Patents

Literature

150results about How to "Variety of styles" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

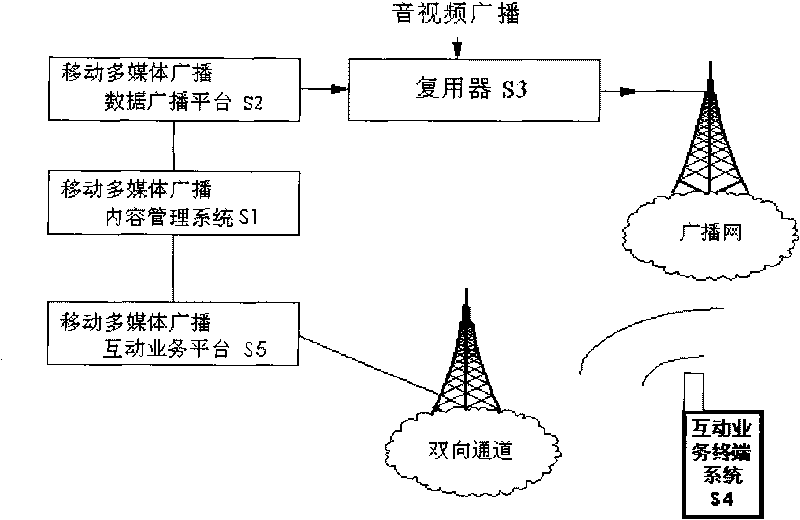

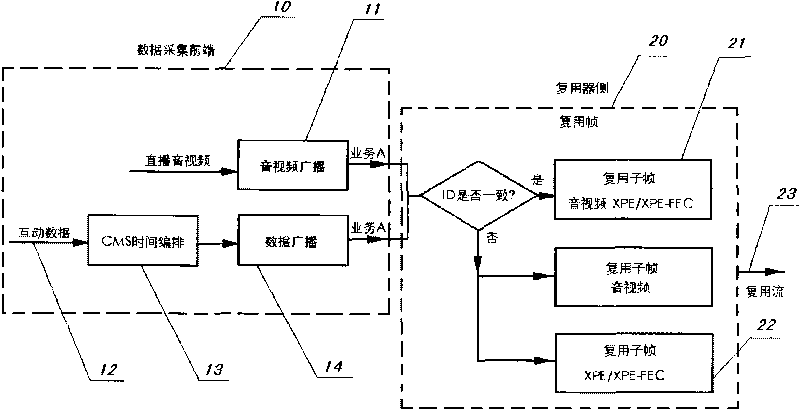

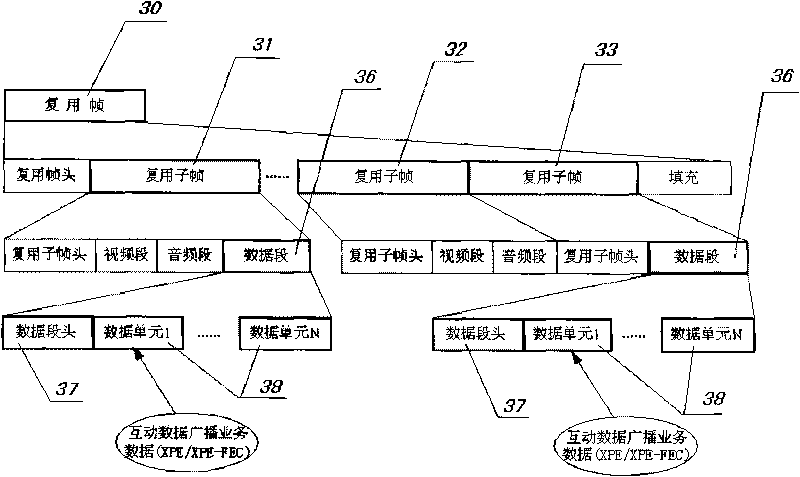

System and method for realizing interactive service of mobile multimedia broadcast

ActiveCN101742246AVariety of stylesFast information feedbackTwo-way working systemsTransmissionMultiplexingInteractive content

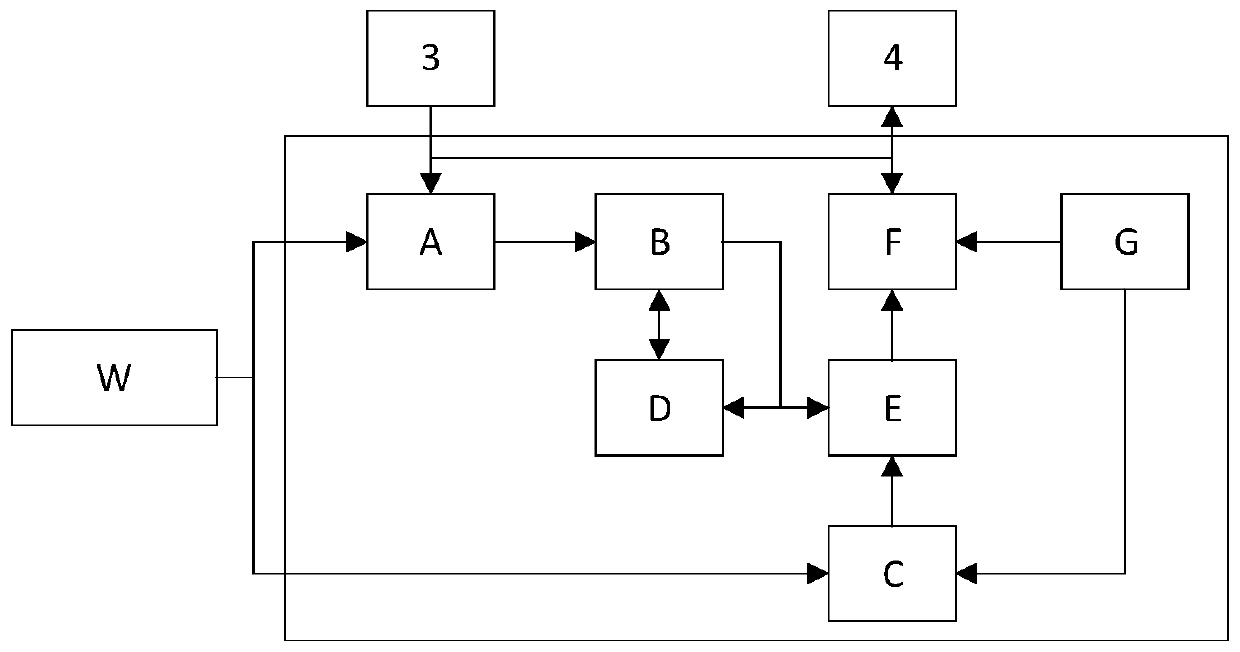

The invention discloses a system and a method for realizing an interactive service of mobile multimedia broadcast. The system comprises a content managing system, a data broadcast platform, an interactive service platform, a multiplexer, a mobile multimedia broadcast network and a mobile multimedia broadcast terminal. The method comprises the following steps: performing broadcast control management after transmitting interactive content with synchronizing information to the data broadcast platform by the content managing system; multiplexing audio, video and interactive data of which the service IDs are consistent to the same multiplexing subframe by the multiplexer; returning an interactive message input by a user at the broadcast terminal to the interactive service platform; sending an interactive response message back to a user terminal by the interactive service platform; and showing the interactive service in the modes of consulting and browsing, leaving words and commenting by the user, recommending programs, chatting online, voting to guess, downloading, paying, shopping and the like at the user terminal. The system and the method solve the problems that a front-end platform and a terminal user cannot interact with each other and that the program style is single; and the developed new broadcasting and receiving mode can be widely used for services of a mobile phone television, a PDA and the like.

Owner:CHINA BROADCAST CORP

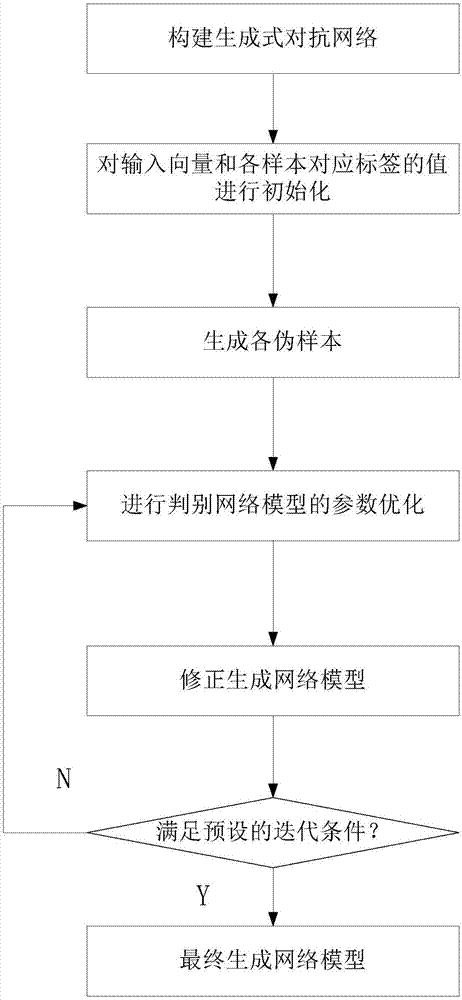

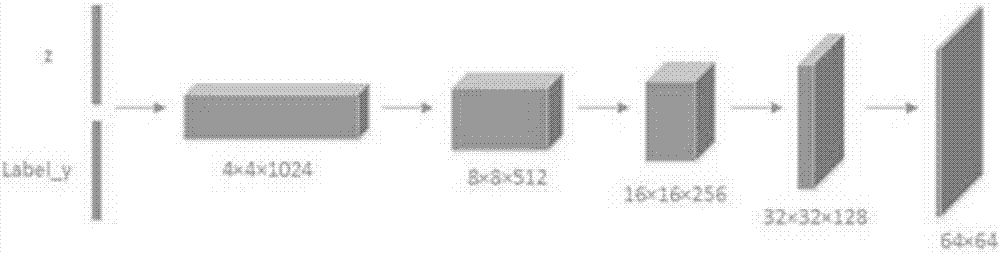

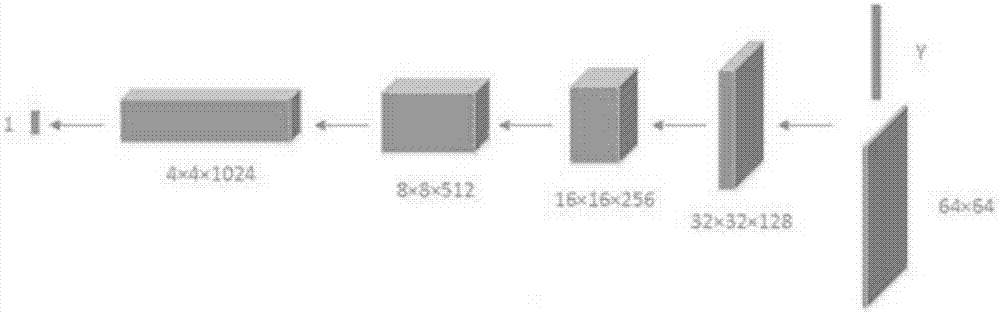

Pixel-level handwriting Chinese-character automatic-generation method, storage equipment and processing device

The invention relates to a pixel-level handwriting Chinese-character automatic-generation method, storage equipment and a processing device. The method includes: inputting a preset input vector and an input Chinese character label value to a final generative network model, which is optimized through iterative training, to obtain a handwriting Chinese-character image corresponding to the Chinese character label value. Generation of the final generative network model includes the steps of: acquiring each pseudo-sample on the basis of a pre-built generative adversarial network which includes a generative network model and a discriminative network model and initialization for input vectors and a value of a label corresponding to each sample; and iteratively carrying out parameter optimization of the discriminative network model and correction of the generative network model until iteration conditions are met, and then outputting the final generative network model. The method can directly generate a specified handwriting Chinese-character sample at a pixel level from a random vector, and has the advantages of no need for support of a component library, extensive acquisition and fully automatic generation, diversified styles and the like.

