Gas injector with multiple valve needles

A gas injector and valve needle technology, applied in fuel injection devices, special fuel injection devices, machines/engines, etc., can solve problems such as wear and tear, and achieve the effect of small injection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

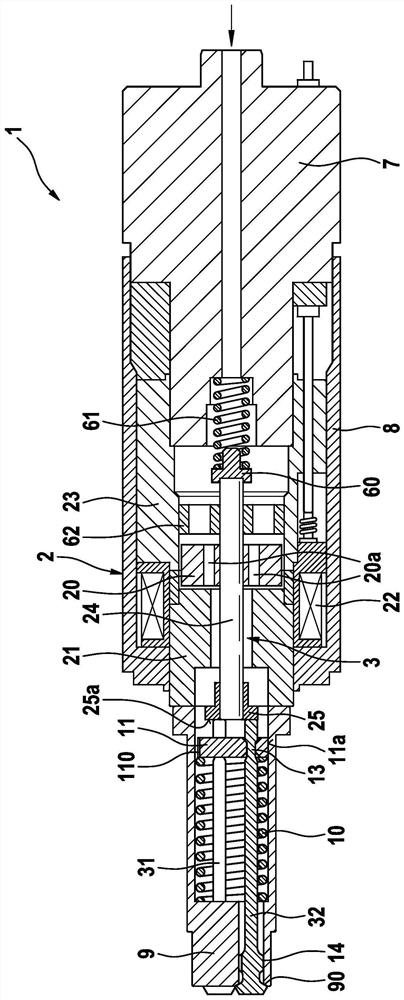

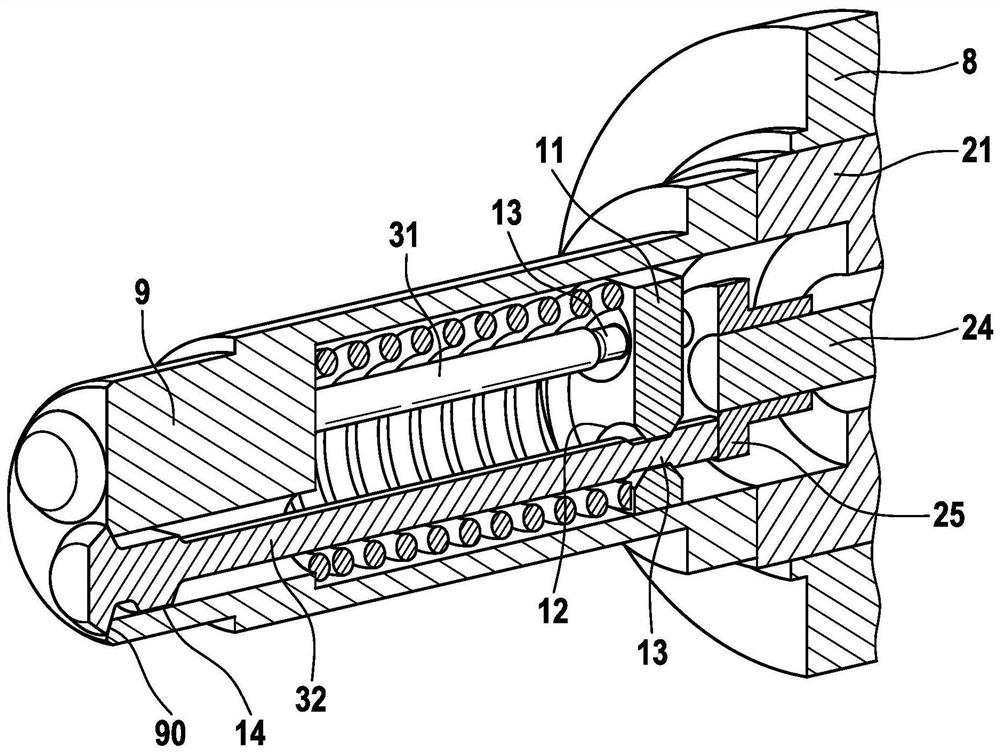

[0033] Below, refer to the attached Figures 1 to 4 , to describe in detail the gas injector 1 according to the first preferred embodiment of the present invention.

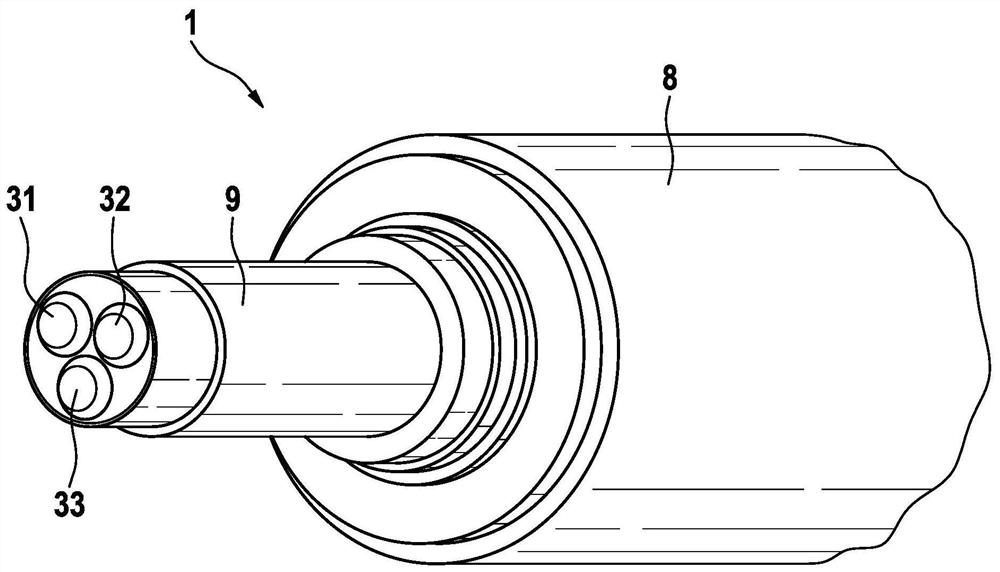

[0034] as from figure 1 As can be seen in the figure, a gas injector 1 for introducing gaseous fuel comprises an electromagnetic actuator 2 , which actuates three valve needles via an actuating unit 3 . as from figure 2 It can be seen that a first valve needle 31 , a second valve needle 32 and a third valve needle 33 are provided. The three valve needles are each arranged at a distance of 120° in the circumferential direction.

[0035] The three valve needles 31, 32, 33 are outwardly opening valve needles and as shown by figure 2 It can be seen that there are valve discs respectively. In this case, the valve disks of the valve needles 31 , 32 , 33 each have the same diameter.

[0036] Electromagnetic actuator 2 includes an armature 20 , which bears against three valve needles 31 , 32 , 33 by means of an a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com