Patents

Literature

31results about How to "Realize automatic unwinding" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

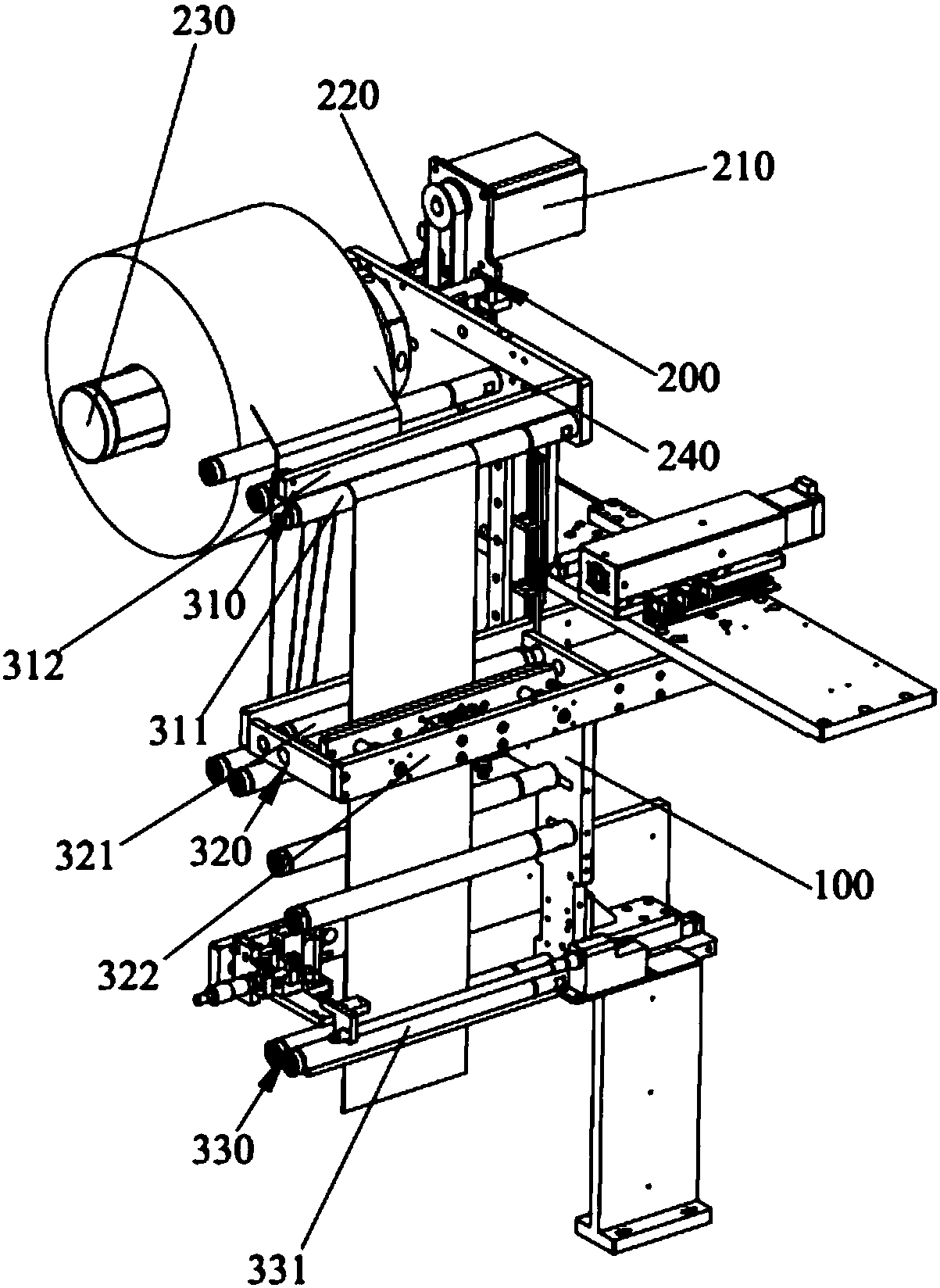

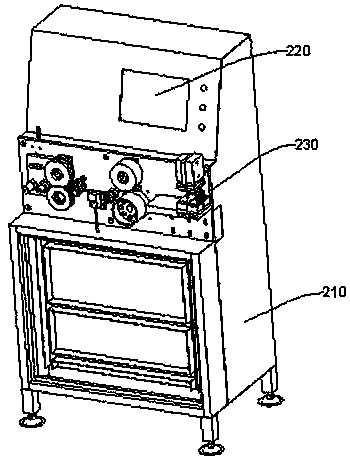

Adhesive tape sticking device

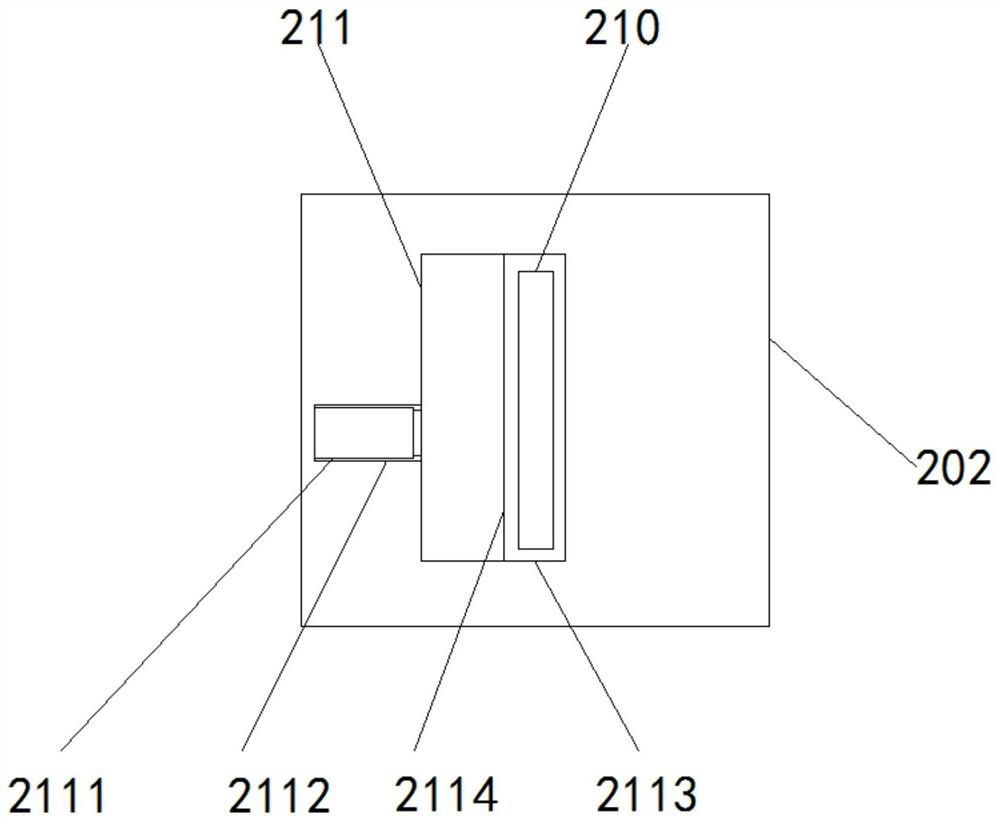

ActiveCN104192624ARealize automatic unwindingRealize automatic bondingFinal product manufactureArticle deliveryAdhesive beltIdler-wheel