Owner:INST OF AUTOMATION CHINESE ACAD OF SCI

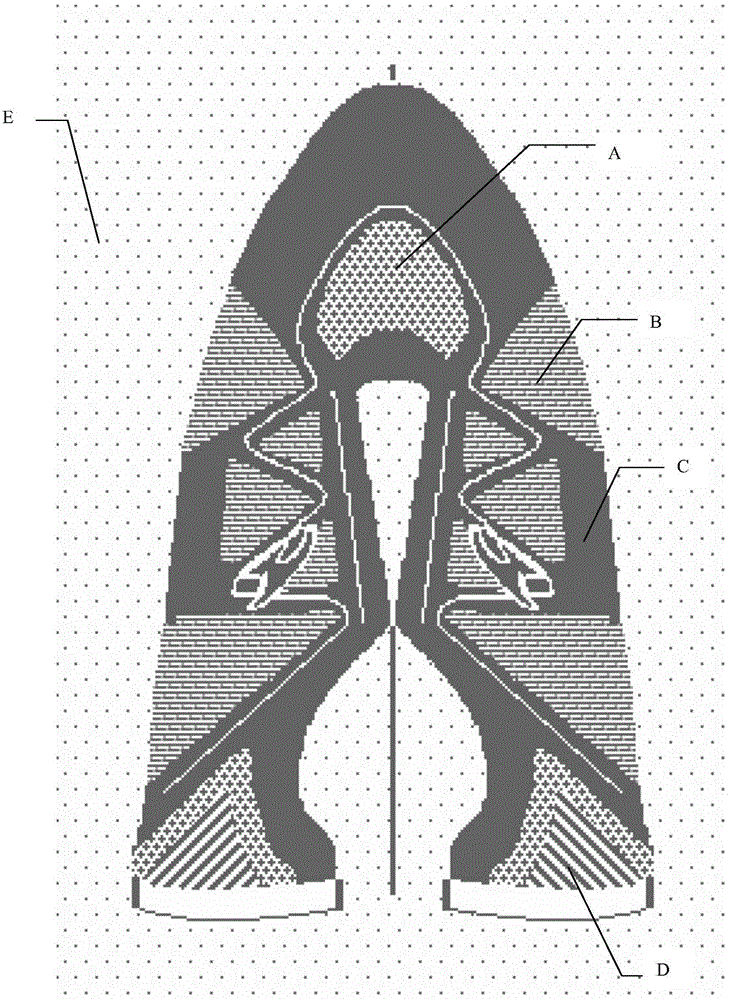

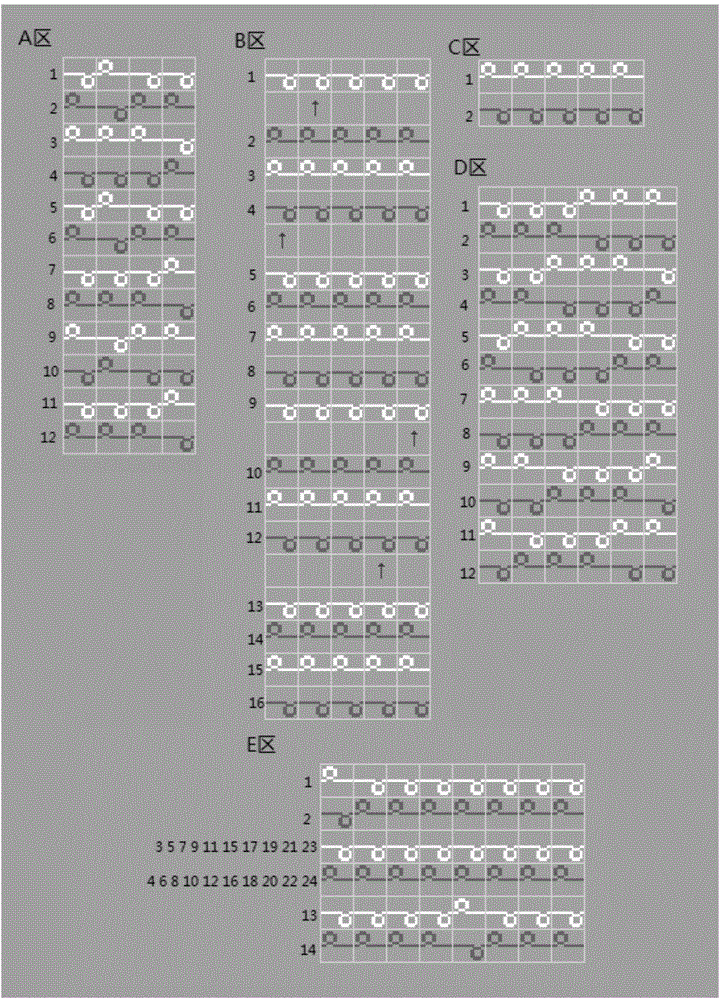

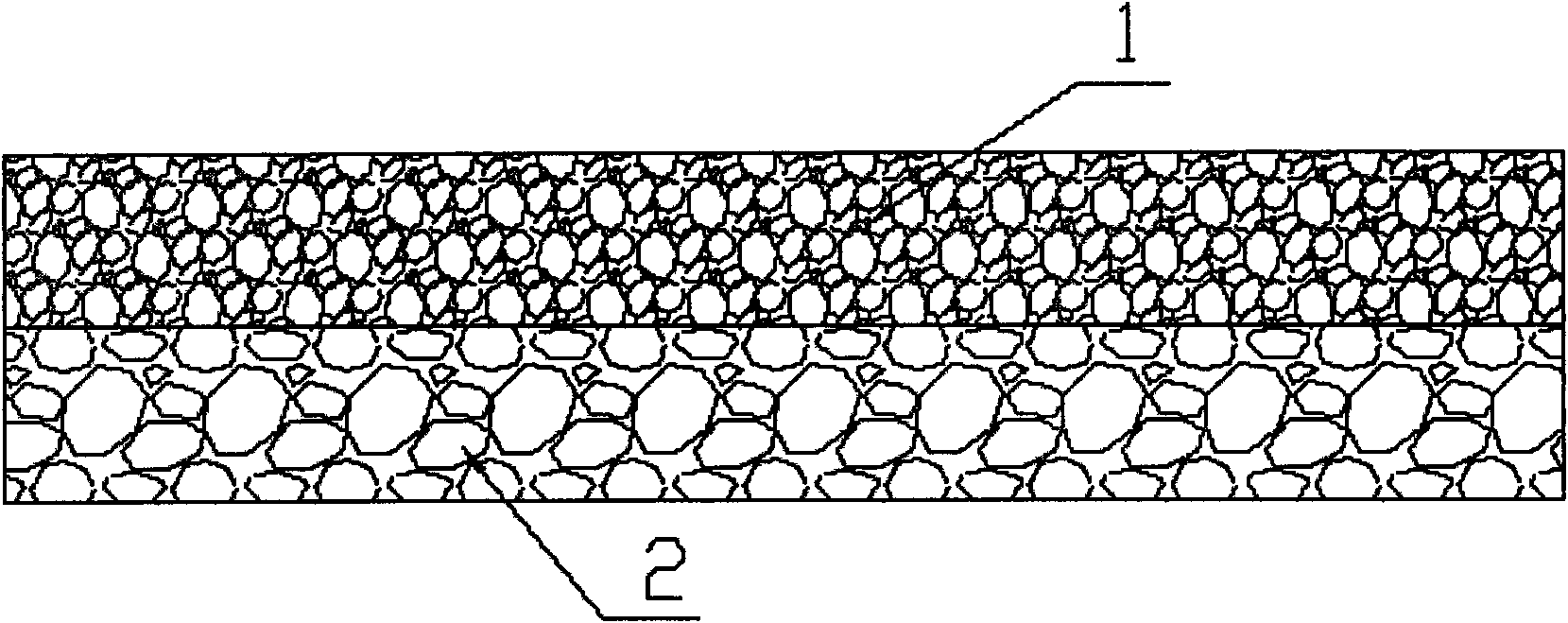

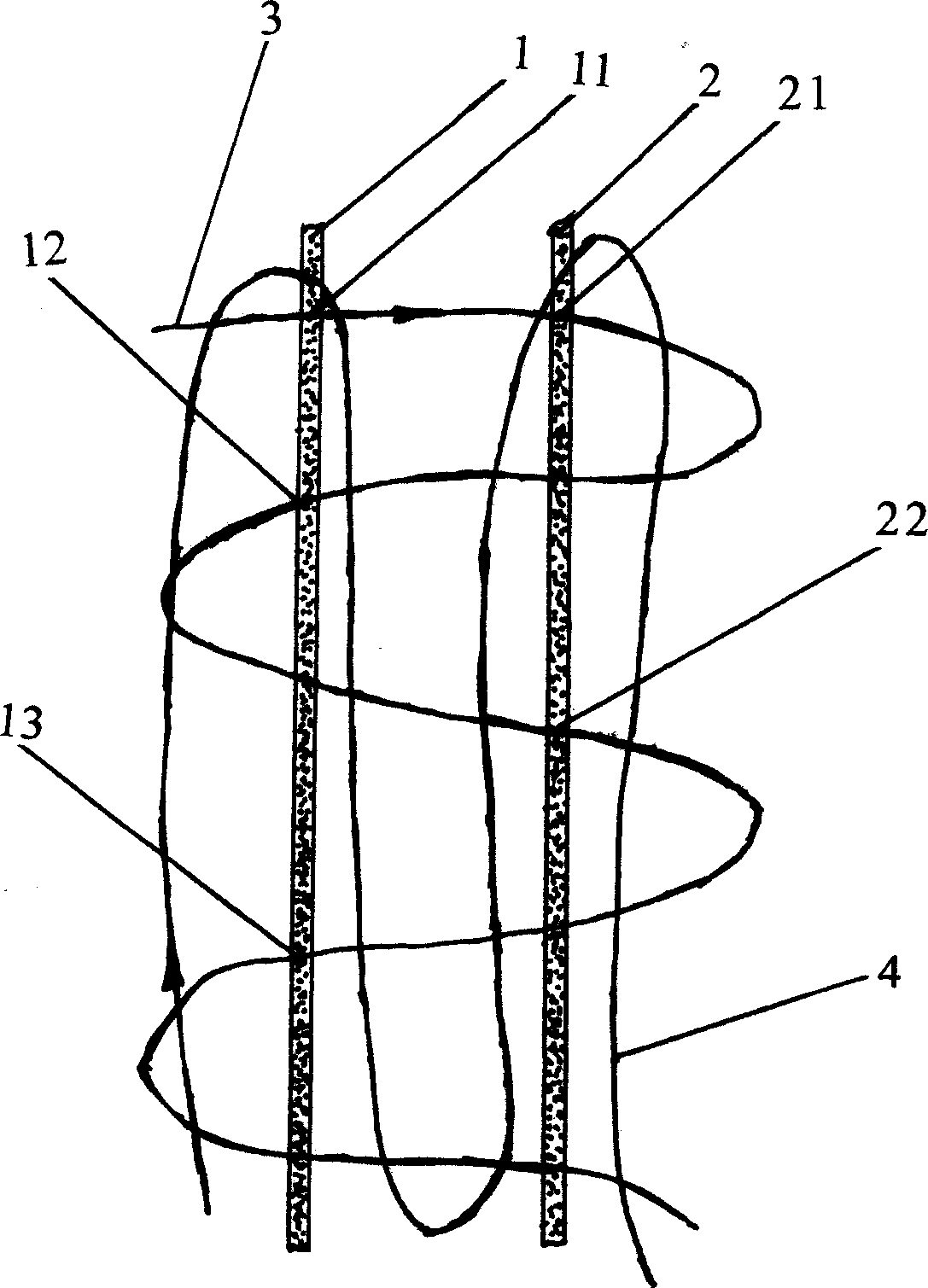

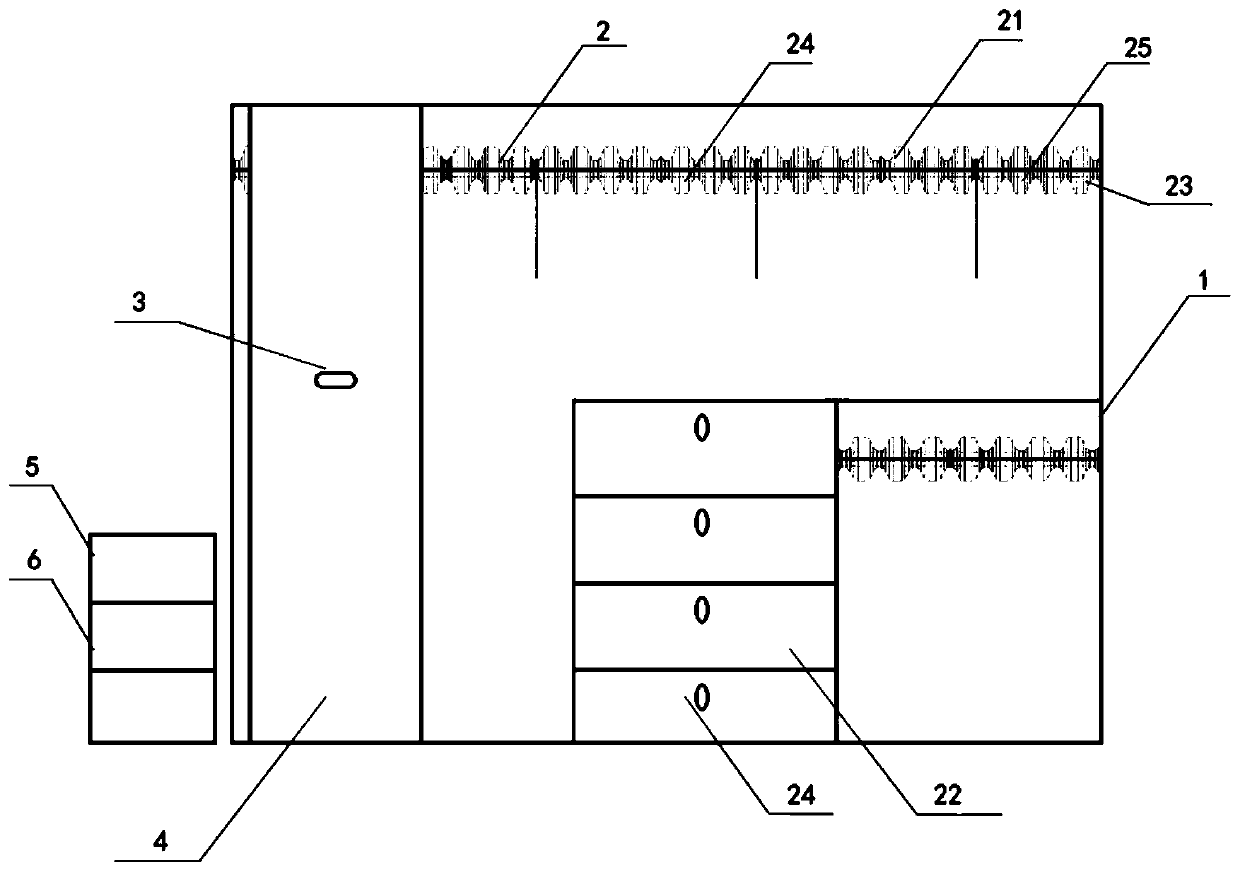

Structure and production method of weft-knitted jacquard shoe upper material

ActiveCN104562401AImprove breathabilityComfortable to wearWeft knittingHeating/cooling textile fabricsEngineeringAir layer

The invention belongs to the field of textiles and provides a structure and a production method of a weft-knitted jacquard shoe upper material. According to the weft-knitted jacquard shoe upper material, terylen low-melting-point color filaments with skin-core structures are adopted, the meshes, esthetic appearance and air permeability of the shoe upper material are realized by utilizing air-layer jacquard tissues as fundamental tissues, loop accumulation tissues or loop transfer tissues on a dual-way jacquard dual-side loop transfer round weft machine; by virtue of cooperation between colors and structural jacquards, functional sections of the shoe upper material are realized; during aftertreatment, a skin layer is fused at a certain temperature under a certain pressure, so that dual-side weft-knitted jacquard shoe upper fabric loops are mutually glued, then cooled and solidified, so that the shoe upper material with appropriate rigidity and hand feeling is obtained; spandex can also be added, so that the elasticity and the density of the fabric are enhanced. The weft-knitted jacquard shoe upper material is variable in pattern, color and style, beautiful in appearance, portable and flexible, favorable in air permeability and comfort in wear; traditional working procedures of cutting, sewing, bonding and the like for shoe materials are not needed, so that the equipment investment and the labor cost are lowered.

Owner:JIANGNAN UNIV

Method for making feather dress

InactiveCN1868354AUniform fleece thicknessVariety of stylesOvergarmentsWoven fabricsEngineeringMechanical engineering

A technology for manufacturing a down jacket includes such steps as preparing net body, carding down for loosening it, spreading the down on a bottom body, covering the down layer with a top net body, needling, sewing both sides, putting the needled layer between external and internal surface fabrics, sewing, cutting to obtain pieces, and sewing the pieces together to obtain a down jacket.

Owner:李可章

Manufacturing method of color concrete fancy permeable terrace

The invention discloses a manufacturing method of a color concrete fancy permeable terrace, and relates to a production method of a permeable terrace. The manufacturing method comprises the following manufacturing steps: (1) compacting ground plain earth; (2) mixing sand stone in a substrate; (3) jolting a ground foundation layer by a flat vibratory unit; (4) spreading a permeable material substrate; (5) compacting and flattening the permeable material substrate, which is spread smoothly; (6) spreading a permeable material surface layer; (7) laying a mold stripping material on the permeable material surface layer; (8) flattening the mold stripping material; (9) laying a fancy mould; (10) extruding the mould to form veins; (11) covering a film and curing; (12) cutting a telescopic seam on the permeable material surface layer; and (13) spraying a closing agent. The invention solves the problems of rigid modeling, rough surface structure, no flower type and pattern on the surface, and short service life of the conventional permeable terraces.

Owner:王建国

Artificial stone producing process

InactiveCN1931545AFlat surfaceRich textureMixing operation control apparatusCeramic shaping apparatusWear resistantArtificial stone

The present invention discloses the production process of artificial stone with resin and powdered material as main components and supplementary material including promoter, curing agent and color paste. The production process includes the following steps: compounding base material; compounding additive; mixing the base material and the additive and setting in molding bed; vacuum treating the molding bed in a vacuum case for 2-3 min and curing naturally before demolding to obtain slab blank; drying and further curing the slab blank; and flattening and polishing to obtain artificial stone product. The artificial stone product is smooth, wear resistant and rich in grains, and has other advantages.

Owner:苏州豪森新颖装饰材料有限公司

Interactive guiding and identifying intelligent wardrobe and using method

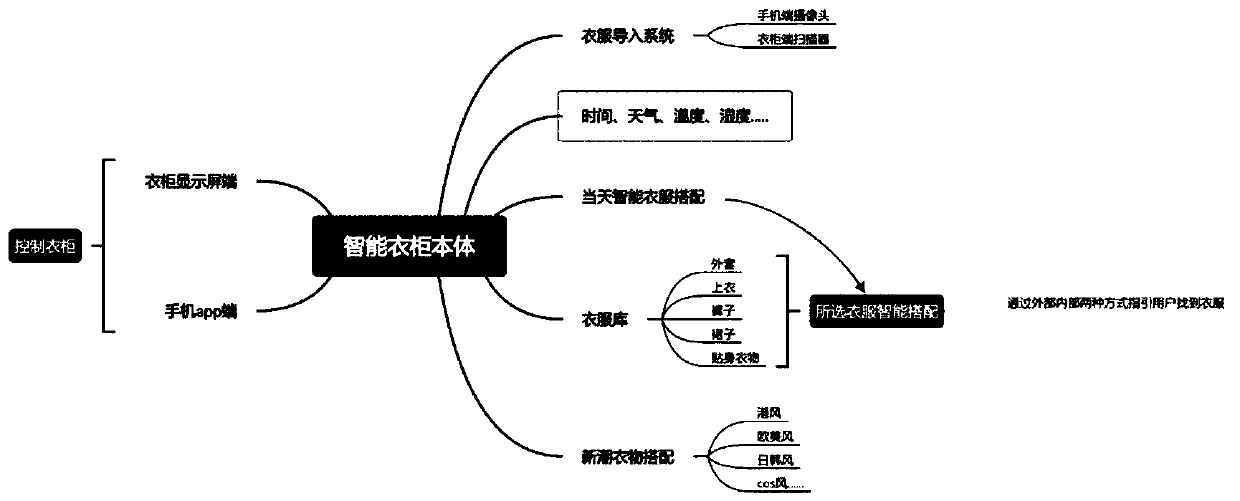

InactiveCN109998286ASolve the difficulty of choosingSolve the problem of finding clothesWardrobesDigital data information retrievalClothes hangerCollocation

The invention discloses an interactive guiding and identifying intelligent wardrobe and a using method. The intelligent wardrobe includes a hardware device and a software system. The hardware device includes an intelligent clothes hanger, a camera, a displayer, a computer and a storage device, wherein the intelligent clothes hanger is arranged in a wardrobe body and has an indicator light guidingand identifying function, and the camera, the displayer and the computer are arranged outside the wardrobe body; the software system is deployed in the computer and includes a clothing identificationmodule, a clothing management module, a reference information module, a guiding and identifying module, a clothing collocation module, a human-computer interaction module and a user management module.The interactive guiding and identifying intelligent wardrobe identifies and reads clothing information through an image identification system, achieves intelligent classification and intelligent collocation on clothes of a user, guides the user to find the location of the clothes as soon as possible through an indicator light guiding scheme, and solves the problem of difficulty of the user in finding the clothes.

Owner:HUBEI UNIV OF TECH

Method for producing liquid wood integral door

The invention discloses a method for producing a liquid wood integral door, which comprises the following steps of: 1) preparing liquid wood, namely (1) drying and grinding raw materials; (2) mixing the raw materials to obtain a mixture; and (3) generating the liquid wood, wherein the liquid wood comprises the following raw materials in part by weight: 100 parts of polyvinyl chloride, 40 parts of calcium carbonate, 60 parts of wood fiber powder, 4.5 parts of stabilizer, 8 parts of chlorinated polyethylene (CPE), 5 parts of acrylamide (ACR), 3 parts of H530, 0.5 part of polyethylene (PE) wax, 0.6 part of stearic acid, and 1 part of pigment; and 2) performing extrusion molding on the liquid wood at one time to obtain the integral door. In the method, the raw materials are molded at one time at a high temperature and under high pressure, do not contain formaldehyde, and are subjected to surface treatment by adopting thermal transfer technology; the integral door is free of paint, has no any toxic harmful gas and smell release in the production and use process, is environmental-friendly and has practicality.

