Plastic sucking forming process for rear television cover

A molding process and TV technology, which is applied in the field of processing and molding TV back covers, can solve the problems of not meeting the requirements of rapid product development, large injection molds, and high mold costs, and achieve high requirements for personalized customization, low mold costs, and easy development. short cycle effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be further described in detail below in conjunction with examples, but the embodiments of the present invention are not limited thereto.

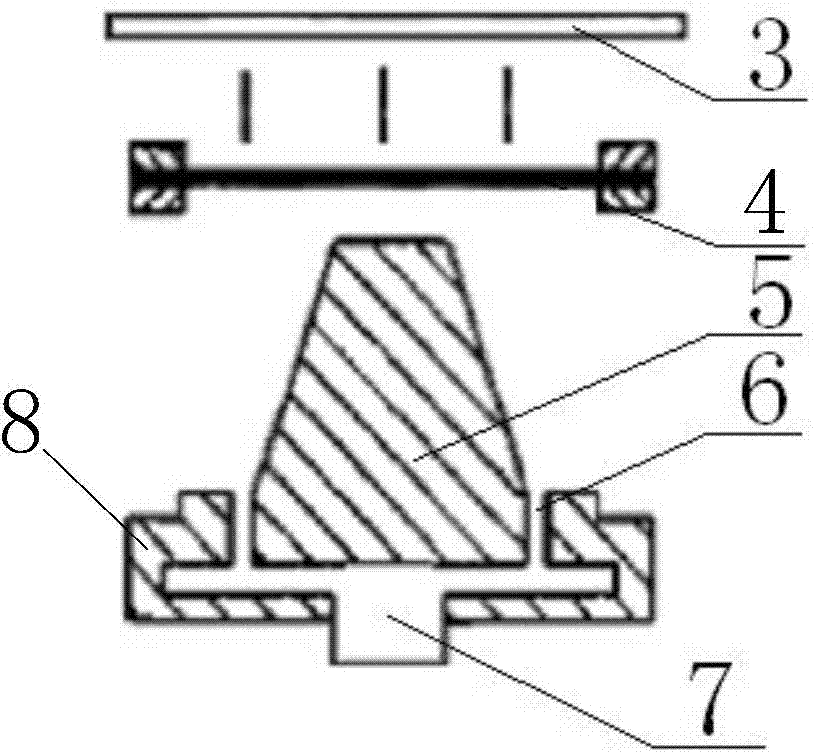

[0026] Such as Figure 1 ~ Figure 4 As shown, a blister-processed TV rear cover molding process includes the following steps:

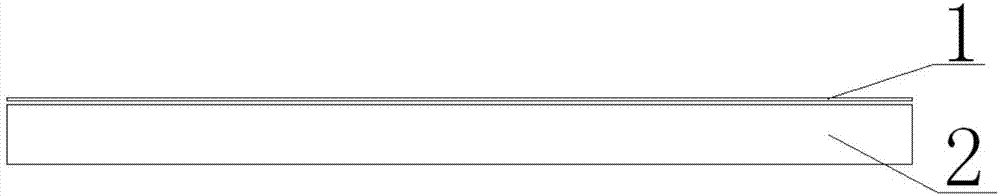

[0027] Step 1. Select thermoplastic plastic sheet 2;

[0028] Step 2: Laminating or silk-screening texture treatment on the upper surface of the thermoplastic sheet 2 so that the upper surface of the thermoplastic sheet is pre-covered with a film layer or a silk-screen ink layer 1;

[0029] Step 3: Cut the thermoplastic sheet 2 after the pre-coated film layer or the silk screen ink layer 1;

[0030] Step 4: Heat and soften the cut pre-coated film layer or the thermoplastic sheet 2 of the silk screen ink layer 1;

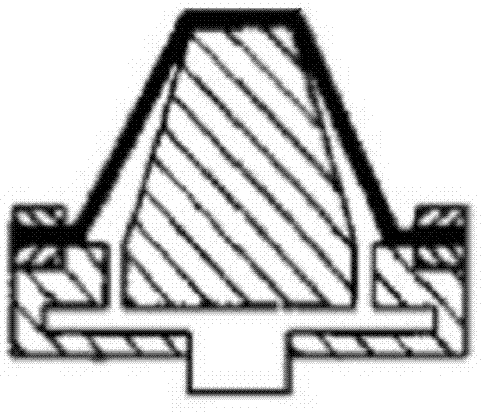

[0031] Step 5. The lower surface of the softened pre-coated film layer or the thermoplastic sheet 2 of the screen printing ink layer 1 is bonded to the convex mold 5 of the TV back...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com