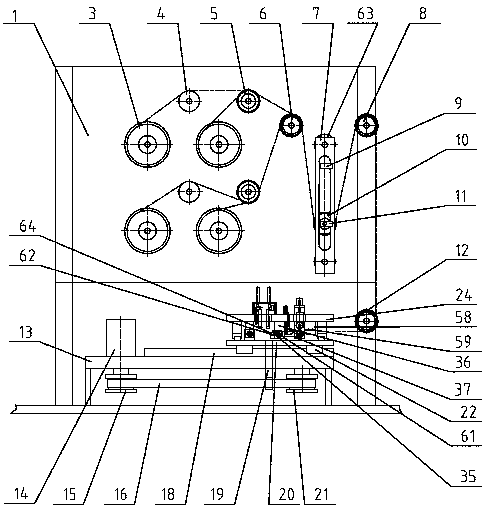

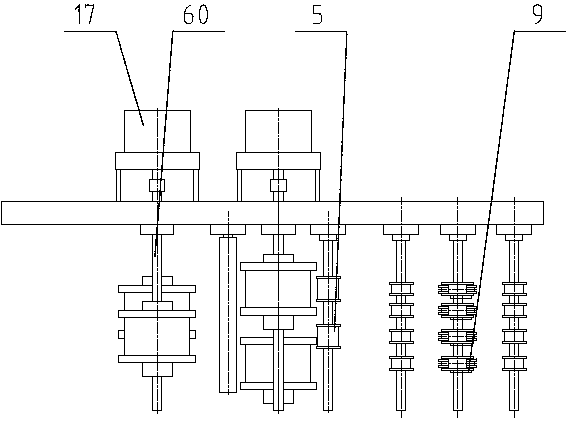

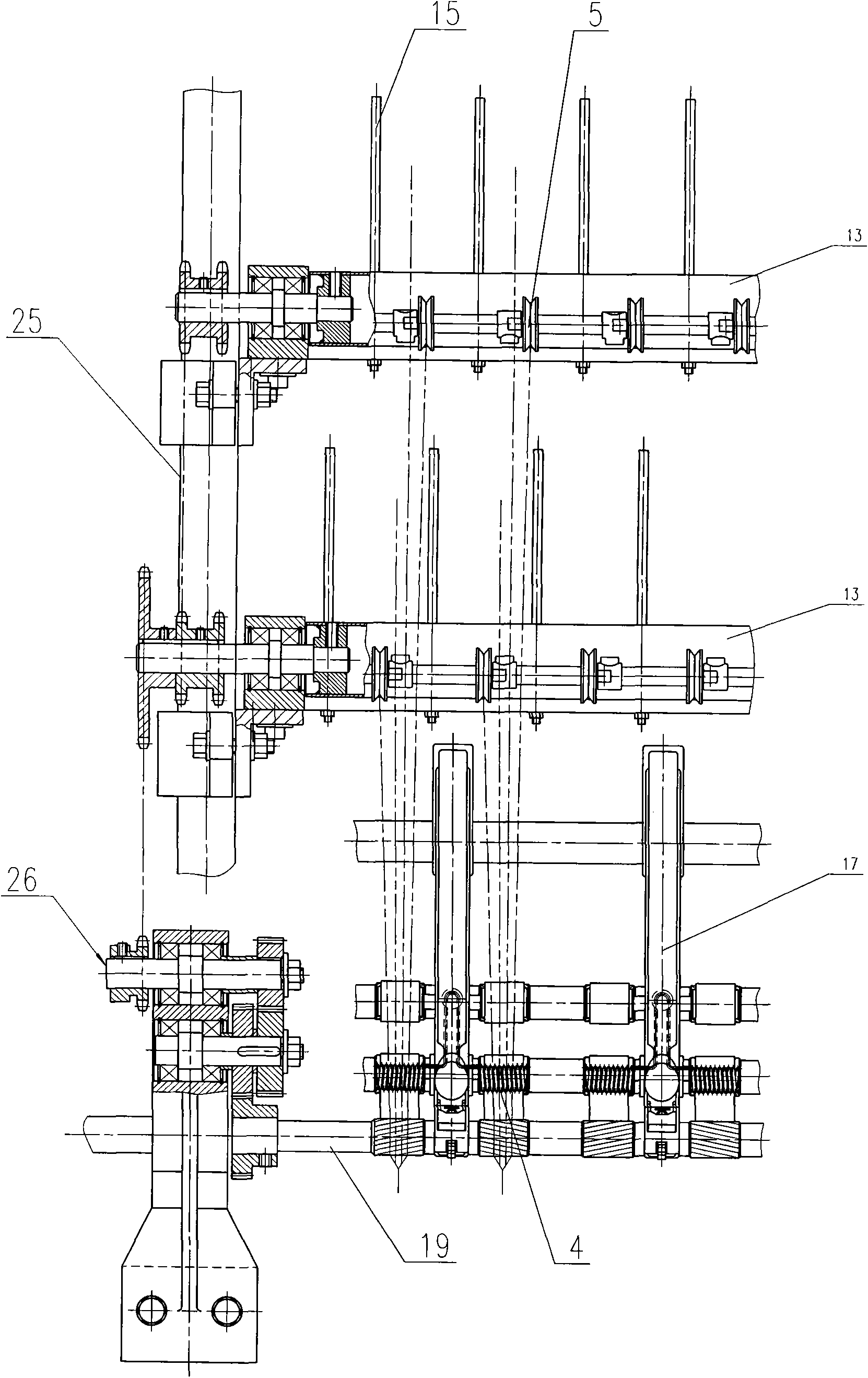

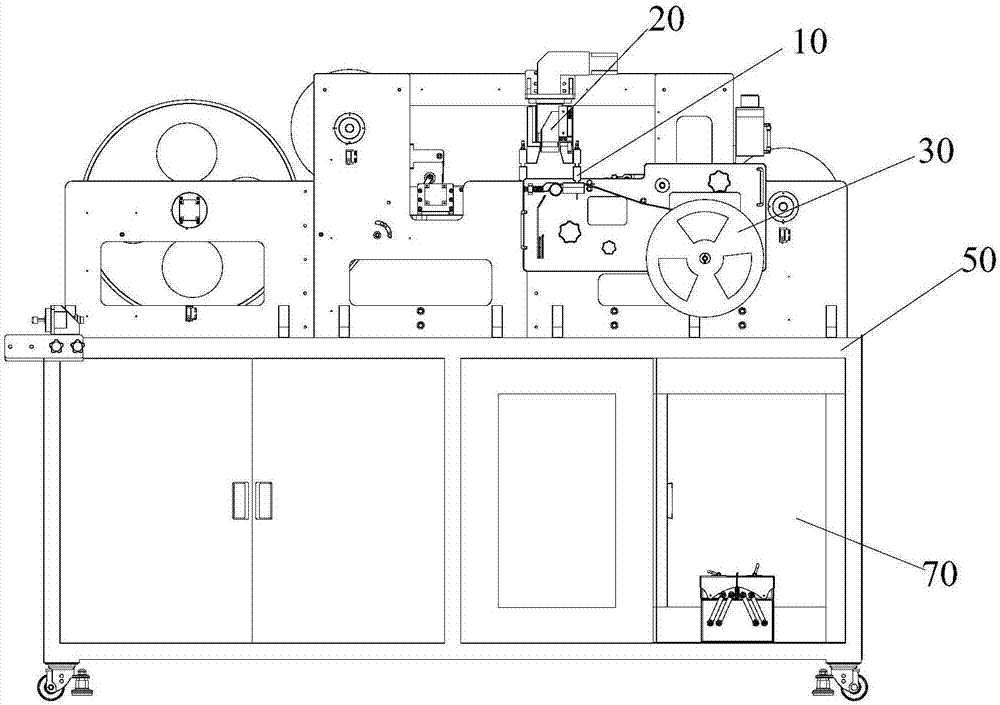

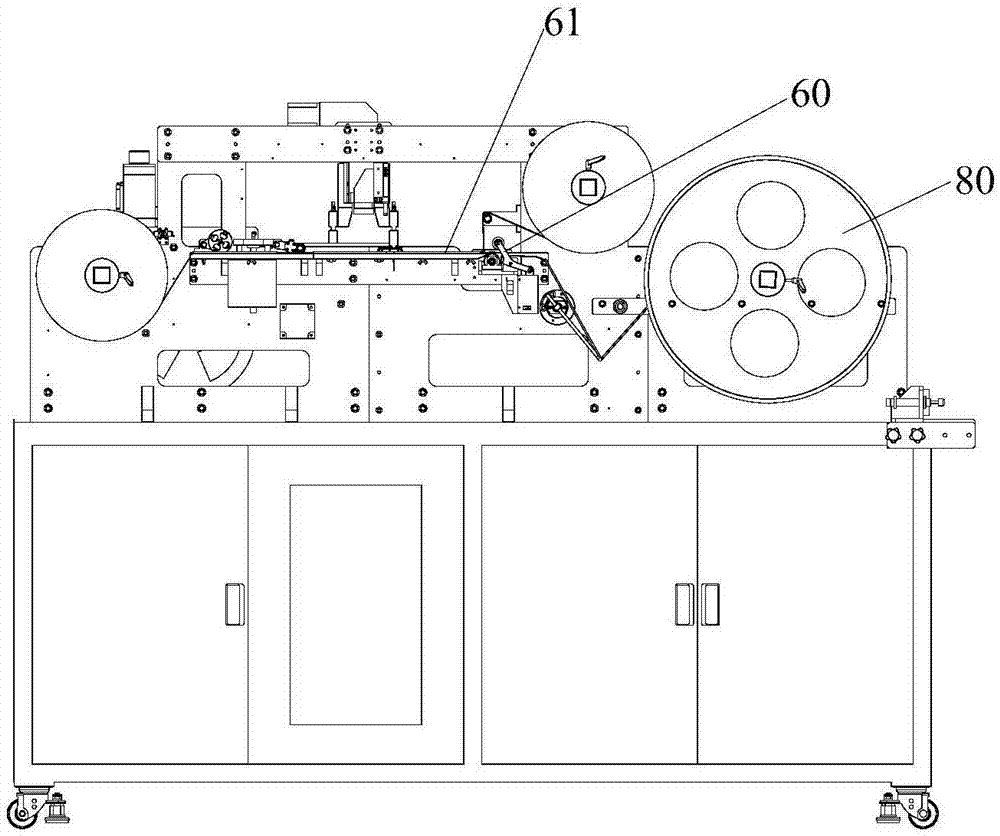

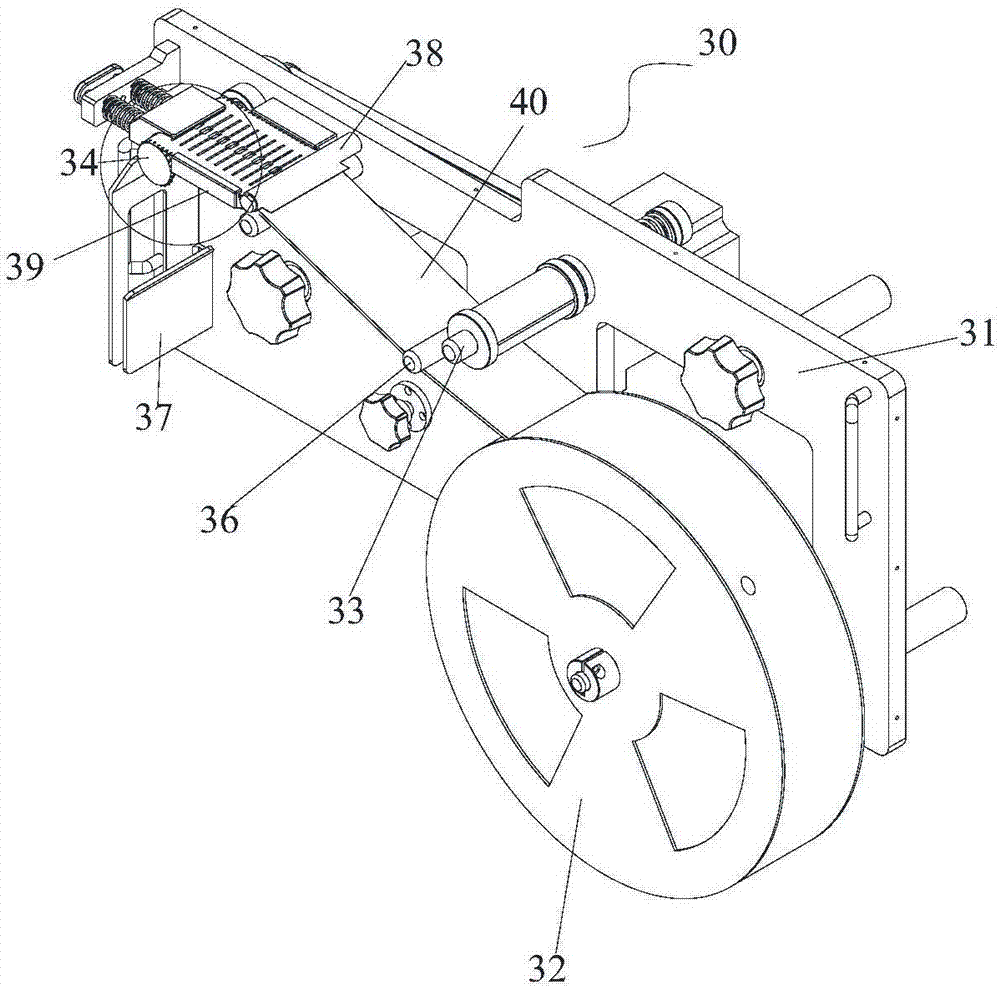

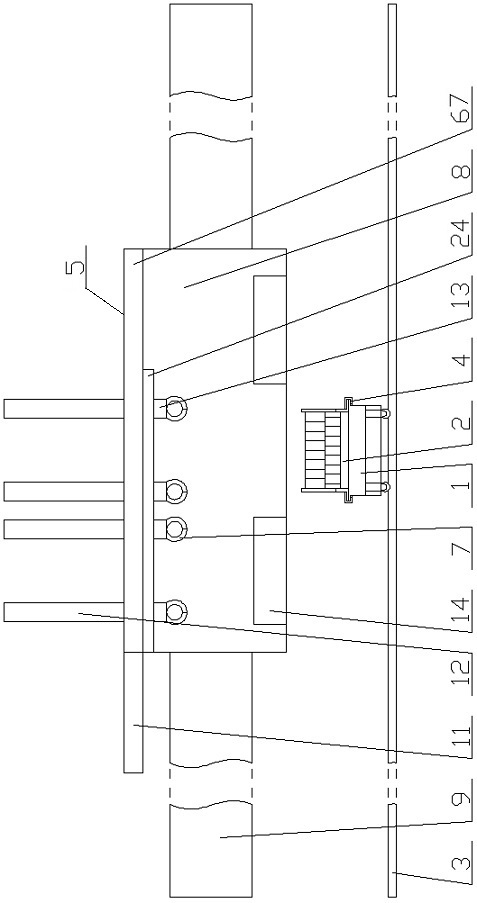

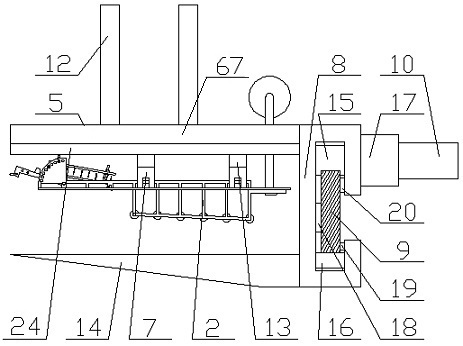

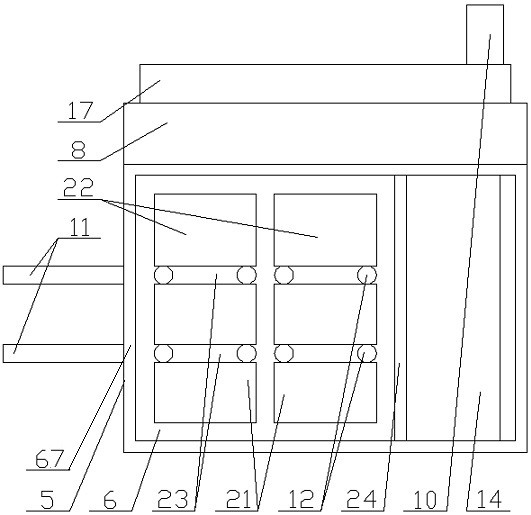

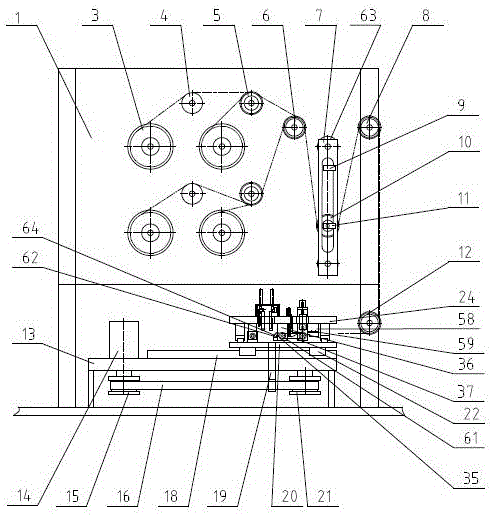

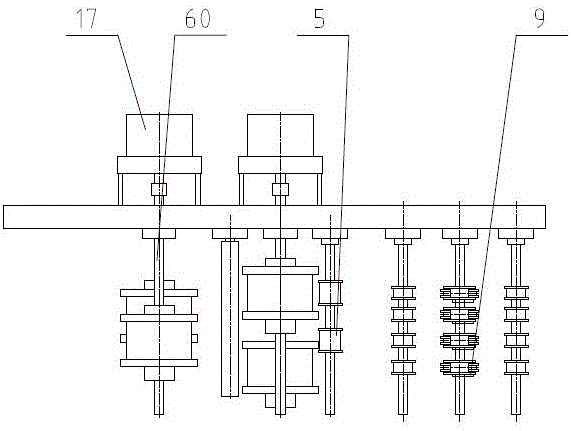

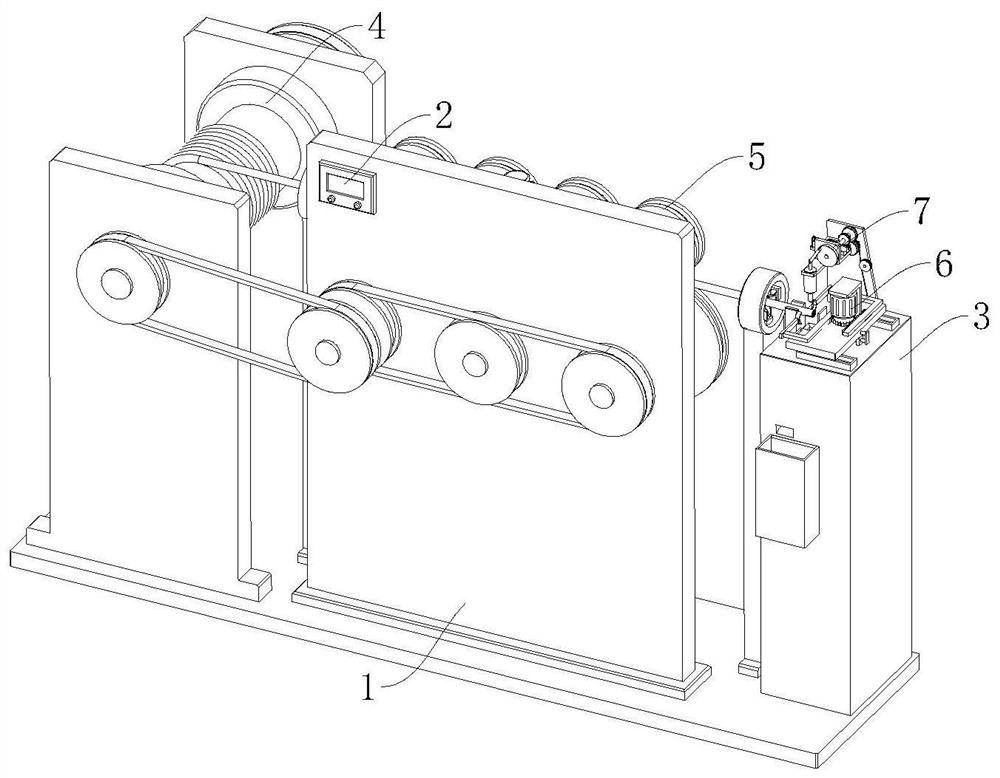

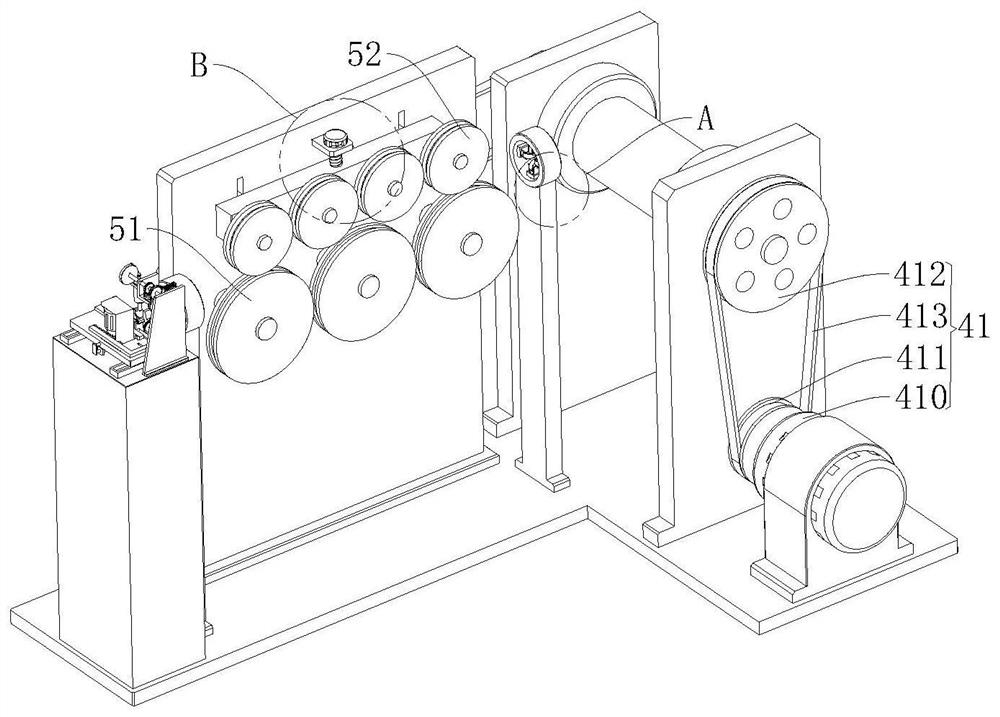

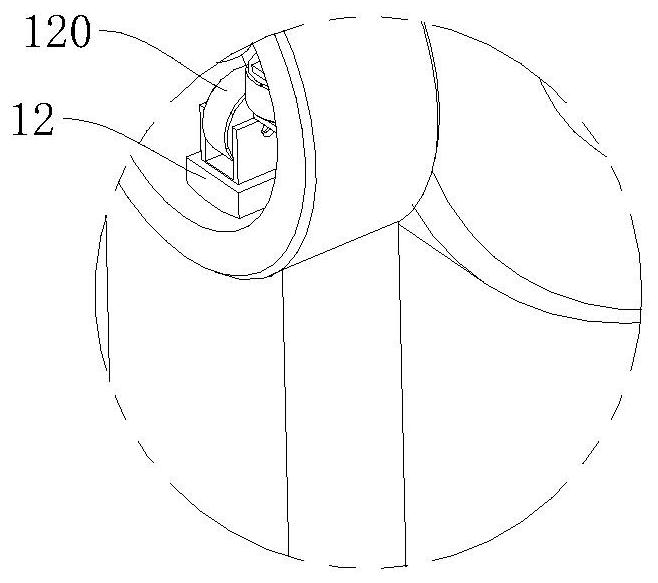

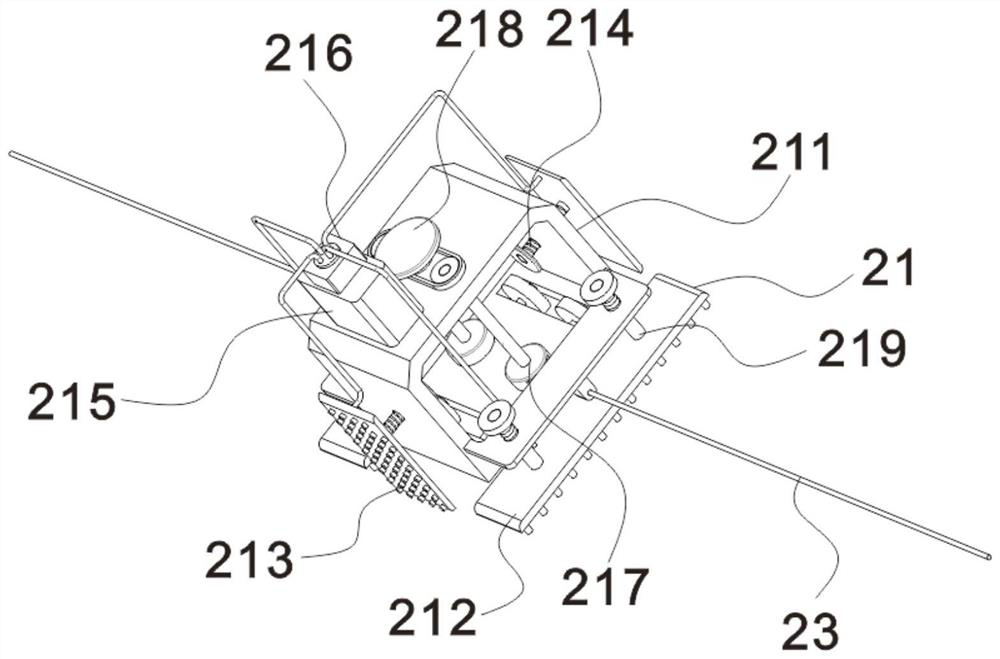

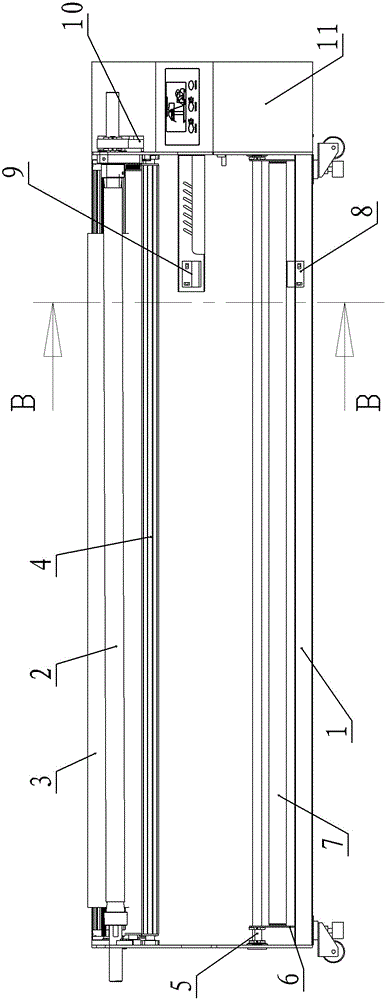

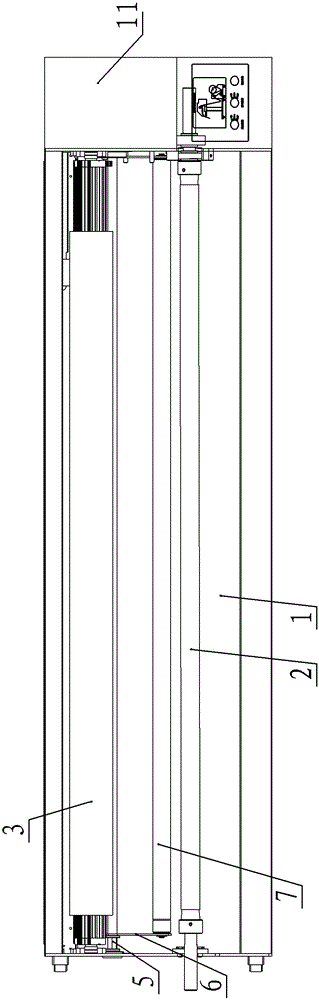

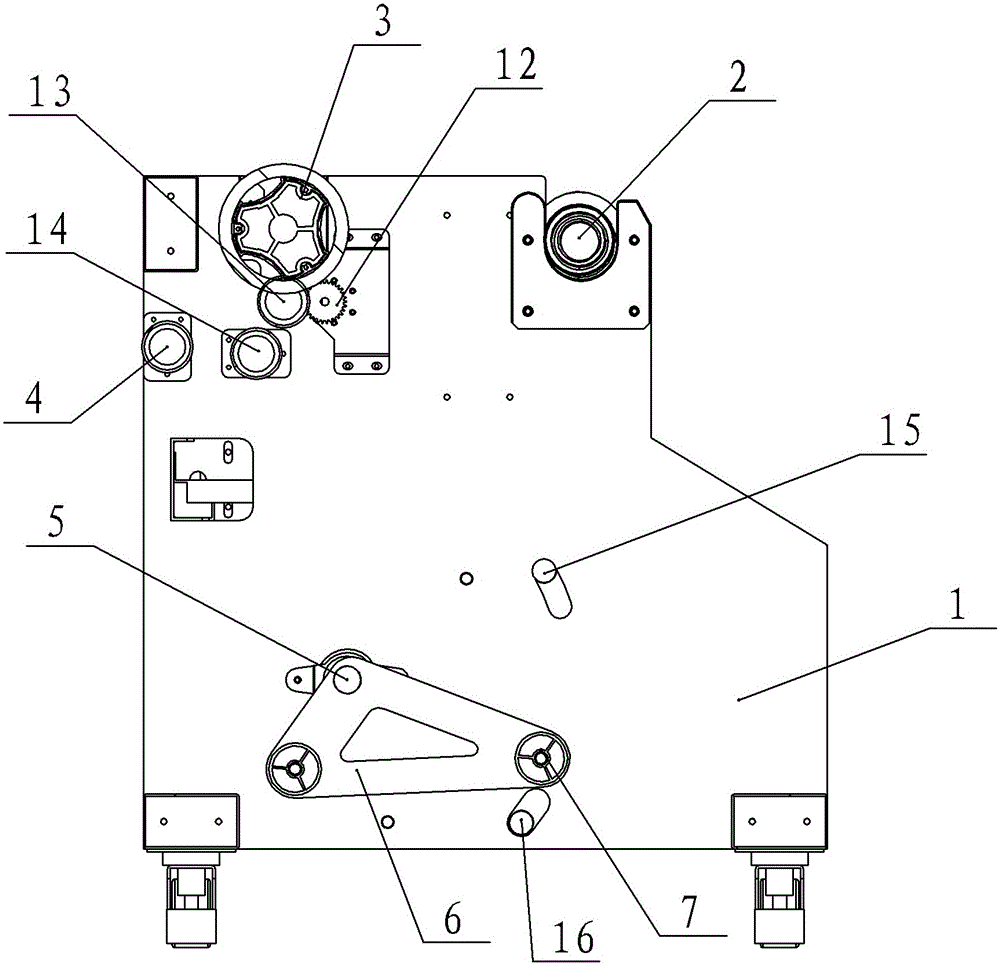

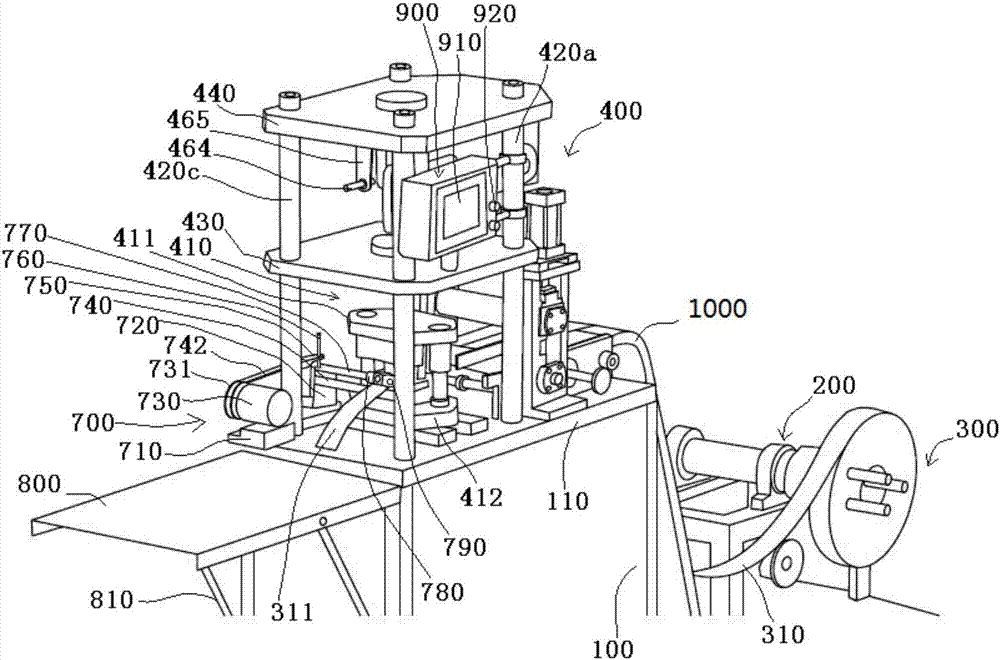

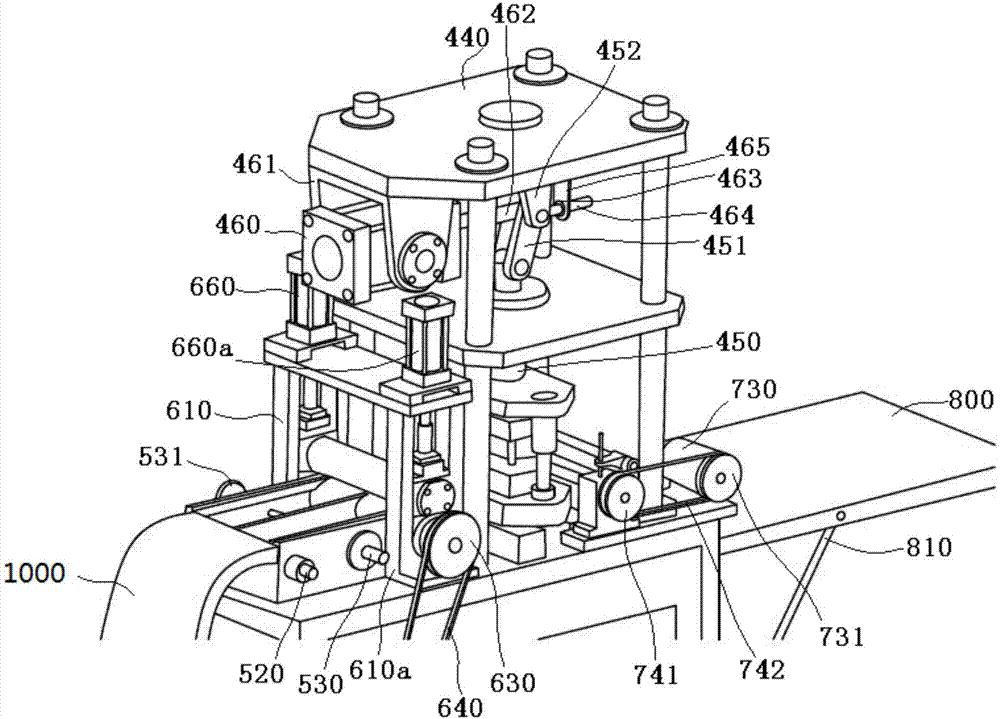

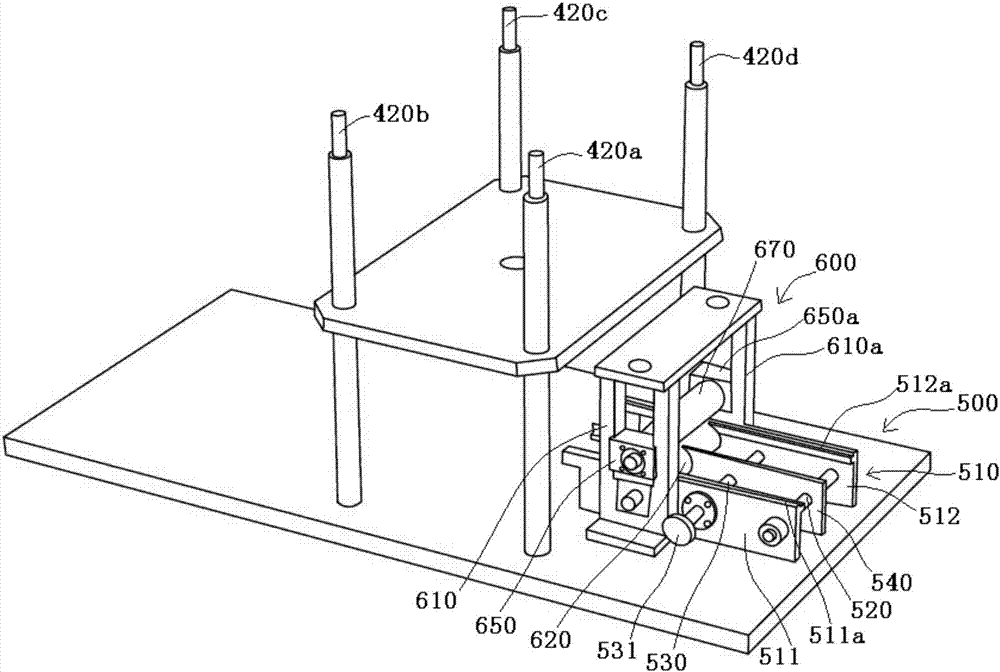

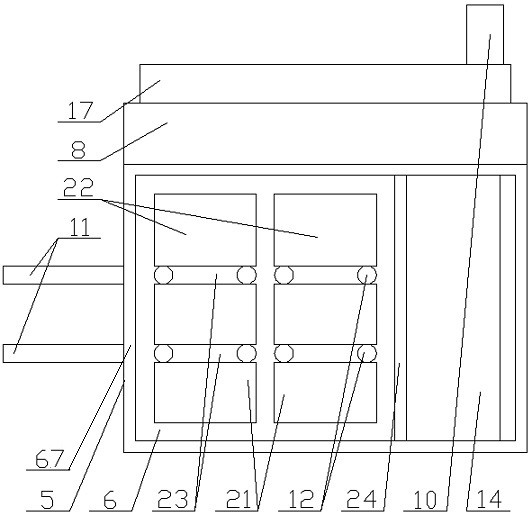

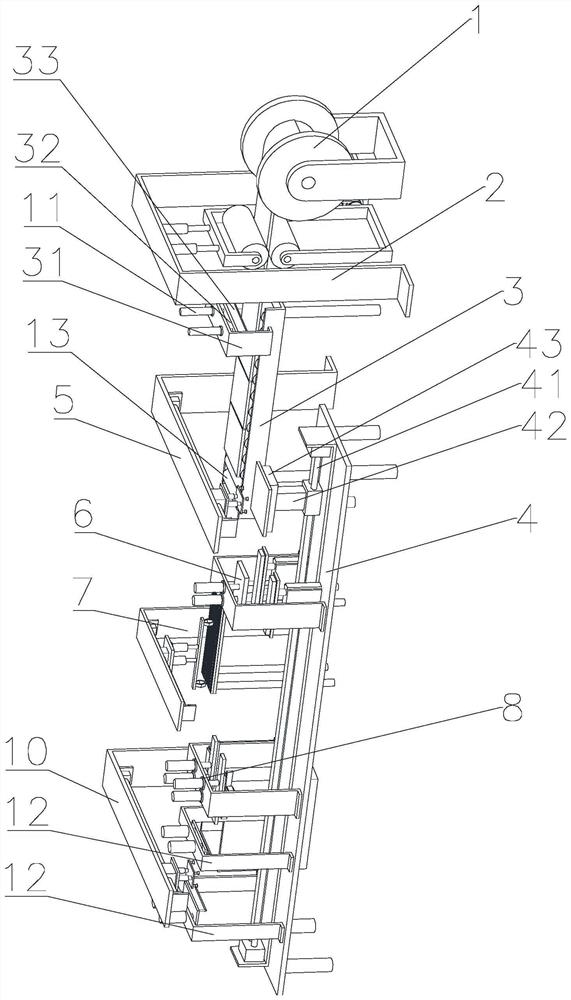

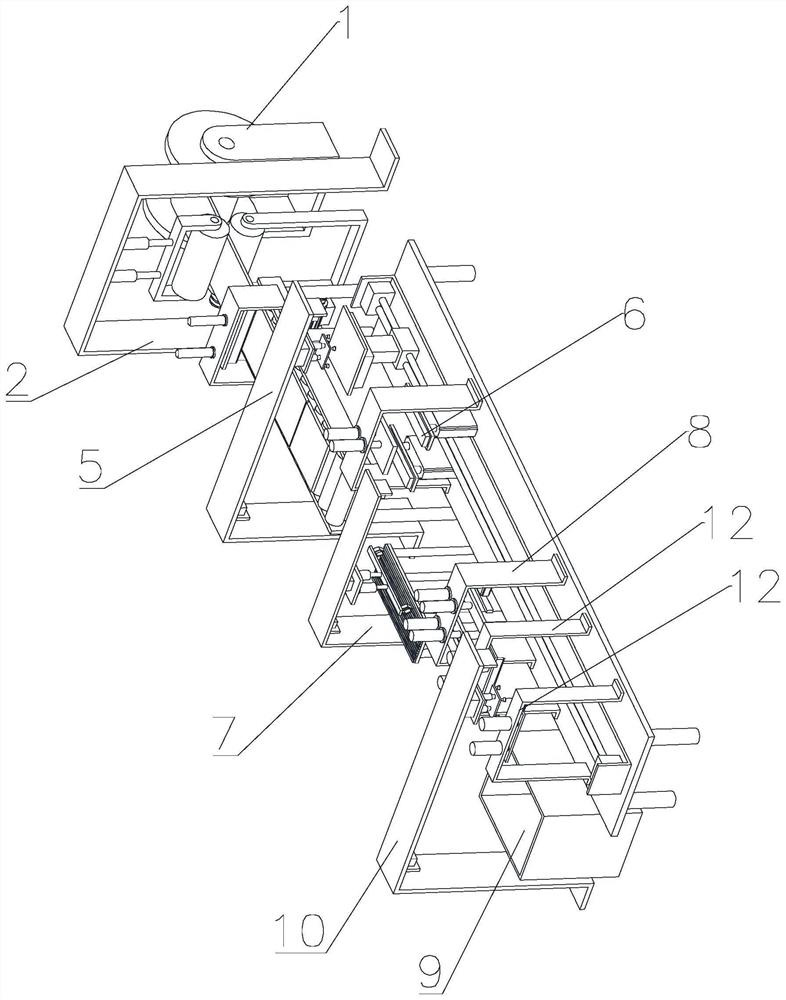

The invention relates to an adhesive tape sticking device. The adhesive tape sticking device comprises a machine frame, an adhesive tape paying-off device, an adhesive tape driving device, an adhesive tape cutting deice, an adhesive tape adsorption device, a press wheel device and a conveying device, wherein the adhesive tape paying-off p device and the conveying device are arranged on the machine frame, the adhesive tape paying-off device comprises an adhesive tape paying-off mechanism and an adhesive tape conveying mechanism, the conveying device comprises a first installation plate and a first movement mechanism, a second installation plate is arranged on the first installation plate, the adhesive tape driving device is fixed to the second installation plate, and the adhesive tape adsorption device and the press wheel device are fixedly arranged on the rear side of the adhesive tape driving device sequentially. The adhesive tape cutting device is arranged between a seventh idler wheel and a ninth idler wheel and comprises a fourth air cylinder, a cutter connecting plate, a cutter and a guide seat. The adhesive tape sticking device can automatically stick adhesive tape to a welding strip of a battery piece, and improve the conversion efficiency of a battery string.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Cloth laser printing machine

PendingCN110171209ARealize automatic unwindingImprove efficiencyPrintingWebs handlingFree stateAutomation