Owner:杨华

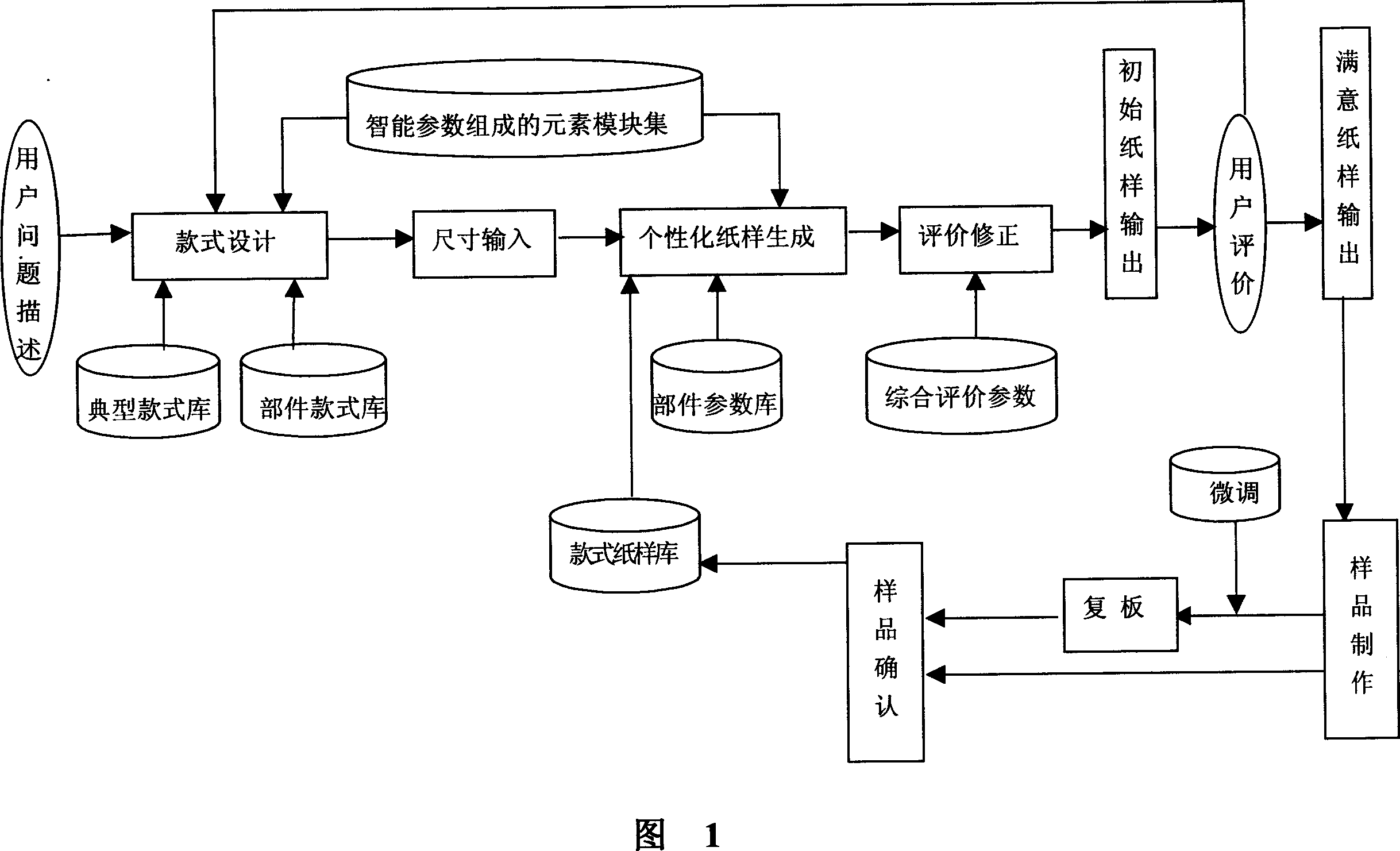

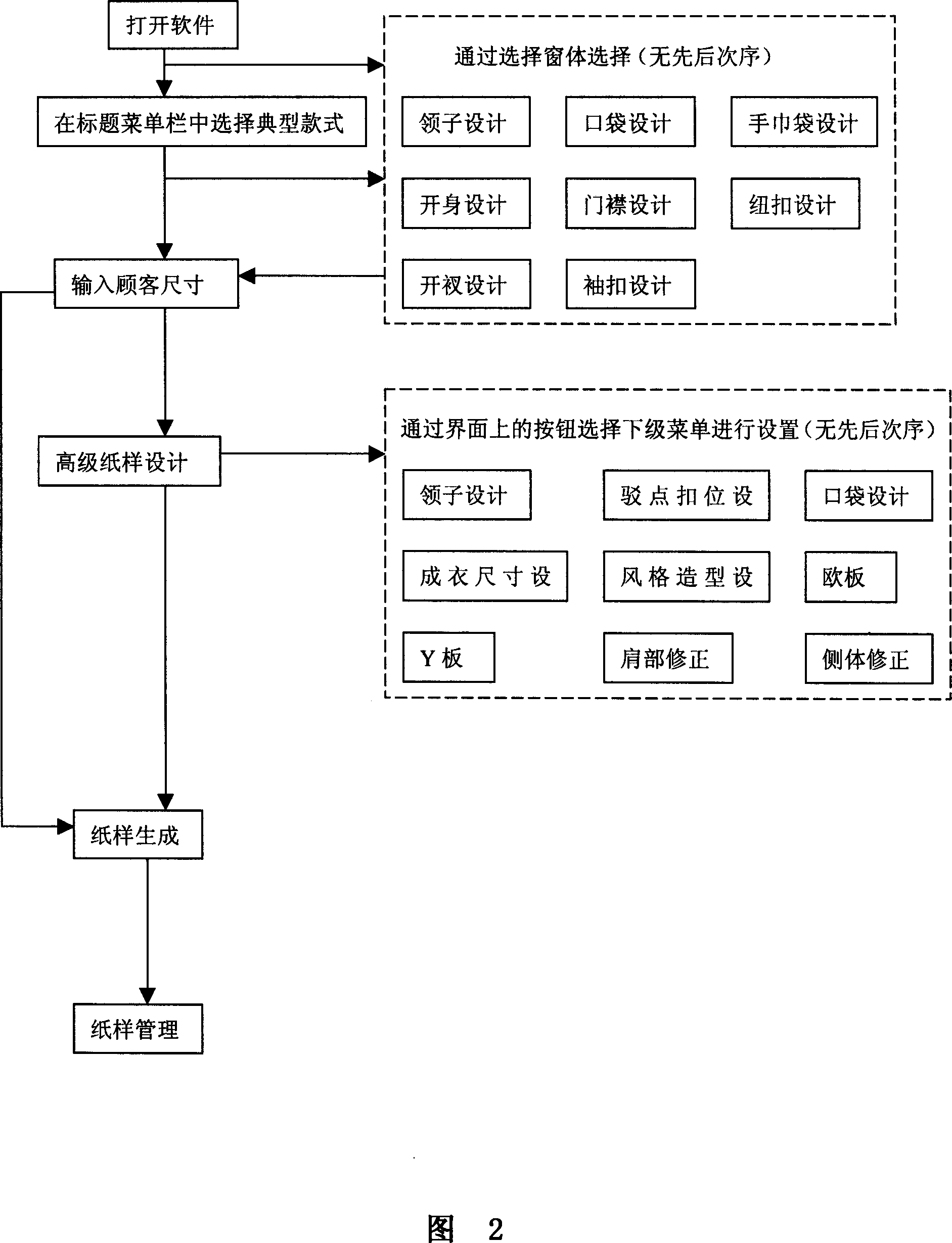

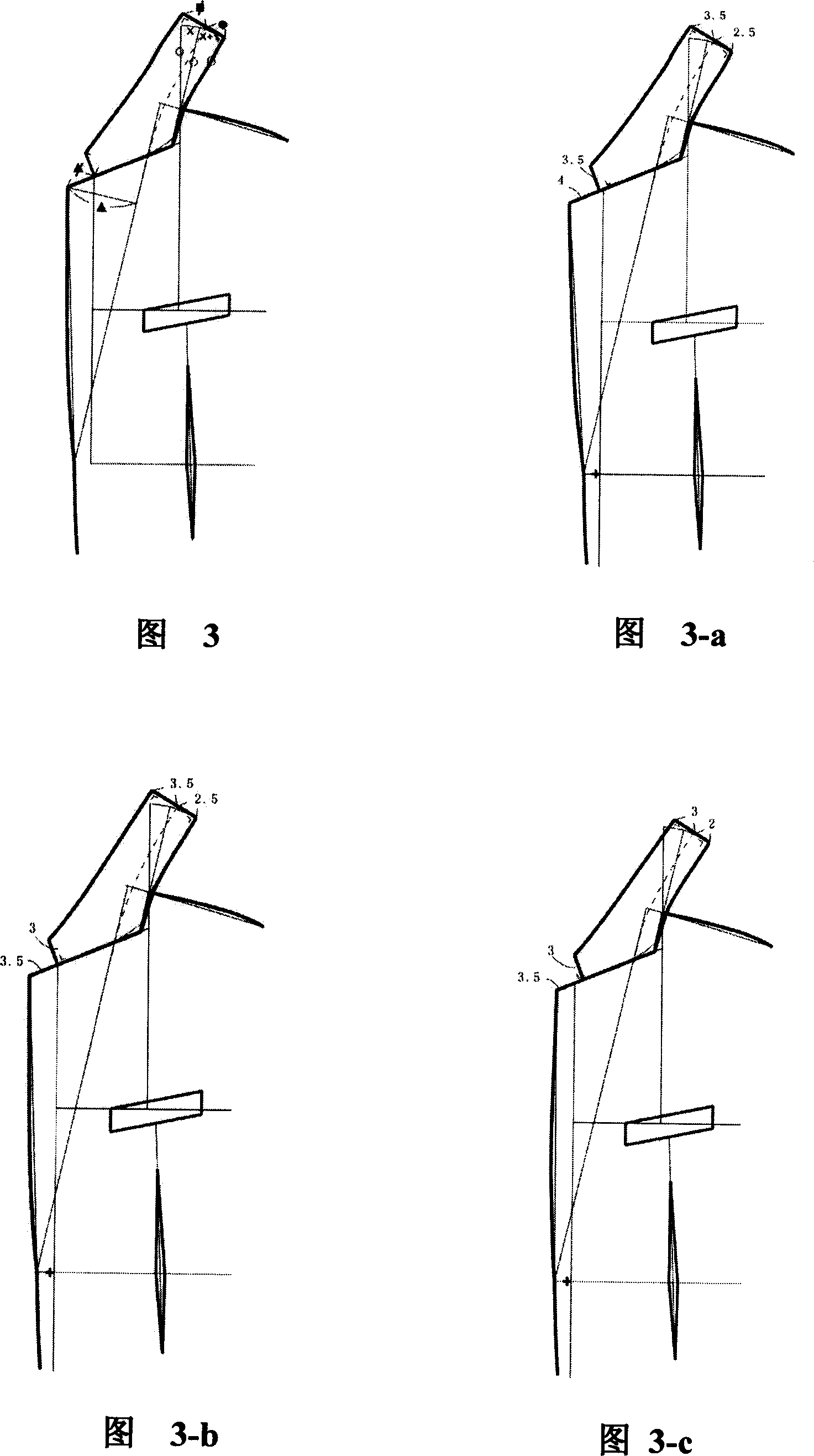

Business suit sample sheet automatic generation system and method

InactiveCN1994173AEver-changing stylesFully automatedSimulator controlClothes making applicancesPersonalizationComputer module

The invention relates to a business suit outture sheet automatic generator and relative method, wherein it comprises format unit formed by typical format unit and format parameter database unit; intelligent parameter unit formed by outture sheet automatic parameter database and advanced outture sheet designer, for generating personal outture sheet via the user description and input size informant to improve the automatic outture sheet parameter database; information processor for generating one outture sheet via parameter reference unit and intelligent unit, to print and store. And the method comprises that: building typical format unit and element format parameter database unit to build menu and intelligent parameter unit, to use knowledge to find the logical algorism of change element in the typical format, to generate curvatures of each part; selecting format, then entering into designing interface, inputting size to generate initial outtuer sheet; user provides correction, to generate sample clothes; then correcting.

Owner:BEIJING INSTITUTE OF CLOTHING TECHNOLOGY

Fabricating process for ecorative door of solid-wood sculpture

InactiveCN101200084AVariety of stylesStrong three-dimensional senseWood working apparatusSolid woodConvex side

The invention relates to a making technology of a solid wood carved decorative door. First, wood is chosen to make a doorframe and a door panels, and then grooves matched with four convex sides of the door panel are made in inner sides of the doorframe, at last the door panel is inset into the doorframe. The decorative door is finished through being fixed by a door corner, and ground, polished and paint dried. The treated solid wood which is carved with various patterns is used as the door panel, which not only can be made into a solid wood door with single-side carving, but also can be made into a light penetrating door in hollow out carving for setting off the pattern. The decorative door has the advantages of multiple styles, strong stereoscopic sense, no cracking, no deformation, waterproofing and anti corrosion, and can be used in hotels, restaurants, business buildings and office buildings with solemn, elegant and beautiful decorating effect.

Owner:崔曙光

Processing method of seamless garment with stereoscopic patterns and applying liquid binder

InactiveCN103315432AFlexible transformationFully express the true color texturePattern makingClothes making applicancesSand blastingLaser cutting

The invention provides a processing method of a seamless garment with stereoscopic patterns and applying liquid binder. The method includes the following steps: (1) providing decorative material a and material b and drawing digital patterns through a laser cutting machine respectively, (2) pleating the decorative material a, (3) smearing the edges of the decorative material a with the butadiene styrene rubber liquid binder and then butt-connecting the decorative material a and the cut material b in an overlapping mode to form a nailing-free and sewing-free portion, (4) heating and pressing the nailing-free and sewing-free portion through a butt fusion die and enabling the butadiene styrene rubber liquid binder at the nailing-free and sewing-free portion to melt and cool for shaping, and (5) performing sand blasting on garment fabric obtained in the step (4). The processing method of the seamless garment with the stereoscopic patterns and applying the liquid binder has the advantages that the garment processed with the method is good in waterproofness, heat preservation performance and air permeability, the integrated bonding processing method saves extra additions for nailing, sewing and the like, reduces the weight and the size of the garment, and is attractive in appearance and multiple in styles due to the fact that the stereoscopic patterns and the sand blasting are adopted.

Owner:天津市宝坻区吉龙服装服饰有限公司

Method for making surface layer of polyvinyl chloride decorative sheet product

InactiveCN102101100AGood physical propertiesImprove deformationPretreated surfacesPolyurea/polyurethane coatingsSurface layerPolyvinyl chloride

The invention relates to a method for making a surface layer of a polyvinyl chloride decorative sheet product. The method aims to solve the technical problems of poor scratch resistance, poor abrasion resistance and poor surface texture of the surface of the conventional polyvinyl chloride (PVC) decorative sheet product. The method for making the surface layer of the polyvinyl chloride decorative sheet product comprises the following steps of: 1) preparing polyurethane double-component synthetic coating into special base paint and special finishing paint in a certain weight ratio; 2) cleaning the surface of the PVC decorative sheet product; 3) spraying the cleaned surface by adopting a spray gun, drying the surface and then conveying the product to a polishing area, and performing surface flattening, sanding and rust removal treatment by adopting dry abrasive paper; and 4) spraying the base paint for the second time by the operating method, conveying the product to the polishing area, performing surface polishing and rust removal treatment by adopting the dry abrasive paper, conveying the product to a paint spraying room, spraying the PVC decorative sheet product by using a spray gun, drying the product and then transferring the product to an airing room, and naturally drying the product to form the surface layer. The method has the advantages of high production efficiency, good surface quality and the like.

Owner:李永霞

Fiberizing, retexturing and recycling technology of fabric rags

InactiveCN101906691AAvoid secondary pollutionReduce usageWeft knittingWarp knittingYarnDying processes

The invention discloses a fiberizing, retexturing and recycling technology of fabric rags, in particular to a fiberizing, retexturing and recycling technology of denim fabric rags. In a treating and recycling process flow, color cotton fiber is directly produced without a bleaching process and spun after compounding cotton and mixing colors to produce dyed yarn in the same confirm color. The dyed yarn is made into chaine and is directly overdyed in a dying process to save a bottom color dying process, reduce the dye consumption, shorten production flows, save water and electricity costs, and take the favorable effects of saving energy and reducing consumption. Meanwhile, the invention can be used for producing overdyed denim fabrics of various color styles.

Owner:开平富琳纺织制衣有限公司

Stereoscopic colorful auto-bonded macromolecular waterproof roll

ActiveCN104369512AGood toughness strengthHigh tensile strengthSynthetic resin layered productsConstructions elementsElastomerPolymer science

The invention relates to a stereoscopic colorful auto-bonded macromolecular waterproof roll. The stereoscopic colorful auto-bonded macromolecular waterproof roll sequentially comprises a membrane layer, a first auto-bonded layer, a core layer, a second auto-bonded layer and a colorful mineral grain layer. The core layer is prepared by 100 parts of polyvinyl chloride resin, 15-25 parts of polyethylene terephthalate-1, 4-cyclohexane dimethanol ester, 10-20 parts of organic fibers and 3-5 parts of ABS high-adhesive powder by weight. Each auto-bonded layer is prepared by 100 parts of modified asphalt, 30-40 parts of naphthenic oil, 10-20 parts of butadiene styrene rubber, 25-35 parts of styrene thermoplastic elastomers, 20-30 parts of talcum powder, 1-2 parts of antioxidant and 3-5 parts of ultraviolet light absorber by weight.

Owner:LIAONING DAYU WATERPROOF TECH DEV

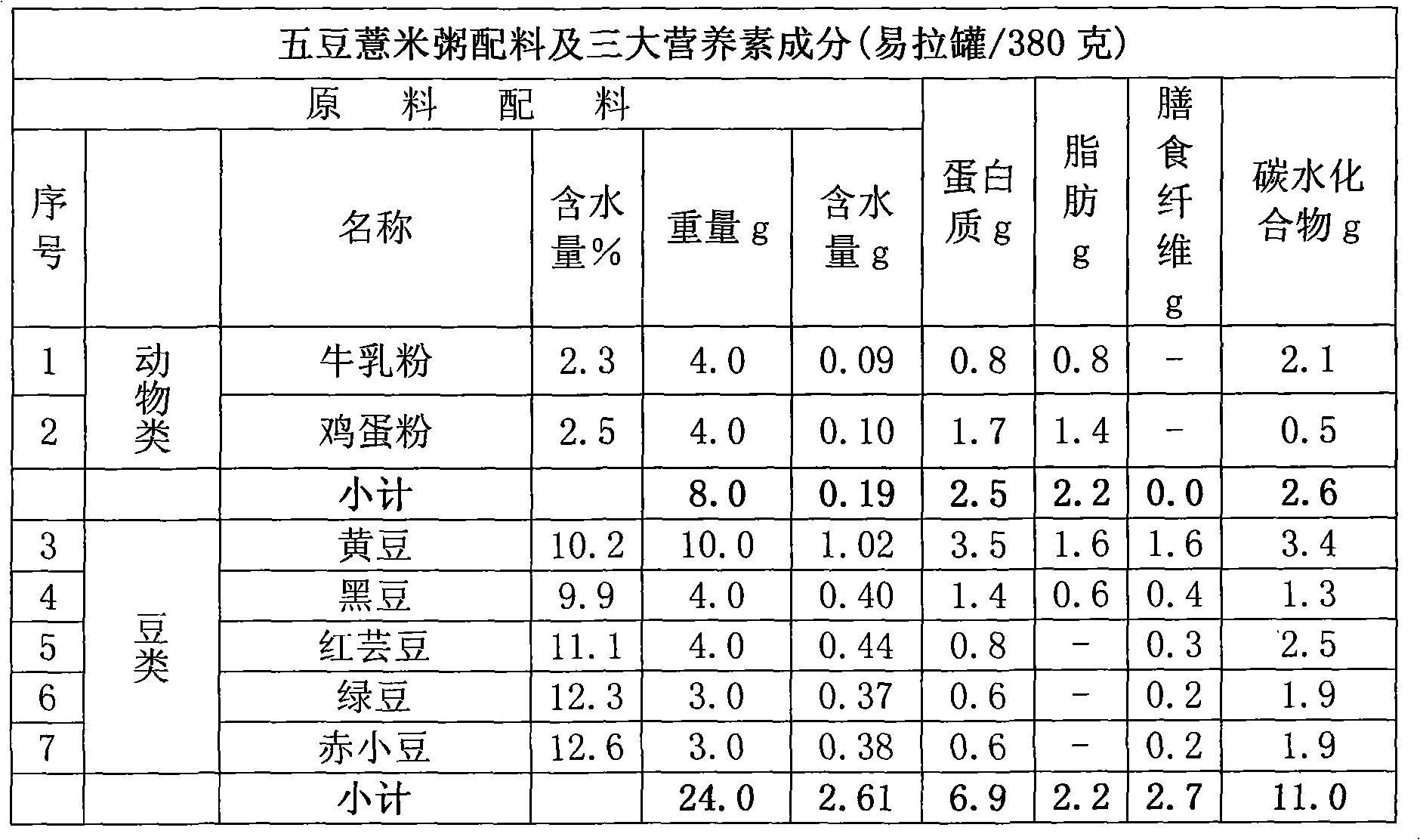

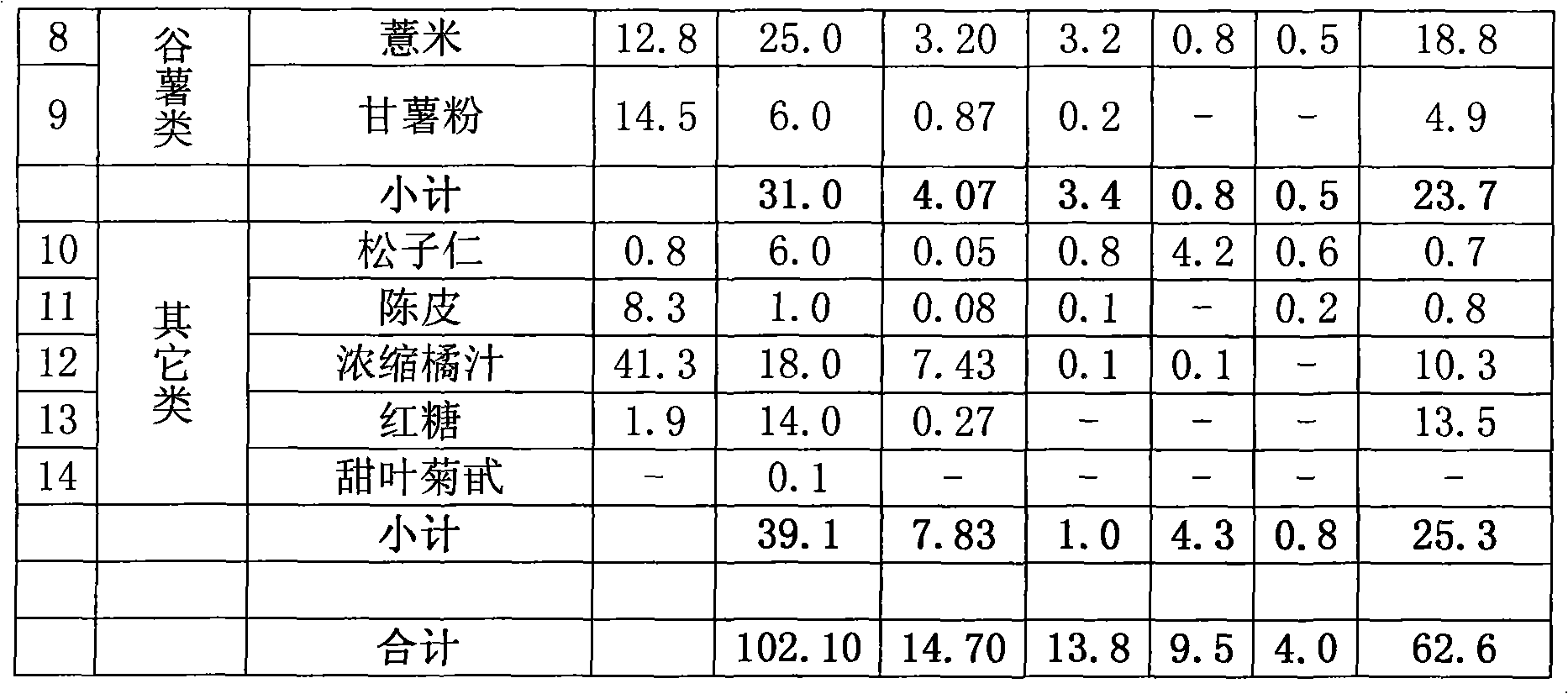

Breakfast product with reasonable food structure and energy constitution

InactiveCN101558881AVariety of stylesMeet the requirements of reasonable food structureFood preparationPearl barleyOrange juice

The invention discloses a breakfast product with reasonable food structure and energy constitution, mainly including the following components: milk powder, egg powder, soybean, black bean, red kidney bean, mung bean, adsuki bean, pearl barley, sweet potato powder, pinenut kernel, dried orange peel, concentrated orange juice with solid content of 59 percent, brown sugar and stevioside. After the technical scheme is adopted, the breakfast which is prepared from the main ingredients of coarse grains, beans, milk and eggs not only has a great variety of models, but also meets the requirement on agreeable meal energy constitution recommended by the World Health Organization (WHO) and the requirement on reasonable food structure presented by the Dietary Guidelines for Chinese Residents (2007).

