Plate of corrosion-resistant plate heat exchanger and corrosion-resistant treatment method of plate

A technology for anti-corrosion treatment and heat exchangers, applied in heat exchange equipment, lighting and heating equipment, laminated components, etc., can solve problems such as corrosion, and achieve the effects of simple manufacturing, improved erosion resistance and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

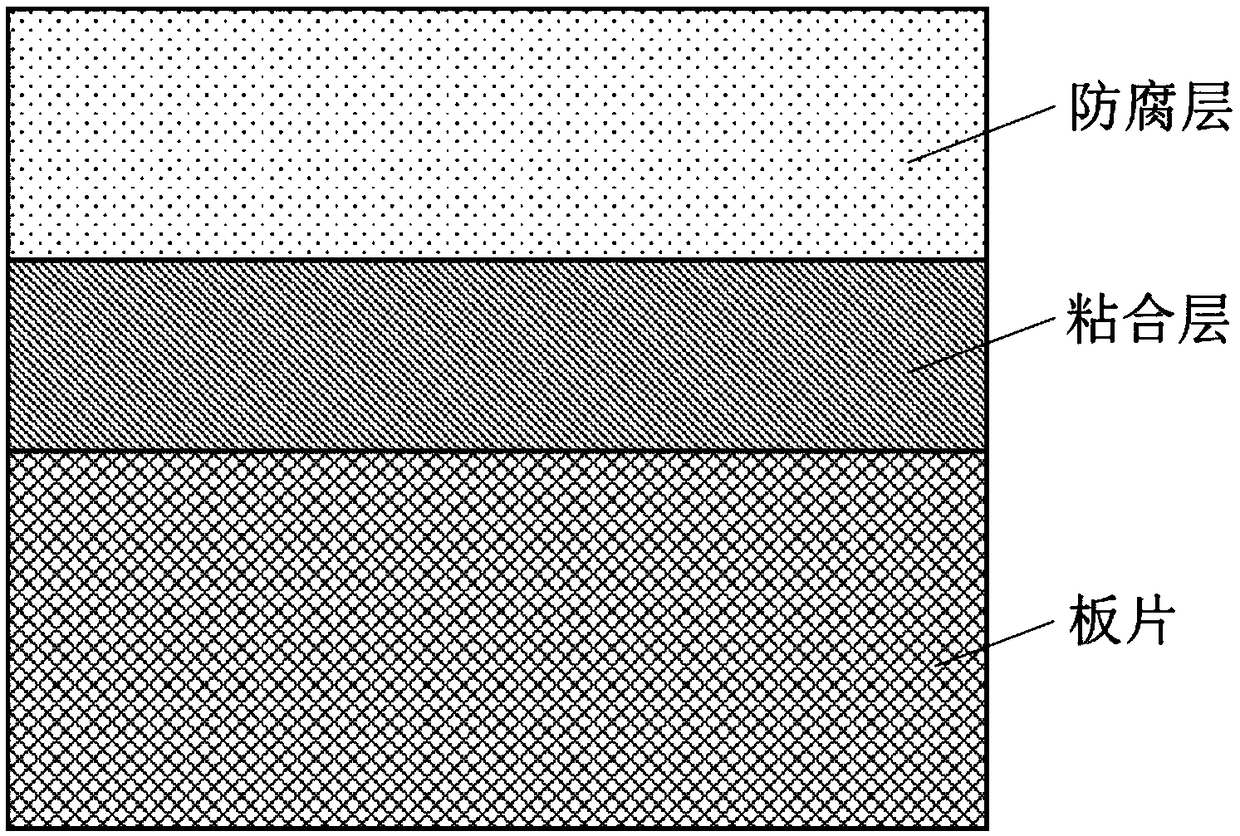

[0044] A fluorine-sprayed anti-corrosion plate heat exchanger plate

[0045] (1) Surface pretreatment: pickling the newly pressed 304 stainless steel sheet with a thickness of 0.5 mm in an aqueous oxalic acid solution with a mass fraction of 40%, adding dodecylbenzenesulfonate with a concentration of 10g / L soaking and stirring in sodium phosphate aqueous solution, and after natural drying, the surface of the plate will appear glossy.

[0046] (2) Mix polyvinyl alcohol, ethanol, deionized water, xylene and talcum powder at a mass ratio of 30:40:5:15:10, put them in an oven, bake at 100°C for 180 minutes, and grind them into powder , use a sieve to filter the solid powder below 200-300 mesh, spray it on the surface of the pretreated plate by electrostatic powder spraying method, and dry it at room temperature. The specific parameters of electrostatic powder spraying are as follows: electrostatic voltage 65kV, air supply pressure 10pa , the electrical circuit entering the powder...

Embodiment 2

[0053] A fluorine-sprayed anti-corrosion plate heat exchanger plate

[0054] (1) Surface pretreatment: pickling the newly pressed 316L stainless steel sheet with a thickness of 0.5mm in an aqueous oxalic acid solution with a mass fraction of 50%, adding dodecylbenzenesulfonate with a concentration of 3g / L soaking and stirring in sodium phosphate aqueous solution, and after natural drying, the surface of the plate will appear glossy.

[0055] (2) Mix polyvinyl alcohol, ethanol, deionized water, xylene and talcum powder at a mass ratio of 30:50:5:5:10, put them in an oven, bake at 100°C for 180min, and grind them into powder , obtain solid powder below 200~300 meshes by sieve filtration, adopt electrostatic powder spraying method (parameters are the same as embodiment 1) to spray to the sheet surface after pretreatment, adopt GB1764-79 standard, lever micrometer method measures spraying thickness, spraying The thickness is 15 μm.

[0056] (3) Grind polytetrafluoroethylene into...

Embodiment 3

[0062] A fluorine-sprayed anti-corrosion plate heat exchanger plate

[0063] (1) Surface pretreatment: pickling the newly pressed 304 stainless steel sheet with a thickness of 0.6 mm in an aqueous oxalic acid solution with a mass fraction of 30%, adding dodecylbenzenesulfonate with a concentration of 5g / L soaking and stirring in sodium phosphate aqueous solution, and after natural drying, the surface of the plate will appear glossy.

[0064] (2) Mix polyvinyl alcohol, ethanol, deionized water, xylene and talcum powder at a mass ratio of 30:35:5:15:15, put them in an oven, bake at 100°C for 180 minutes, and grind them into powder , obtain solid powder below 200~300 meshes by sieve filtration, adopt electrostatic powder spraying method (parameters are the same as embodiment 1) to spray to the sheet surface after pretreatment, adopt GB1764-79 standard, lever micrometer method measures spraying thickness, spraying The thickness is 20 μm.

[0065] (3) Grind polytetrafluoroethylen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com