Telescopic non-woven fabric and method of manufacturing the same

A technology of non-woven fabric and stretchability, which is applied to the base fabric of ear loops or poultice, the manufacture of non-woven fabrics, and the field of bandages. It can solve the problem of insufficient stretchability or texture of non-woven fabrics and the difficulty of obtaining non-woven fabrics Strength, difficulty in forming firm joints and other issues, to achieve the effect of excellent stretchable non-woven fabrics, good texture, and excellent balance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Next, the present invention will be specifically described by way of examples, but the present invention is not limited to the following examples. In addition, definitions and measurement methods of terms used in Examples and Comparative Examples are as follows.

[0049] (1) Melting point and softening point: (unit: °C)

[0050] Using the differential scanning calorimeter DSC-Q10 manufactured by TA Instruments, the temperature corresponding to the peak on the melting absorption curve obtained when the temperature of the thermoplastic polymer is raised at 10° C. / min is defined as the melting point of the thermoplastic polymer, as follows The extrapolated melting onset temperature of is set as the softening point, and the extrapolated melting onset temperature is the temperature of the intersection obtained by extrapolating the tangent line drawn at the point of the maximum inclination of the upright part of the peak and the baseline before the peak .

[0051] (2) Denie...

example 2~ example 7、 comparative example 1~ comparative example 5

[0074] Nonwoven fabrics were produced in the same manner as in Example 1, except that the combinations and mixing ratios of heat-shrinkable conjugate fibers and heat-shrinkable conjugate fibers, and the temperatures of heat treatment (1) and heat treatment (2) shown in Table 3 were changed, The elongation recovery rate and the strength at elongation were also measured.

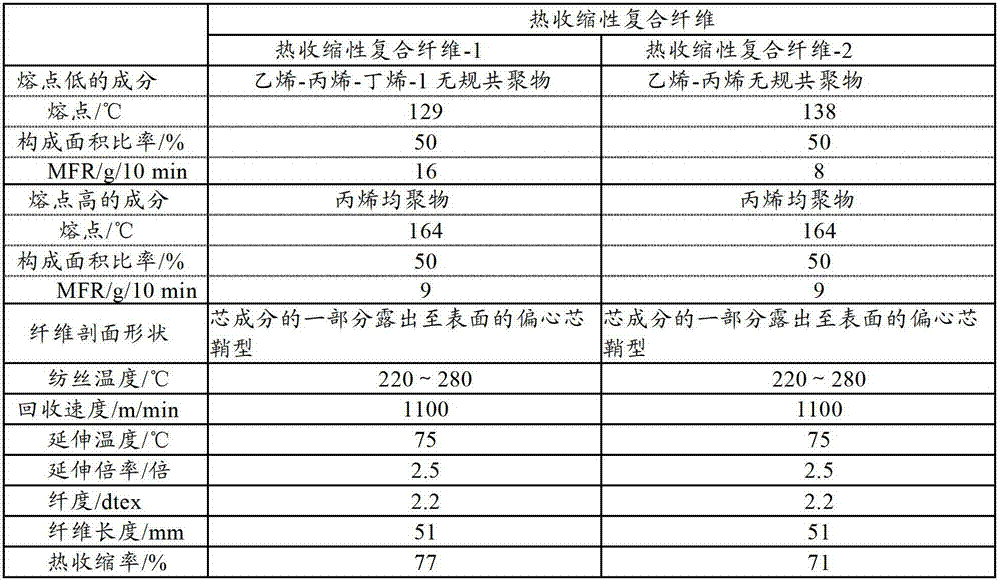

[0075] [Table 1]

[0076]