Owner:冯乐东

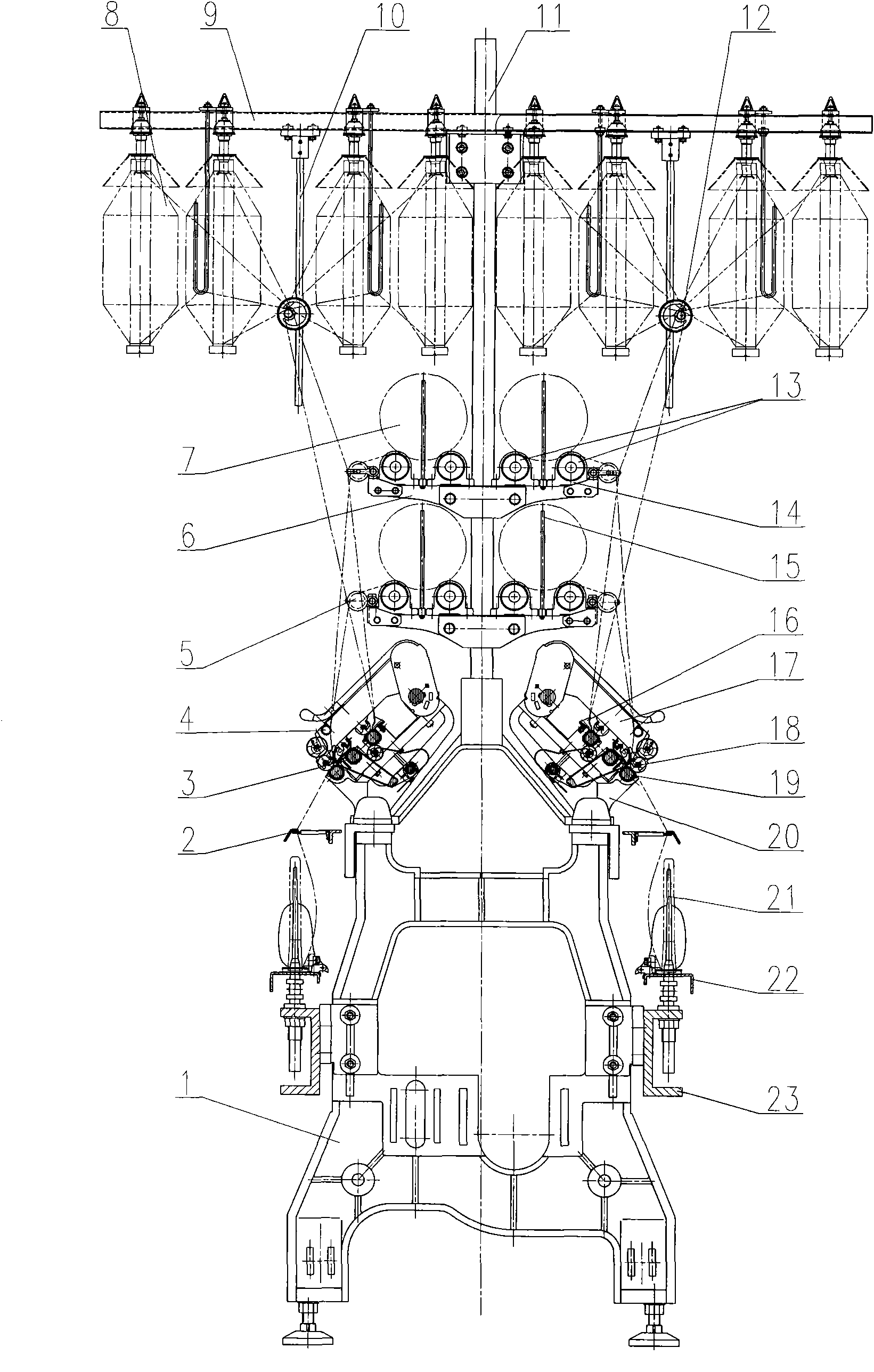

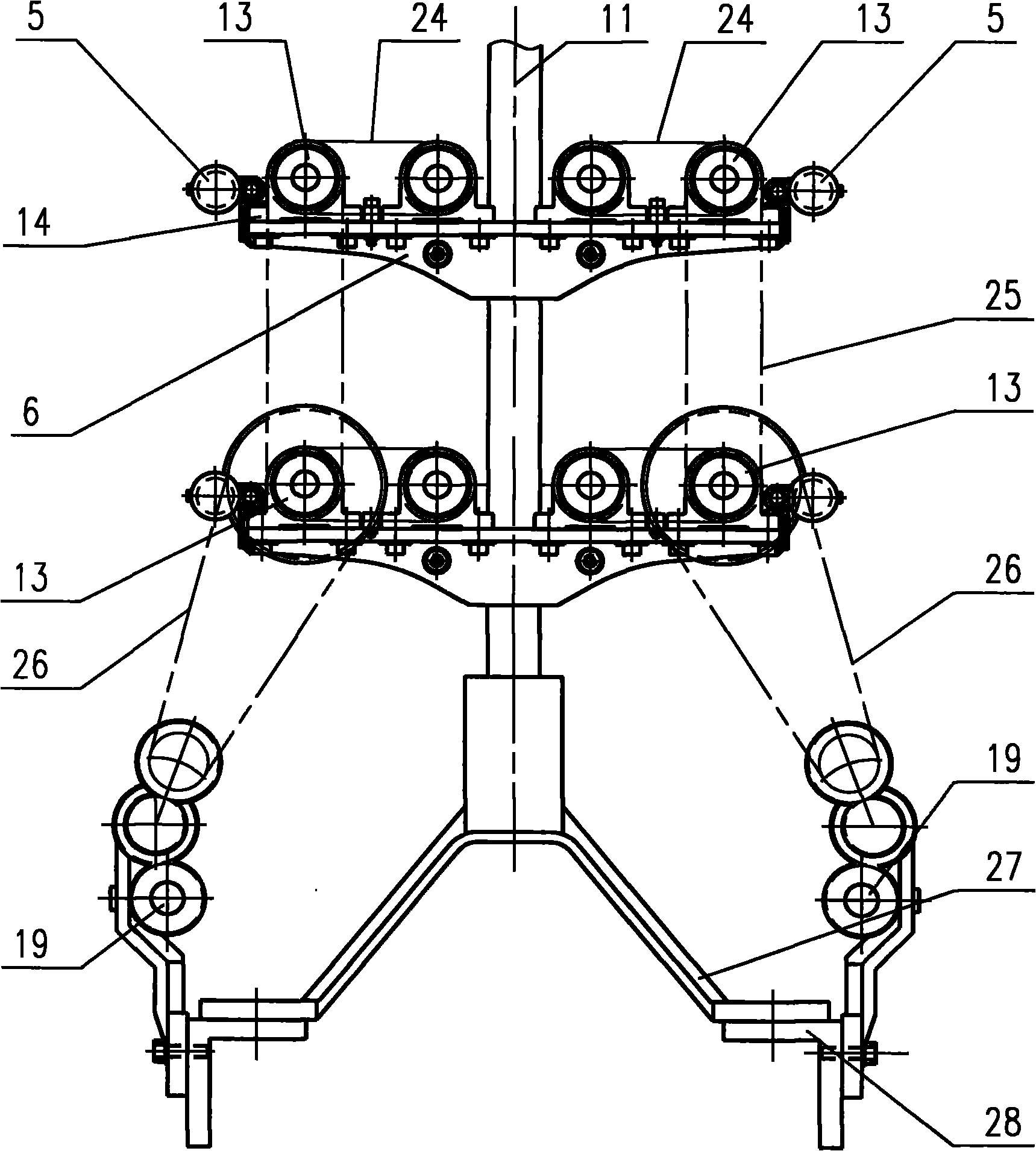

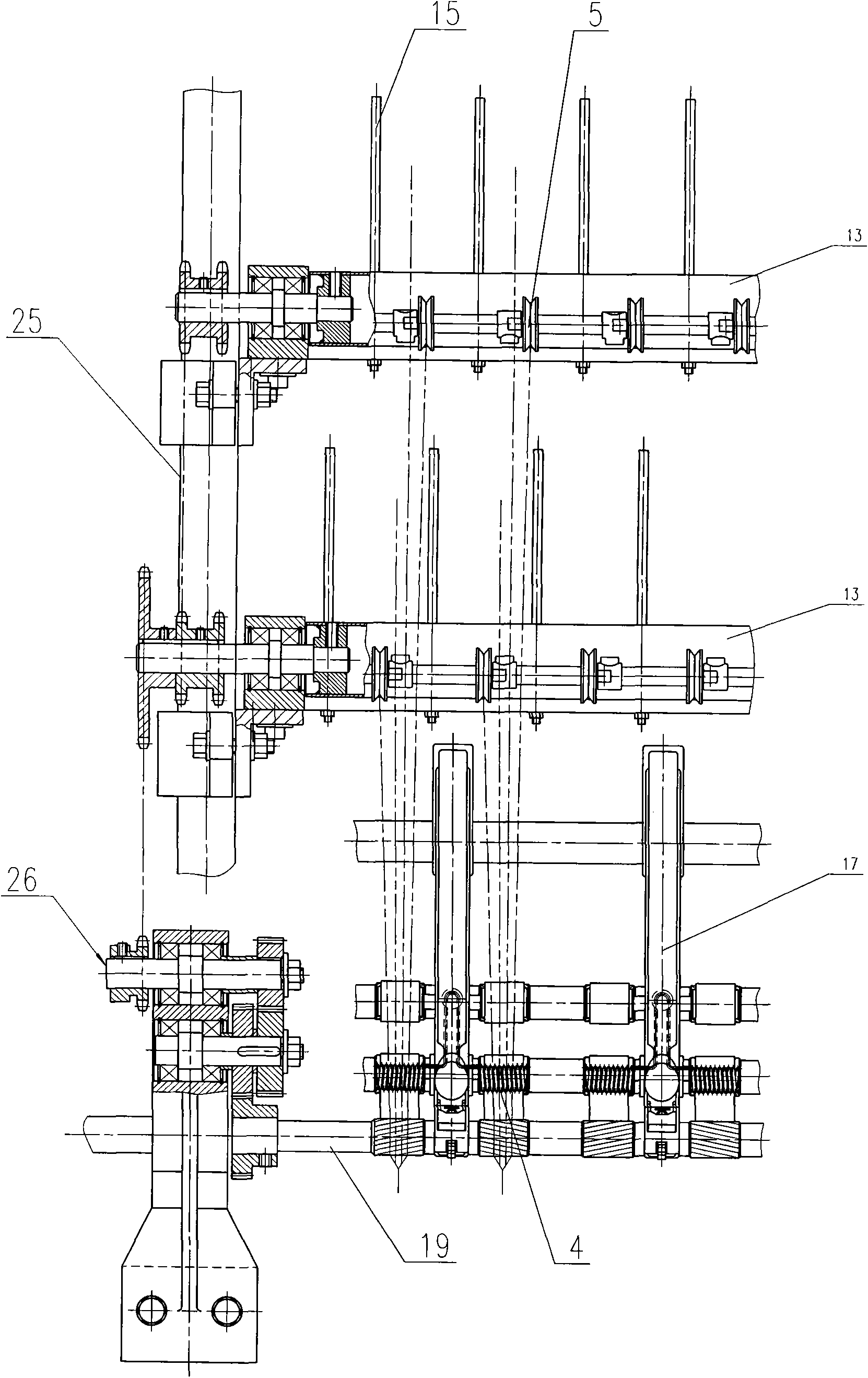

Embedded compound spinning frame and spinning method thereof

InactiveCN101956255AReduce force requirementsGood evenness indexContinuous wound-up machinesFiberYarn

The invention discloses an embedded compound spinning frame. Two layers of unwinding brackets and four parallel unwinding rollers are arranged on an upright post of a creel; the unwinding rollers positioned on the same side of the unwinding brackets mutually drive and are connected by a vertical driving pair of the unwinding rollers; and at least one unwinding roller in the unwinding rollers on the same side of the unwinding brackets is in driving connection with a front roller of a drawing mechanism through an unwinding roller driving device. When in spinning, two rovings hung on the creel respectively enter a drawing area of the drawing mechanism in parallel through roving horn mouths for drawing; two unwound filaments roll from different unwinding rollers and respectively enter the rear side of a tong port of the front roller of the drawing mechanism through a filament guider; and the two filaments and two drawn rovings are combined on the rear side of the tong port of the same front roller, output and twisted from the front side of the tong port of the front roller and wound on a spinning tube of a spindle. The invention not only can conveniently spin short fibers and other low-grade raw materials, but also has the advantages of abundant yarn type structures, dry resultant slivers and superior filoplume indexes.

