Preparation method for clean foam magnesium in bionic field

A technology for cleaning foam and magnesium foam, which is applied in the field of preparation of through-hole foam magnesium, can solve the problems of difficult preparation of large parts and high cost, and achieve the effect of solving heterogeneous residues, low cost and broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

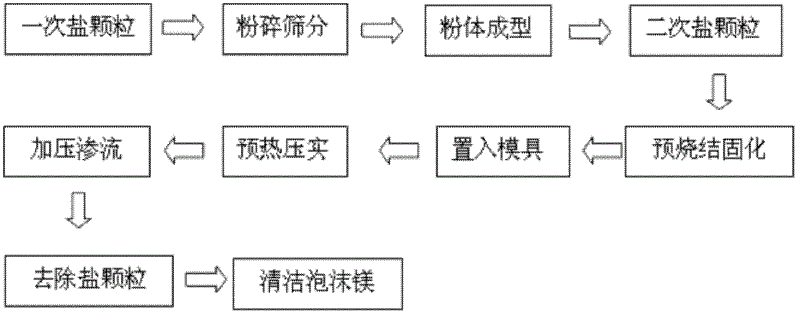

[0046] Example 1: The preparation method of the cleaning foam magnesium that is used in bionic field is characterized in that comprising the following steps:

[0047] (1) Firstly, the primary NaCl particles are dried and ball-milled into powder, passed through a 200-mesh sieve, and the NaCl powder is granulated to prepare secondary particles with a particle size of 0.1-5 mm, and the obtained particles are sequentially passed through 8 mesh, 12-mesh, 16-mesh, 30-mesh, 60-mesh and 100-mesh sieves to screen secondary particles of different sizes;

[0048] (2) Put the granular raw material obtained in step (1) into a muffle furnace for pre-sintering, keep it at 600-700°C for 10-120min, take it out and cool it naturally;

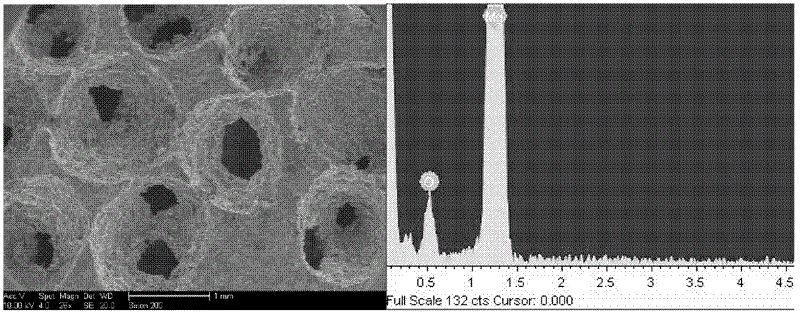

[0049] (3) Seepage: Melt magnesium metal at 660-700°C, spread SY-LF1 covering agent on the molten metal, and then pre-sinter the particles in step (2) (which can be particles of the same mesh level or a variety of different meshes Number of particles mixed) pr...

Embodiment 2

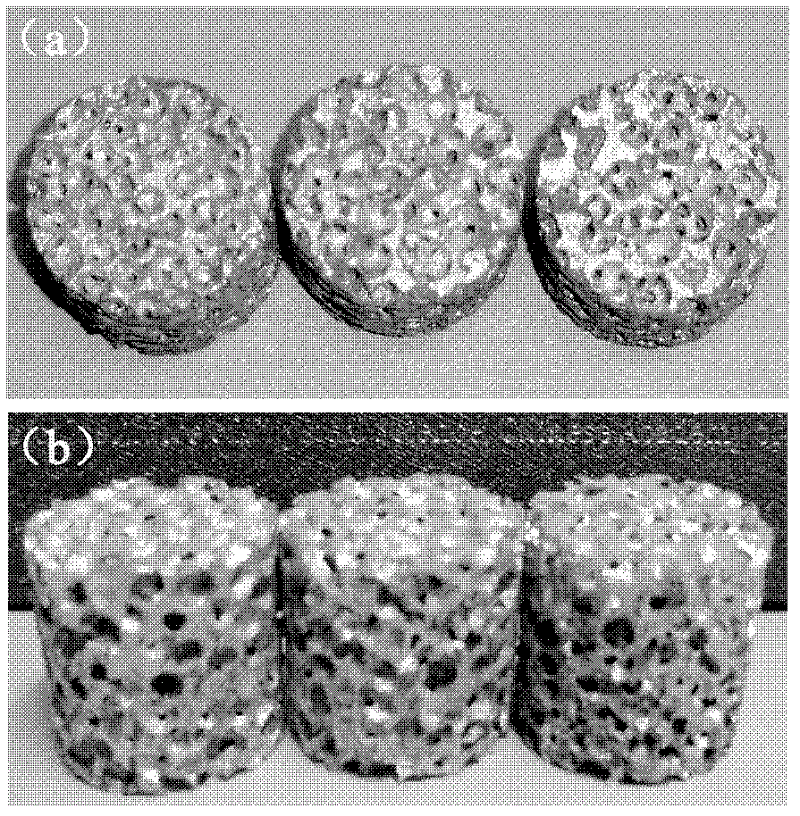

[0051] Example 2: Put secondary NaCl spherical particles with an average diameter of 1 mm into a metal mold with a diameter of 105 mm and a height of 90 mm, vibrate, compact, and preheat in a resistance furnace; raise the temperature to 650 ° C and keep it for 1 hour; then in 0.5 Under atm, molten metal magnesium at 680°C is percolated and casted into preheated blocks at 650°C under the protection of argon; after cooling, the spherical salt particles are removed by washing with water to obtain spherical clean foam magnesium with a porosity of 60%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com