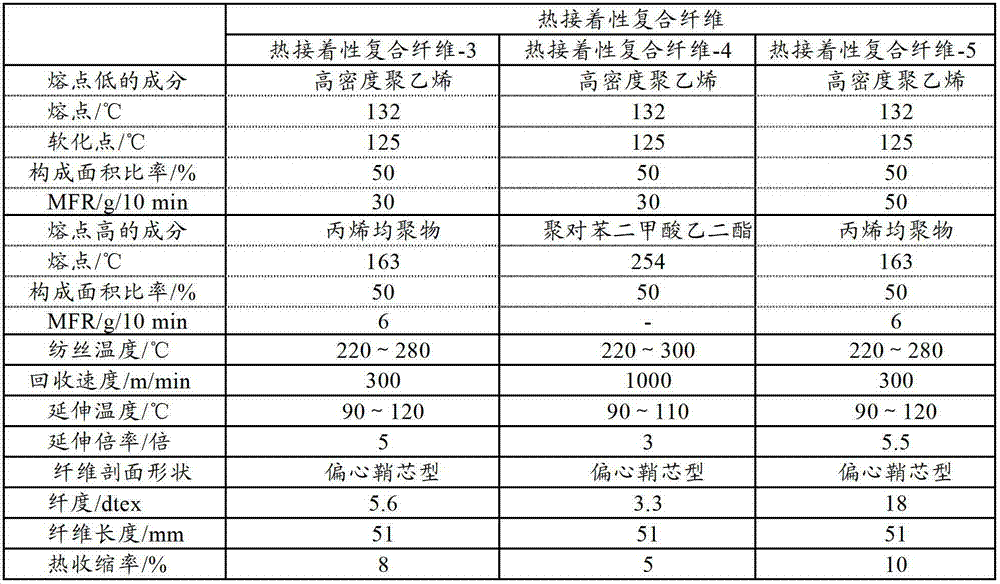

[0077] [Table 2]

[0078]

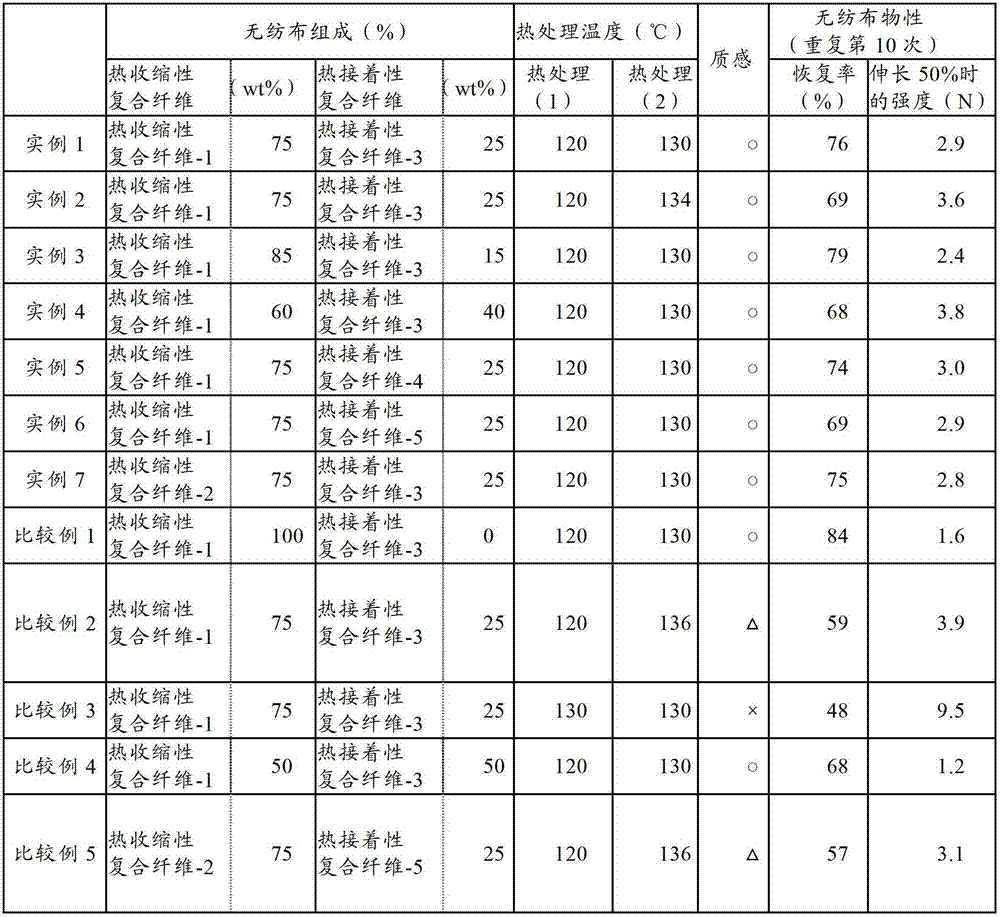

[0079] [table 3]

[0080]

[0081] As is clear from the results of Examples 1 to 7, the texture of the stretchable nonwoven fabric of the present invention is good, and when the repeated tensile test is performed, the elongation recovery rate is the same as that at the time of the tenth elongation of 50%. Excellent balance of strength.

[0082] On the other hand, when the heat-adhesive conjugate fiber was not used as in Comparative Example 1, although the elongation recovery rate was good, the strength at the 10th elongation was extremely low,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com