Energy-saving and low-pollution method for processing soft yarns

A processing method and low-pollution technology, which is applied in the field of yarn processing, can solve the problems of high energy consumption, high yarn cost, and large pollution, and achieve the effects of good warmth retention, cost reduction, and reduced use ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] An energy-saving and low-pollution yarn softening method is provided. The yarn as the main component is compounded with the yarn containing water-soluble vinylon components, and then the yarn is de-dimensionalized to make a product.

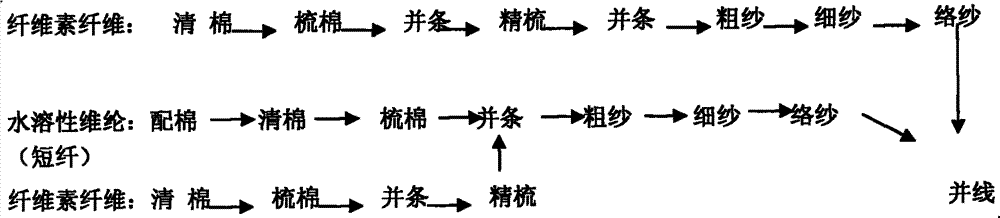

[0018] The said yarn as the main component is the yarn obtained from cellulose fiber through the processes of cleaning, carding, drawing, combing, drawing, roving, spun yarn and winding in sequence.

[0019] Yarns containing water-soluble vinylon components are yarns obtained from water-soluble vinylon staple fibers through the processes of blending, cleaning, carding, drawing with cellulose fibers, roving, spun yarn, and winding, in which the cellulose fibers are cleaned , carded, drawn and combed cellulose fibers, in the two components of water-soluble vinylon staple fiber and cellulose fiber, water-soluble vinylon staple fiber accounts for 40-60%, and the yarn as the main component and water-soluble vinylon The compounding method of the...

Embodiment 2

[0021] An energy-saving and low-pollution yarn softening processing method, the yarn as the main component is compounded with the core-spun yarn containing water-soluble vinylon component, and then the product is made by deviating.

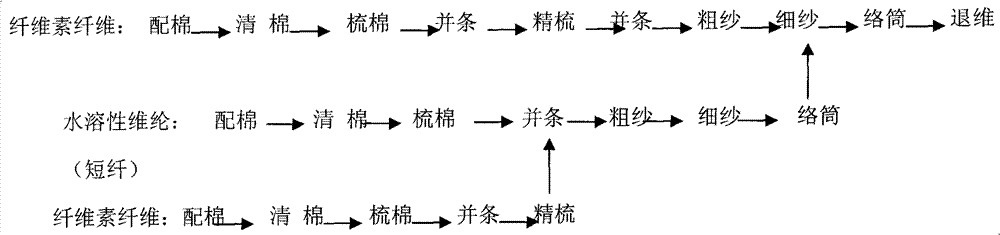

[0022] The yarn as the main component is the outer covering yarn, which is obtained from cotton fibers through blending, cleaning, carding, drawing, combing, drawing, roving and spun yarn in sequence.

[0023] Yarns containing water-soluble vinylon components are yarns obtained from water-soluble vinylon staple fibers through cotton blending, cleaning, carding, drawing with cotton fibers, roving, spun yarn, and winding processes in sequence. Cotton, carded, drawn and combed cotton fibers, in the two components of water-soluble vinylon staple fiber and cotton fiber, water-soluble vinylon staple fiber accounts for 40-60%, as the main component of the yarn and water-soluble vinylon component The yarn composite method is core-spun composite. The yarn ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com