Owner:DONGFEI MAZUOLI TEXTILE MACHINERY +1

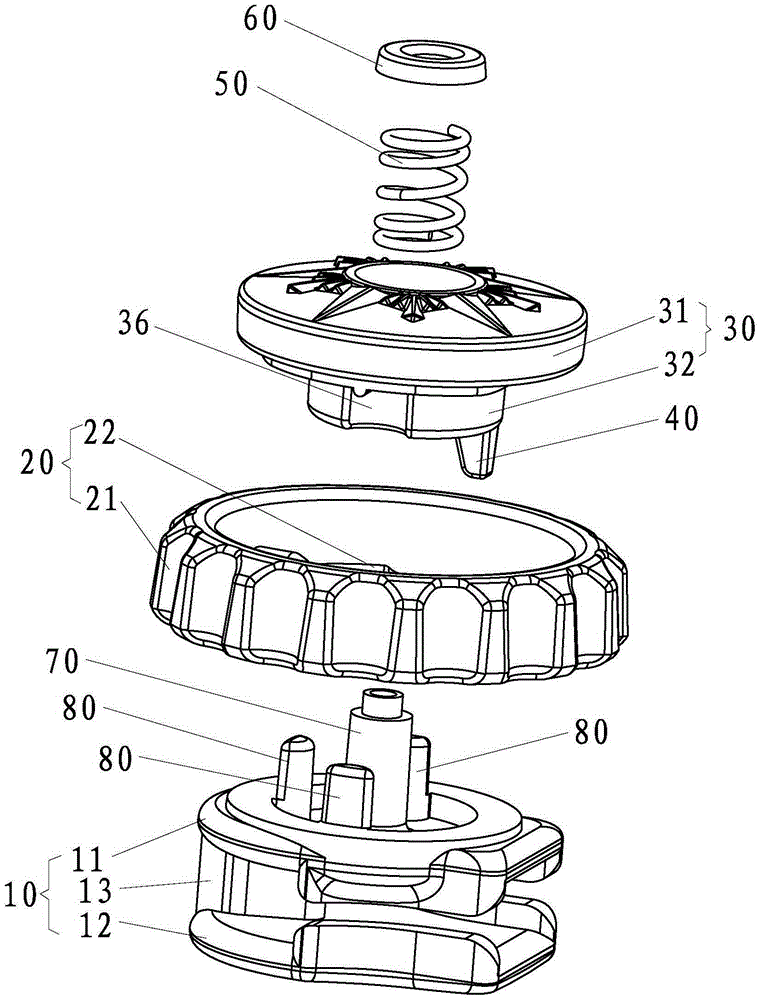

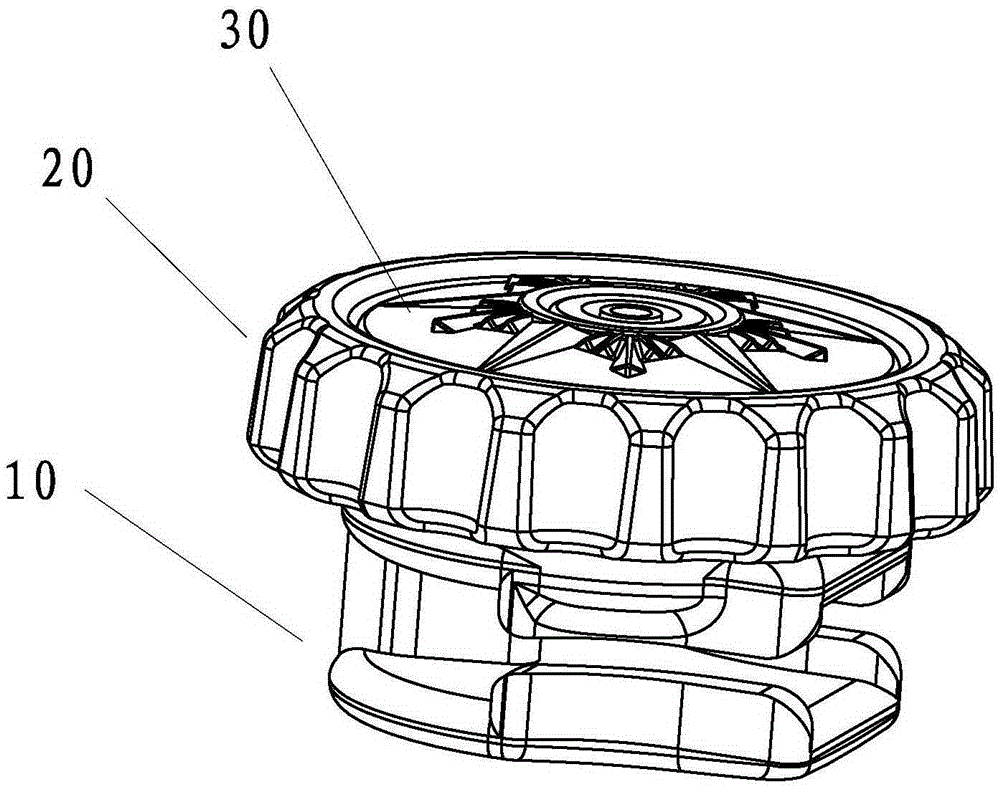

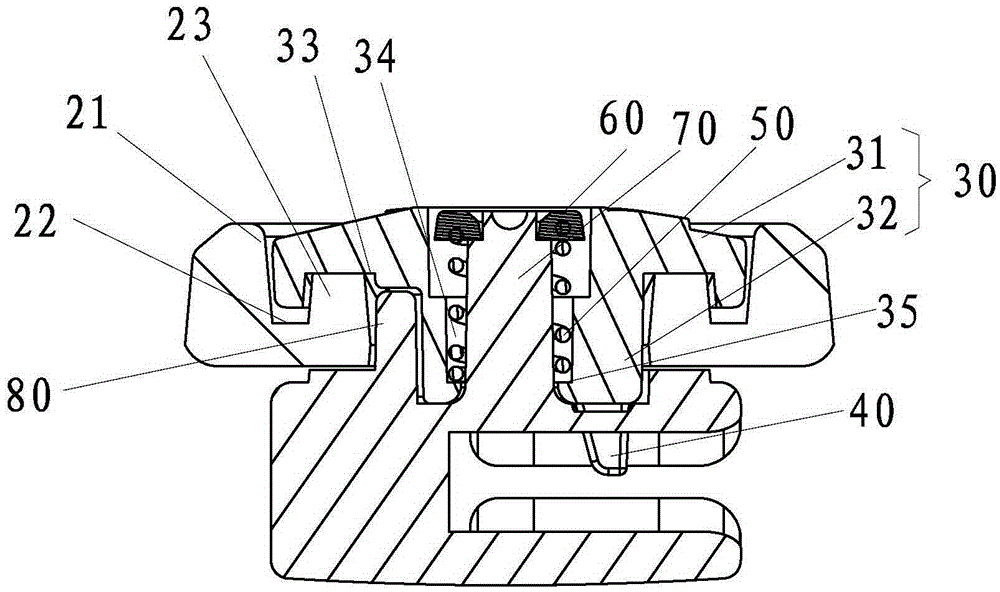

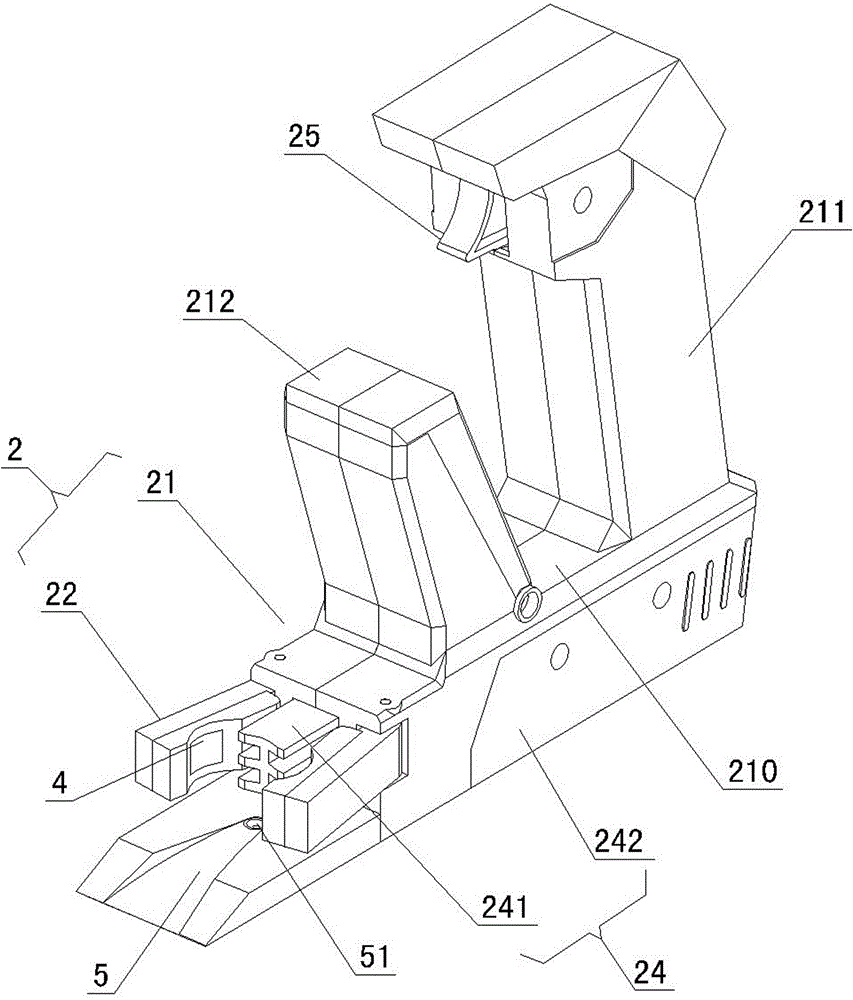

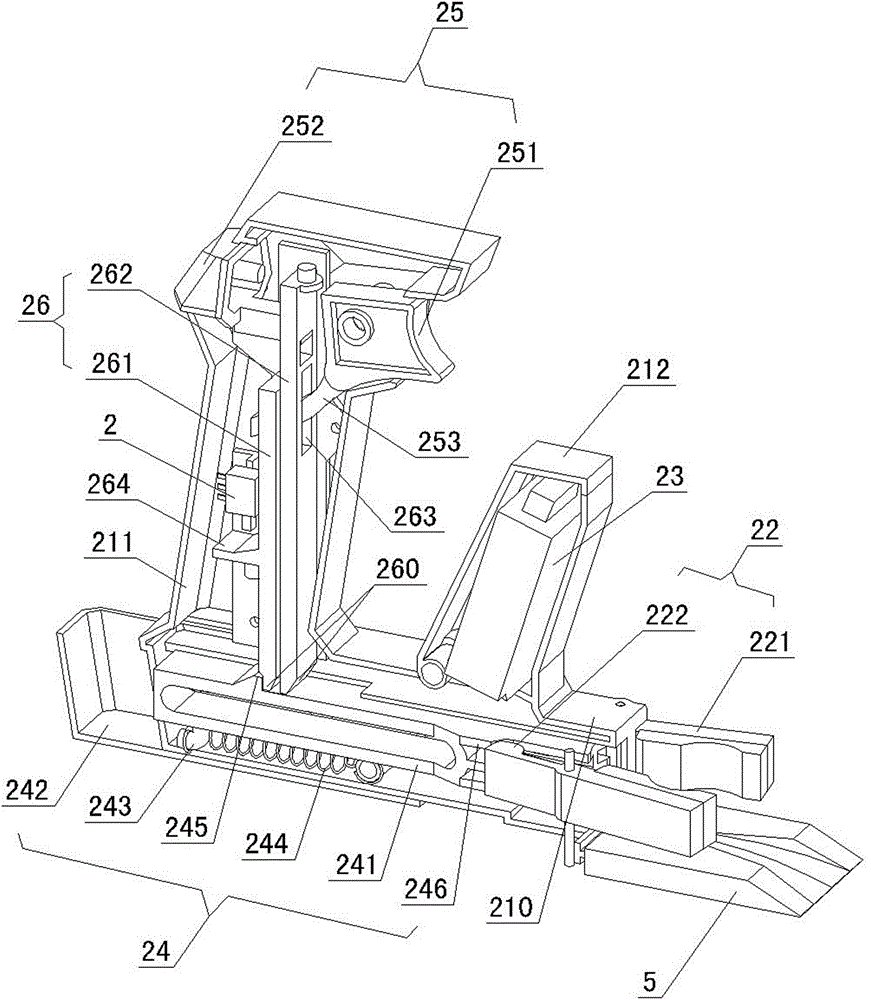

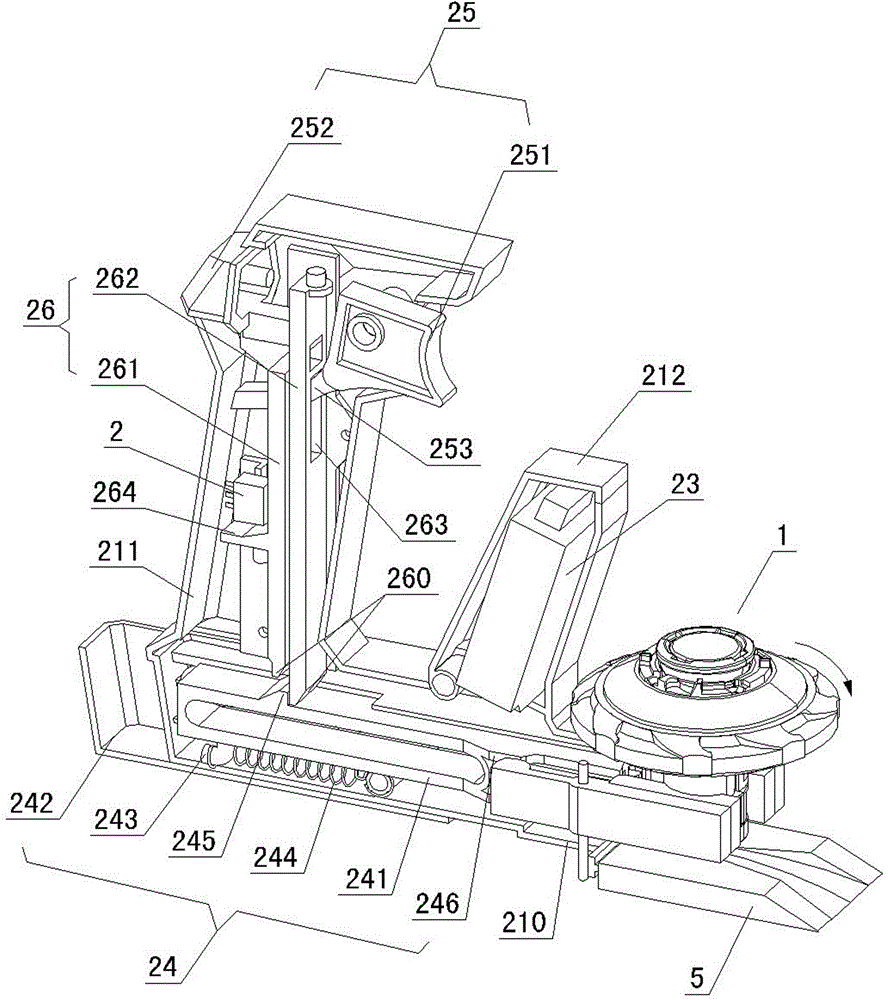

Rotary knob type needle locking head

The invention relates to a rotary knob type needle locking head which comprises a pull head body, a moving part, a spring and a rotating part. The pull head body comprises an upper wing plate, a lower wing plate and a connecting column, wherein a guide column is arranged on the upper wing plate. The rotary knob type needle locking head further comprises the moving part capable of moving in the axial direction of the guide column, wherein a locking needle is arranged on the moving part, the guide column is sleeved with the moving part, the moving part is sleeved with the rotating part, a limiting portion is arranged on the guide column, and an elastic part is arranged between the limiting portion and the moving part. The rotary knob type needle locking head further comprises a control mechanism for driving the moving part to lift and move, wherein the control mechanism is composed of sunken portions and protruding portions which are matched mutually. Therefore, unlocking of a zipper can be achieved only through small-angle rotation, and operation is very quick and convenient. After the protruding portions break away from the sunken portions, the locking needle is always located at the position breaking away from the zipper, and smooth and stable sliding of a pull head on the zipper can be ensured. When the pull head slides to a predetermined position, the rotating part is turned again to enable the protruding portions to fall into the sunken portions, the moving part returns under the effect of the elastic part, and the locking needle achieves zipper braking.

Owner:晋江市金圣拉链科技有限公司

T-type multifunctional small block and its production forming method

InactiveCN1341798AReduce dosageIncrease productivityConstruction materialCeramic shaping apparatusMultiple formsAdditional values

The present invention relates to a T-type multifunctional small block and its production forming method. Said invention adopts T-shaped block type series and composite forming process to solve the problem of combination of several layer materials in the production of concrete small blocks, and greatly raise technical content and additional value of product, implement high prefabrication extent ofsmall blocks, improved reinforcement scheme of block and block bonding body, and can more flexibly and reaonsably arranged steel bar, can conveniently make construction and can flexibly form various structures with different forms, and can obviously raise strength of block hollow bonding body so as to raise quality and efficiency of building construction.

Owner:虞新华

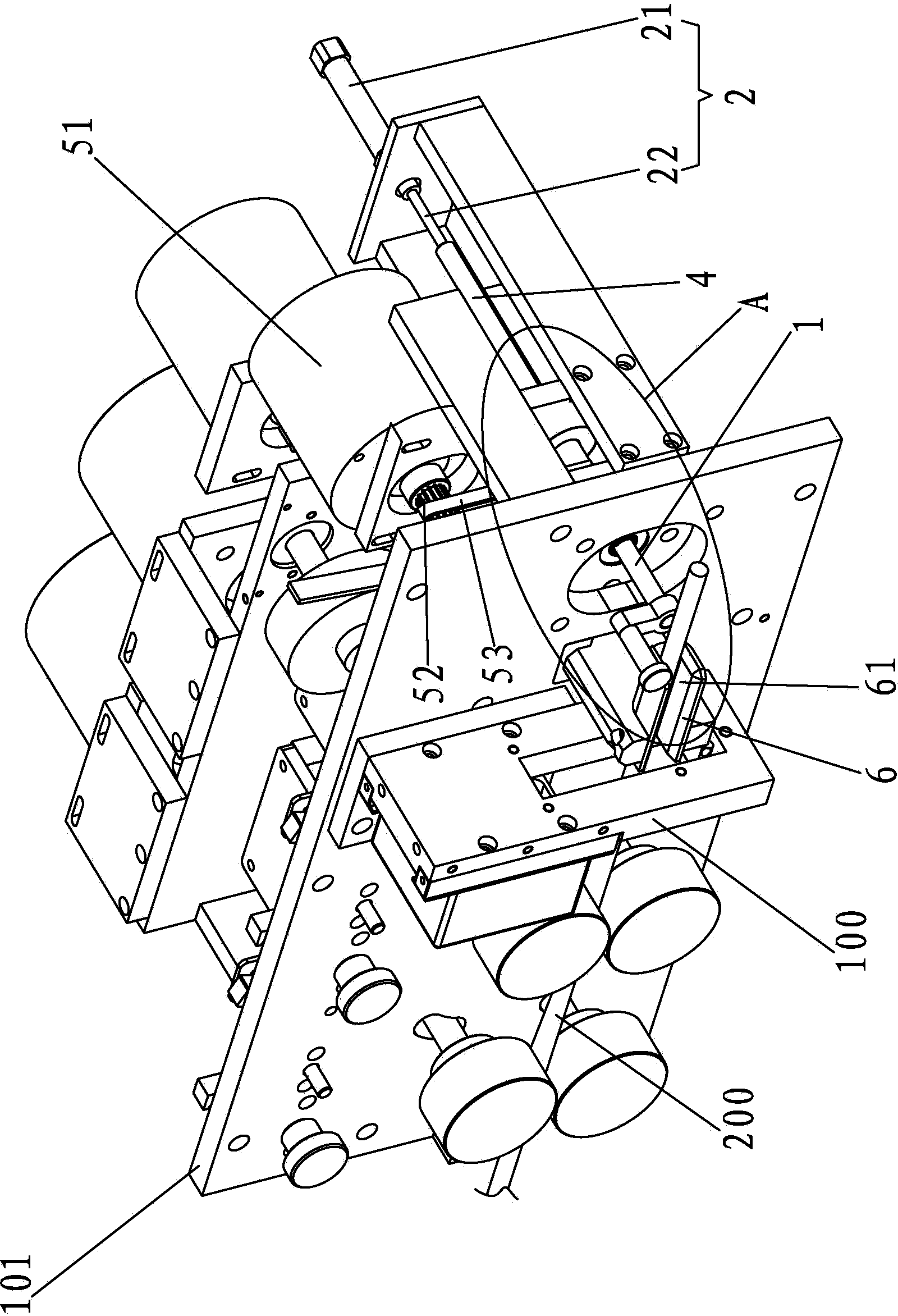

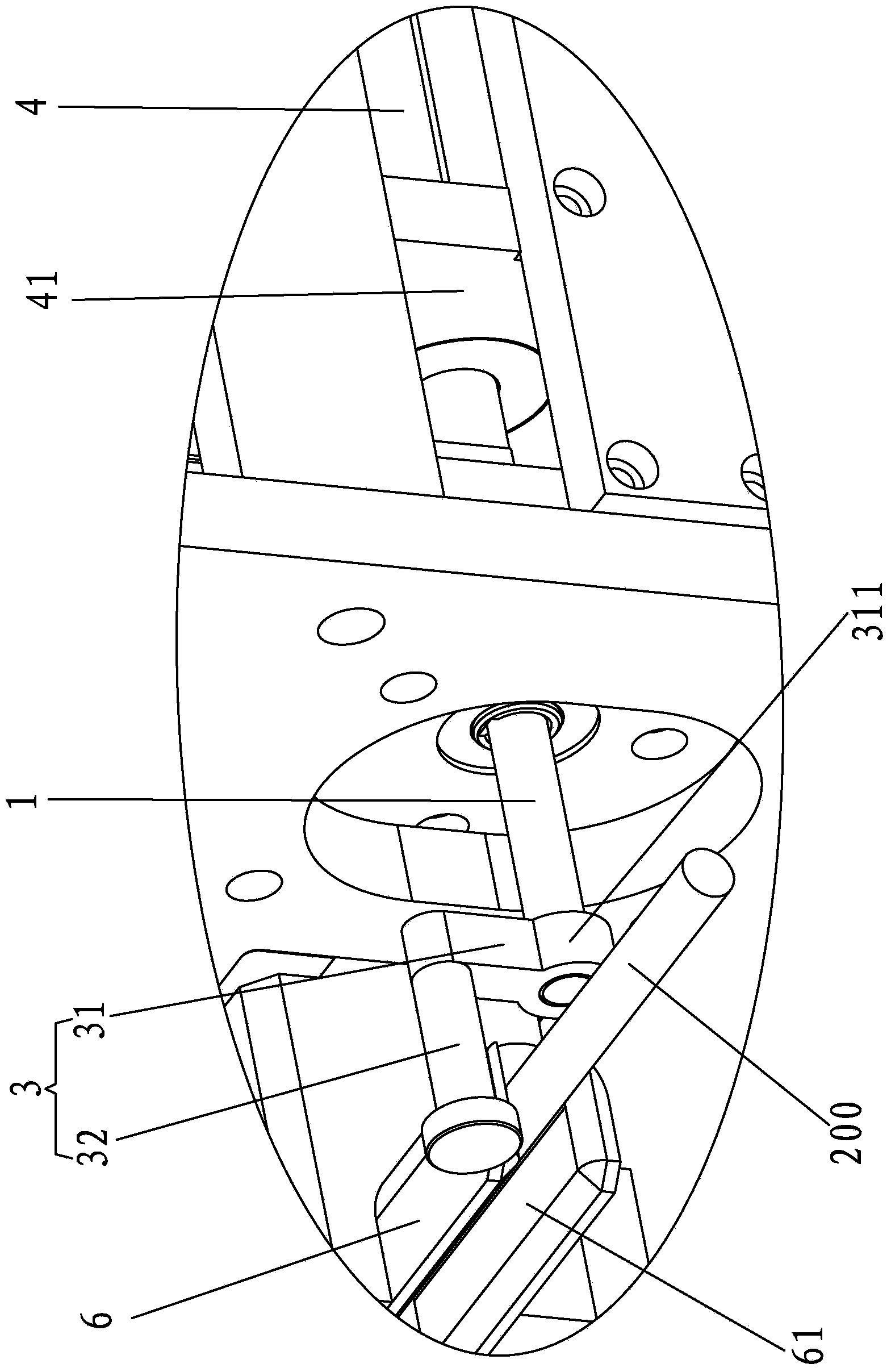

Improved bending device of automatic wire stripping machine

ActiveCN103779761AVariety of stylesOvercome the problem of single styleLine/current collector detailsElectric wire

The invention provides an improved bending device of an automatic wire stripping machine. The improved bending device comprises a bending rod, a telescopic control mechanism and a rotating control mechanism. The bending rod is transversely placed, a bending piece is arranged at the first end of the bending rod and comprises a vertical rod and a cross rod, wherein the cross rod is arranged perpendicular to the first end of the vertical rod, the second end of the vertical rod and the first end of the bending rod are mutually perpendicularly connected, the cross rod is located above or below an electric wire of the outlet of a knife rest assembly of the automatic wire stripping machine, the second end of the bending rod is sleeved with a casing pipe which can rotate relative to the second end of the bending rod and can horizontally move, the output end of the telescopic control mechanism and the casing pipe are fixedly connected together, and the second end of the bending rod is in rotating control connection with the output end of the rotating control mechanism. According to the bending device, finished products with one or more bent positions can be bent, the finished products are diversified in style, the problems that a traditional bending device can bend finished products with only one bent position, and the finished products are single in style are solved, and the improved bending device has the advantages of being high in speed and working efficiency.

