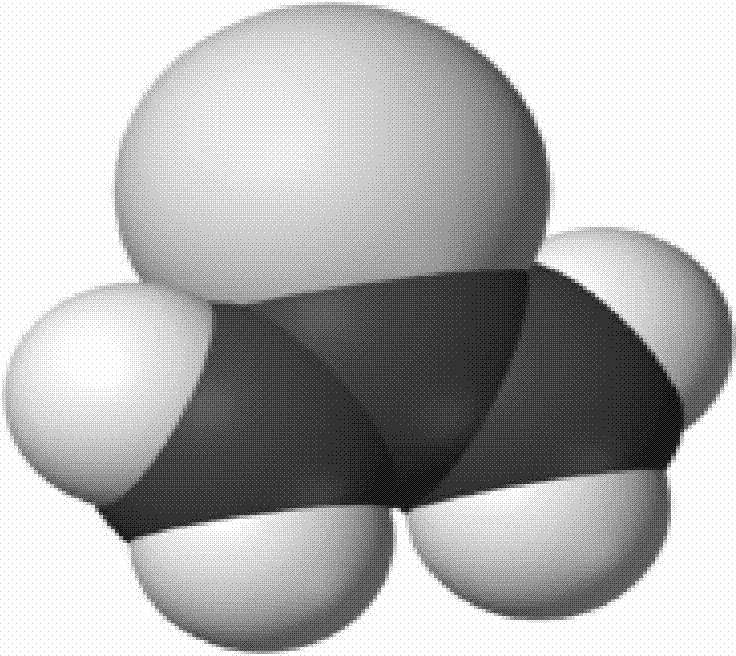

Embodiment 1

[0052] The test material is a 10mm×10mm×2mm red copper plate, which is put into the sulfuric acid with a mass percentage of 98% sulfuric acid 400g / L, hydrogen peroxide with a mass percentage of 30% hydrogen peroxide 150g / L, and a thiourea content of 50g / L. Deplating solution, the reaction temperature is 80°C. The copper plate reacts quickly in the deplating solution and dissolves completely, and the reaction speed is 55 μm / min (thickness direction of the plate).

Embodiment 2

[0054] The test material is a nickel plate of 10mm×10mm×2mm, which is put into the sulfuric acid with a mass percentage of 98% sulfuric acid 300g / L, hydrogen peroxide with a mass percentage of 30% hydrogen peroxide 120g / L, and a thiourea content of 30g / L. Deplating solution, the reaction temperature is 75°C. The nickel plate reacts quickly in the deplating solution and dissolves completely, and the reaction speed is 57μm / min (thickness direction of the plate).

Embodiment 3

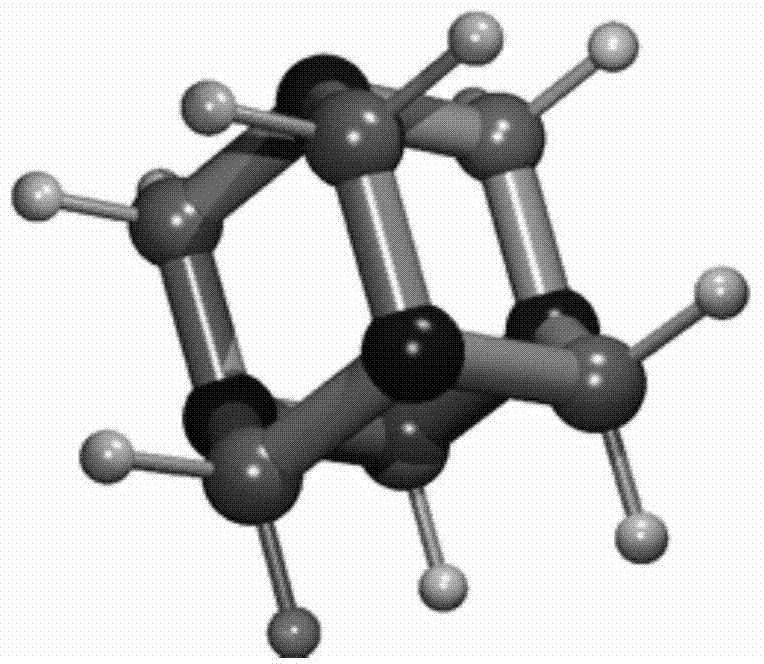

[0056] The test material is a copper-plated stainless steel piece of 20mm×12mm×0.32mm. The base stainless steel is 304L, and the thickness of the copper plating layer is 0.02mm. 30% hydrogen peroxide 100g / L, deplating solution with urotropine content of 50g / L, and the deplating temperature is 20°C. The copper plating layer reacts in the stripping solution, wherein the copper plating layer is stripped, the stripping is complete, and the carbon steel substrate does not appear to be seriously corroded. The deplating speed is 23 μm / min (thickness direction of the coating).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com