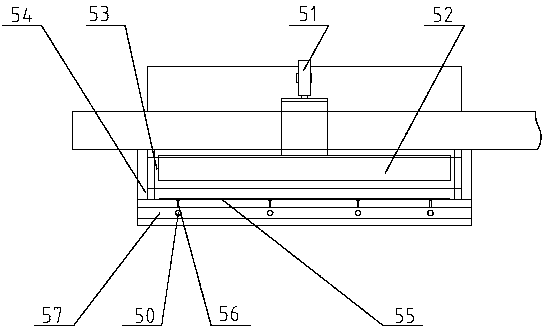

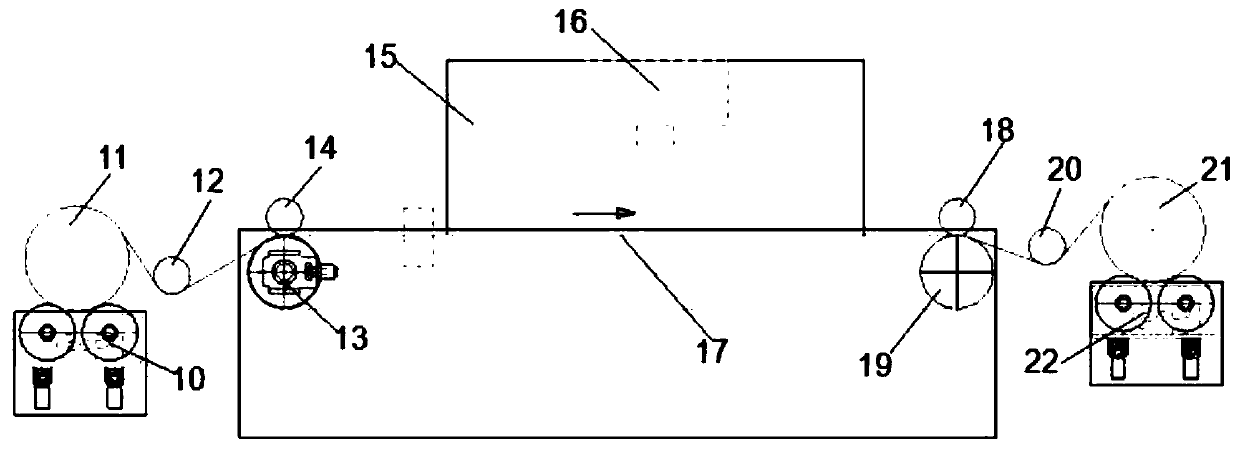

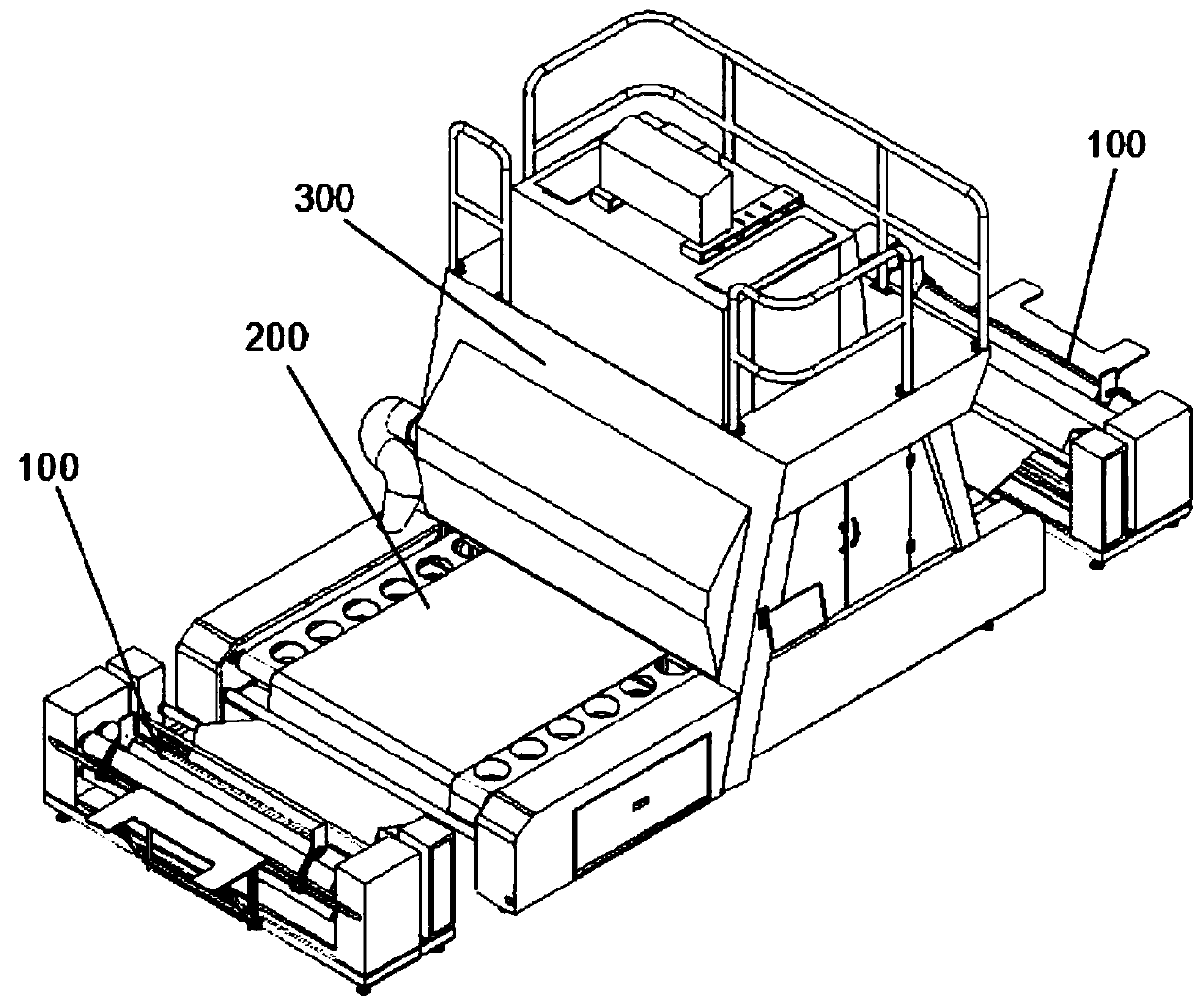

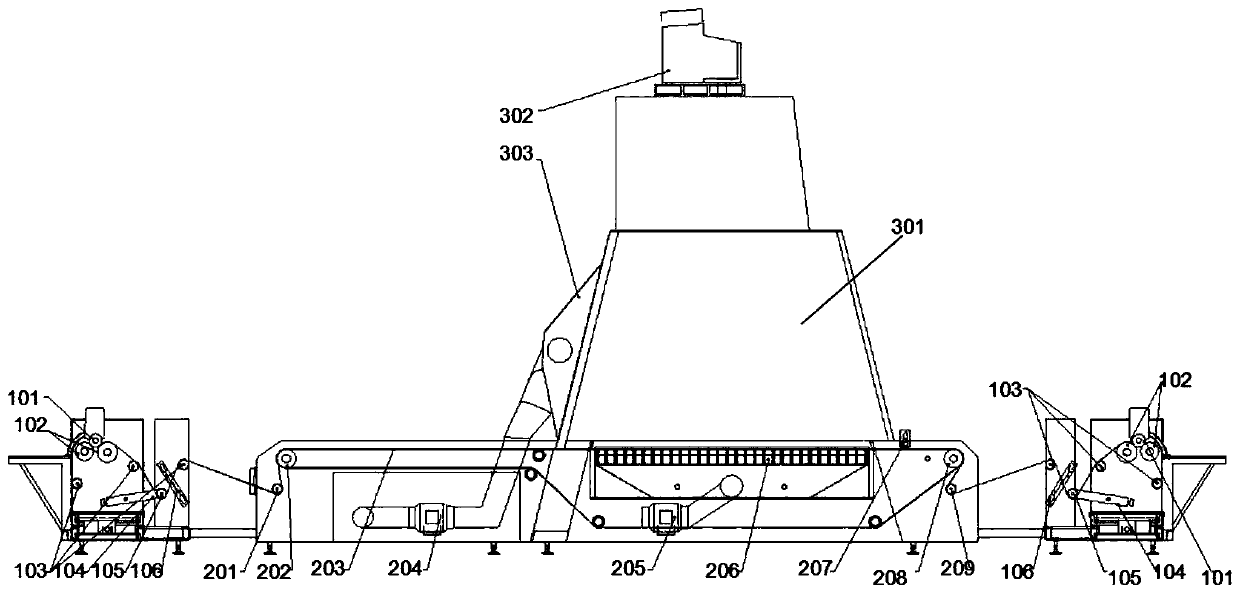

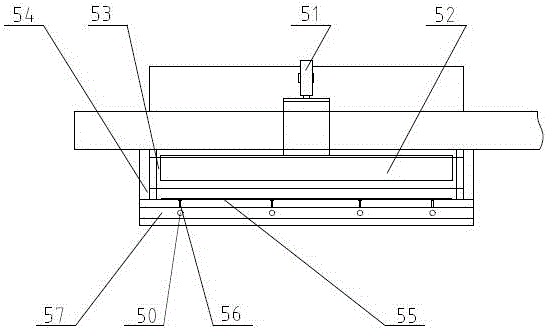

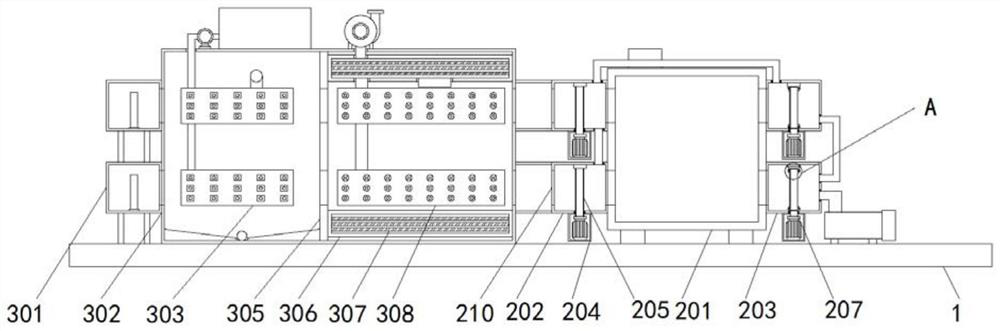

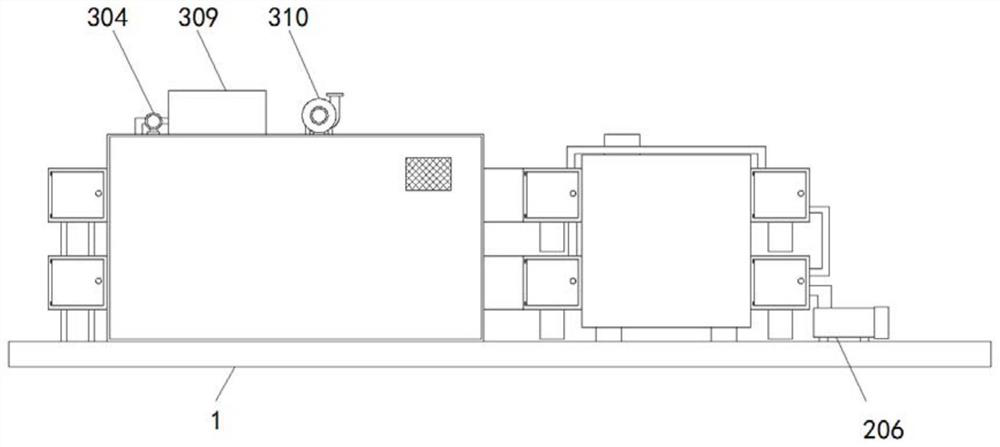

The invention provides a cloth laser printing machine. The machine comprises two symmetrically arranged cloth winding / unwinding devices, a vacuumizing conveying device and a laser printing device, wherein the cloth winding / unwinding devices comprise winding / unwinding rollers arranged on a winding / unwinding rack, a plurality of cloth winding / unwinding guide rollers arranged behind the winding / unwinding rollers, tension adjusting rollers arranged between the cloth winding / unwinding guide rollers correspondingly, cloth winding / unwinding tension adjusting mechanisms which are arranged on one side of the tension adjusting rollers correspondingly and are used for adjusting the tension of the tension adjusting rollers, and center deviation correcting mechanisms which are arranged on one side of the tension adjusting rollers correspondingly; the vacuumizing conveying device is arranged between the cloth winding / unwinding devices which are symmetrically arranged; and the laser printingdevice is arranged on the vacuumizing conveying device. The cloth laser printing machine is flexible in production and high in automation degree, the longitudinal tension of cloth in the moving process can be reduced and eliminated, accurate laser printing can be carried out on various types of cloth in a tension-free state or a micro-tension state, and the printing precision and efficiency are improved.

Owner:广州市森特自动化控制技术有限公司

Embedded compound spinning frame and spinning method thereof

InactiveCN101956255AReduce force requirementsGood evenness indexContinuous wound-up machinesFiberYarn

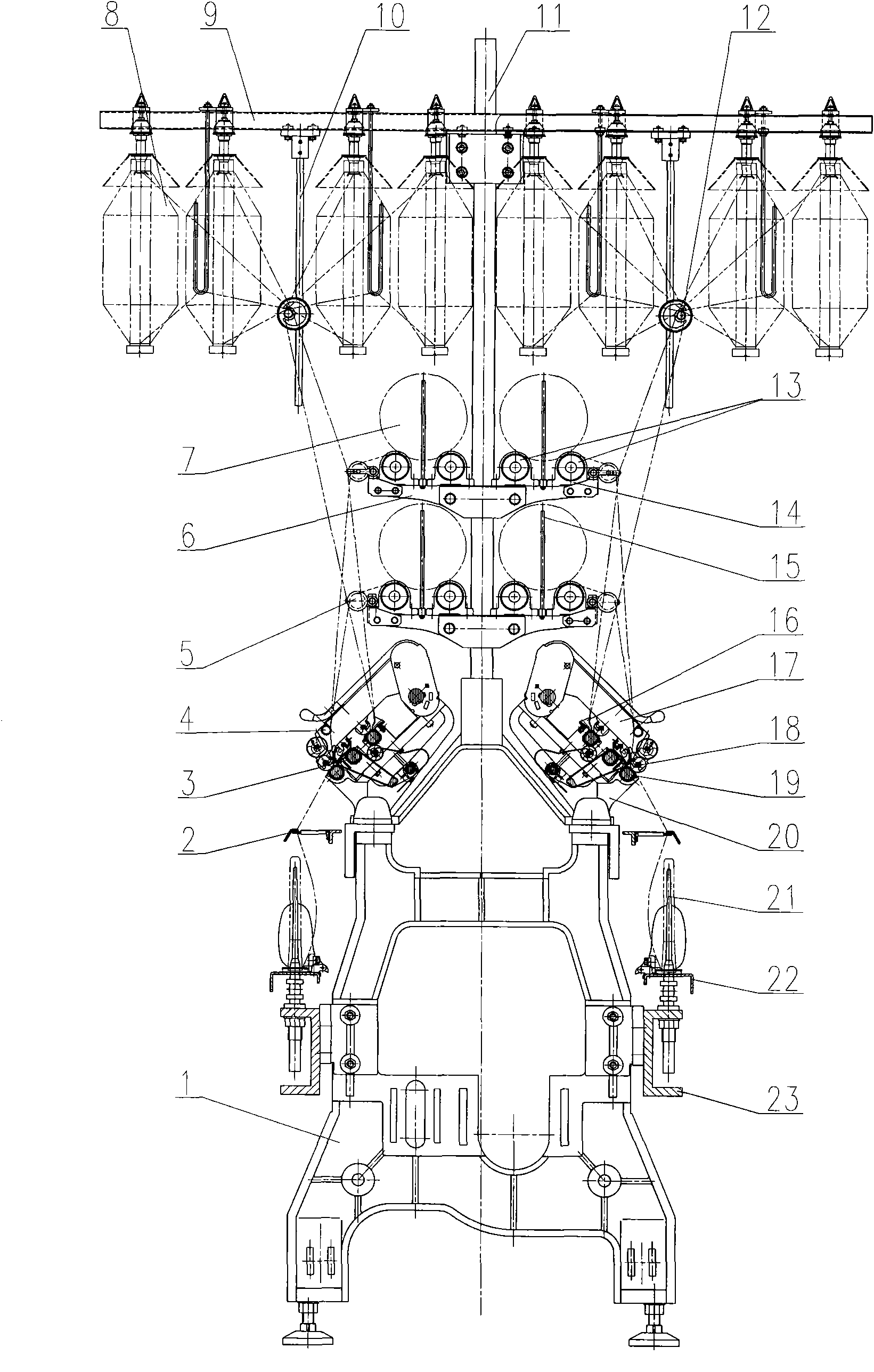

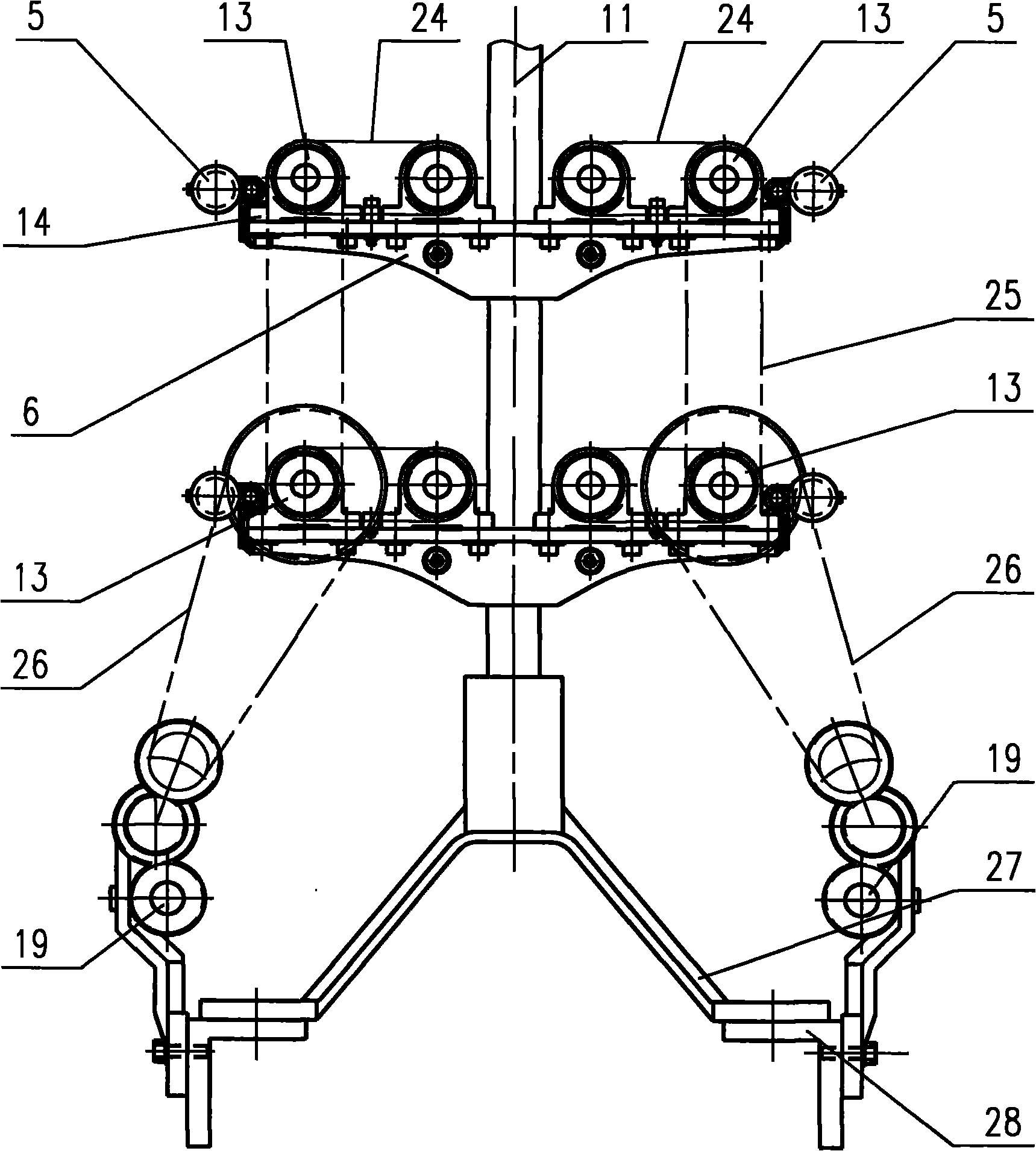

The invention discloses an embedded compound spinning frame. Two layers of unwinding brackets and four parallel unwinding rollers are arranged on an upright post of a creel; the unwinding rollers positioned on the same side of the unwinding brackets mutually drive and are connected by a vertical driving pair of the unwinding rollers; and at least one unwinding roller in the unwinding rollers on the same side of the unwinding brackets is in driving connection with a front roller of a drawing mechanism through an unwinding roller driving device. When in spinning, two rovings hung on the creel respectively enter a drawing area of the drawing mechanism in parallel through roving horn mouths for drawing; two unwound filaments roll from different unwinding rollers and respectively enter the rear side of a tong port of the front roller of the drawing mechanism through a filament guider; and the two filaments and two drawn rovings are combined on the rear side of the tong port of the same front roller, output and twisted from the front side of the tong port of the front roller and wound on a spinning tube of a spindle. The invention not only can conveniently spin short fibers and other low-grade raw materials, but also has the advantages of abundant yarn type structures, dry resultant slivers and superior filoplume indexes.

Owner:DONGFEI MAZUOLI TEXTILE MACHINERY +1

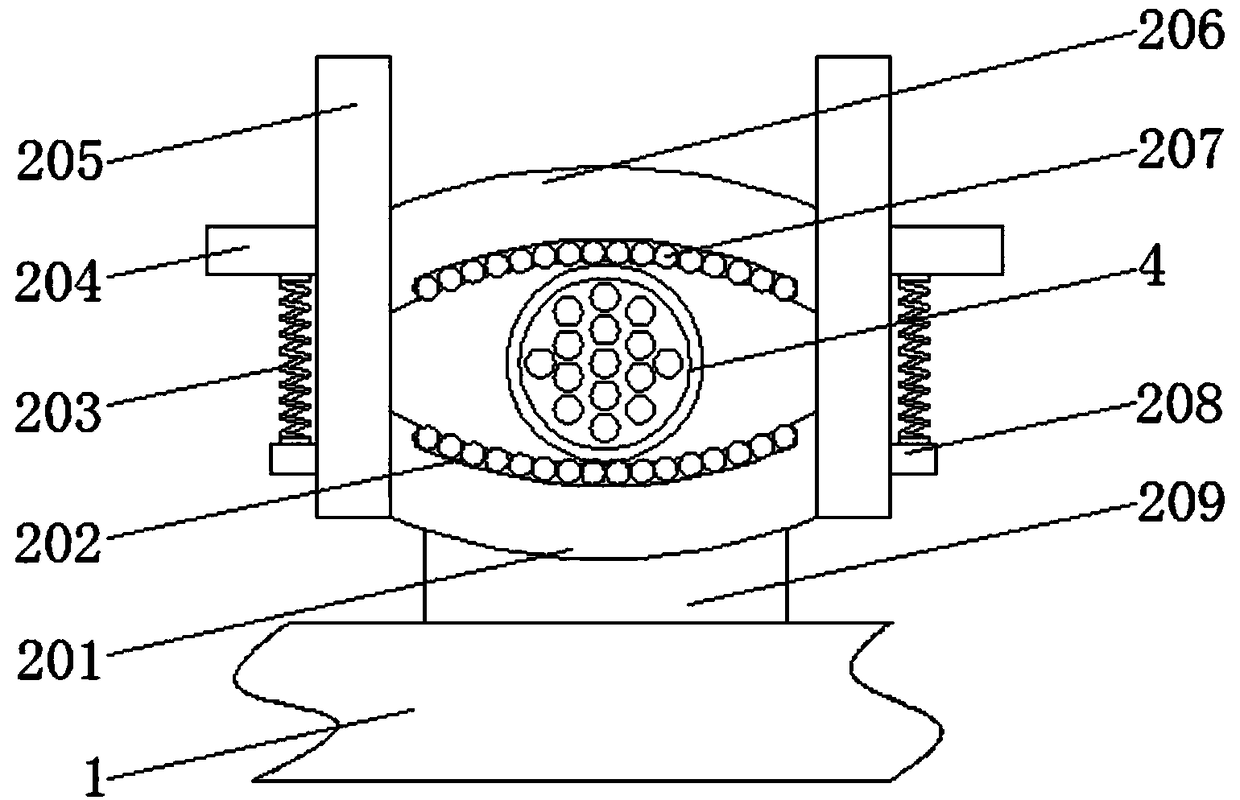

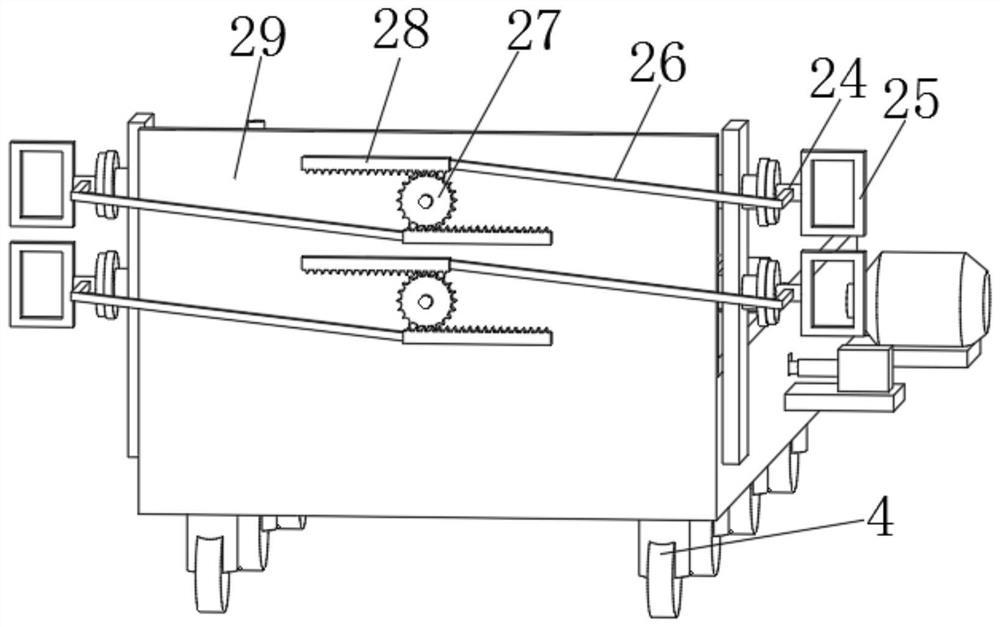

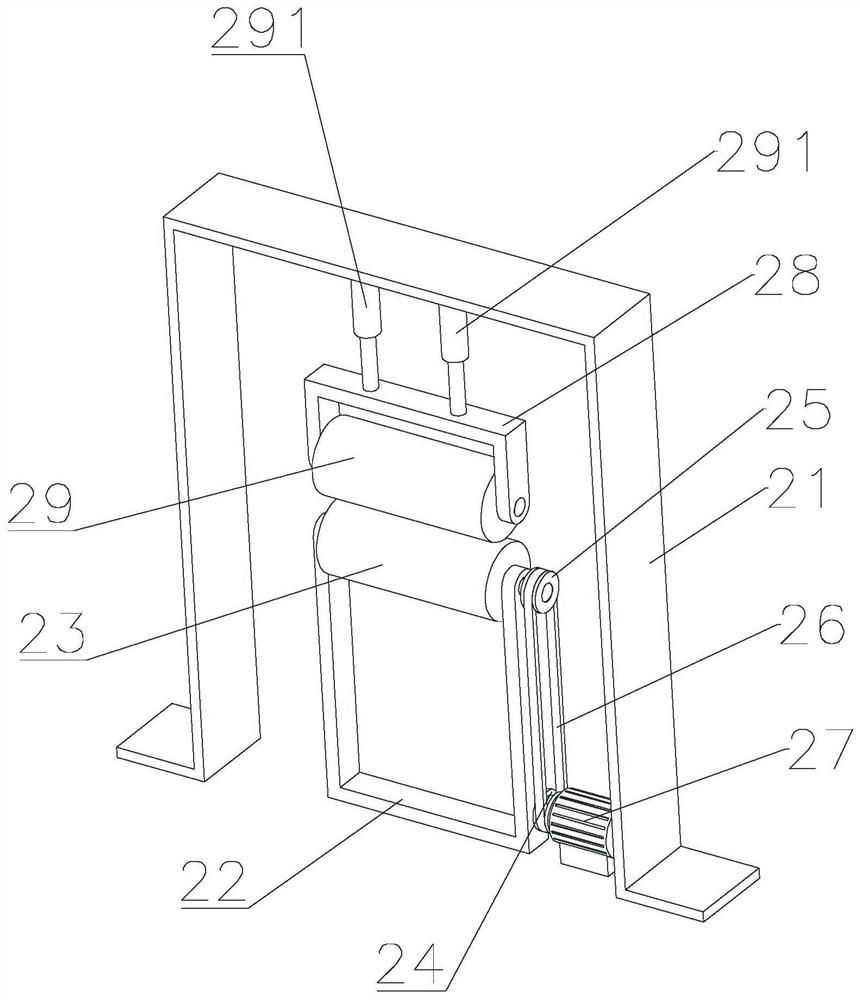

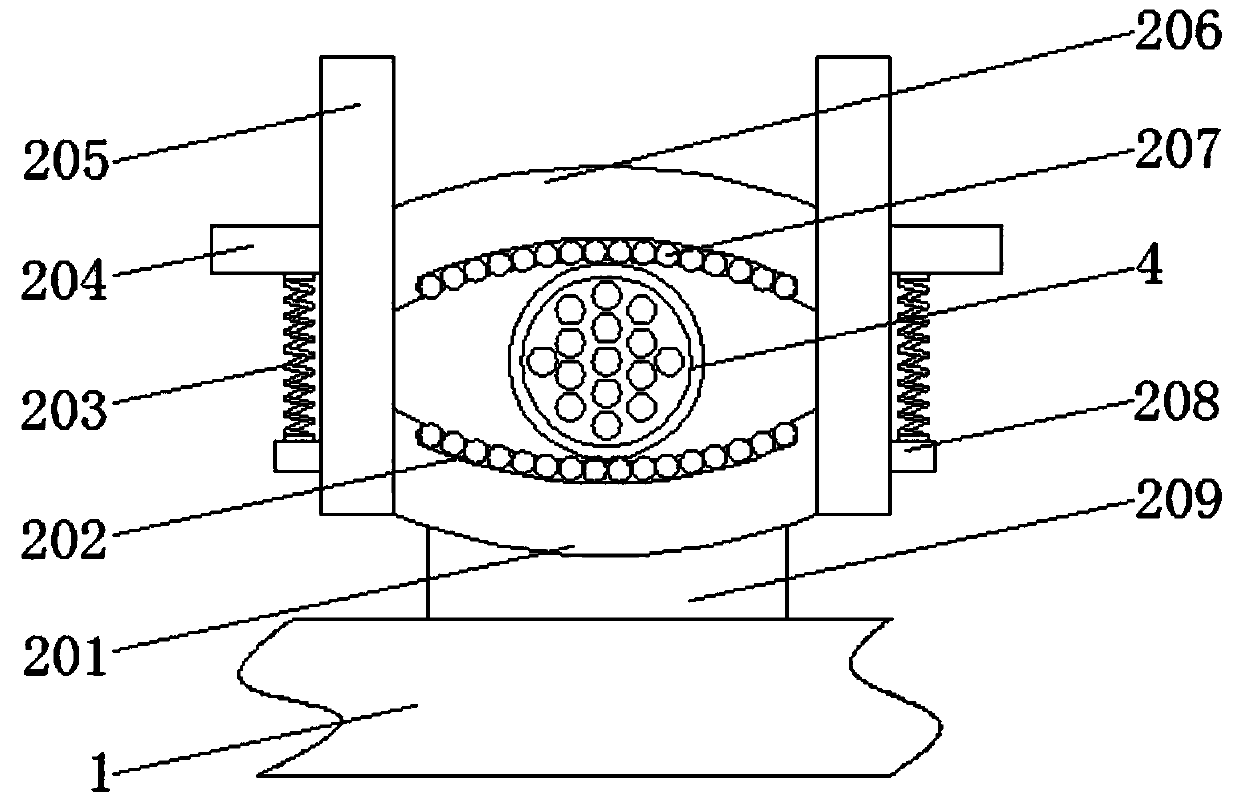

Tension-free leather unwinding device with dust removal function

ActiveCN103318671ARealize automatic unwindingImprove dust removal effectCleaning using toolsWebs handlingEngineeringMechanical engineering

A tension-free leather unwinding device with a dust removal function comprises a framework, a load bearing roller, a driving roller and a dust adhering roller. The load bearing roller, the driving roller and the dust adhering roller are arranged on the upper portion of the framework, the driving roller and the dust adhering roller are mounted in such a manner that the surface of the driving roller is tangent to the surface of the dust adhering roller, an upper leather detection probe and a lower leather detection probe are arranged on the outer side of the framework and are positioned on the lower portion of the driving roller, and shaft ends of the driving roller and shaft ends of the load bearing roller are respectively connected with driving mechanisms; an adjusting mechanism is further arranged on the lower portion of the framework and comprises a swing frame, a fixing roller and an adjusting roller, the fixing roller is mounted on the framework, the swing frame is sleeved on the fixing roller, the adjusting roller is mounted at the other end of the swing frame and can axially swing around the fixing roller along with the swing frame, and an upper adjusting roller detection probe and a lower adjusting roller detection probe are arranged on the framework and are positioned on a movement track of the adjusting roller; leather is mounted on the load bearing roller, is downwardly wound around the adjusting roller, then is bent upwards and penetrates a gap between the driving roller and the dust adhering roller. The tension-free leather unwinding device has the advantages that the leather can be automatically unwound in a tension-free manner, dust can be automatically removed when the leather is unwound, and a dust removal effect is good.