Owner:泉州市高敏自动化机电有限公司

High-temperature ceramic grisaille painting decorating method

The invention provides a high-temperature ceramic grisaille painting decorating method. The method is characterized in that high-temperature ceramic grisaille painting decorating is served as an application background, high-temperature glaze, high-temperature coloring materials and various additives are reasonably mixed, a technical barrier of decorating before glazing in a high-temperature glaze grisaille painting decorating process is broken through, decorating and glazing are integrated so as to realize an artistic effect of simultaneous decorating and glazing, complicated processes are simplified, and a unique artistic style is obtained. A fired product has the advantages of smooth and bright surface, unique decoration pattern style, various random patterns, smoothness, naturality, full quality and vividity, various decorative effects, accurate expression and wide market prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

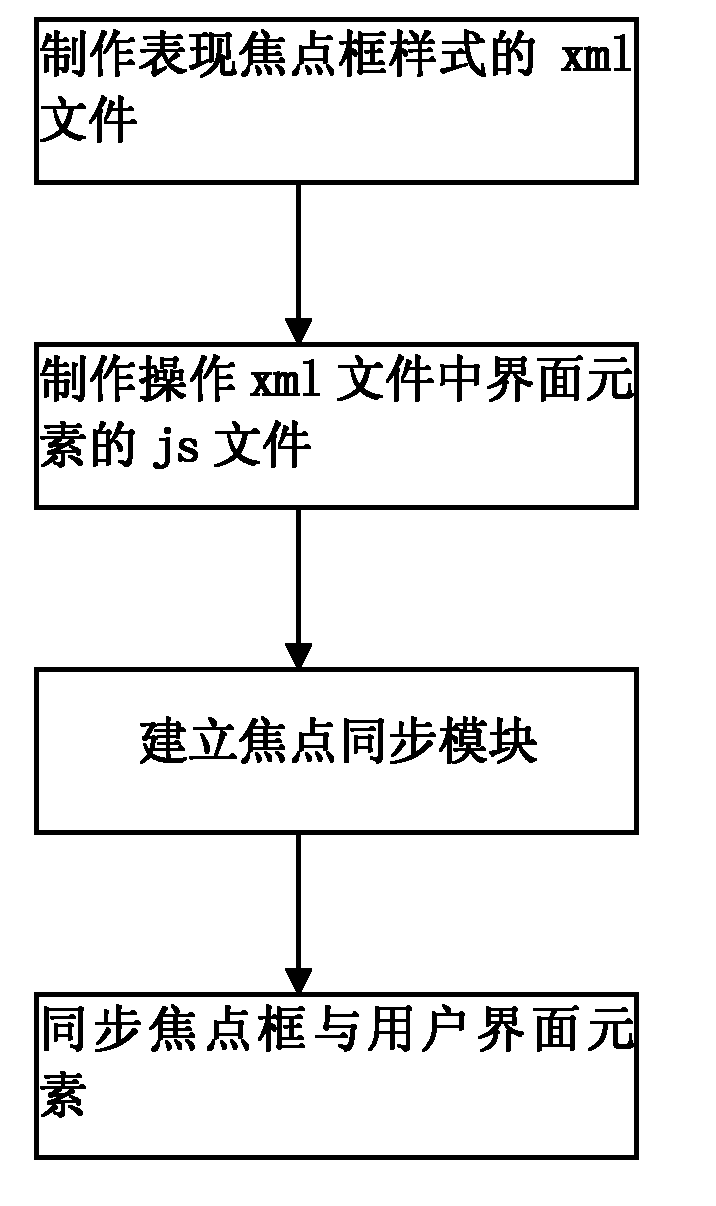

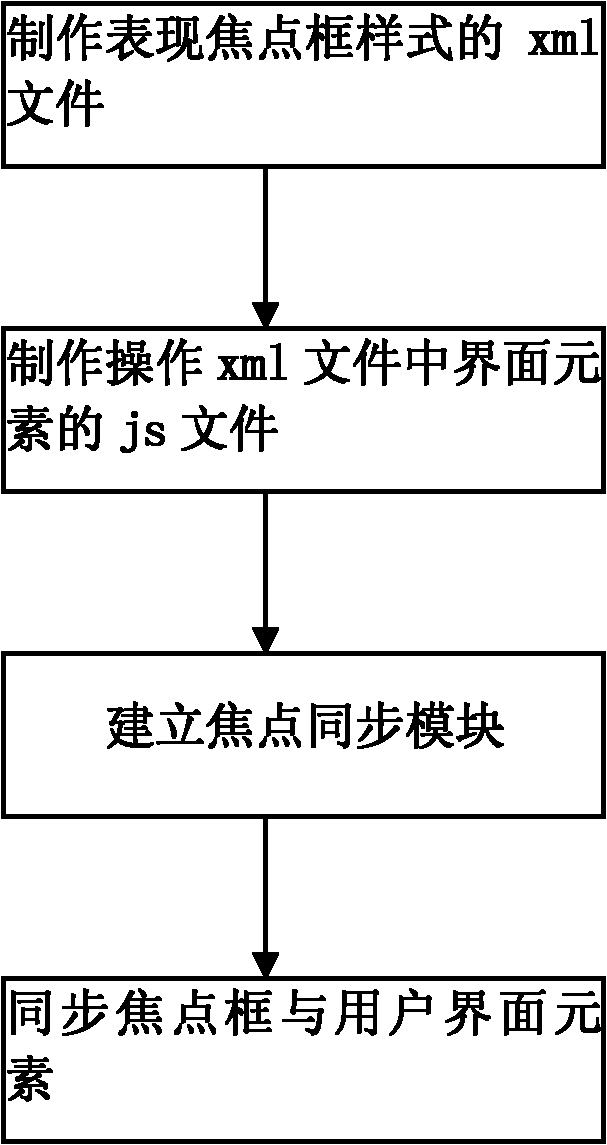

Method for realizing customization of focus rectangle style of user interface elements

InactiveCN101814031AVariety of stylesMeet customized needsSpecific program execution arrangementsSoftware engineeringComputer software

The invention relates to computer software technology, in particular to a method for realizing customization of a focus rectangle style of user interface elements in embedded environment. The invention discloses the method for realizing the customization of the focus rectangle style of the user interface elements and solves the problem of single focus rectangle style in the conventional technology. The technical scheme comprises the main points of: a, preparing an xml file which is used for expressing the focus rectangle style; b, preparing a js file which is used for operating interface elements in the xml file; c, establishing a focus synchronization module which is used for receiving a keypress response of a user; d, receiving keypress input of the user and acquiring the next focus element by using a focus element navigation module; e, transferring the next focus element which serves as the input quantity to the focus synchronization module; and f, synchronizing the focus rectangle to the current focus element by the focus synchronization module. The method for realizing the customization of the focus rectangle style of the user interface elements has the advantages of realizing diversification of the focus rectangle style and meeting the requirements of different manufacturers and developers on customization.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Method for making wool cotton dress

InactiveCN101081099AReduce labor intensityImprove cleanlinessOvergarmentsWoven fabricsPunchingPulp and paper industry

The present invention relates to tailoring technology, and is especially wool-padded clothes tailoring process. The process of tailoring wool-padded clothes includes the following steps: making net fabric for wrapping wool, bulking and carding wool material, spreading wool on the bottom layer of net fabric, covering the wool with upper layer of net fabric, entangling in a needle punching machine to combine the wool and the net fabrics, sewing two sides and winding to obtain wool padding, sandwiching the wool padding between the facing fabric and the lining fabric and sewing to obtain wool-padded clothes blank, and cutting and sewing to obtain wool-padded clothes.

