Embedded compound spinning frame and spinning method thereof

A compound spinning and spinning frame technology, applied in the field of spinning, can solve problems such as difficult to spin high-count yarn and ultra-high-count yarn, short fiber waste, difficult to spin short fiber or ultra-short fiber yarn, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

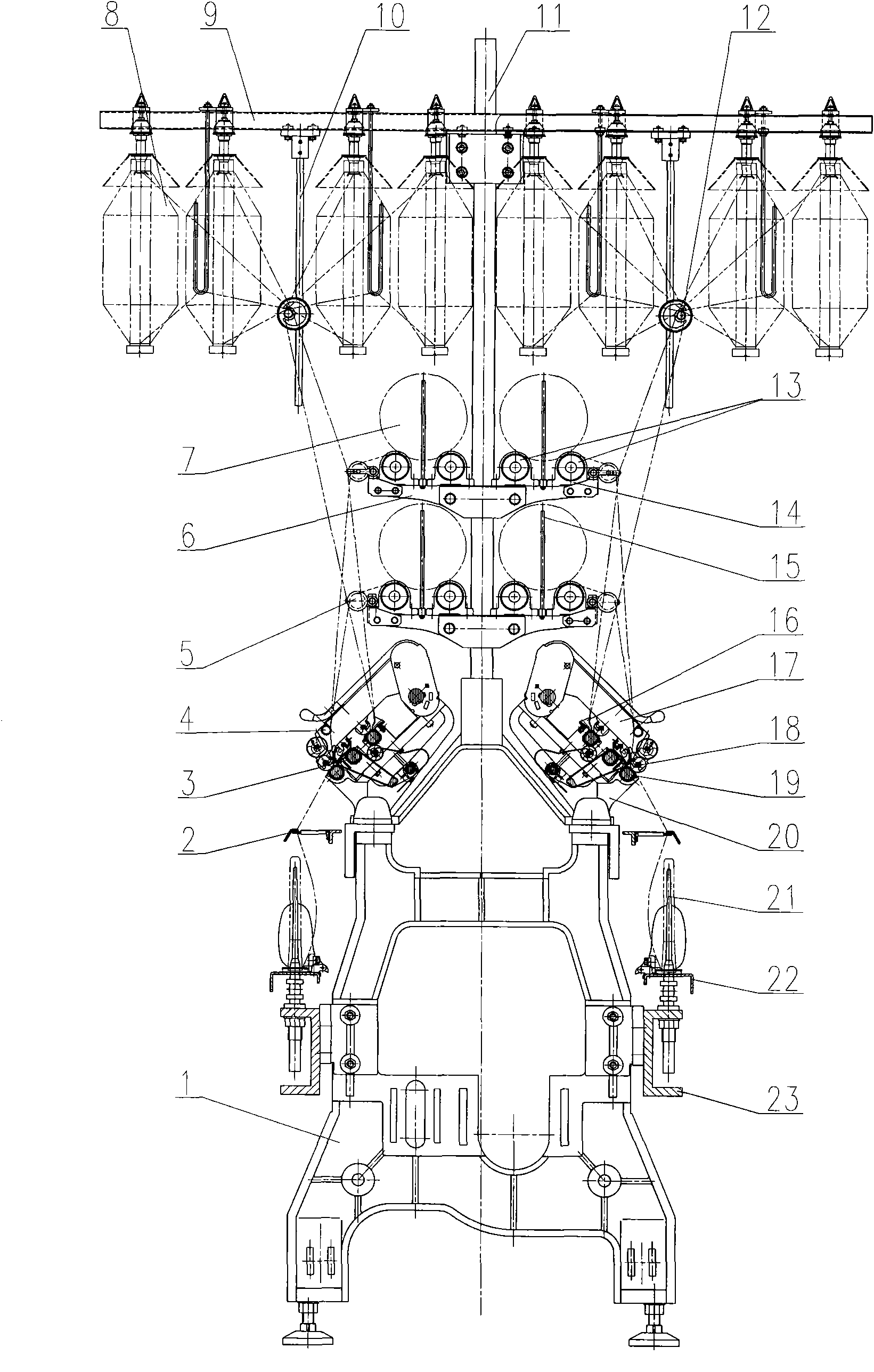

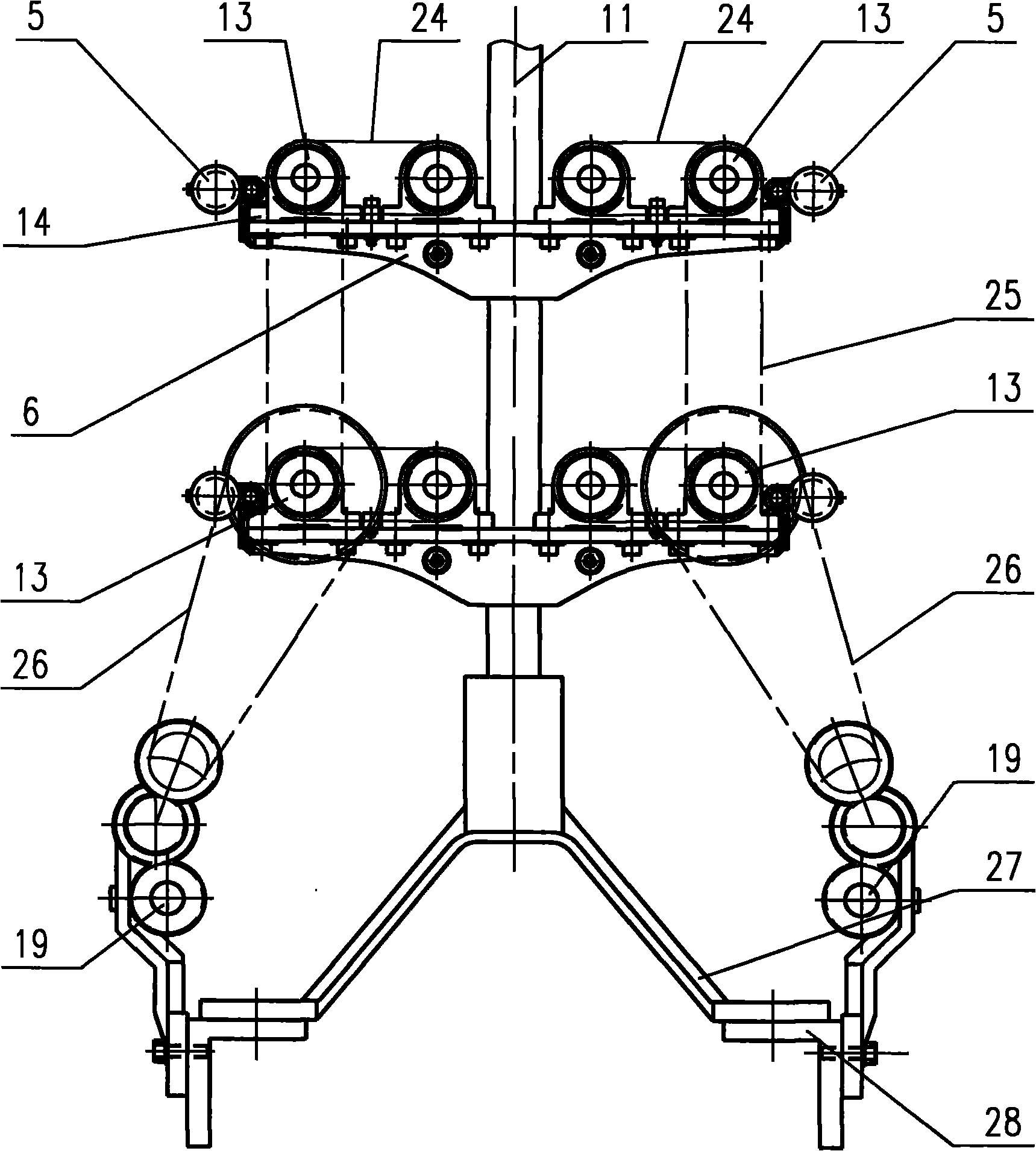

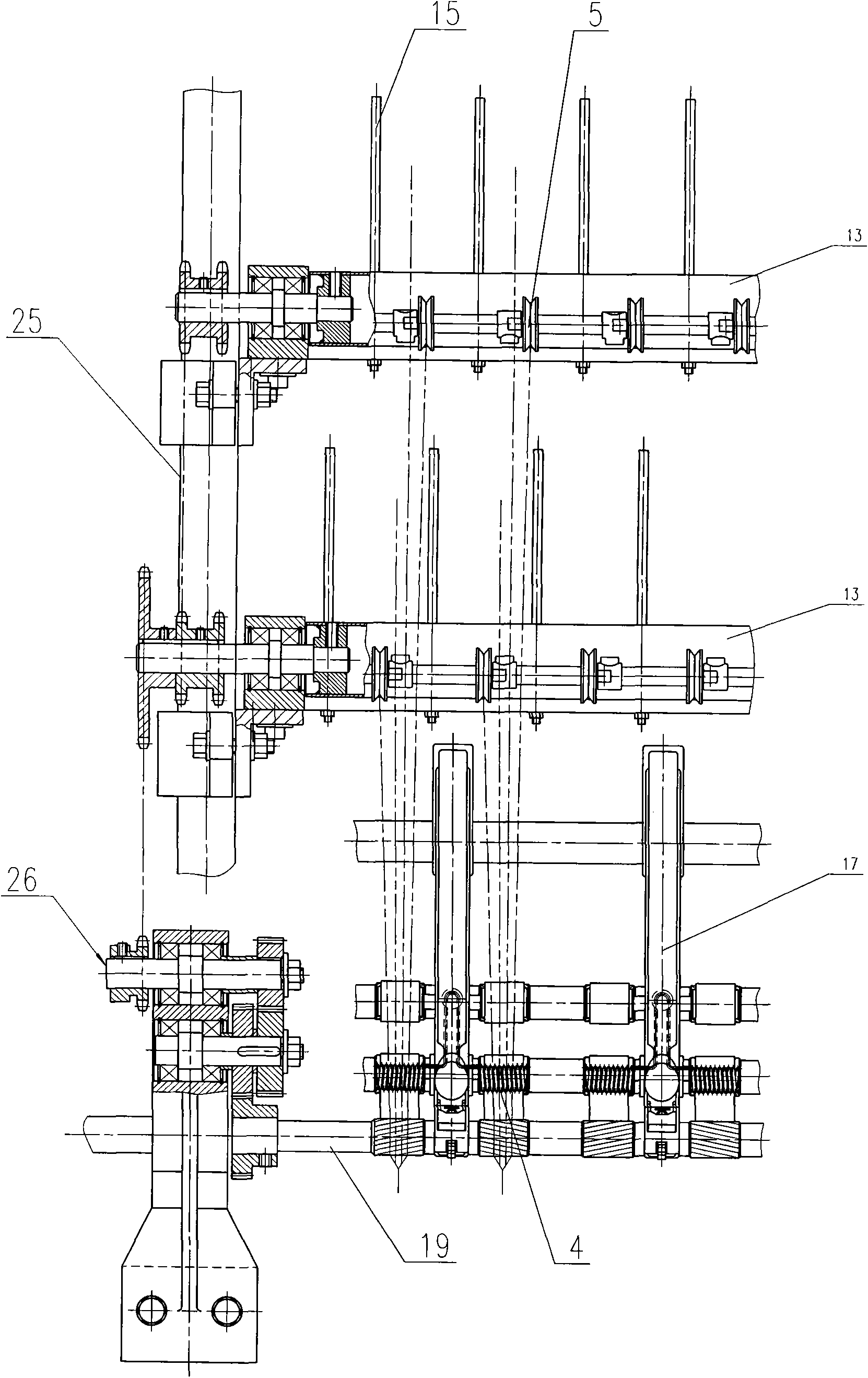

[0014] figure 1 The shown embedded composite spinning frame includes a frame composed of a wall panel 1, a dragon rib 23, a beam 28, etc., and a drafting mechanism 3 and a roving frame column 11 installed on the frame. A roving frame 9 for suspending the roving 8 is installed at the upper end of the roving frame column 11. The roving frame 9 adopts a single-layer 8-row structure. A yarn guide rod 12 is installed on the lower side of the roving frame 9 through a guide rod support 10. Two layers of unwinding brackets 6 are installed from top to bottom in the middle section of the roving frame column 11. Each layer of unwinding bracket 6 is equipped with four unwinding supports 14 arranged in parallel along the length of the spinning frame. The unwinding roller 13, the upper and lower unwinding brackets 6 and the unwinding roller 13 on the upper and lower layers have the same structural form. The two unwinding rollers 13 on the same side of the roving frame column 11 support filame...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com