Owner:NEW CENTURY DIGITAL PRINT TECH

RFID electronic label laminating equipment for tires

PendingCN107973163AGood consistencyImprove efficiencyTyresRecord carriers used with machinesEngineeringRubber material

The invention provides RFID electronic label laminating equipment for tires. The laminating equipment comprises a rack, a feeding mechanism arranged on the rack and a laminating mechanism arranged onthe rack. The laminating mechanism is used for pressing rubber materials and electronic chips of materials to be conveyed from the feeding mechanism. The feeding mechanism comprises a bracket, a rolling portion arranged on the bracket and a driving wheel rotationally arranged on the bracket. One ends of the materials to be conveyed are arranged on the rolling portion and the other ends of the materials to be conveyed are matched with the driving wheel so that the materials to be conveyed can be moved under the drive of the driving wheel. By the adoption of the technical scheme, the problem that manual feeding efficiency is low in the prior art can be solved.

Owner:QINGDAO HIGHWAY IOT TECH CO LTD +1

Cable anti-winding collecting device

The invention discloses a cable anti-winding collecting device comprising a base; the top portion of the base is connected with an anti-winding device through a sliding groove in a sliding mode; one side of the top portion of the base is fixedly connected with a rotating support; the end face of the rotating support is provided with a collecting roller in a sleeving mode; one side of the collecting roller is rotatably connected with a handle; the anti-winding device comprises a sliding rail; the surface of the sliding rail is connected with the sliding groove in a sliding mode; the top portionof the sliding rail is fixedly connected with a supporting arc; two sides of the supporting arc are both fixedly connected with fixed supports; and the surfaces of the fixed supports are provided with spring-back sliding grooves. The invention relates to the technical field of cable machinery tool. According to the cable anti-winding collecting device, the anti-winding device straightens the winding inner diameter of a cable insulation layer by squeezing, the winding degree of the cable is relieved, balls can effectively defuse extrusion force on the cable surface, the cable is prevented fromirreversibly deforming and causing damage, the collecting operation is more smooth by the balls, and effort is saved.

Owner:温州拓远电气有限公司

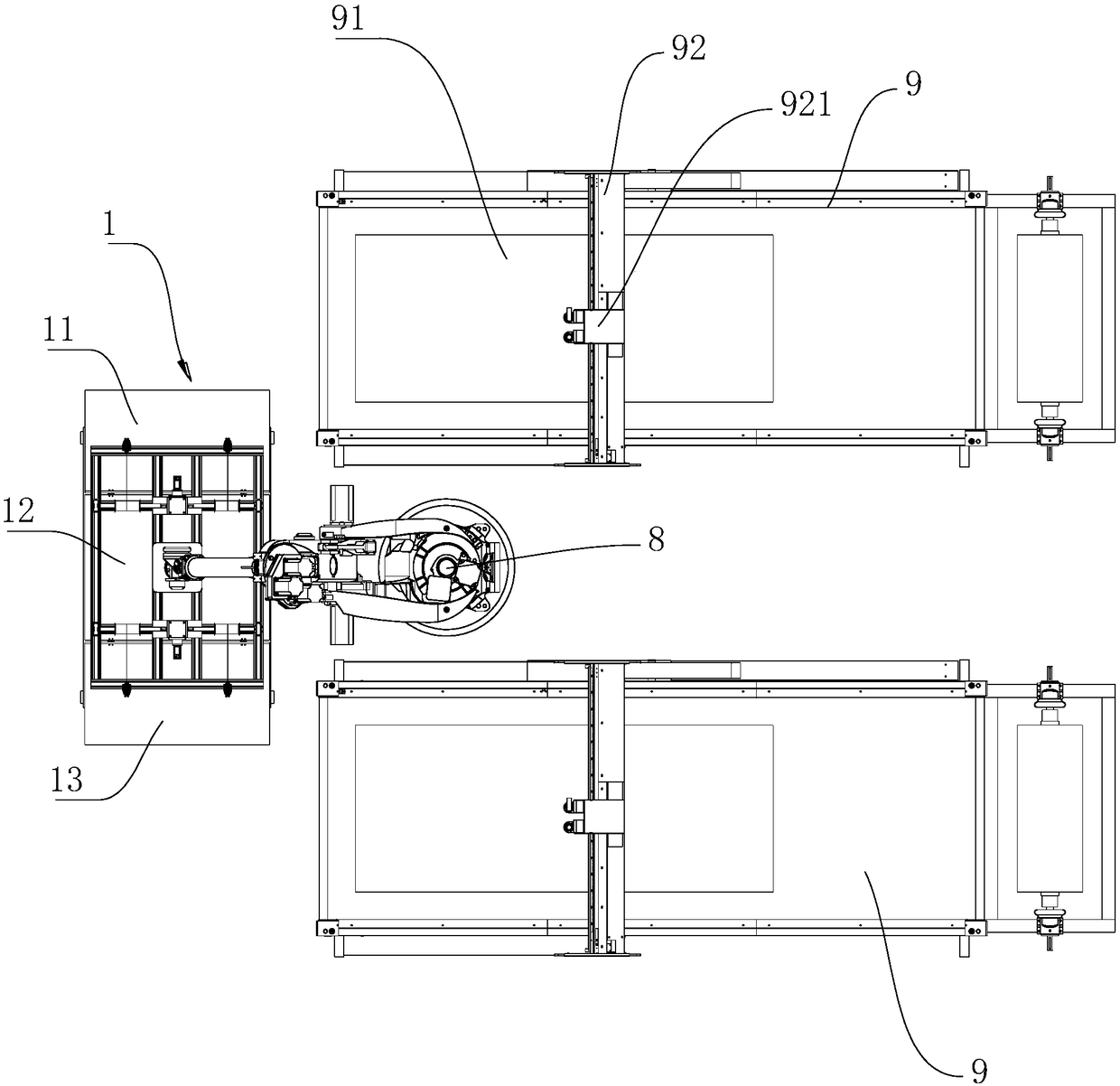

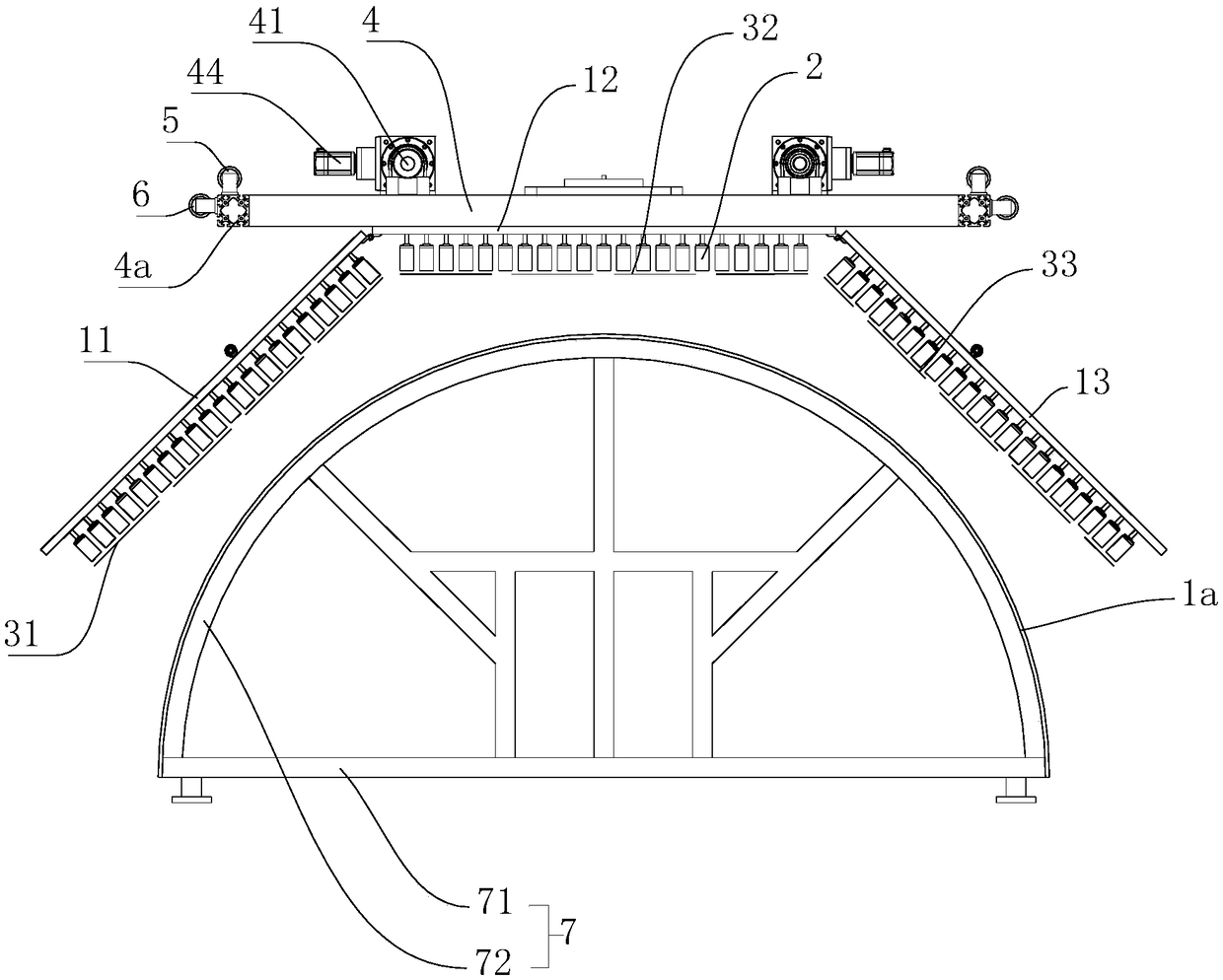

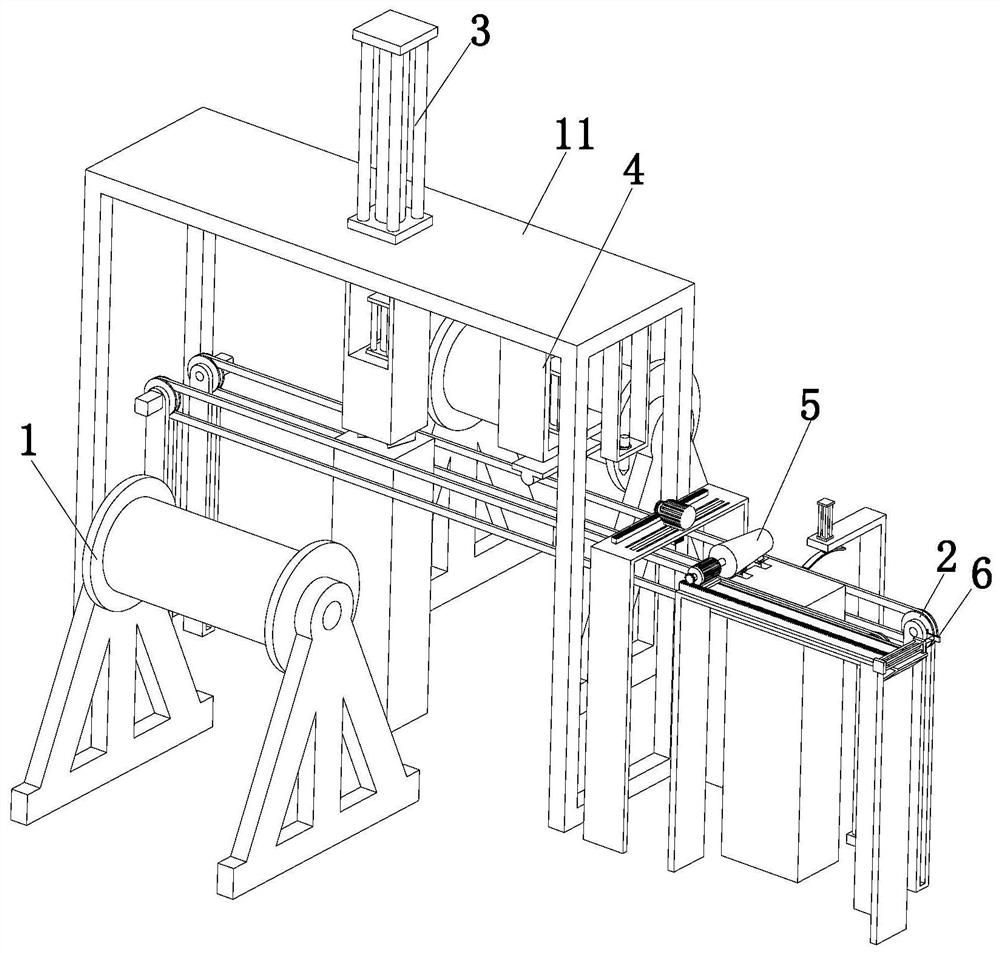

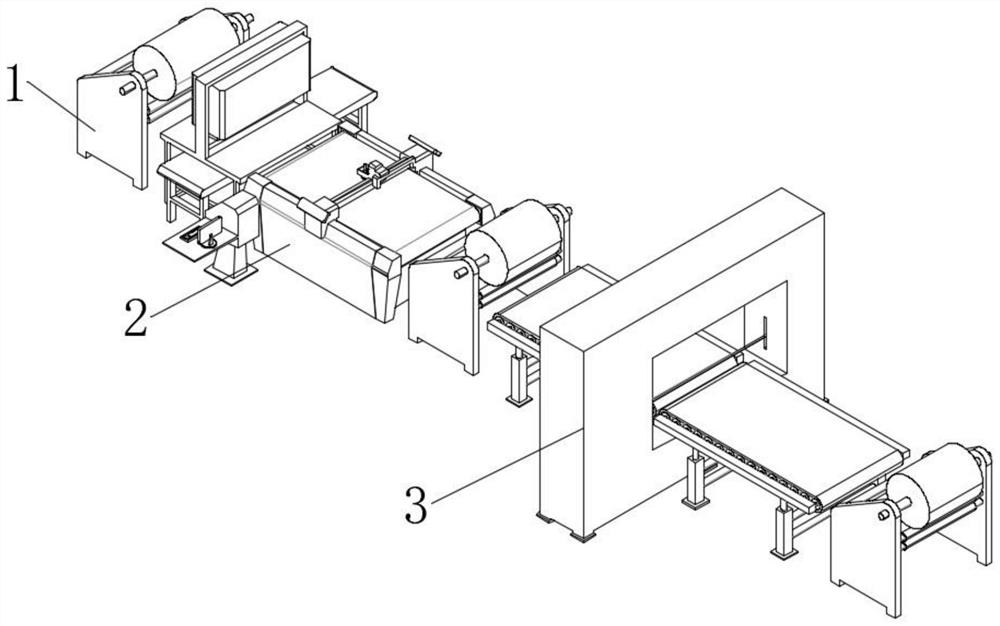

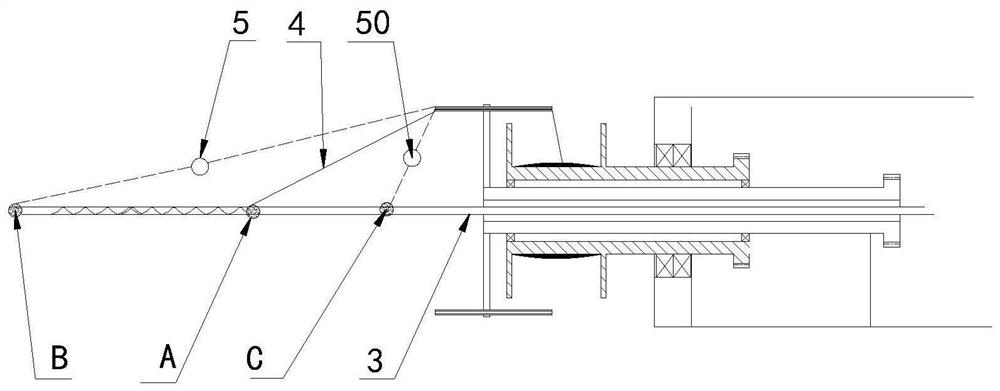

Automatic laying production line and control method of wind turbine blade root preform

PendingCN109130245AImprove molding qualityReduces the chance of interlayer wrinklingProduction lineElectricity

The invention discloses an automatic laying production line and a control method of wind turbine blade root perform, and belongs to the field of laying equipment. The production line comprises a cutting station, a conveying device and a variant structure, wherein the variant structure comprises a cloth take-up frame body and a semicircular molding surface; the cloth take-up frame body comprises afirst frame body, a second frame body and a third frame body; two ends of the second frame body are respectively hinged with the first frame body and the third frame body; needling sucking discs are arranged on the lower sides of the first frame body, the second frame body and the third frame body and form a first adsorption plane, a second adsorption plane and a third adsorption plane; when clothis absorbed by the cloth take-up frame body, the first adsorption plane and the third adsorption plane synchronously rotate reversely upwards around a hinge point until the first adsorption plane, the second adsorption plane and the third adsorption plane are at the same height; when the cloth is molded by the cloth take-up frame body, the first adsorption plane and the third adsorption plane synchronously rotate reversely downwards around the hinge point. According to the production line, preforms can be molded one by one, the probability of occurrence of interlayer folds among the preformsis reduced, and the production efficiency is improved.

Owner:NEWTRY COMPOSITE

Automatic waterproof coiled material feeding device

The invention provides an automatic waterproof coiled material feeding device and belongs to the technical field of waterproof coiled materials. The automatic waterproof coiled material feeding devicecomprises a paving and pasting trolley, an unwinding and cutting mechanism and a drying and melting mechanism. A waterproof coiled material discharge tank is arranged on a paving and pasting trolleyframe of the paving and pasting trolley. A waterproof coiled material of an unwinding mechanism of the unwinding and cutting mechanism is mounted on an unwinding wheel disk. A feeding lower roll shaftof a feeding assembly is rotatably arranged on a feeding support. An upper feeding roll shaft is rotatably arranged on upper roll shaft adjusting blocks. A lower cutting base of the cutting assemblyis provided with a cutting groove. A cutting knife rest is arranged on a cutting knife rest guide rail in an up-down sliding mode. A cutting knife is mounted on the lower side of the cutting knife rest. One end of an arc-shaped discharge plate is mounted on one side of the lower cutting base. Drying and melting sliding blocks of the drying and melting mechanism are slidably arranged on drying andmelting guide rails. A drying and melting lead screw is in threaded connection with drying and melting lead screw nuts. Drying and melting spray nozzles are mounted on the corresponding drying and melting sliding blocks. The automatic waterproof coiled material feeding device implements automatic unwinding, drying, melting and cutting of the waterproof coiled material to achieve automatic feedingof the waterproof coiled material.

Owner:周梅

Optical fiber laying device for leakage detection of concrete pool, and laying method

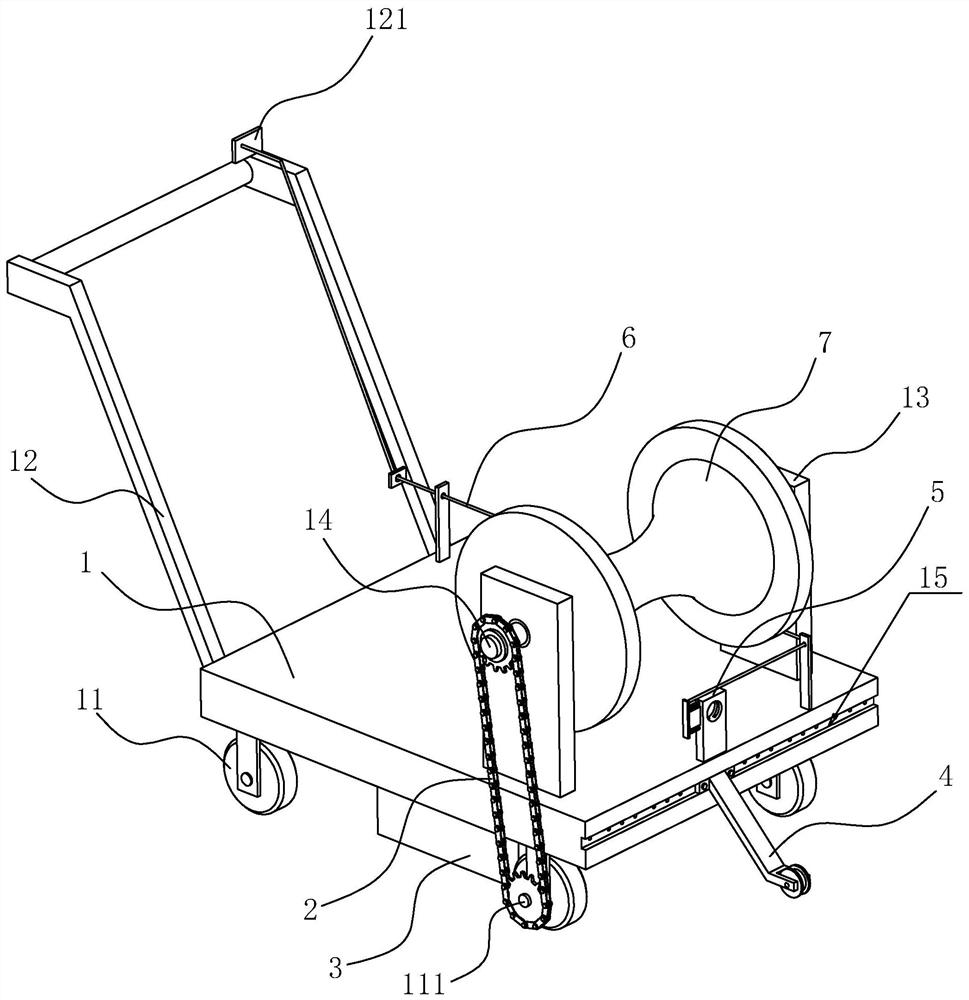

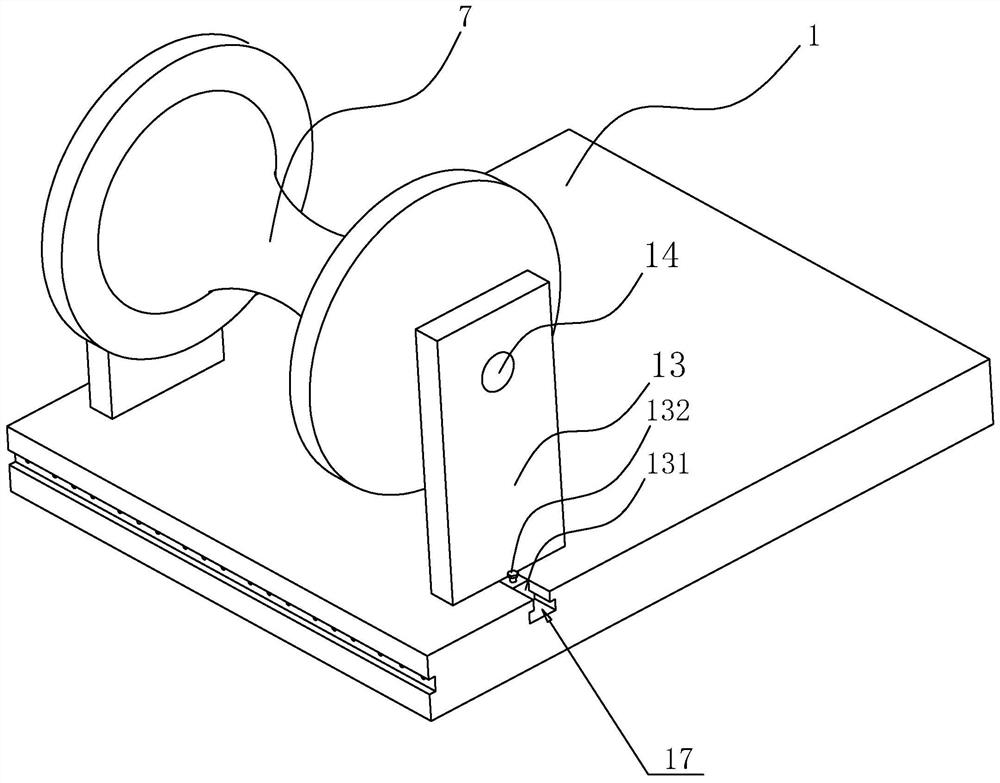

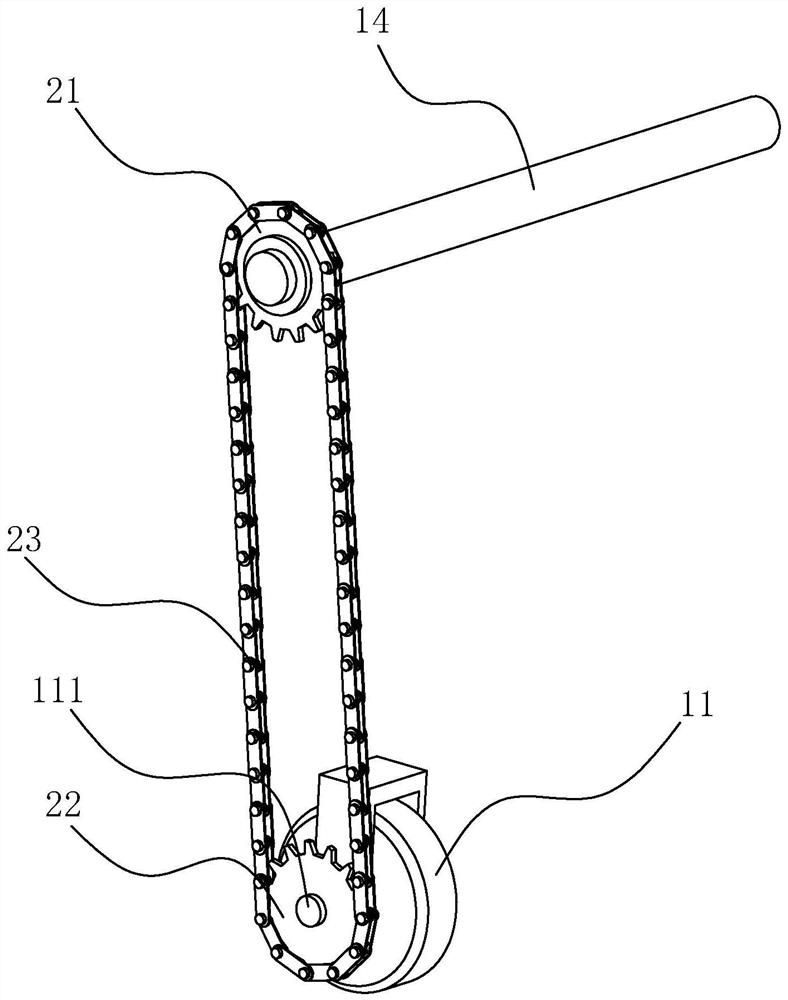

InactiveCN113406761ARealize automatic unwindingNot easy to shiftFilament handlingOptical fibre/cable installationMechanical engineeringWater pool

The invention relates to an optical fiber laying device for leakage detection of a concrete pool, and a laying method, and belongs to the field of building construction equipment. The optical fiber laying device comprises a base, wherein rollers are arranged at the bottom of the base, a push-pull handle is arranged at one end of the base, two supporting seats are arranged on the base, an unwinding shaft used for installing an optical fiber disc is rotationally arranged between the two supporting seats, a linkage assembly is arranged between the roller and the unwinding shaft, and the linkage assembly is used for driving the unwinding shaft and the roller to rotate synchronously. According to the invention, the manual labor intensity in the optical fiber unwinding process can be reduced while the unwinding effect is improved.