Owner:李可章

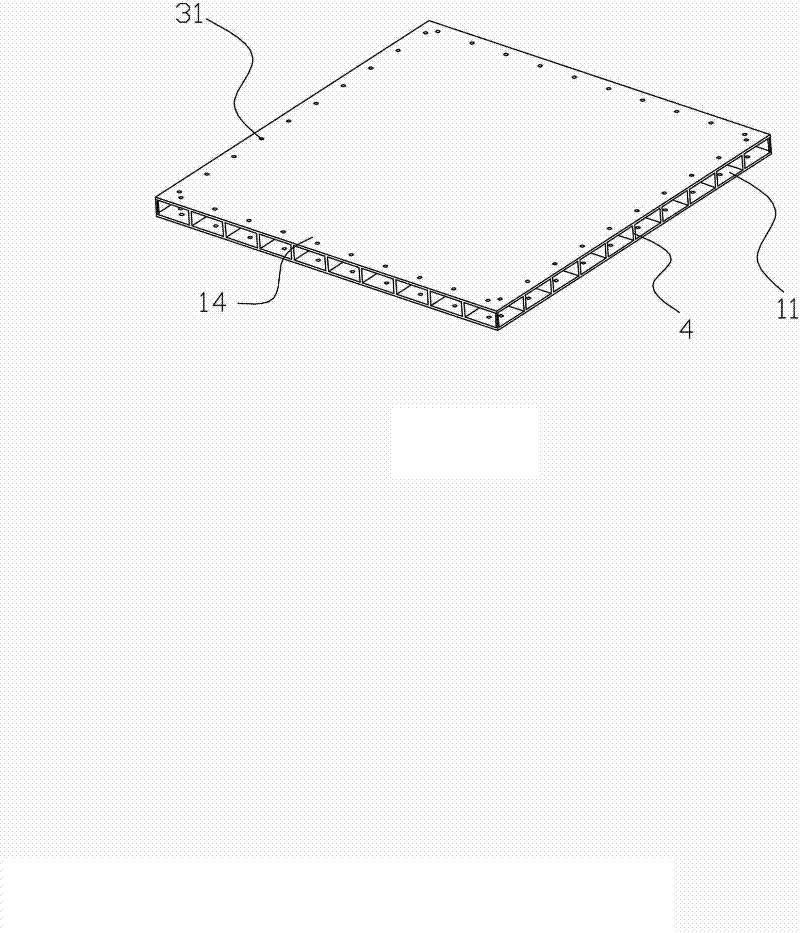

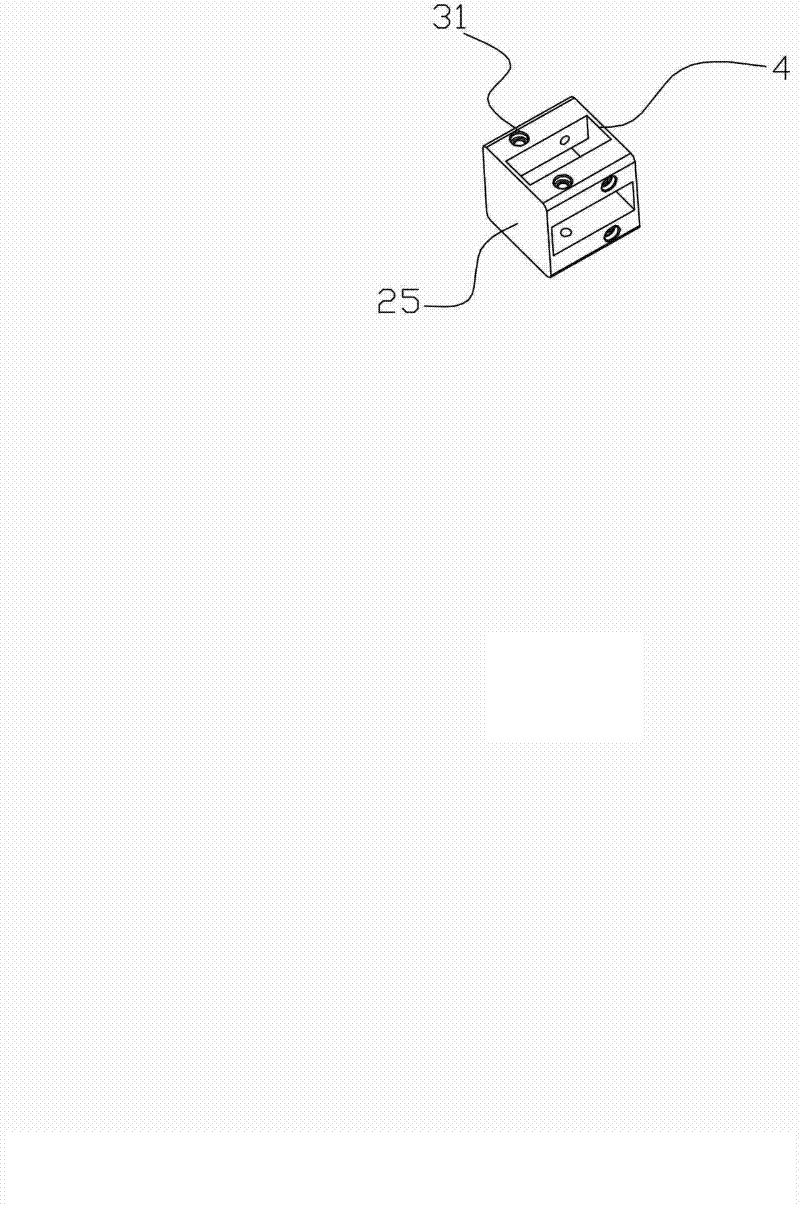

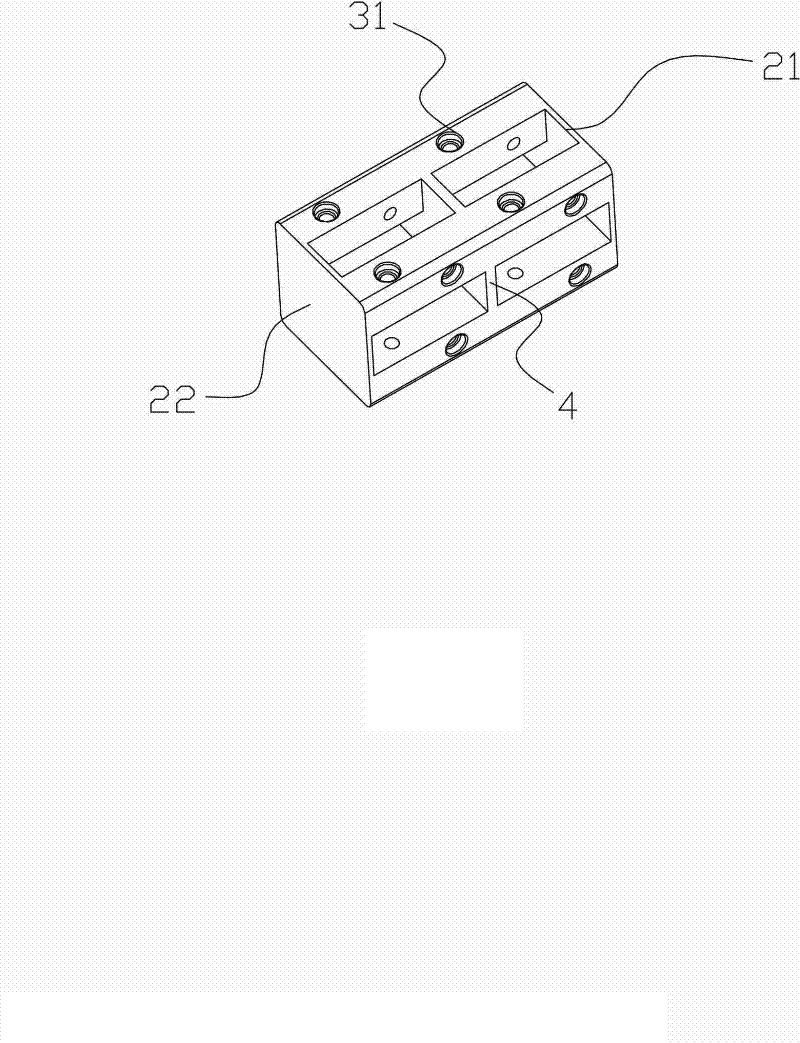

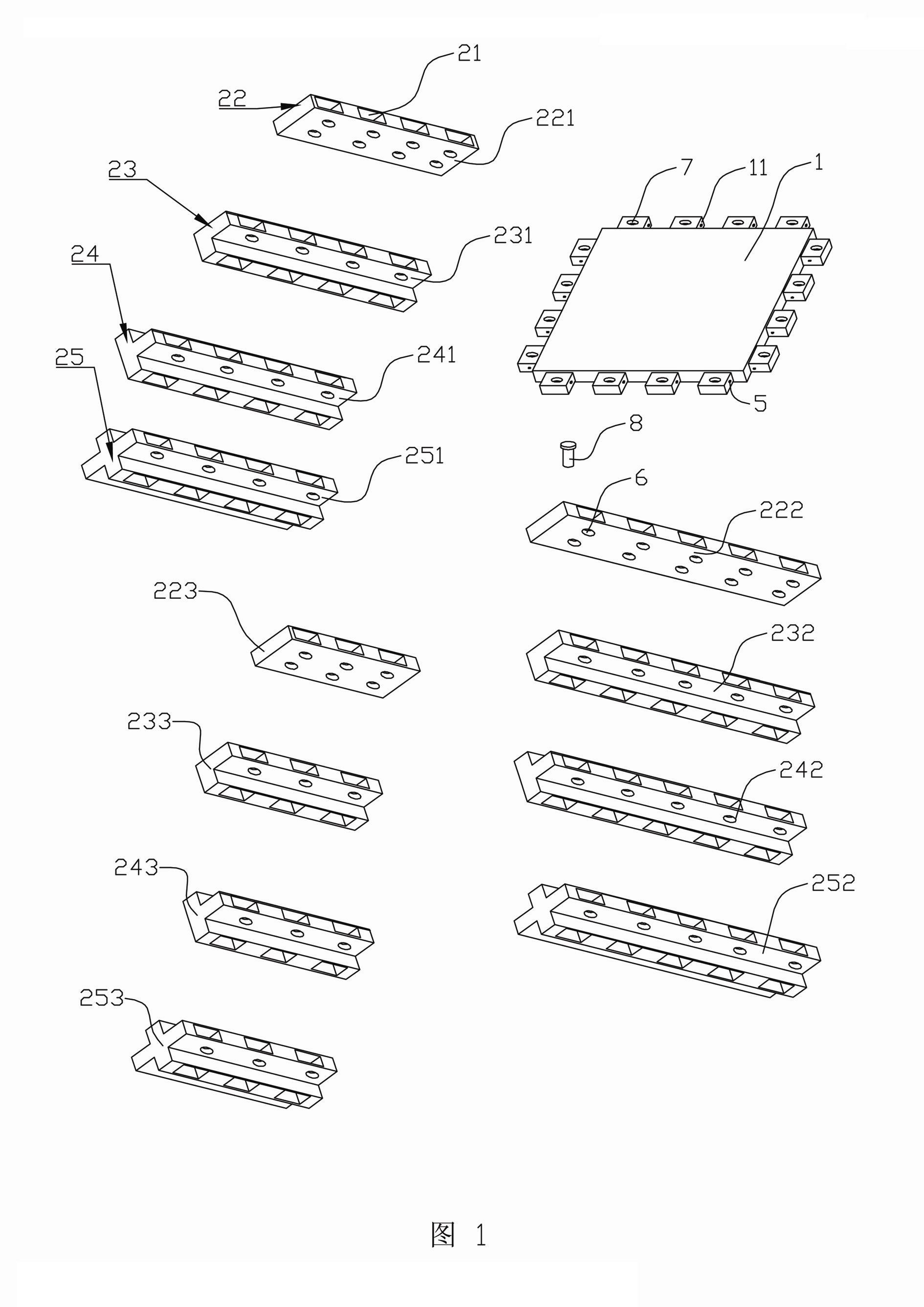

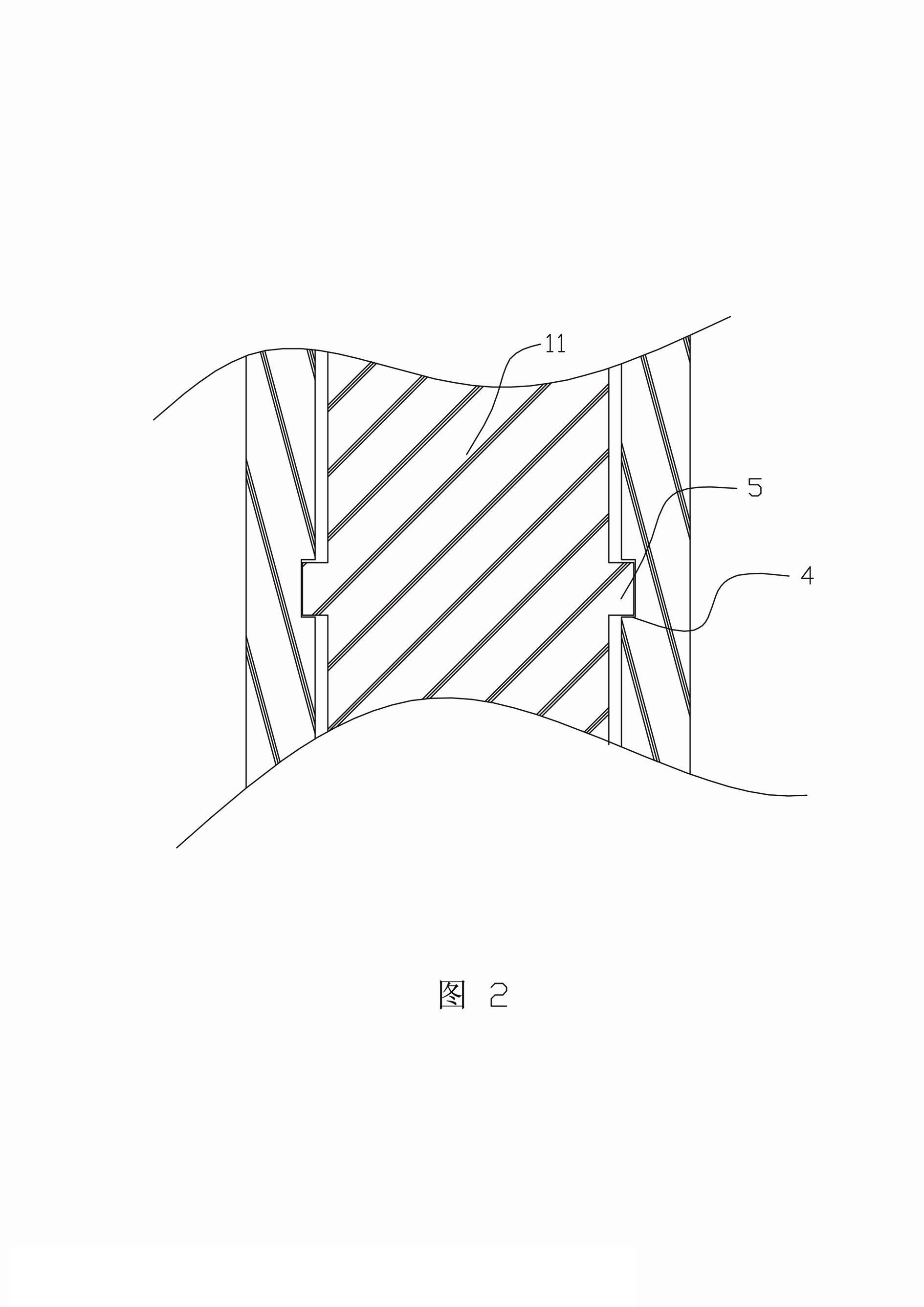

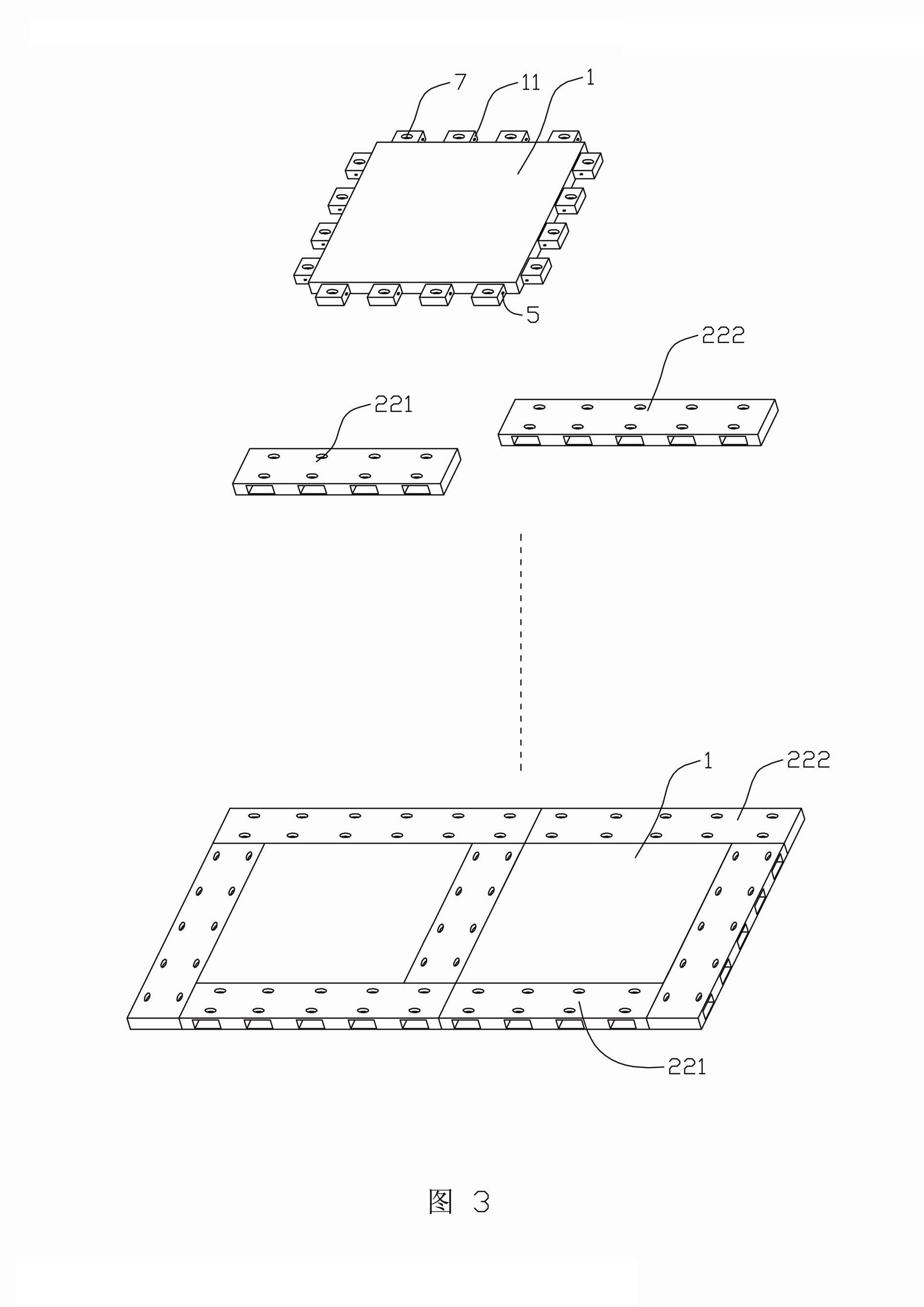

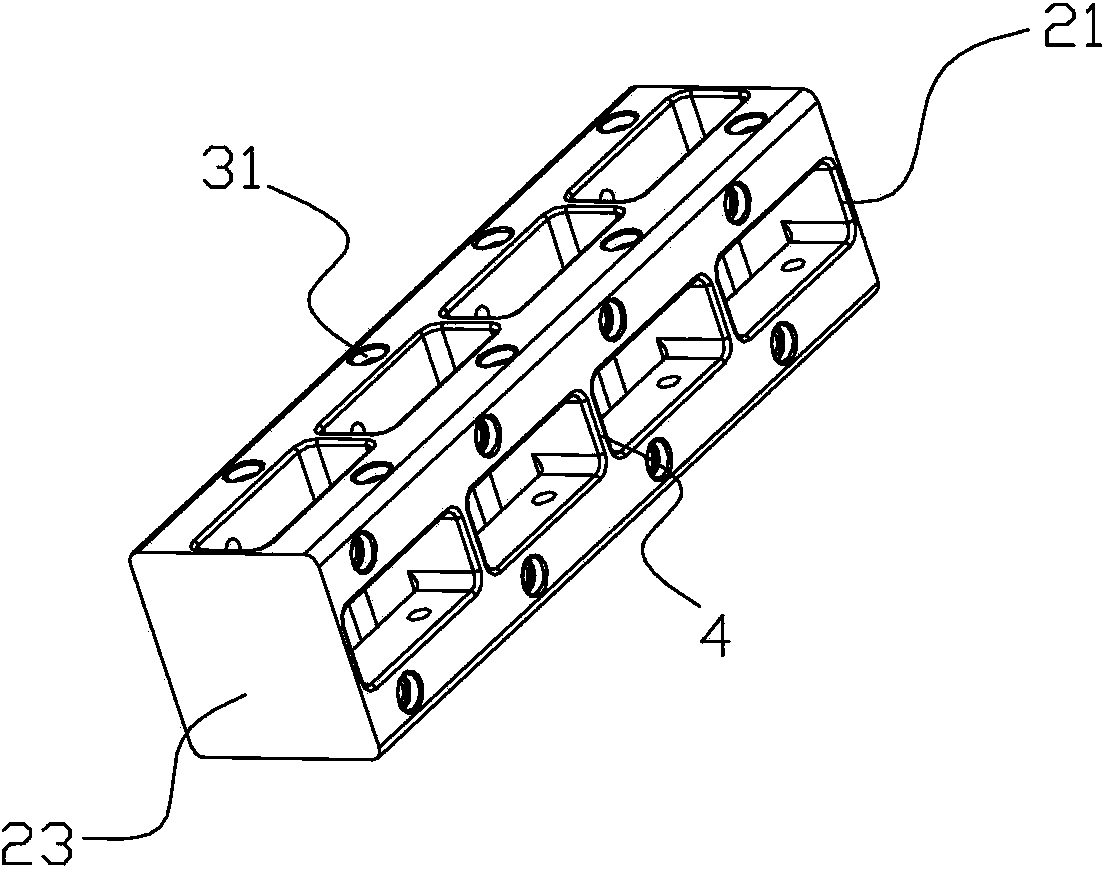

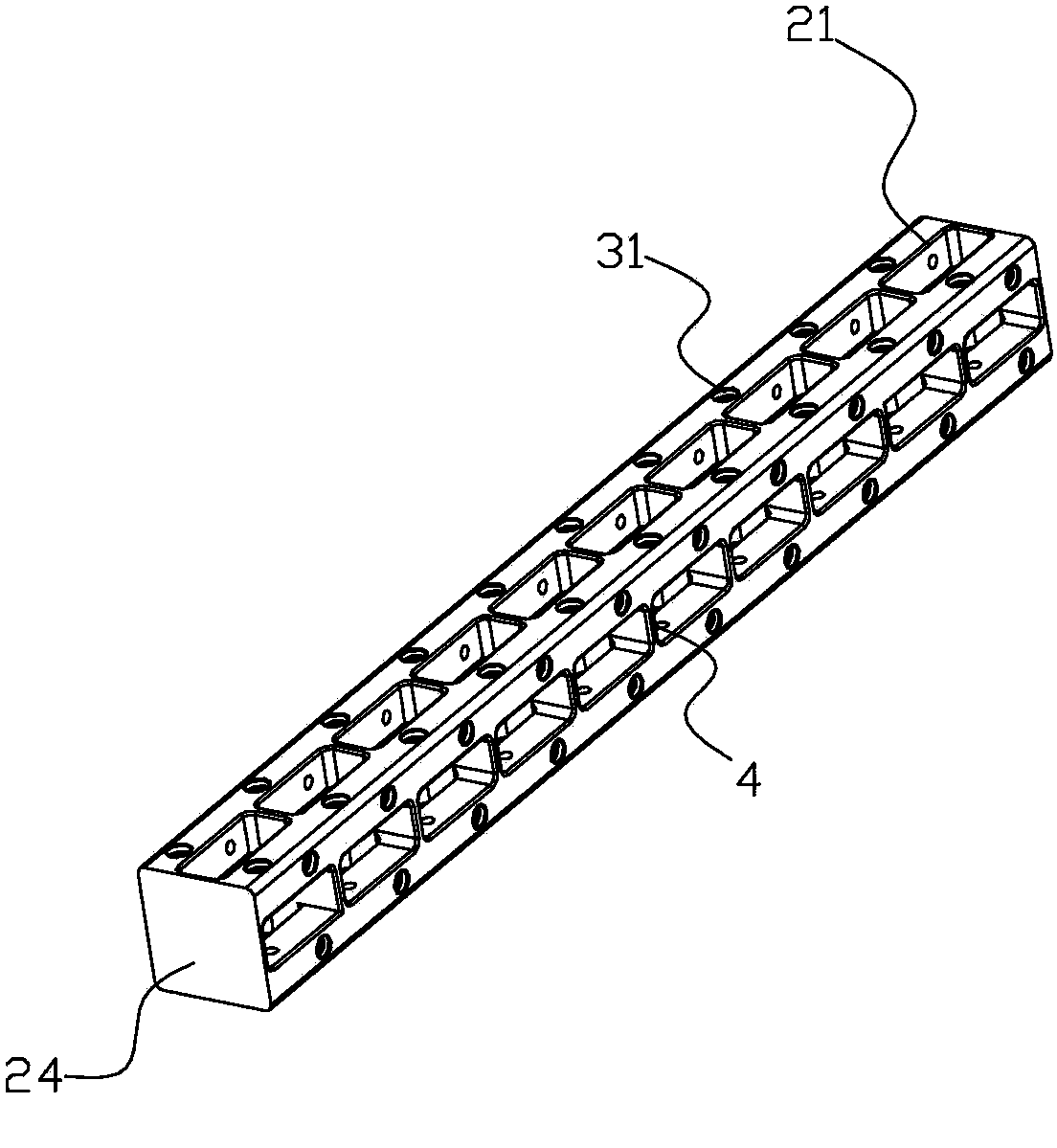

Standardized component used for assembling furniture/pet house/mobile house

Disclosed is a standardized component used for assembling furniture / a pet house / a mobile house. The standardized component comprises panels, connecting bars and inserting ends, wherein the side edges of the panels and the side surfaces of the connecting bars are respectively provided with inserting slots matched with the inserting ends in an insertion-connection way, each panel has two side surfaces and four side edges, each of the four side edges is formed by a plurality of identical minimum units, and each minimum unit is formed by an inserting slot and side walls forming the inserting slot in an enclosing way; each connecting bar has four side surfaces and two end surfaces, each of the four side surfaces is formed by a plurality of identical minimum units, and each minimum unit is formed by an inserting slot and side walls forming the inserting slot in an enclosing way. The standardized component not only solves the problems that gaps exist between adjacent connecting bars, the splicing is inconvenient, modeling types are not abundant and the like, but also can be spliced more simply and be produced more easily.

Owner:福建吉信德科技有限公司

An Assembled Furniture/Pet House

InactiveCN102269203AEasy to assembleEasy to disassembleAnimal housingSheet joiningEngineeringSurface plate