Owner:泰贻建设集团有限公司

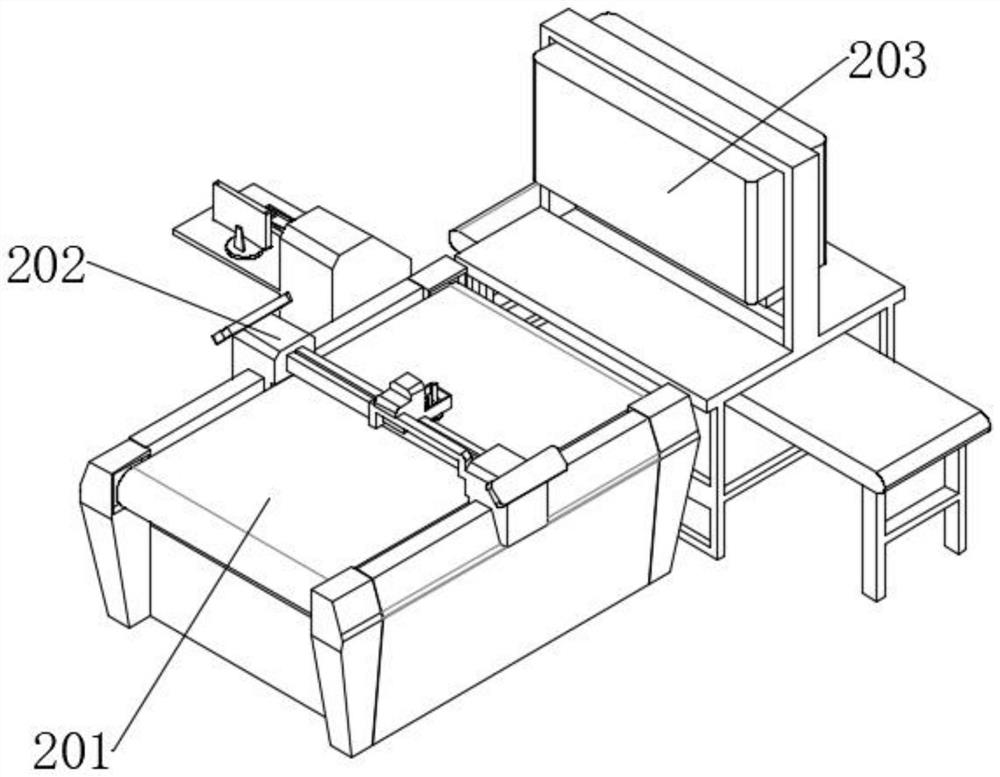

Automatic forming equipment for expandable polyethylene heat insulation cup sleeve

InactiveCN112971498ARealize automatic cutting operationRealize automatic glue applicationLiquid surface applicatorsCoatingsAutomatic processingMoulding device

The invention discloses automatic forming equipment for an expandable polyethylene heat insulation cup sleeve, and belongs to the technical field of automatic cup sleeve machining. The equipment comprises an expandable polyethylene unwinding frame, a mounting frame, an arc-shaped cotton moving device, an arc-shaped cutting device, an ironing and glue dispensing device, an automatic forming device and a forming and discharging device, wherein the expandable polyethylene unwinding frame is located at one end of the mounting frame, the arc-shaped cotton moving device is located below the mounting frame, the arc-shaped cutting device is arranged on the mounting frame, the ironing and glue dispensing device comprises an ironing and glue dispensing part and a glue dispensing and uniform smearing part, the ironing and glue dispensing part is arranged on the mounting frame, and the automatic forming device is arranged on the side of the arc-shaped cotton moving device. The automatic forming device comprises a supporting table, a coiling piece and a flattening piece, the coiling piece is located beside the arc-shaped cotton moving device, the flattening piece is located above the supporting table, and the forming and discharging device is located beside the automatic forming device. According to the invention, automatic processing and forming operation of the cup sleeve is realized, and the working efficiency is improved.

Owner:黄波

Automatic barbell disc production process

InactiveCN112808490AImprove feeding efficiencyRealize automatic feeding processWrapping material feeding apparatusSpray boothsManufacturing engineeringSpray painting

The invention discloses an automatic barbell disc production process and belongs to the technical field of barbell disc processing. The automatic barbell disc production process comprises the following steps: 1, automatically clamping and moving a barbell disc to an annular rotating device; 2, hanging the barbell disc on a hook frame; 3, conveying the barbell disc on the hook frame to a paint spraying device; 4, automatically spraying paint on the barbell disc; 5, quickly curing the paint layer on the barbell disc; 6, automatically printing the barbell disc; 7, automatically unwinding the barbell disc packaging film; 8, wrapping the barbell discs with film bags; and 9, automatically discharging and boxing the wrapped barbell discs. The automatic barbell disc production process is ingenious in design, working procedures are smoothly connected, the barbell discs are automatically machined, manual assistance is not needed, and the machining efficiency of the barbell discs is improved.

Owner:骆茂斌

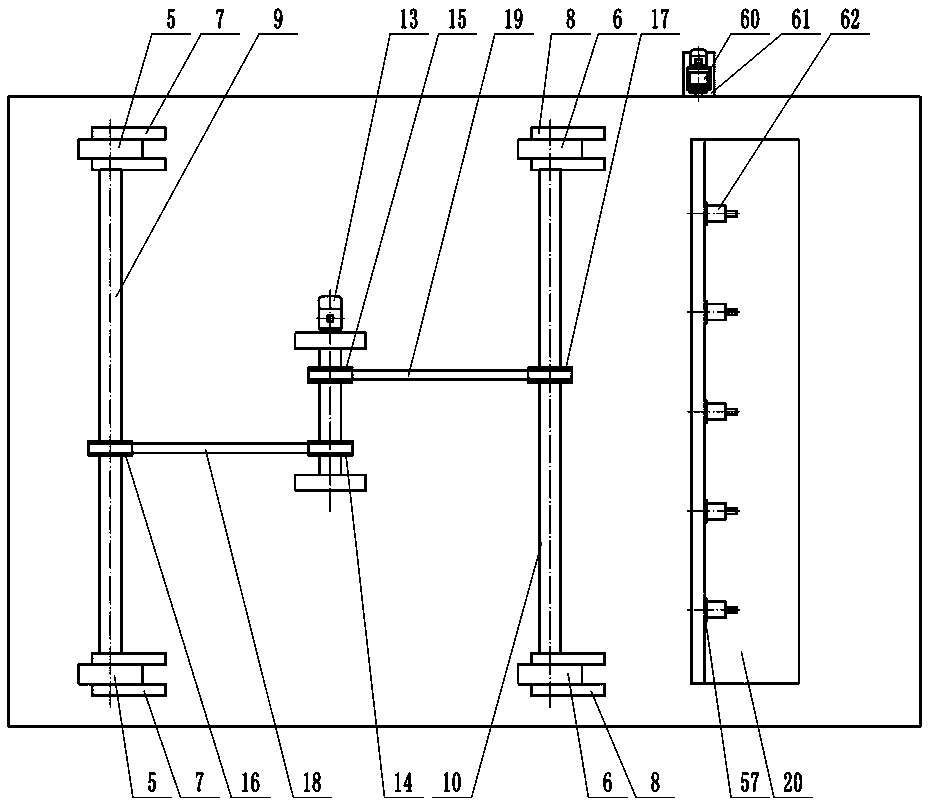

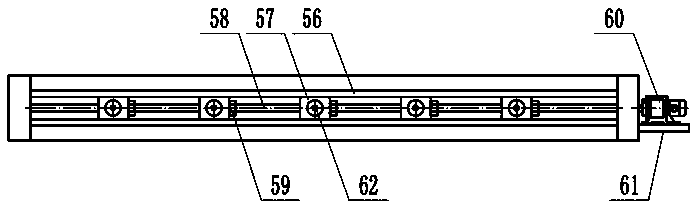

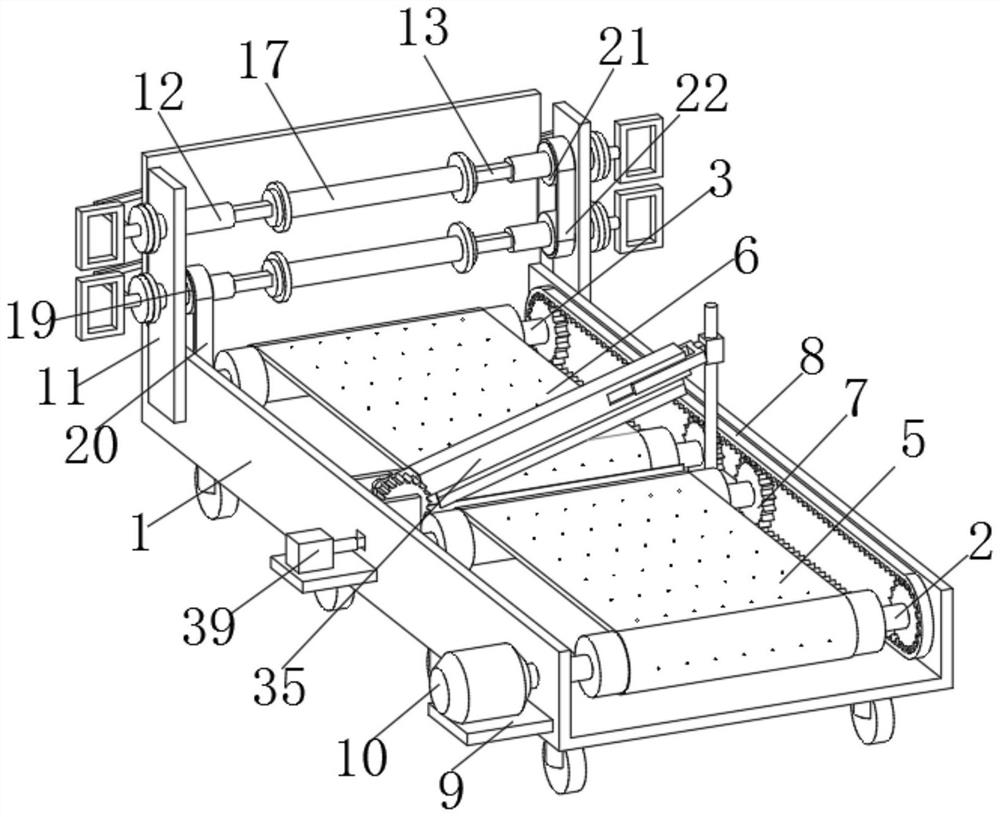

Method for controlling cotton felt tailoring size precision

The invention discloses a method for controlling cotton felt tailoring size precision, and belongs to the field of cotton felt tailoring methods. The method for controlling cotton felt tailoring sizeprecision can achieve production technology automation. A reeling and unreeling device can achieve automatic unreeling and unreeling of reeled cloth, a horizontal tailoring device can achieve horizontal-direction tailoring of the cloth, the tailoring thickness is adjustable, and a vertical tailoring device can tailor the cloth into the needed shape. In the production process, an integrated vacuumdust removal device body is adopted, it is ensured that waste fiber and dust generated in the tailoring process are automatically collected, and green and environment-friendly production is ensured. In the vacuum dust removal device body, the principle of heat expansion and cold shrinkage is adopted for achieving the following operation: in the normal work process, gathering fiber capturing hooksare in a bending state, so that felt fiber scraps are conveniently captured, in the process that the fiber capturing hooks are cleaned through hot water, the fiber capturing hooks are in a vertical state, and accordingly the felt fiber scraps captured by the fiber capturing hooks are conveniently cleaned.

Owner:HAIAN DISCORY INSTR CO LTD

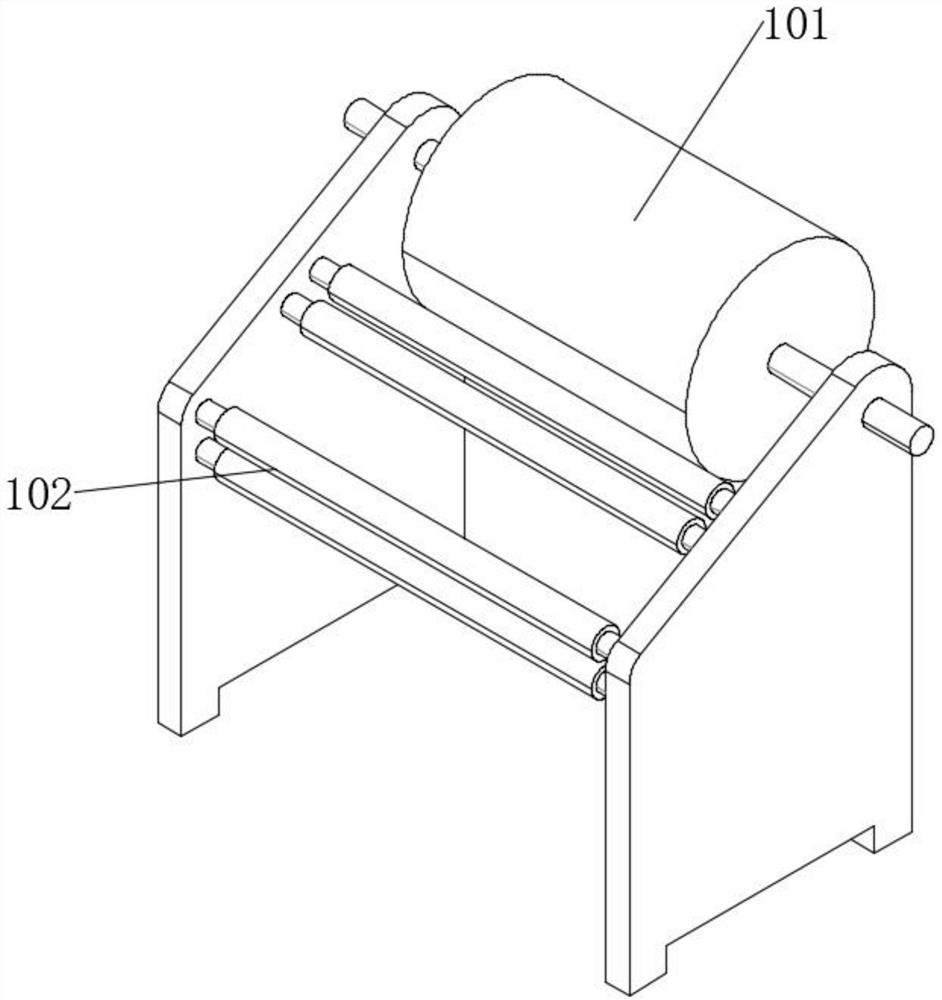

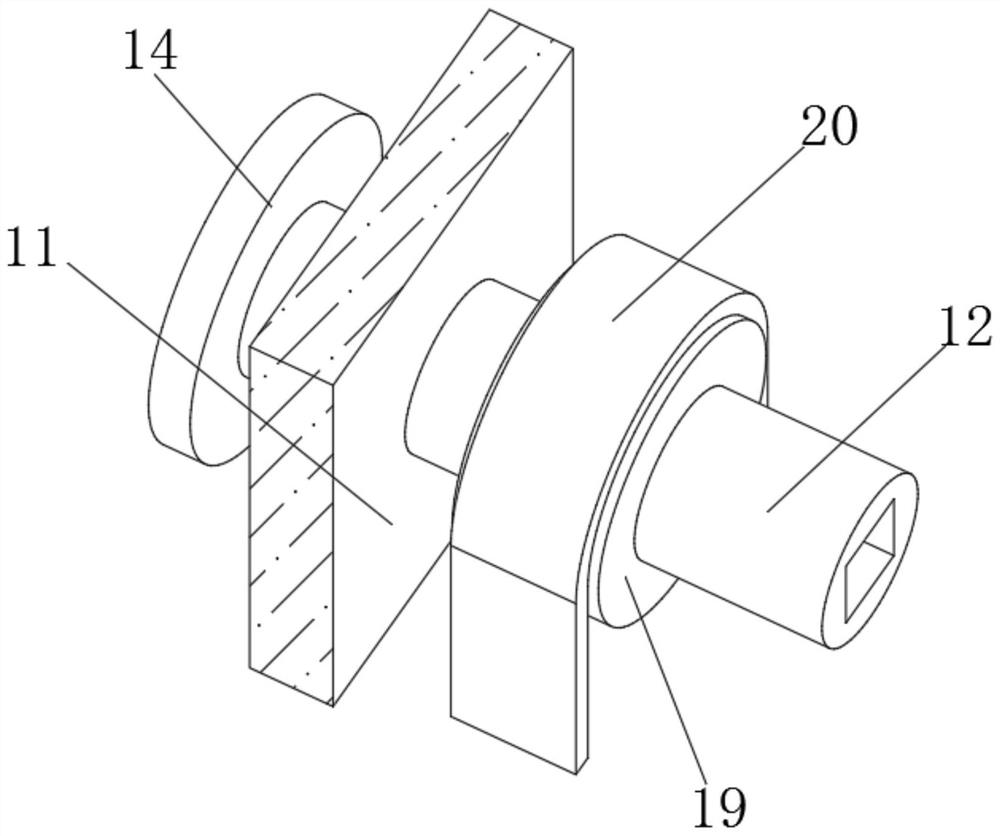

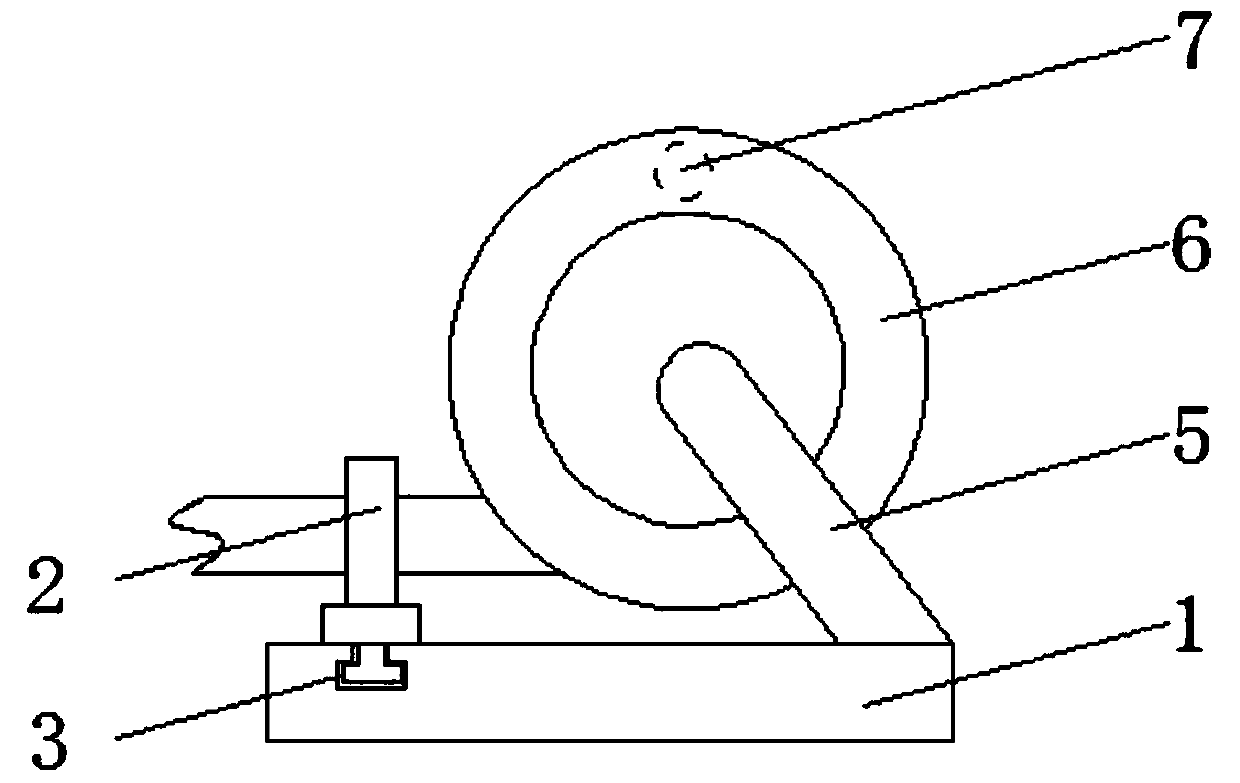

Automatic unwinding mechanism used for cloth

The invention discloses an automatic unwinding mechanism used for cloth. The mechanism comprises a fixed support, an unwinding device and a tension device; the unwinding device and the tension deviceare mounted on the fixed support, the unwinding device comprises an unwinding drive assembly, an unwinding flange, an unwinding drive shaft and an unwinding fixing plate, the unwinding flange is mounted on the unwinding fixing plate, the unwinding drive shaft sequentially penetrates the unwinding fixing plate and the unwinding flange and then is connected with an unwinding drive assembly in a drive manner, through the unwinding device and the tension device, automatic unwinding of the cloth is achieved, traditional manual unwinding of cloth can be replaced, efficiency is high, and the cloth cannot be damaged.

Owner:钟立朋

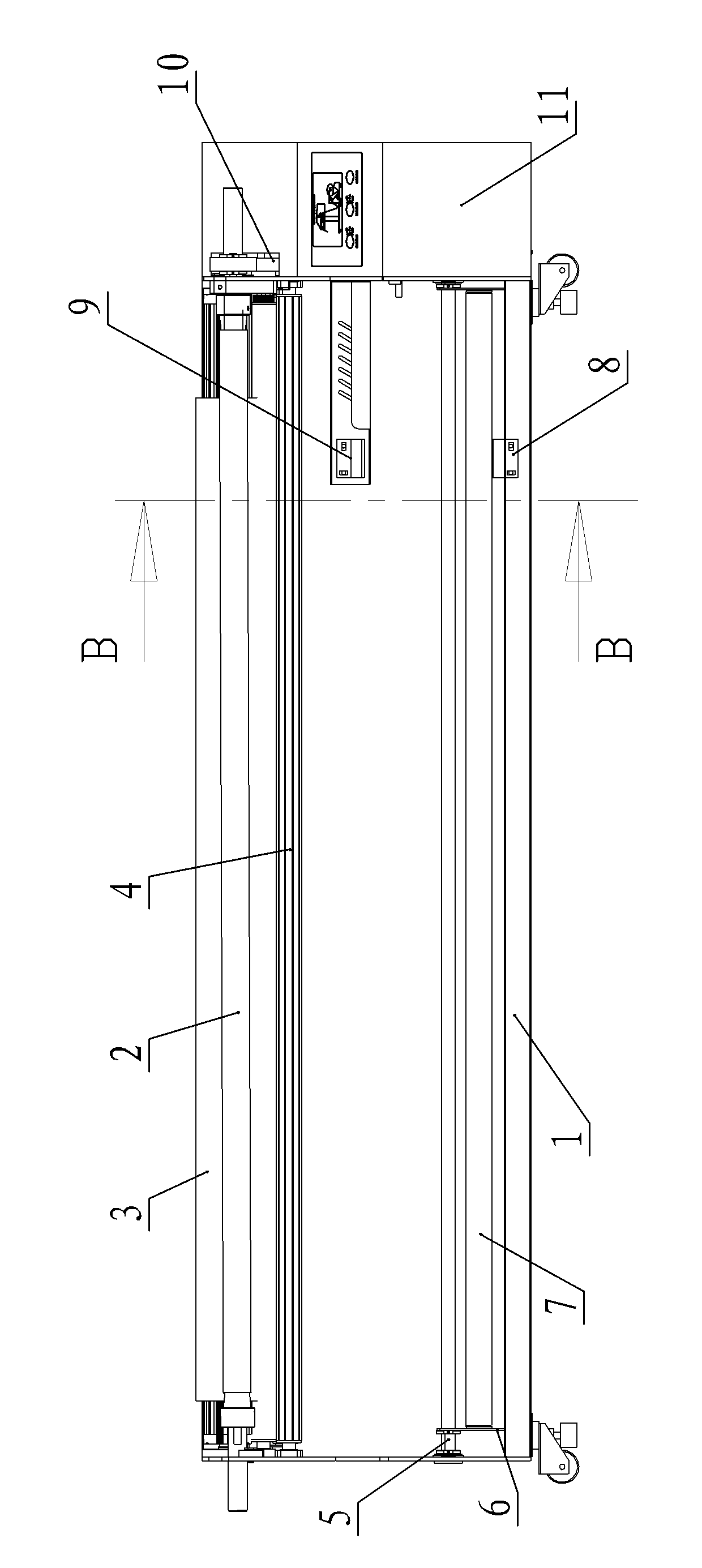

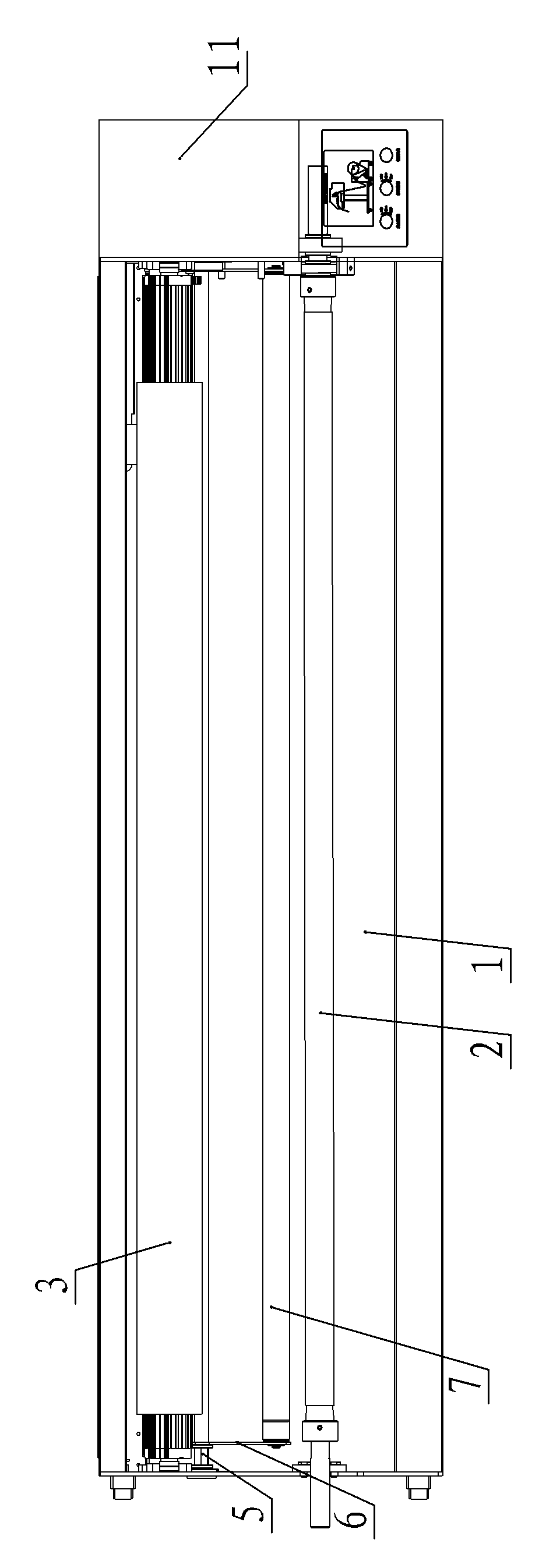

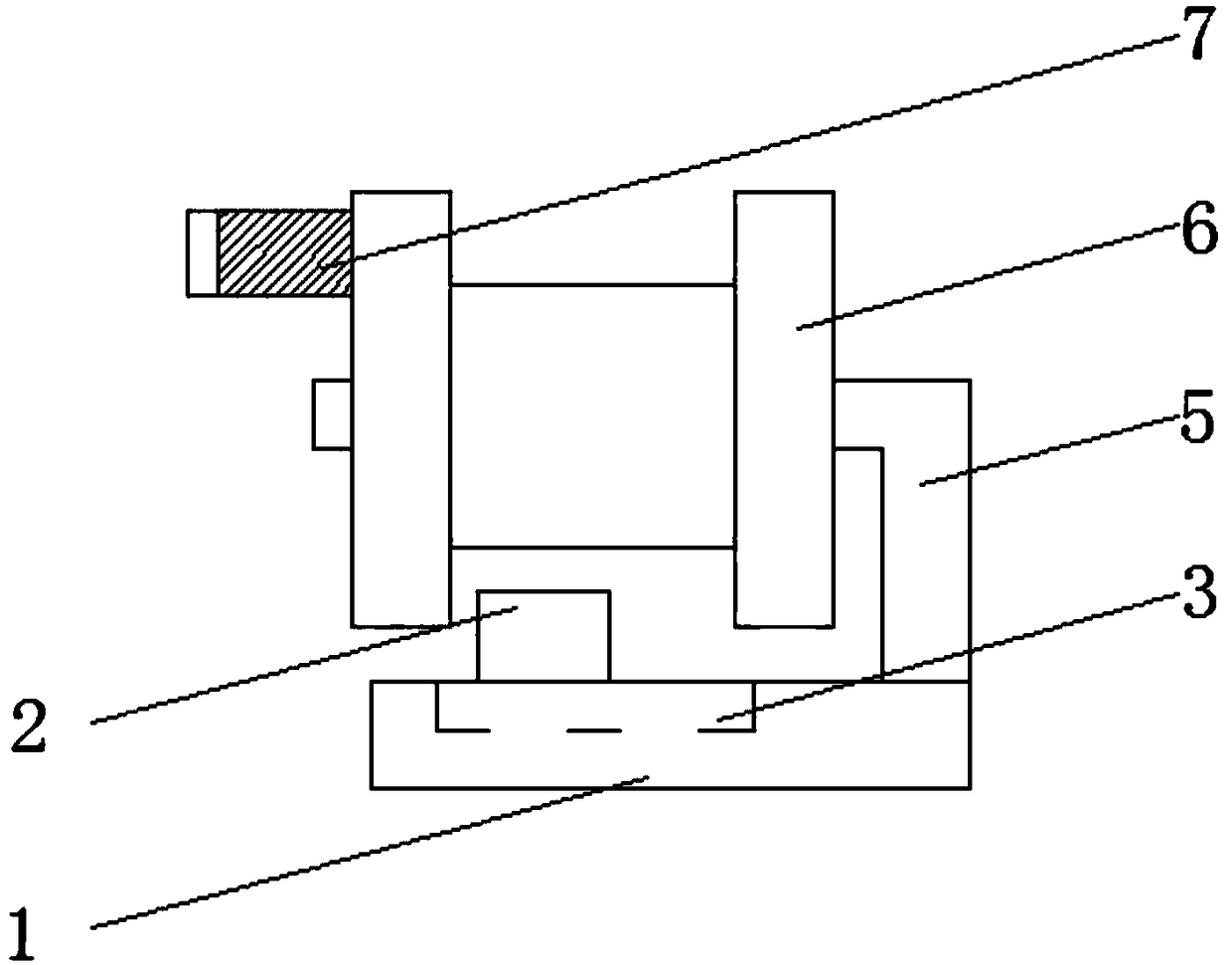

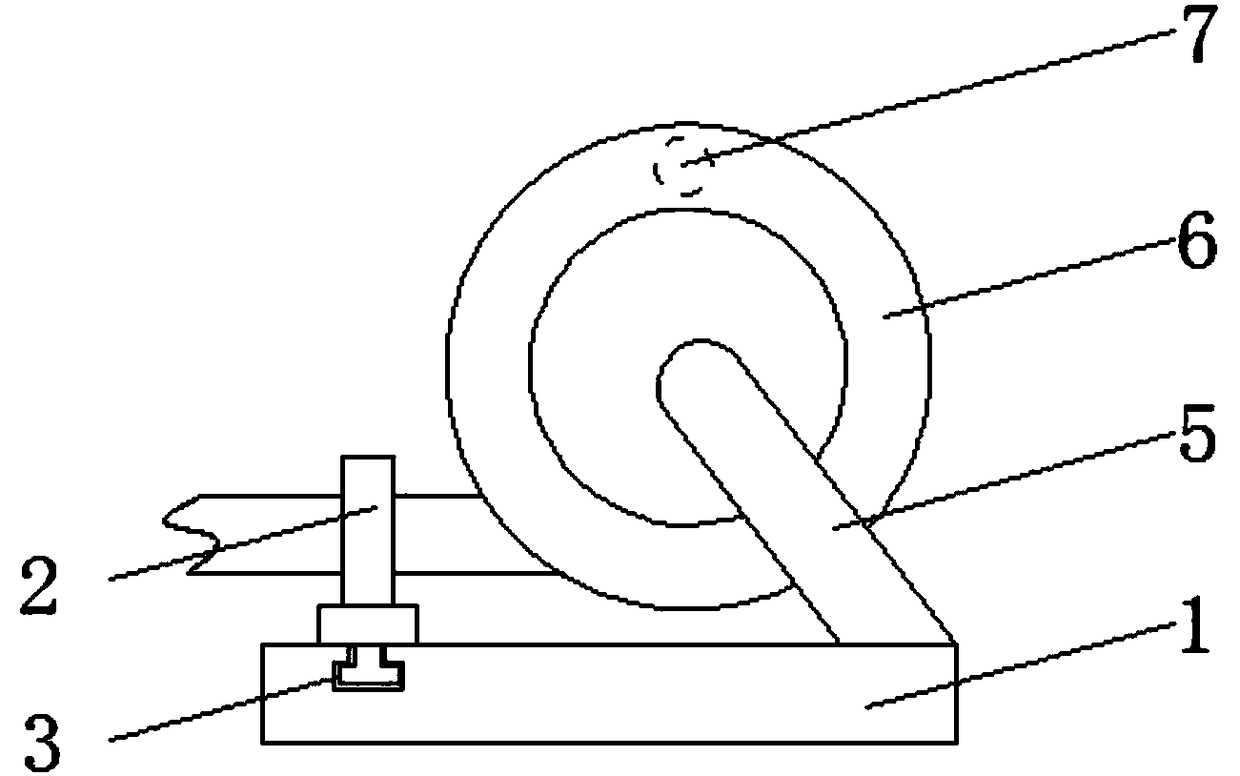

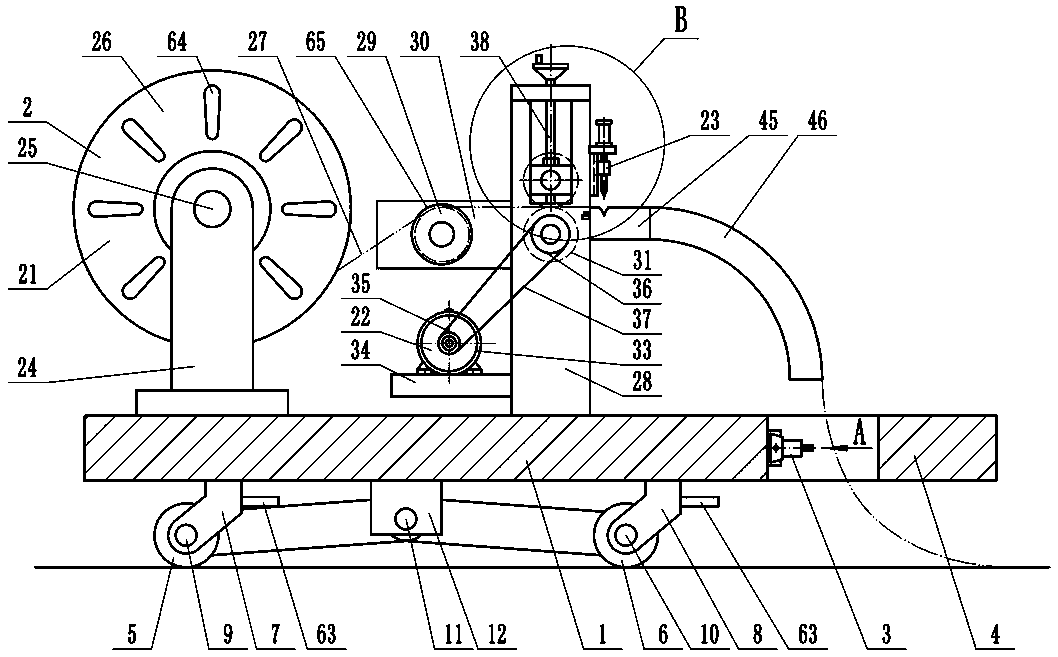

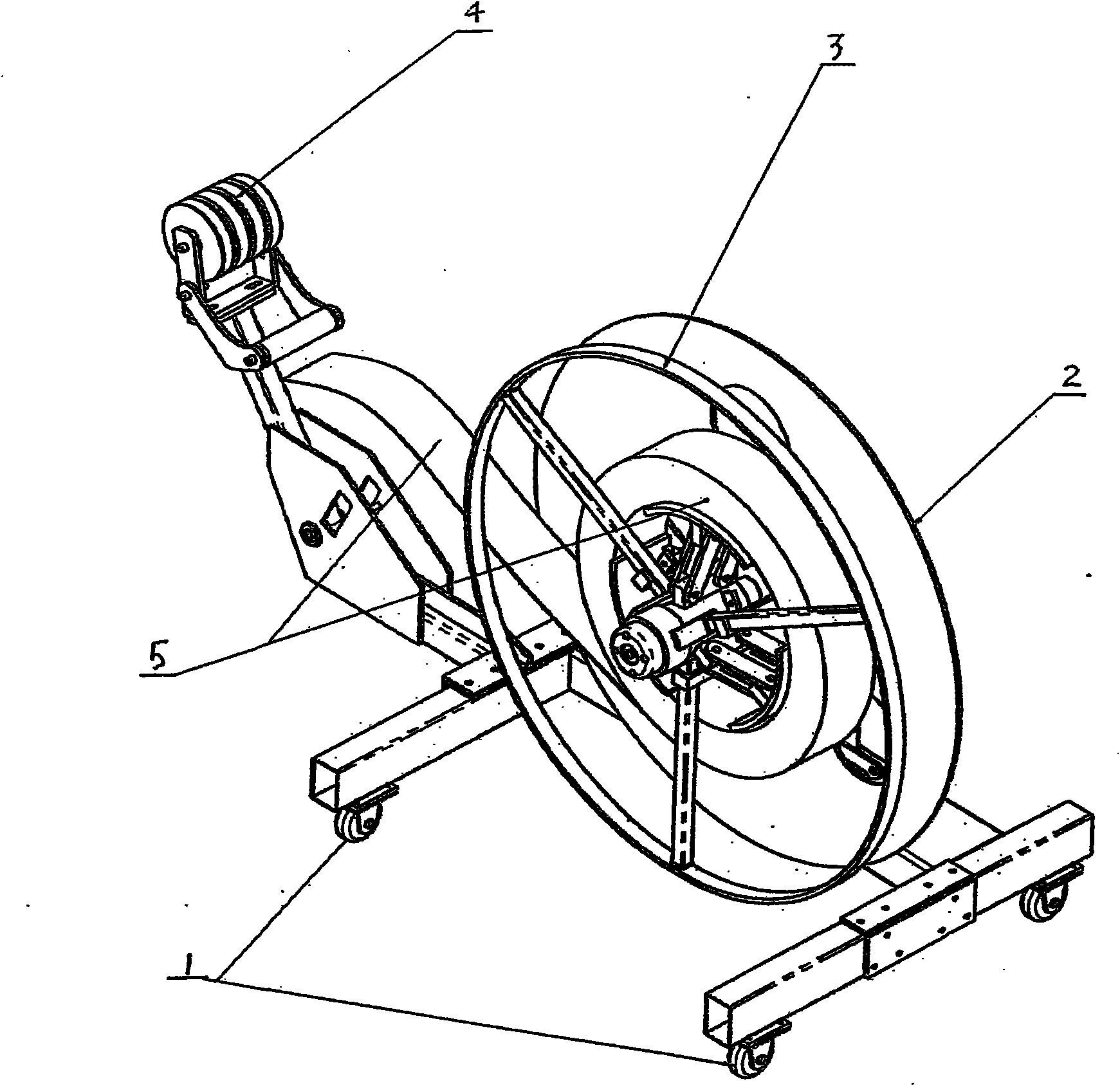

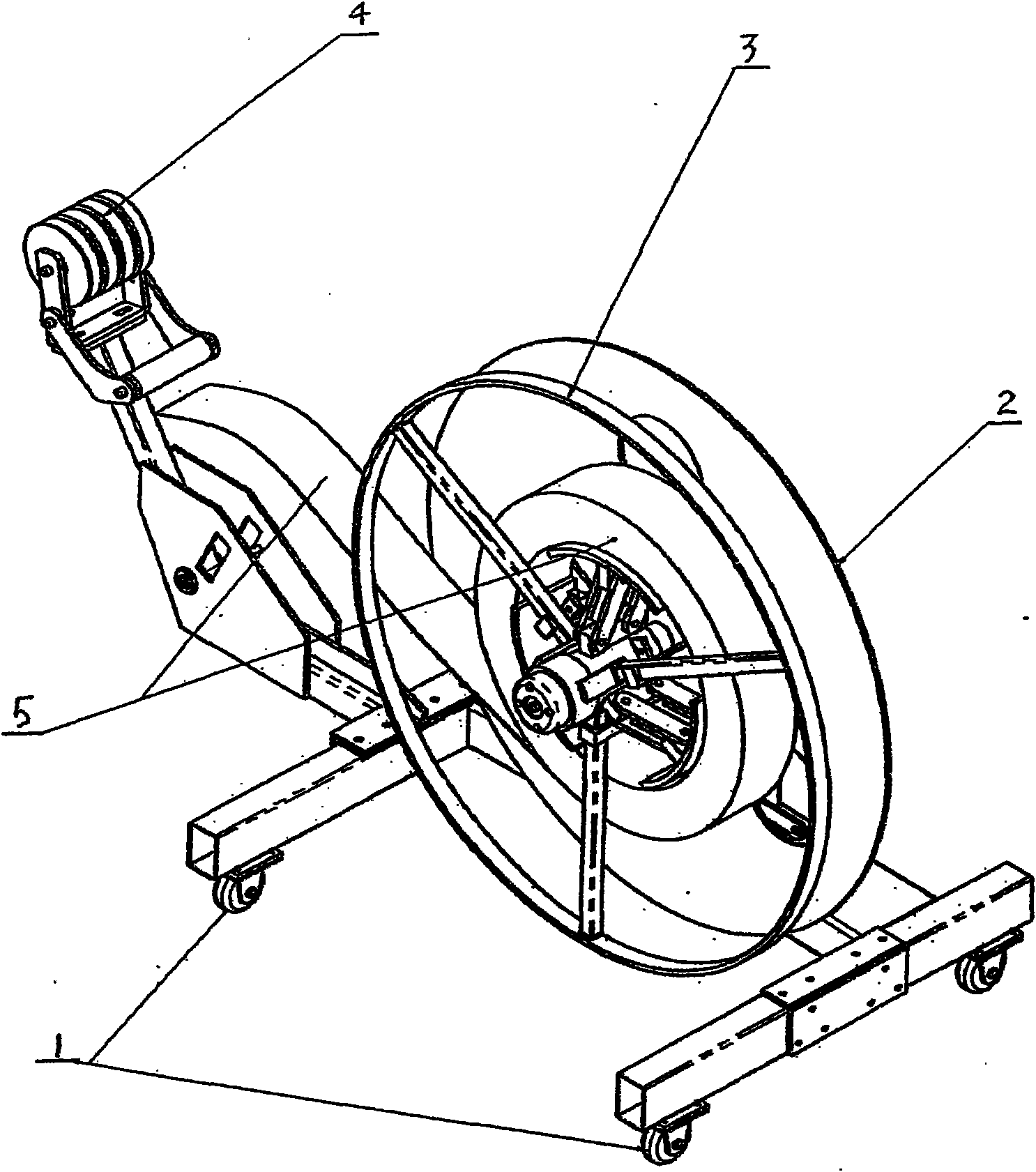

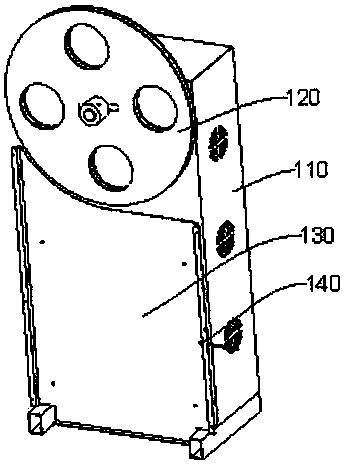

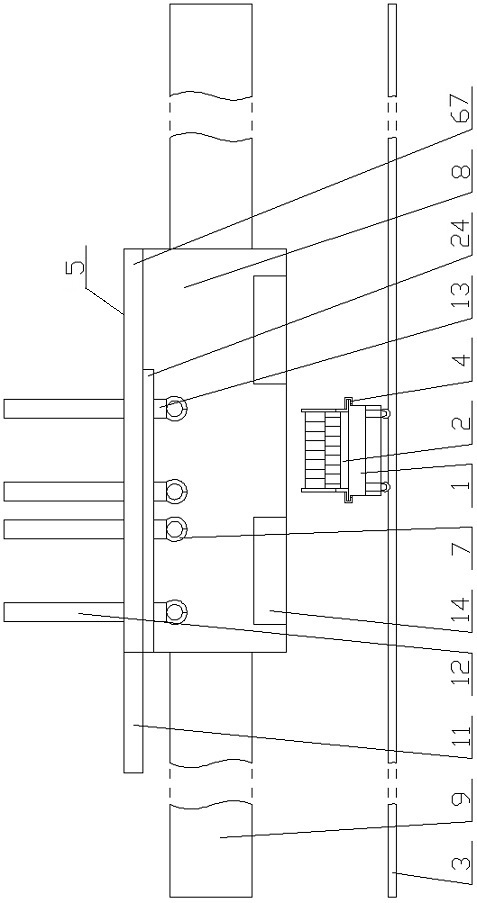

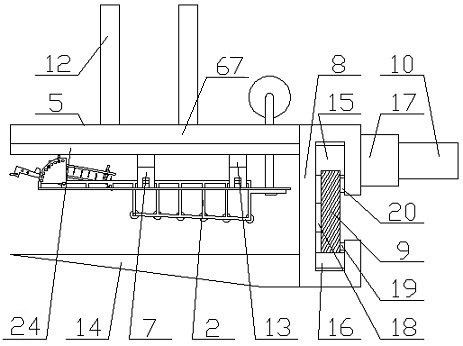

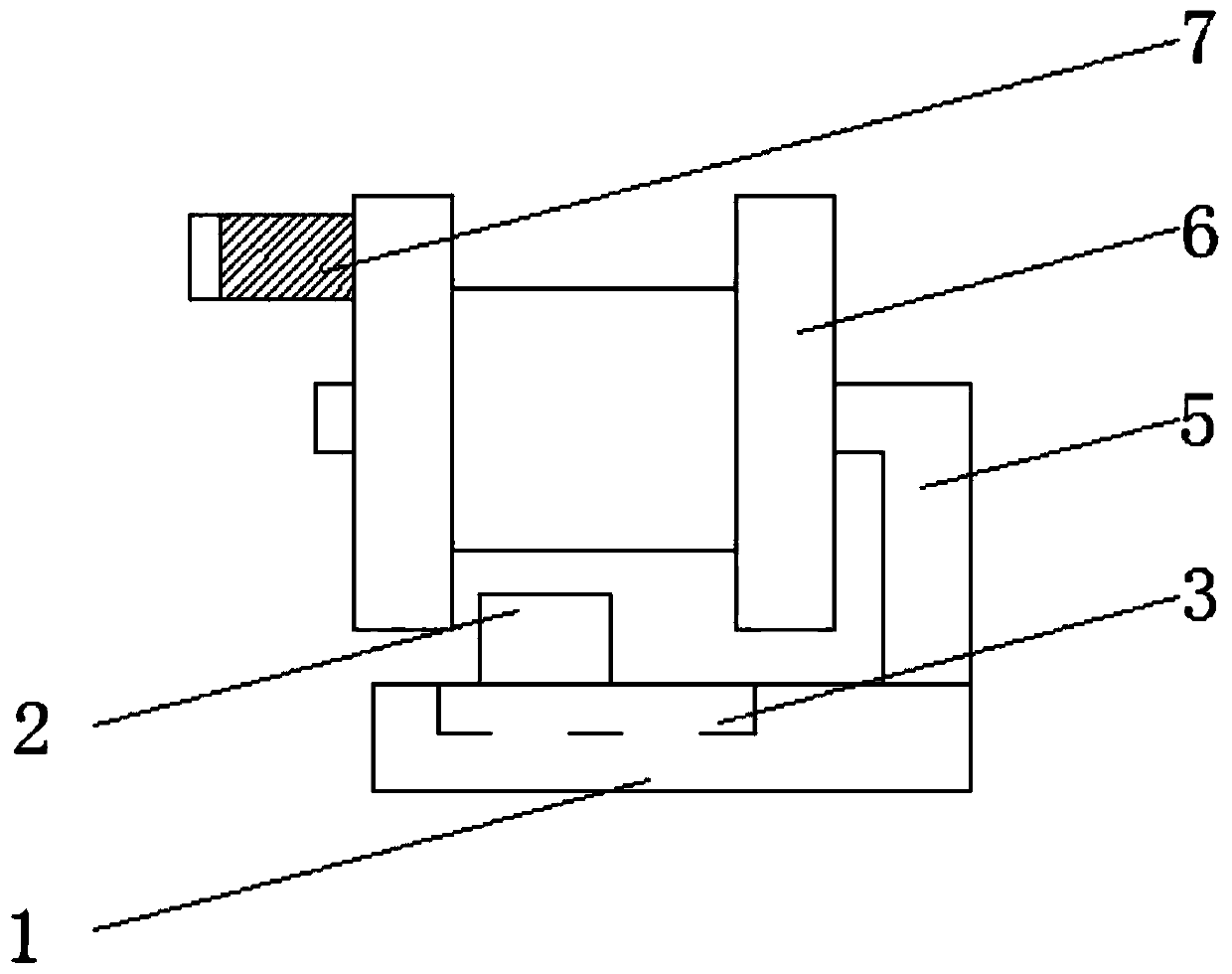

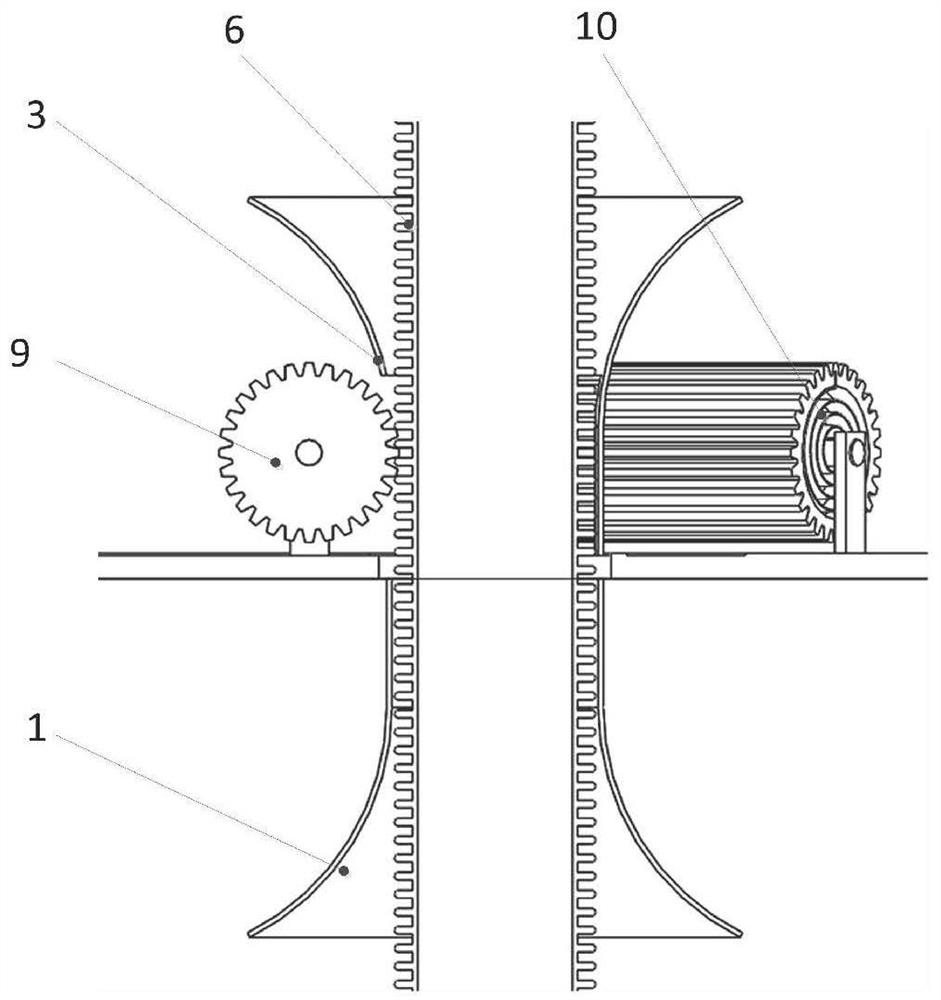

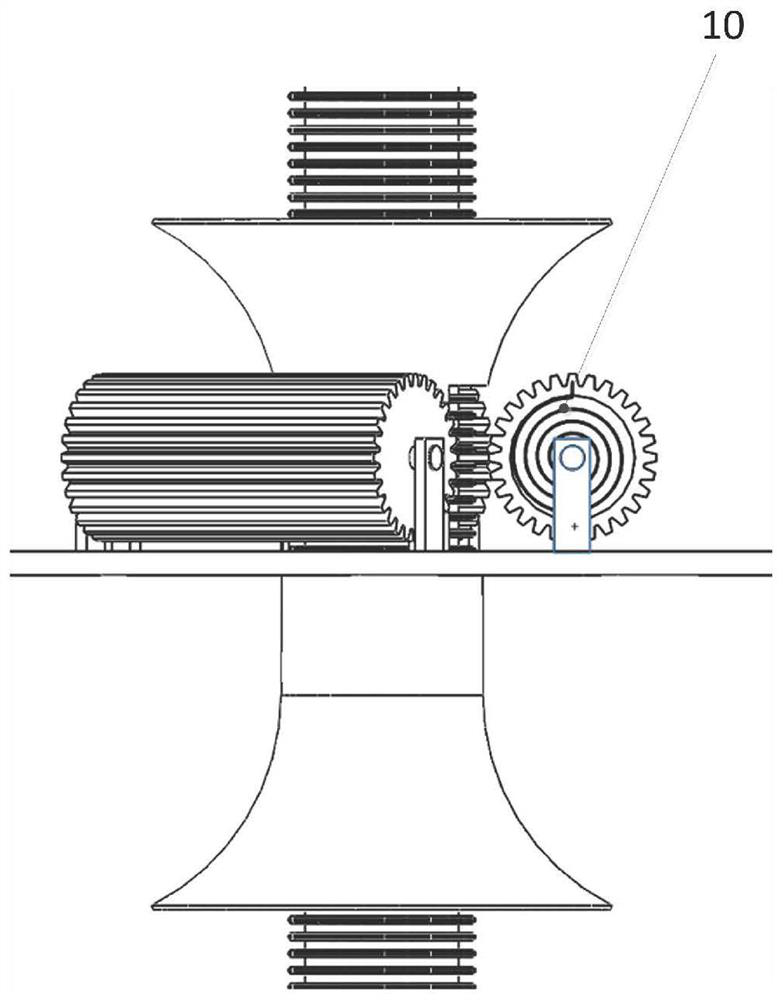

Uncoiler for spiral duct molding machine

The invention relates to an uncoiler for a spiral duct molding machine. The uncoiler is used for automatically uncoiling strip steel-shaped coil stock, and comprises an uncoiler frame (1), a disk plate (2), a stock stop disk (3) and an expansion wheel stand (4), wherein the disk plate (2) is upwards arranged on the uncoiler frame (1); the stock stop disk (3) is arranged on the disk plate (2); and the expansion wheel stand (4) is arranged on the rear side of the expansion wheel stand (4). The uncoiler can automatically uncoil the strip steel-shaped coil stock.