Owner:XIAMEN SUNNYPET PROD

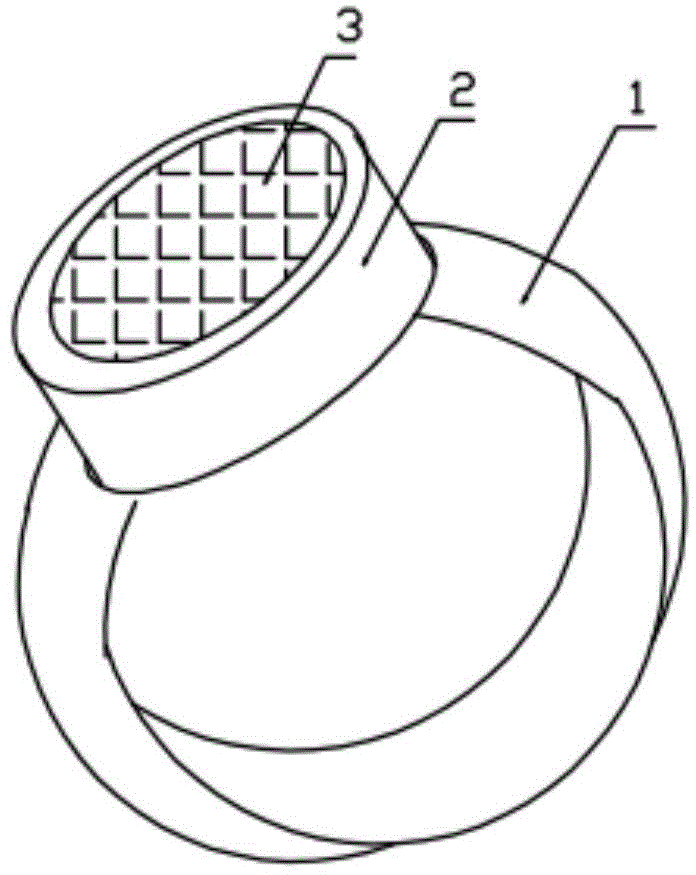

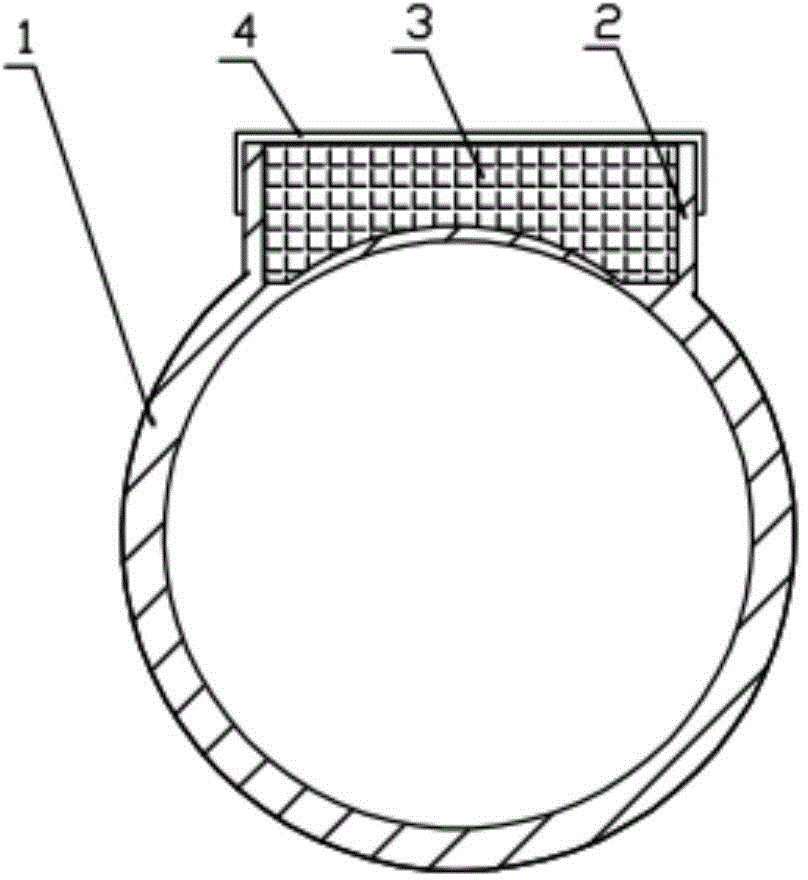

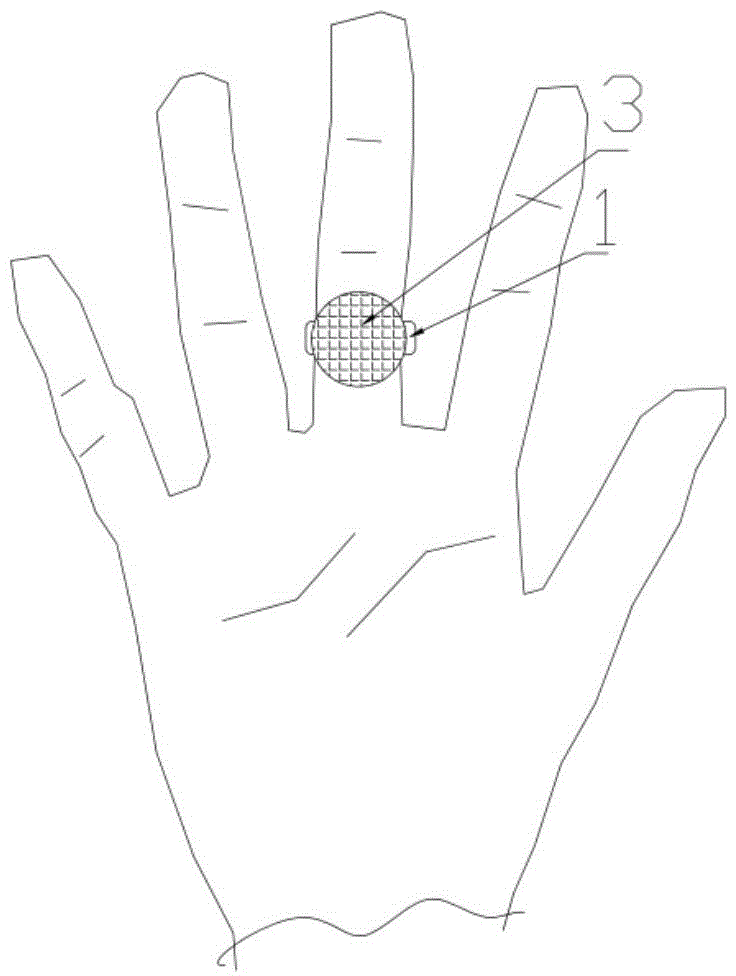

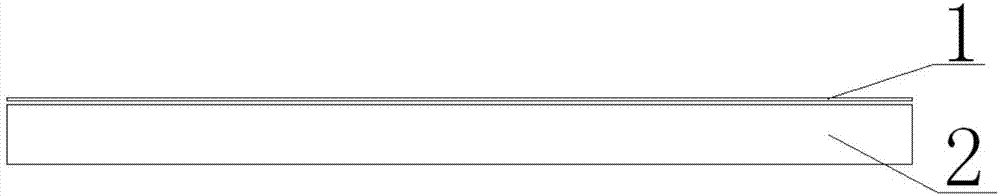

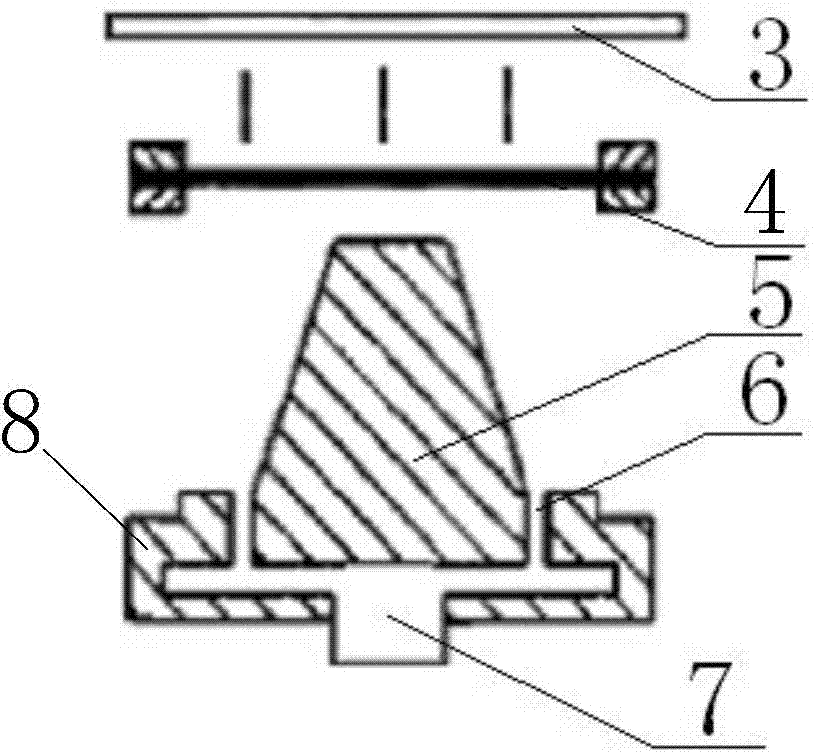

Finger wetting ring used for counting of accountant

The invention relates to a finger wetting ring used for counting of an accountant. The finger wetting ring comprises a ring body which a user can wear on one finger, a containing box is fixed on the ring body, moisture preserving padding is arranged in the containing box, a sealing protective film is arranged on the containing box, and the moisture preserving padding is sponge or non-woven cloth containing moisture preserving liquid. The finger wetting ring has the advantages of being convenient to carry, small in size, clean, sanitary and capable of ensuring counting quality and speed.

Owner:吴丽波

Plastic sucking forming process for rear television cover

The invention discloses a rear television cover machined by a plastic sucking process. A to-be-machined rear cover panel is subjected to surface laminating or texture screen printing before plastic sucking; the plastic sucking process is characterized in that a method of manufacturing an opened shell product by virtue of a thermoplastic plastic sheet is adopted, and the plastic sheet is cut into certain size, is heated to be softened, is attached to the contour surface of a specific mold after deformed by virtue of air pressure difference of two surfaces of the sheet or mechanical pressure, is subjected to cooling setting and is trimmed. The rear television cover machined by the plastic sucking process has the advantages that the machining process is simple, the machining mold is simple to develop, low in cost and short in developing period, and standardized design of formed parts is facilitated.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Top toy device capable of being accelerated

The invention discloses a top toy device capable of being accelerated. The top toy device comprises a top toy and a remote control device and is characterized in that the top toy comprises a rotating body and a top body, a motor is arranged in the middle of the top body, a rotating shaft of the motor is located on the central axis of the top body and extends upwards to be connected with the rotating body so that the motor can drive the rotating body to rotate, the rotating body rotates to exert reactive force on the top body to make the top body rotate reversely, and then the whole top toy is driven to rotate. The top toy is simple in structure and low in cost, the gravity is stable and centralized, rotation is more stable and longer, the remote control device is designed in the mode that the motor of the top toy is controlled to act through a vibration control part, when played, the top toy can be controlled just by shaking the remote control device, the control mode is more novel and advanced, the top toy device can be popular with children better, the problem that the top toy can not be controlled in the fighting process is solved, and the interactivity and the interestingness of the top toy in the playing process are effectively improved.

Owner:ALPHA GRP CO LTD +2

High-molecular, transparent and colorful self-adhesive coiled material and production process thereof

InactiveCN105924885AHigh transparencyAging resistantLaminationLamination apparatusEpoxyAsphalt shingle

The invention discloses a high-molecular, transparent and colorful self-adhesive coiled material and a production process thereof. The self-adhesive coiled material comprises the following raw materials in parts by weight: 15-30 parts of butyl-reclaimed rubber, 1-8 parts of EVA, 1-8 parts of epoxy, 1-8 parts of SBS-1401 and 45-60 parts of C5 hydrogenated petroleum resin. The raw materials, after being weighed according to the parts by weight, are evenly stirred in a container; the self-adhesive coiled material is obtained after the primary and secondary hot melt vertical compression. The self-adhesive coiled material has the advantages of high transparency, thermal insulation, ageing resistance and high adhesion, can effectively reduce roof temperature and production cost, and is conducive to environment protection; the self-adhesive coiled material can withstand the temperature as high as 110 DEG C; the bonding strength is larger than 1.5 N / mm; and the self-adhesive coiled material remains flexible at the temperature below minus 20 DEG C, and has excellent practicability and high temperature resistance. The self-adhesive coiled material has the appearance effect of asphalt shingle, concrete tile, terracotta and metal tile, and is compatible with different outer wall colors and styles, highly three dimensional, and rich in style and color.

Owner:GUIZHOU SHENGYUAN WATERPROOF MATERIAL

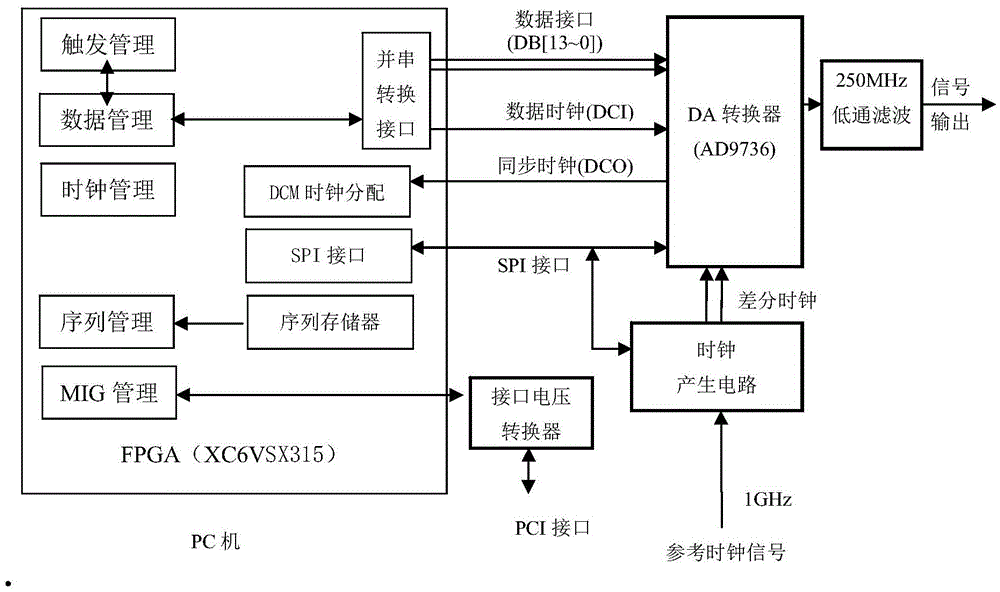

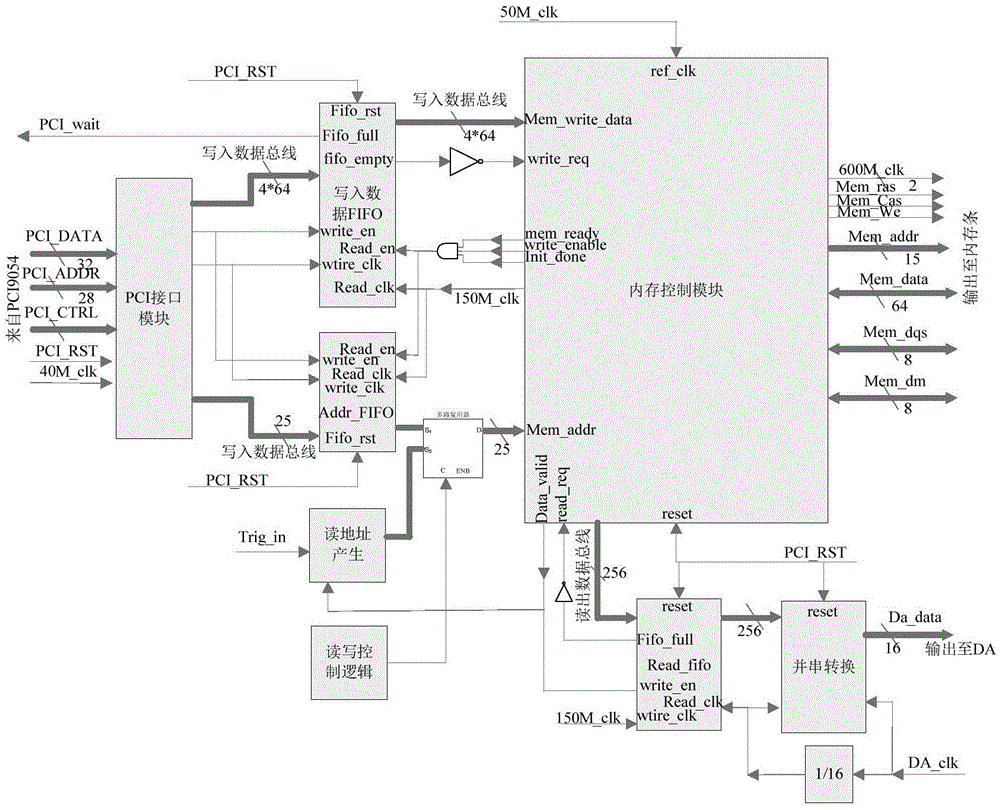

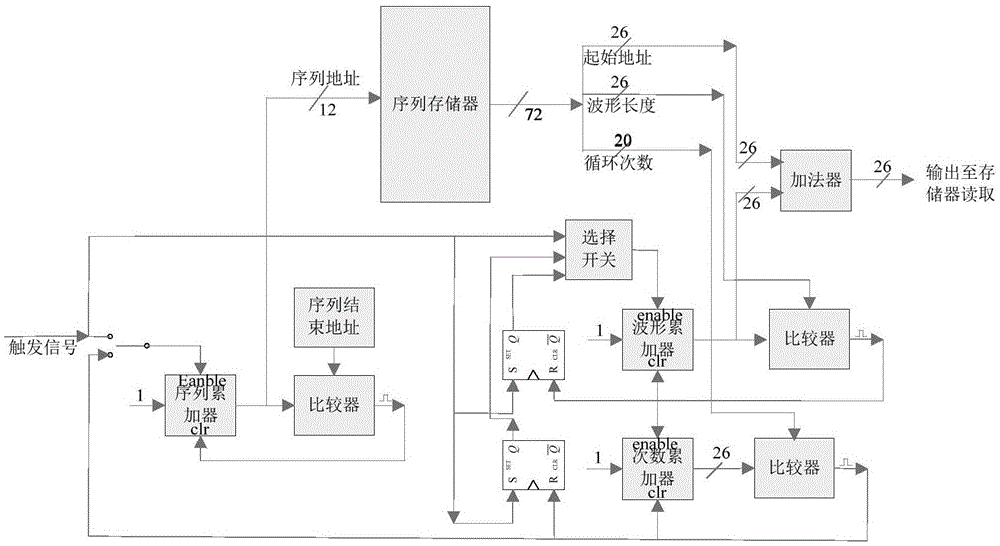

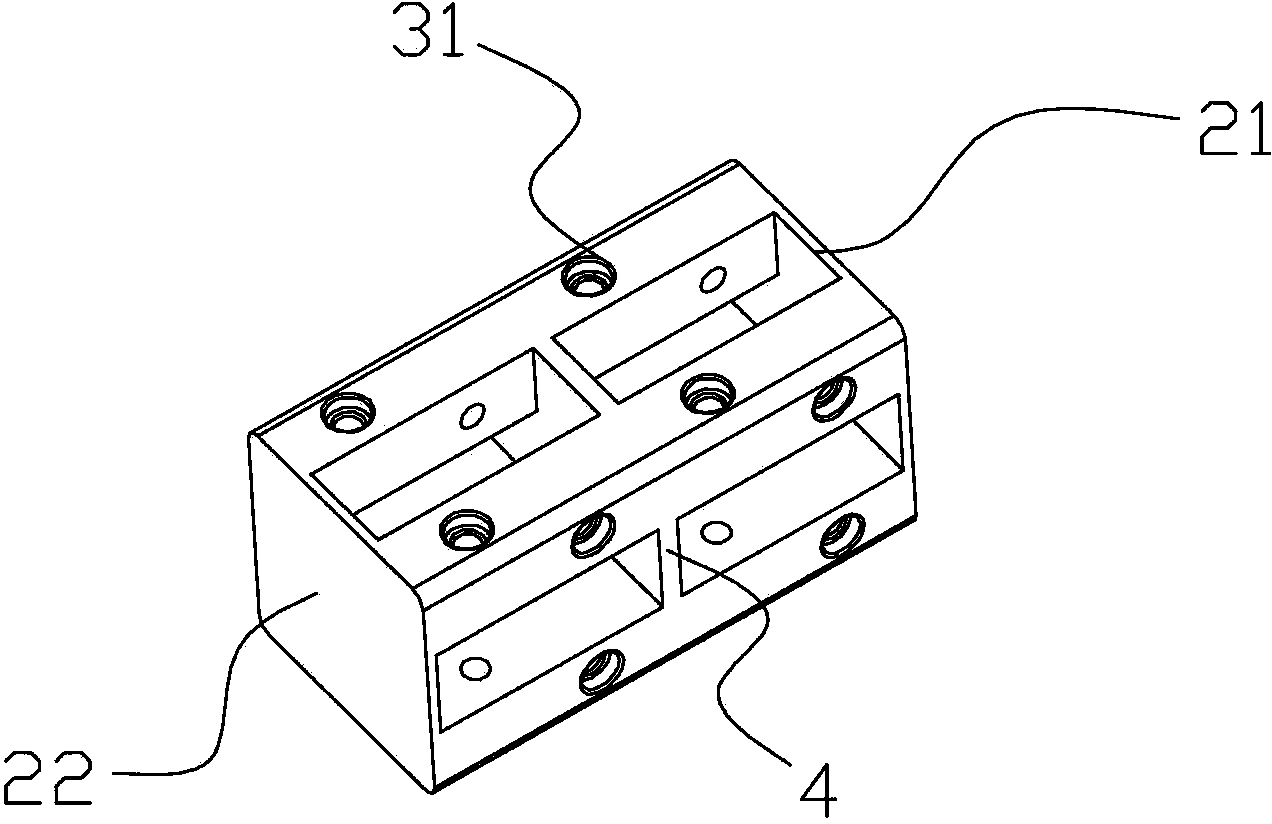

An Arbitrary Waveform Generating System and Method

InactiveCN103488244BQuick switchHigh resolutionDigital function generatorsSignal frequencyDigital signal processing

The invention discloses an arbitrary waveform generation system and method for variable-speed waveform data playback based on complex combined triggering. The system comprises a waveform data storage unit and a trigger mode based waveform editing and trigger playback unit; the trigger mode based waveform editing and trigger playback unit comprises a waveform reading address generation subunit and a complex wave synthesis subunit; the waveform reading address generation subunit comprises a pulse gating module, a trigger module, a trigger reset module, a waveform trigger module, a waveform trigger reset module, a waveform trigger buffer module, a sequence trigger module, a sequence trigger repeating module and a sequence trigger setting module. On the basis of real-time digital signal processing, complex combined trigger and variable-speed waveform data playback technologies, the system and method gives full play to the characteristics of all-digital waveform synthesis, high resolution, good signal stability, many signal styles, various modulation and the like, and has the advantages of quick switching, capability of changing length of signal cycles and the like.

Owner:THE 41ST INST OF CHINA ELECTRONICS TECH GRP

Standardized component used for assembling furniture/pet house/mobile house

Disclosed is a standardized component used for assembling furniture / a pet house / a mobile house. The standardized component comprises panels, connecting bars and inserting ends, wherein the side edges of the panels and the side surfaces of the connecting bars are respectively provided with inserting slots matched with the inserting ends in an insertion-connection way, each panel has two side surfaces and four side edges, each of the four side edges is formed by a plurality of identical minimum units, and each minimum unit is formed by an inserting slot and side walls forming the inserting slot in an enclosing way; each connecting bar has four side surfaces and two end surfaces, each of the four side surfaces is formed by a plurality of identical minimum units, and each minimum unit is formed by an inserting slot and side walls forming the inserting slot in an enclosing way. The standardized component not only solves the problems that gaps exist between adjacent connecting bars, the splicing is inconvenient, modeling types are not abundant and the like, but also can be spliced more simply and be produced more easily.

Owner:福建吉信德科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com