Owner:JIANGYIN SANBEN TECH CO LTD

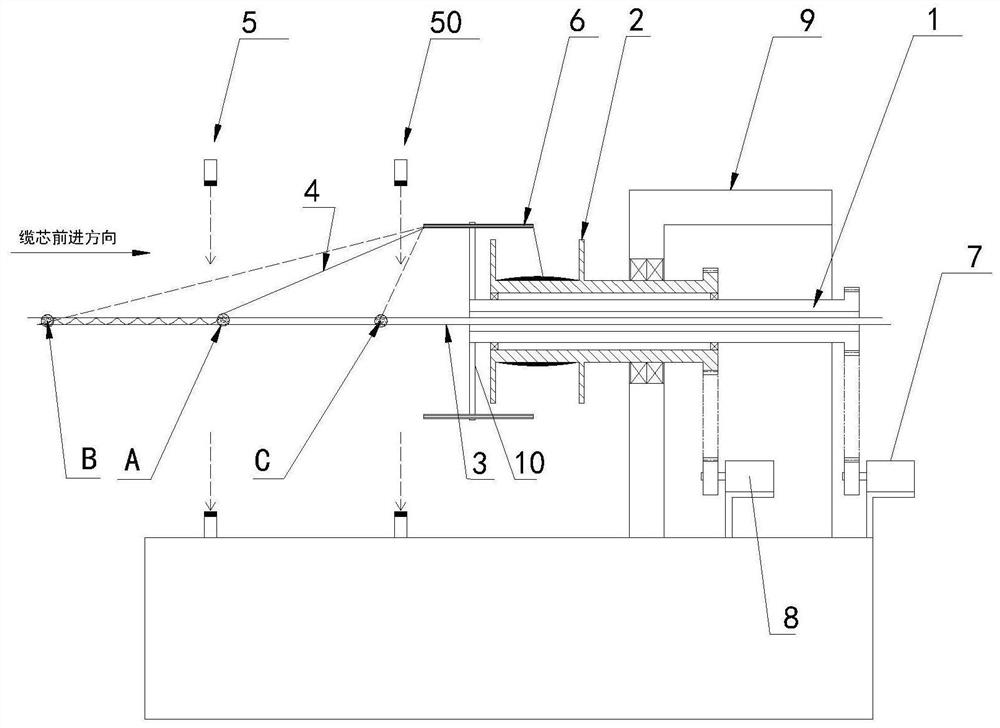

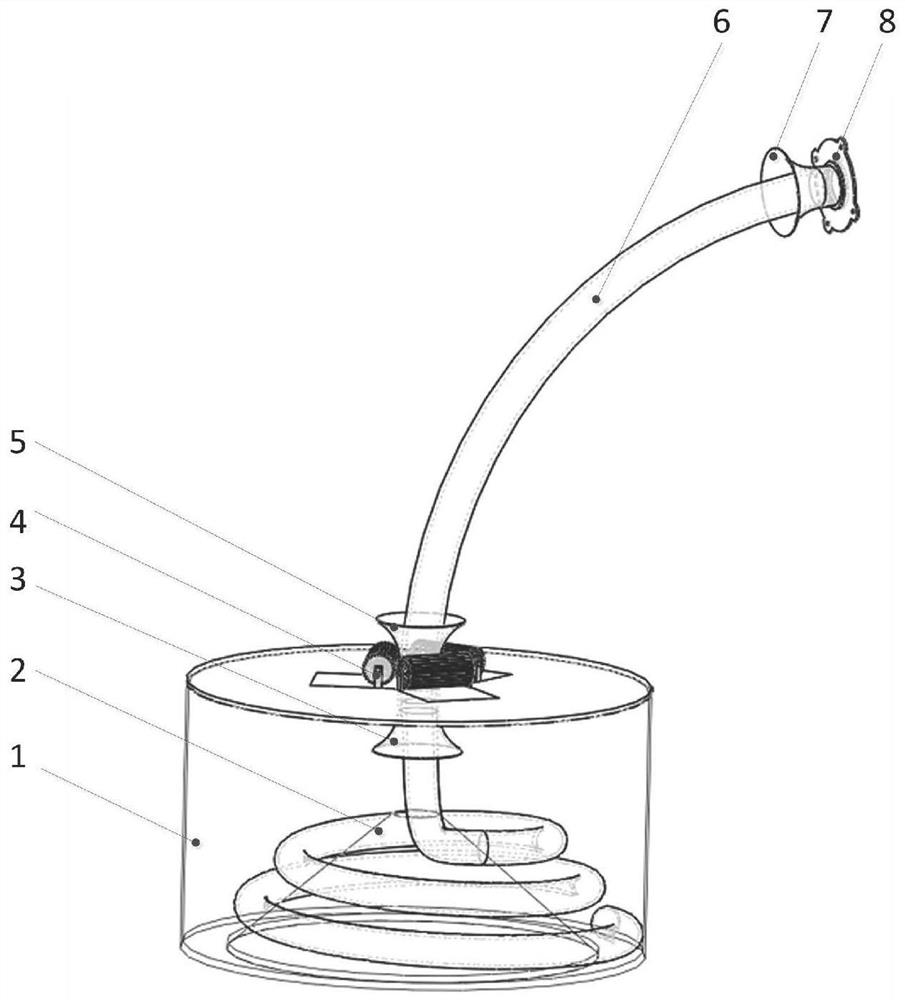

Yarn unwinding system for cable and using method of yarn unwinding system

InactiveCN113064245AReduce configurationAvoid the phenomenon of being easily cutFibre mechanical structuresYarnStructural engineering

The invention relates to a yarn unwinding system for a cable and a using method of the yarn unwinding system. The yarn unwinding system comprises a hollow main shaft which can rotate around the axis of the hollow main shaft and is used for a cable core to pass through, and a yarn channel for yarn to pass through is arranged on the peripheral surface of the hollow main shaft; the yarn unwinding system further comprises a yarn storage barrel which can rotate around the axis of the yarn storage barrel and is used for winding yarn, and the yarn storage barrel and the hollow main shaft are coaxially arranged; the yarn unwinding system further comprises a detection device which is used for detecting the position of a yarn retreating point and comprises a first sensor and a second sensor which are distributed on the upstream of the hollow main shaft at intervals in the cable core advancing direction, and the yarn retreating point is the intersection point of the yarn and the cable core; the yarn retreating point is provided with a safety area, and the first sensor is configured to be triggered when the yarn retreating point leaves the safety area in the direction opposite to the advancing direction of the cable core; and the second sensor is configured to stop being triggered when the yarn retreating point leaves the safety area in the advancing direction of the cable core. The problem that the actual position of the yarn cannot be judged in the prior art, so that the yarn enters yarn unwinding equipment due to the too low yarn unwinding speed, or the yarn is broken due to the too high yarn unwinding speed can be solved.

Owner:FENGHUO COMM SCI & TECH CO LTD

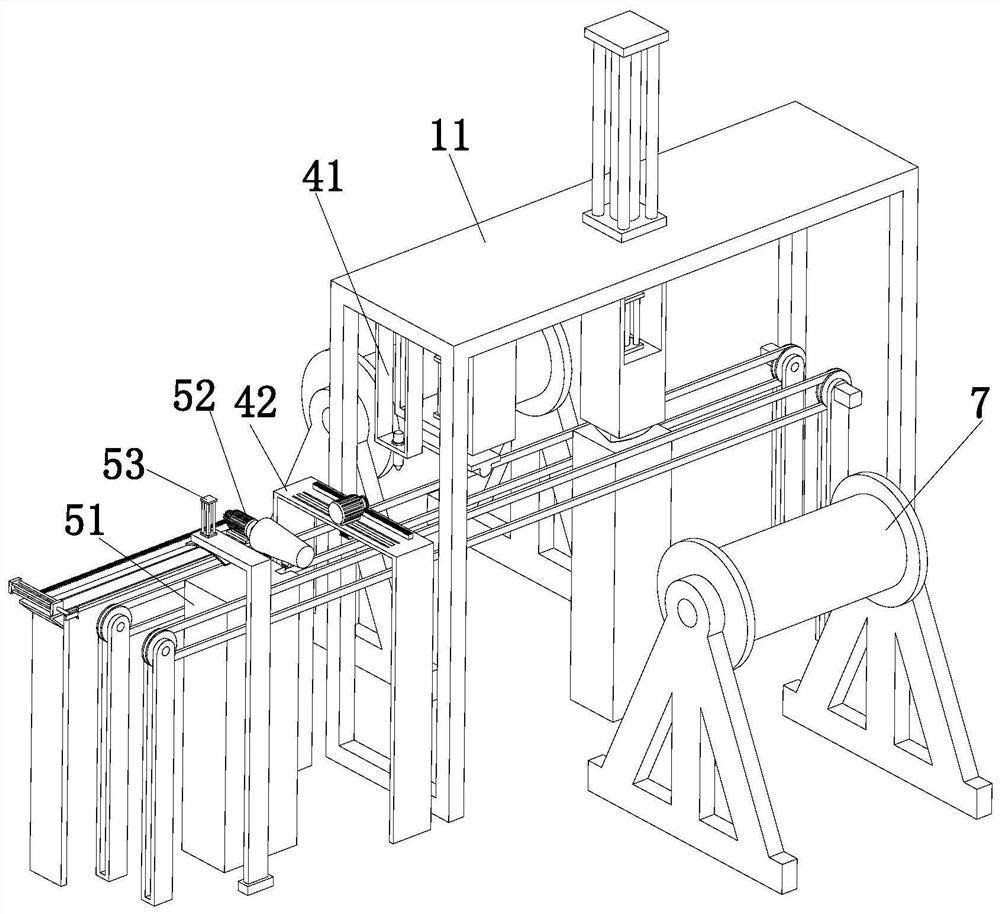

Manufacturing equipment and manufacturing process for environment-friendly activated carbon fiber cylinder

ActiveCN113319909AFast manufacturingEasy to disassemble and replaceMetal working apparatusWebs handlingElectric machineryActive carbon

The invention discloses manufacturing equipment for environment-friendly activated carbon fiber cylinder, and relates to the technical field of activated carbon fiber manufacturing. The manufacturing equipment comprises a U-shaped rack; two first conveying shafts and two second conveying shafts are rotatably connected to the inside of the U-shaped rack and located on the same horizontal plane; a first conveying belt is tensioned on the two first conveying shafts; a second conveying belt is tensioned on the two second conveying shafts; two mounting plates are fixedly connected to one side of the U-shaped rack; and a motor and an electric push rod are respectively and fixedly connected to the tops of the two mounting plates. According to the manufacturing equipment for the environment-friendly activated carbon fiber cylinder, the motor drives the two conveying belts and two winding drums to move, then a fibrofelt and a protection net are put down, and the automatic unwinding is achieved; and when the fibrofelt and the protection net fall on the second conveying belt, movable nails can be clamped into the fibrofelt and the protection net, so that the fibrofelt and the protection net move along with movement of the second conveying belt and the first conveying belt, and the shearing is facilitated.

Owner:湖南省金湄泉饮料有限公司

Glass fiber tape feeding system facilitating replacement of glass fiber tape roll

ActiveCN113752415AQuick changeIncrease productivityCoatingsTubular articlesGlass fiberStructural engineering

The invention discloses a glass fiber tape feeding system facilitating replacement of a glass fiber tape roll. An unwinding and feeding frame is detachably and fixedly connected to a notch of an epoxy dipping tank, an unwinding and feeding frame replacement device comprises a base frame arranged horizontally, a movable groove slidably connected with a track beam is fixedly connected to the bottom of one side of the base frame, and a transverse moving frame is arranged in the base frame. The transverse moving frame reciprocates in the base frame through a driving device C in the direction parallel to the track beam, two lifting frames are further arranged at the bottom of the transverse moving frame in the extending direction of the track beam, and the lifting frames move up and down through driving devices D correspondingly. The two sides of the bottoms of the lifting frames are further provided with grabbing clamps which are driven by a driving device E and used for clamping the unwinding and feeding frame. According to the structure, the glass fiber tape feeding system facilitating replacement of the glass fiber tape roll achieves rapid replacement of the unwinding and feeding frame for the glass fiber tape, the replaced glass fiber tape can also be directly used for production, and the production efficiency is improved.

Owner:盐城品冠高压电气有限公司

A tape sticking device

ActiveCN104192624BRealize automatic unwindingRealize automatic bondingFinal product manufactureArticle deliveryEngineeringIdler-wheel

The invention relates to an adhesive tape sticking device. The adhesive tape sticking device comprises a machine frame, an adhesive tape paying-off device, an adhesive tape driving device, an adhesive tape cutting deice, an adhesive tape adsorption device, a press wheel device and a conveying device, wherein the adhesive tape paying-off p device and the conveying device are arranged on the machine frame, the adhesive tape paying-off device comprises an adhesive tape paying-off mechanism and an adhesive tape conveying mechanism, the conveying device comprises a first installation plate and a first movement mechanism, a second installation plate is arranged on the first installation plate, the adhesive tape driving device is fixed to the second installation plate, and the adhesive tape adsorption device and the press wheel device are fixedly arranged on the rear side of the adhesive tape driving device sequentially. The adhesive tape cutting device is arranged between a seventh idler wheel and a ninth idler wheel and comprises a fourth air cylinder, a cutter connecting plate, a cutter and a guide seat. The adhesive tape sticking device can automatically stick adhesive tape to a welding strip of a battery piece, and improve the conversion efficiency of a battery string.

Owner:WUXI LEAD INTELLIGENT EQUIP CO LTD

Stainless steel band vacuum coating device

PendingCN113604789AStable and uniform colorAvoid extended timeVacuum evaporation coatingSputtering coatingEngineeringVacuum pump

The invention relates to a stainless steel band vacuum coating device. The stainless steel band vacuum coating device comprises a bottom plate and a coating device body, the coating device body is arranged at the top of the bottom plate, and a cleaning device is arranged at the top of the bottom plate; the coating device body comprises a vacuum coating machine, two first vacuum chambers are fixedly connected to the left side of the vacuum coating machine, two second vacuum chambers are fixedly connected to the right side of the vacuum coating machine, power structures are fixedly connected to the bottoms of the first vacuum chambers and the bottoms of the second vacuum chambers, a first rotating rod is rotationally connected to the inner side of the first vacuum chamber, a vacuum pump is fixedly connected to the top of the bottom plate, a second rotating rod is rotationally connected to the inner bottom wall of the second vacuum chamber, and a third rotating rod is rotationally connected to the inner top wall of the second vacuum chamber. According to the stainless steel band vacuum coating device, the whole roll of stainless steel band can be subjected to an integrated coating mode, so that a large amount of manpower is not needed for auxiliary work such as cutting and collecting, a large amount of manpower resources are saved, and the production efficiency is improved.

Owner:SHANDONG HONGWANG INDUSTRY CO LTD

Automatic forming process for pearl wool heat insulation cup sleeve

InactiveCN112936368ARealize automatic cutting operationRealize automatic glue applicationLiquid surface applicatorsCoatingsProduction lineAdhesive glue

The invention discloses an automatic forming process for a pearl wool heat insulation cup sleeve, and belongs to the technical field of automatic processing of cup sleeves. The automatic forming process comprises the following steps: 1, automatically unwinding pearl wool; 2, automatically cutting the pearl wool into an arc shape; 3, moving the cut arc-shaped surface to an ironing and dispensing station; 4, ironing one end of arc-shaped cotton; 5, dispensing at the ironing part of the arc-shaped cotton; 6, uniformly smearing glue at the ironing part of the arc-shaped cotton; 7, automatically rolling the arc-shaped cotton into a cup sleeve; 8, firmly pressing the adhesion part of the cup sleeve; and 9, automatically discharging the cup sleeve. The automatic forming process is ingenious in design and smooth in procedure connection, automatic forming of the pearl wool heat insulation cup sleeve is achieved, the automation degree is high, one person can take charge of one production line, the productivity is multiple times that of manual forming of the cup sleeves, the productivity is greatly improved, and remarkable economic value is achieved.

Owner:黄波

A kind of equipment for cutting off the insulation layer of the cable end before the installation of the cable joint

ActiveCN113178821BAvoid it happening againEasy dockingApparatus for removing/armouring cablesInsulation layerElectrical conductor

The invention relates to the field of cable technology, in particular to a cable end insulation layer removal equipment before installation of cable joints, including a base and a vertical plate, and also includes a controller, a processing table, an unwinding mechanism, a straightening mechanism, a cutting mechanism and a cleaning mechanism. mechanism, unwinding mechanism includes unwinding roller and drive assembly, straightening mechanism includes adjustment assembly, three driving pressure rollers and four driven pressure rollers, cutting mechanism includes tightening assembly, peeling assembly and two semicircular cutters The cleaning mechanism includes a punching bag, an extruding assembly, and a traction assembly. The driving assembly, the tightening assembly, the stripping assembly and the controller are all electrically connected. The present invention relates to a cable end insulation layer cutting device before installation of a cable joint. It can ensure a neat cut and facilitate the installation of joints. At the same time, it has a cleaning function during cutting. It can effectively remove impurities such as dander, facilitate conductor spraying, and ensure that the connecting pipe and conductor are fully fitted, and there is no need for manual unwinding, saving time and effort.

Owner:芜湖市科特电线电缆有限公司

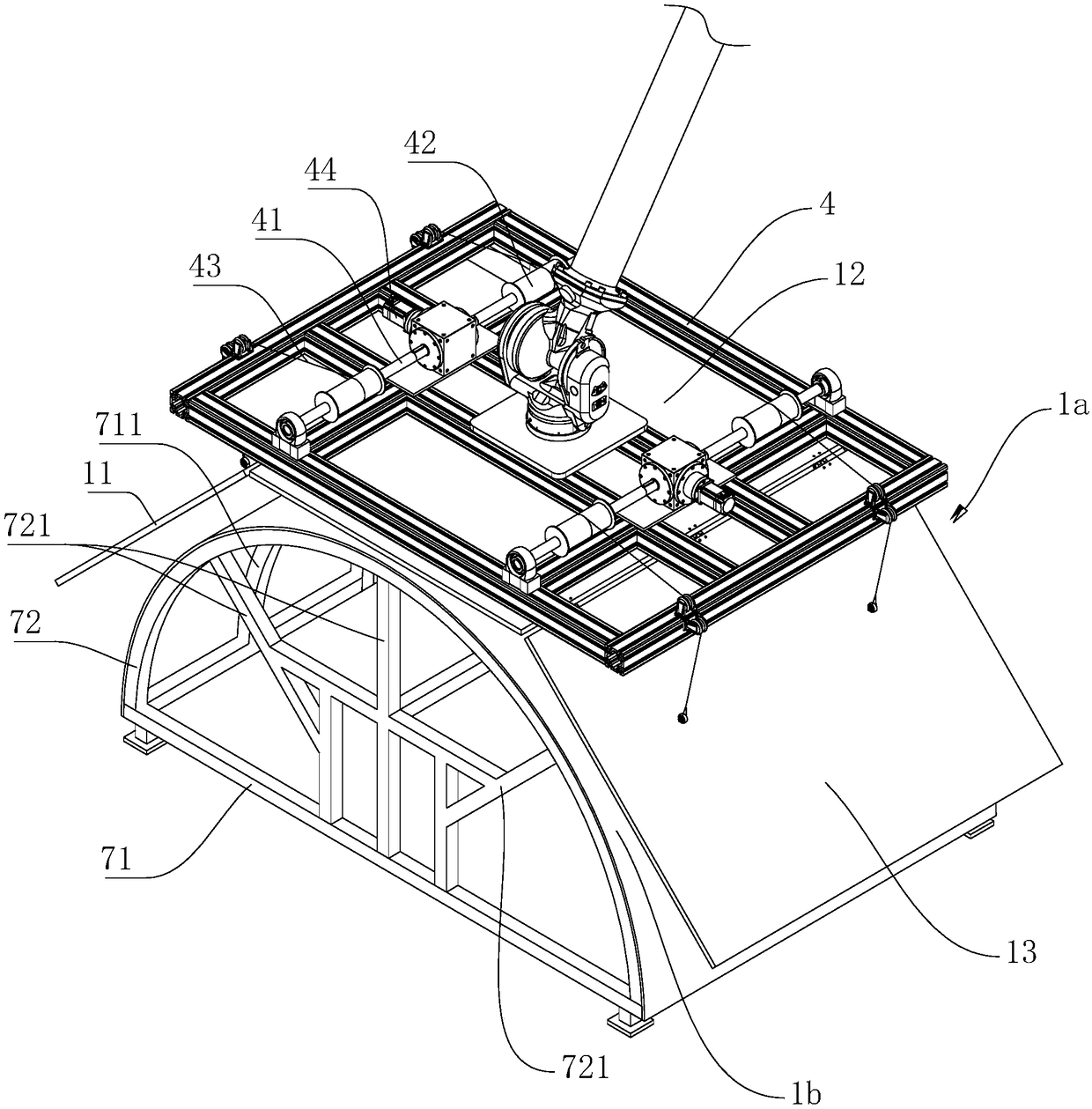

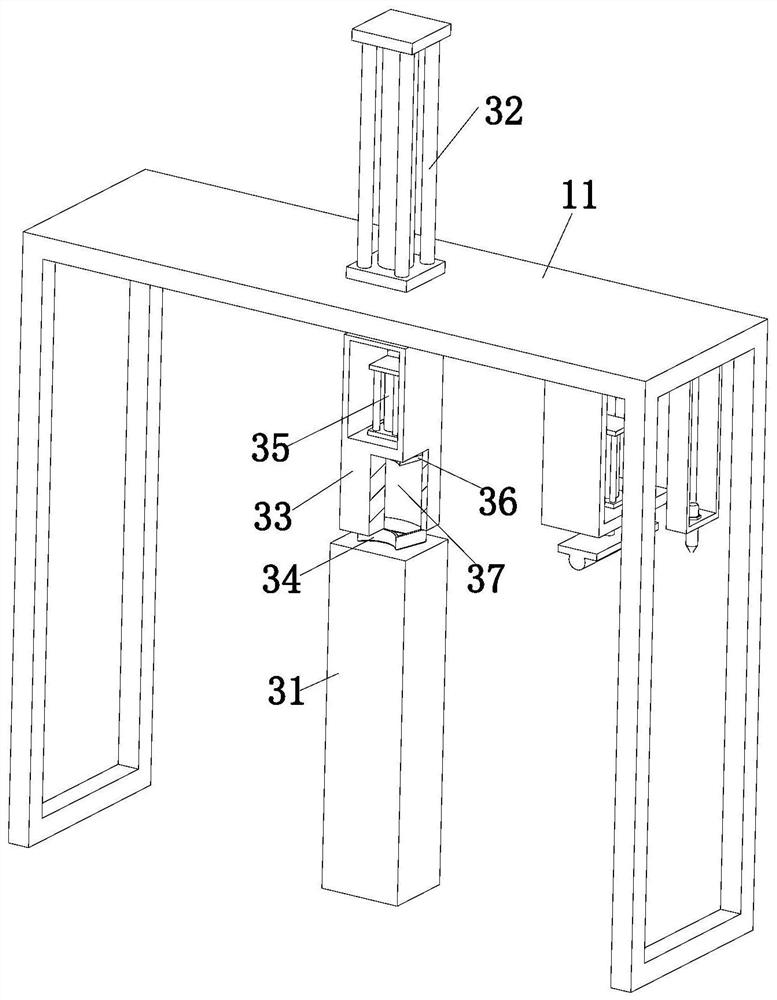

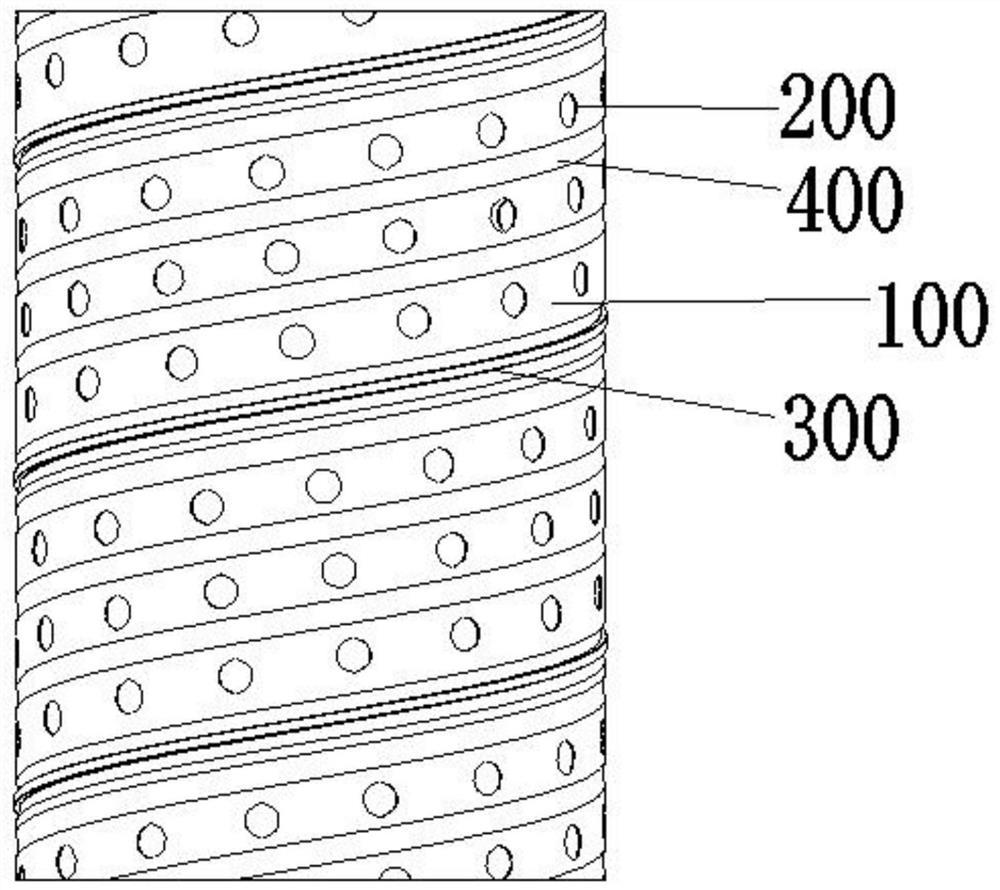

A continuous molding device for filter center pipe

ActiveCN112475026BRealize continuous processing and formingImprove processing efficiencyPunchingEngineering

The invention provides a continuous forming device for a central tube of a filter, comprising an unwinding device; a punching device installed on the right side of the unwinding device; a pushing device installed on the right side of the punching device; and a pushing device installed on the right side of the pushing device The coiling device; the cutting device installed at the front end of the coiling device, the cutting device includes a rotating shell, the center of the rotating shell is provided with a center hole matching the coiling shaft, and the cutting wheel is fixed on the On the installation shaft, one end of the installation shaft is fixed on the rotating shell, the positioning guide wheel is installed on one side of the center hole of the rotating shell, and the pneumatic pull rod is installed on one side of the rotating shell, the pneumatic pull rod and the rotating shell They are fixedly connected by a tie rod shaft. The continuous forming device of the central tube of the filter can realize automatic unwinding, punching, stable feeding, automatic coiling and cutting of the coiled plate, realize continuous processing and forming of the central tube, and greatly improve the processing efficiency and quality of the central tube.

Owner:佛山市豹王滤芯制造有限公司

Portable rust removal equipment for H-shaped steel welding bead in steel structure parking equipment

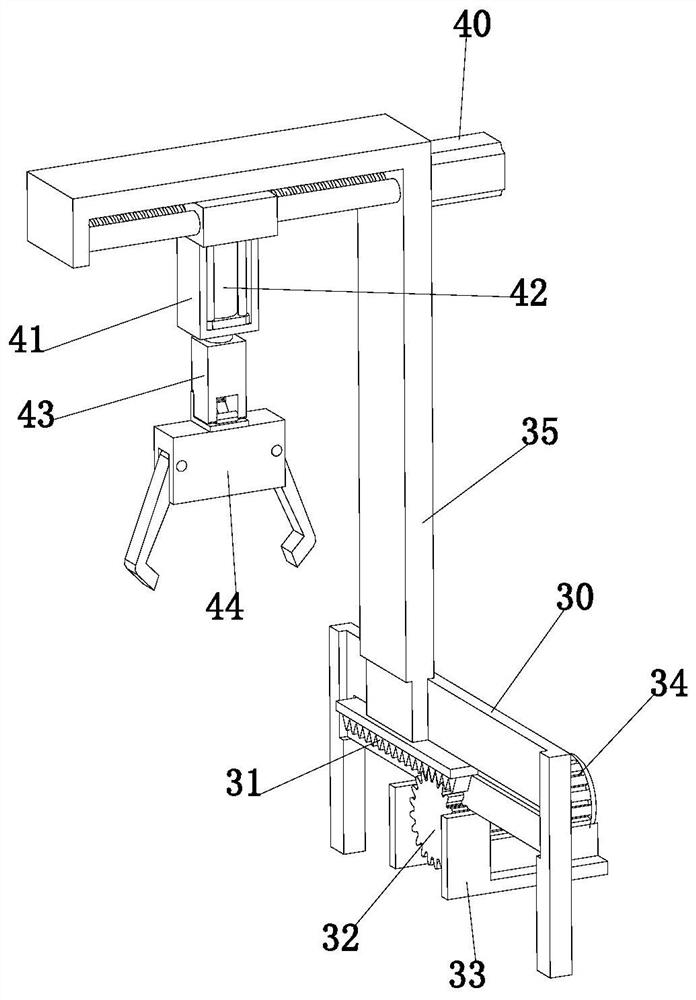

ActiveCN113579959AEasy to carryRealize automatic unwindingGrinding carriagesGrinding drivesGear wheelTraction cord

The invention discloses portable rust removal equipment for an H-shaped steel welding bead in steel structure parking equipment, and belongs to the technical field of H-shaped steel welding bead rust removal. The portable rust removal equipment comprises: an H-shaped steel welding bead body; and rust removal maintenance equipment which comprises a walking piece arranged at the top in the H-shaped steel welding bead body, wherein traction ropes are arranged on the two sides of the walking piece, and the two ends of each traction rope are connected with traction pieces. The walking range of the walking piece is limited through limiting pieces in the traction pieces on the left side and the right side, during rust removal, a contact gear at the position can be meshed with a transmission gear by opening an electromagnet on one side, at the moment, a driving device can be opened to drive a roller body to wind or unwind the traction ropes, the walking pieces walk, and a contact gear on the other side is in a non-meshed state with the transmission gear, so that automatic unwinding can be realized, the walking pieces walk on the H-shaped steel welding bead body in a reciprocating manner under the action of the traction pieces on the two sides to realize rust removal operation, and the working efficiency is improved while the labor intensity of workers is reduced.

Owner:YINGKOU DONGSHENG STEEL STRUCTURE CO LTD

Tension-free, dust-removing leather unwinding device

ActiveCN103318671BRealize automatic unwindingImprove dust removal effectCleaning using toolsWebs handlingEngineeringMechanical engineering

Owner:NEW CENTURY DIGITAL PRINT TECH

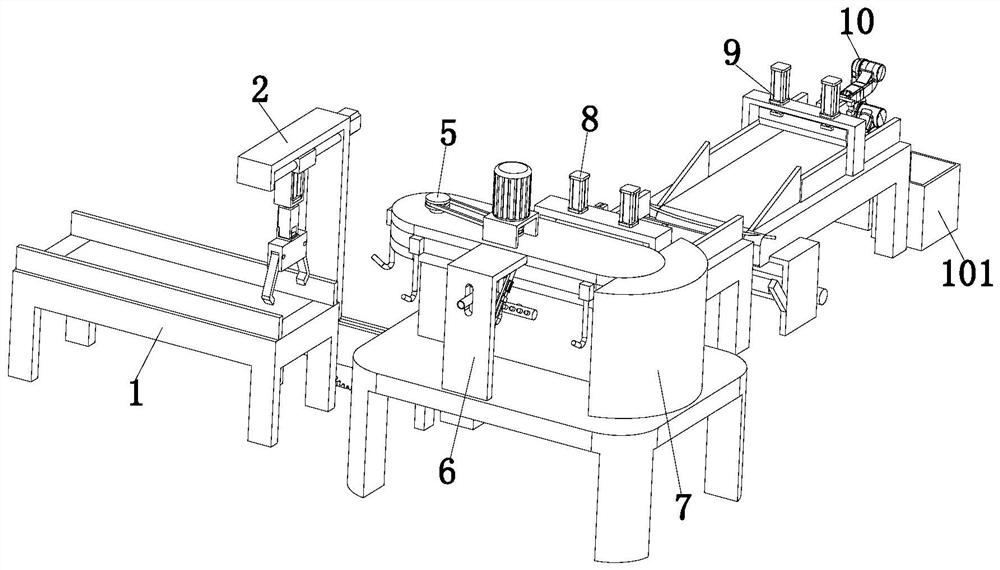

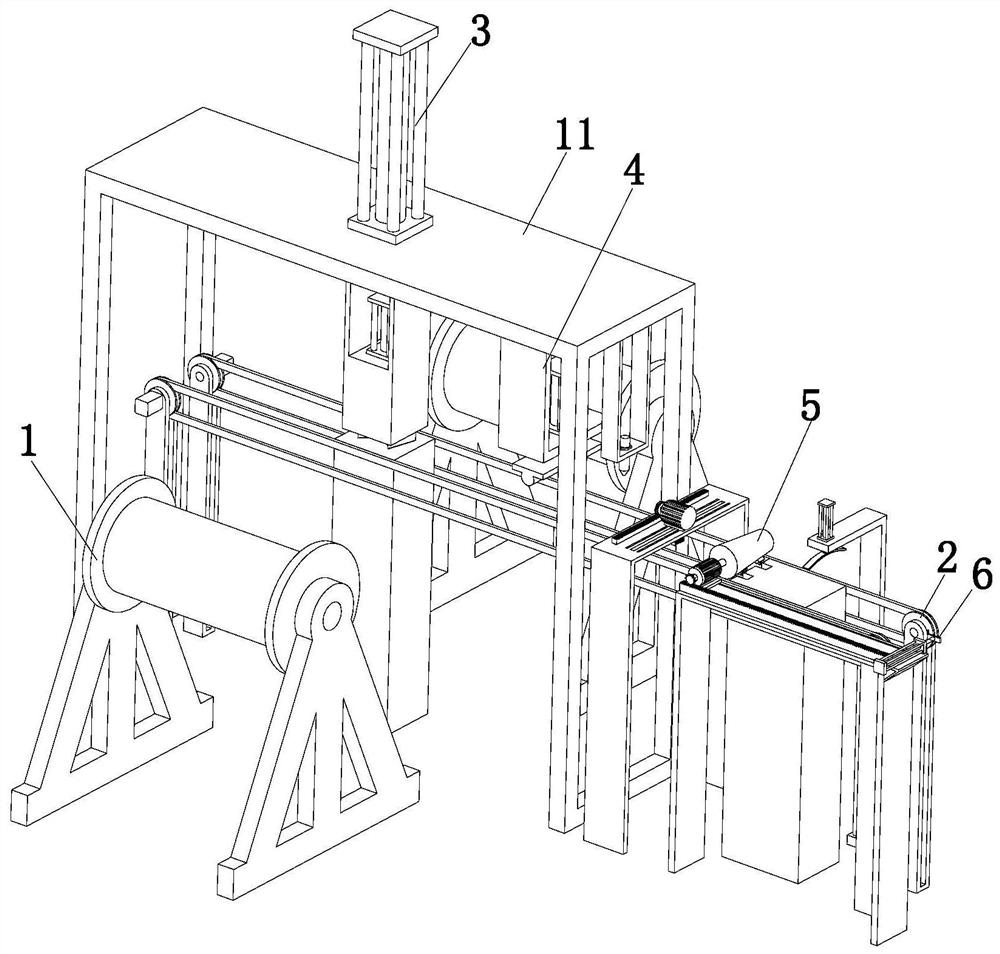

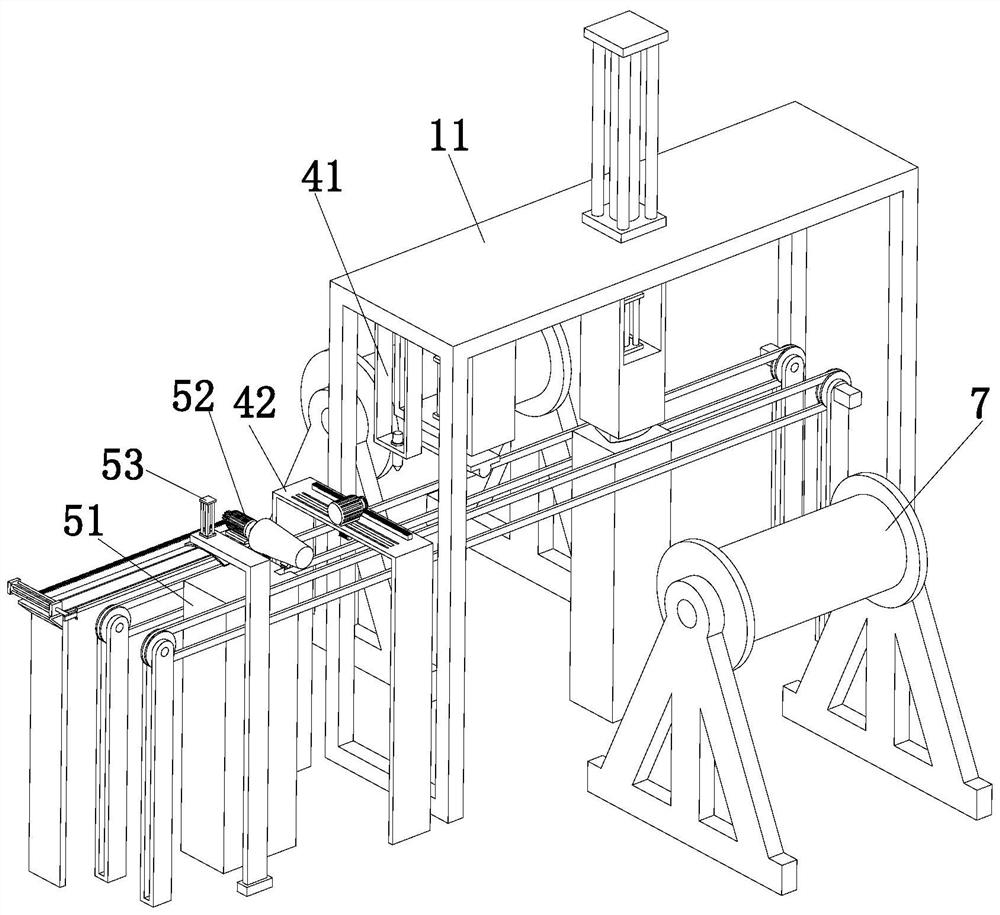

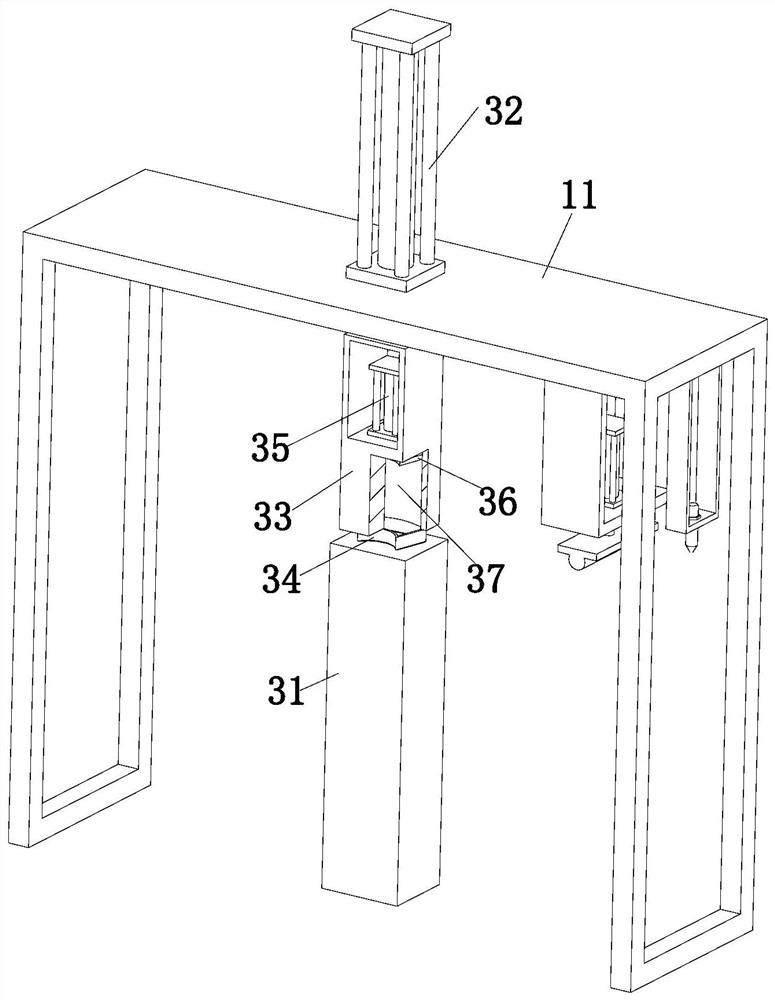

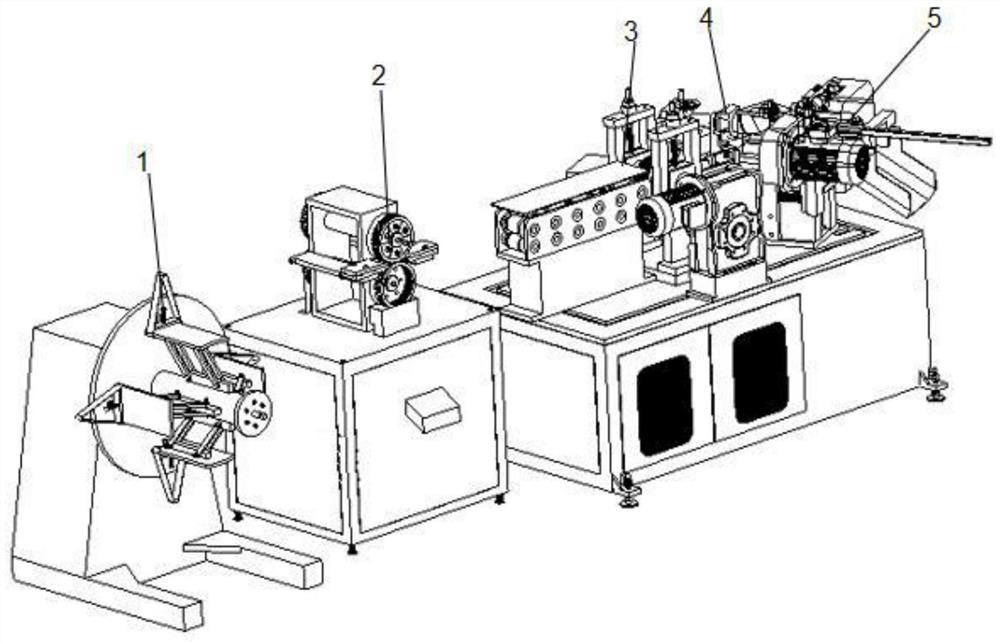

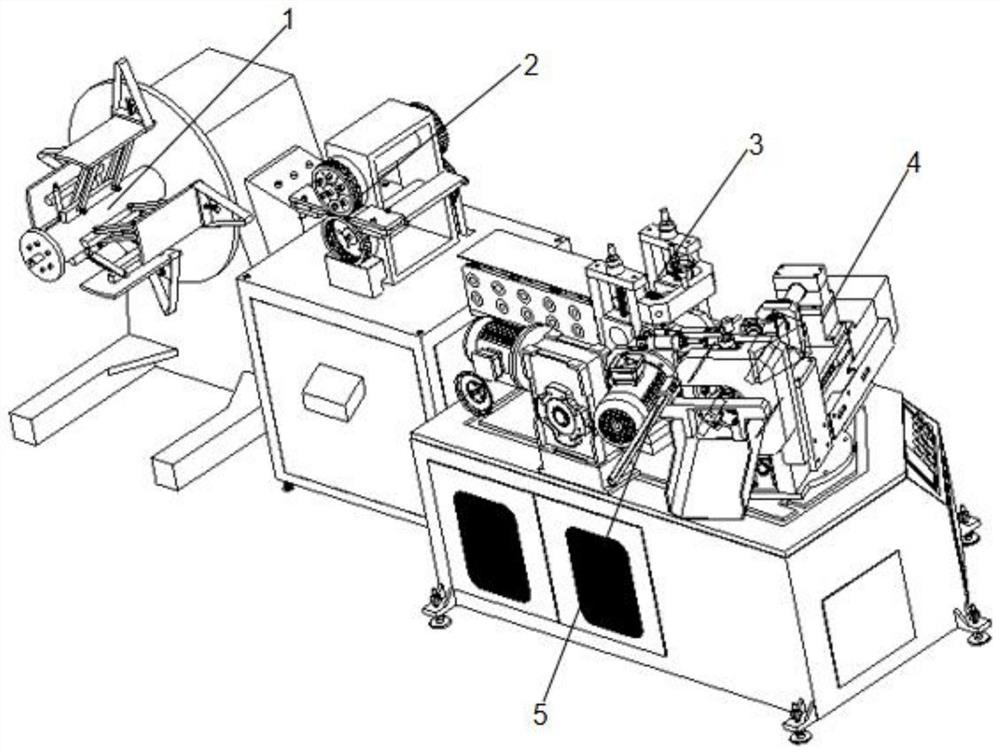

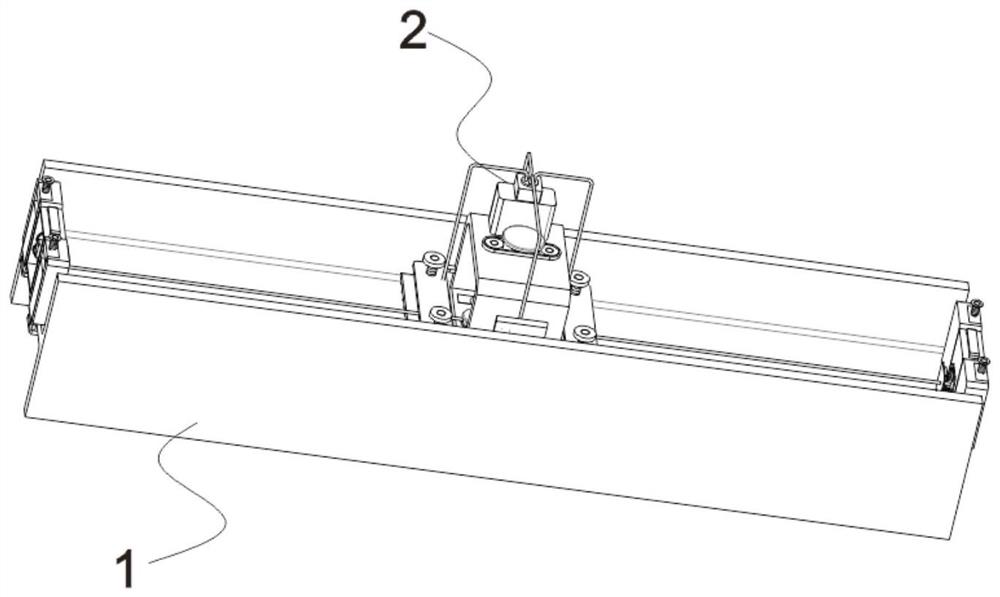

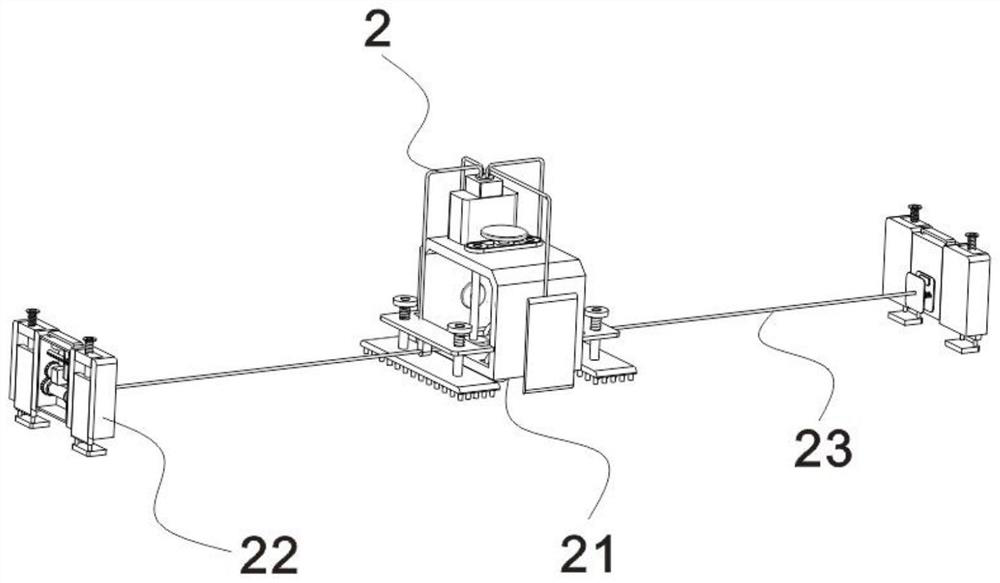

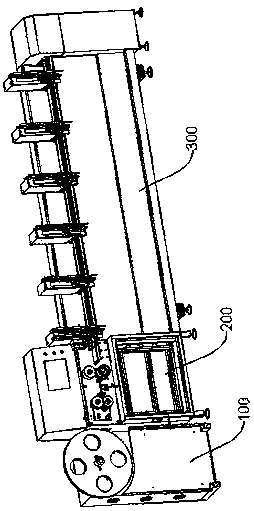

A fully automatic punching and shearing machine

ActiveCN104826916BRealize automatic unwindingRealize automatic feedingMetal-working feeding devicesStripping-off devicesEngineeringFully automatic

Disclosed in the invention is a full-automatic punching and shearing machine comprising a punching and shearing machine rack, a punching and shearing machine, an uncoiler, an intermittence feeding mechanism, and a discharging mechanism. To be specific, the punching and shearing machine is installed at the punching and shearing machine rack. The uncoiler carries out uncoiling on a band coiling element and sends the uncoiled band out. The intermittence feeding mechanism is installed at the punching and shearing machine rack and is located at a feeding side of the punching and shearing machine; and the uncoiled band sent out by the uncoiler is sent to the punching and shearing machine by the intermittence feeding mechanism in an intermittence mode. The discharging mechanism is installed at the punching and shearing machine rack and is located at a discharging side of the punching and shearing machine; and the discharging mechanism pulls a sheet material cut from the band out of the punching and shearing machine. According to the invention, automatic uncoiling and automatic feeding of band coiling elements can be realized automatically; the cut sheet materials can be discharged and laminated automatically; and thus the work efficiency is improved. In addition, the full-automatic punching and shearing machine can be applied to cutting of bands with different widths and different thicknesses; and the application range is wide.

Owner:上海维埃姆电气有限公司

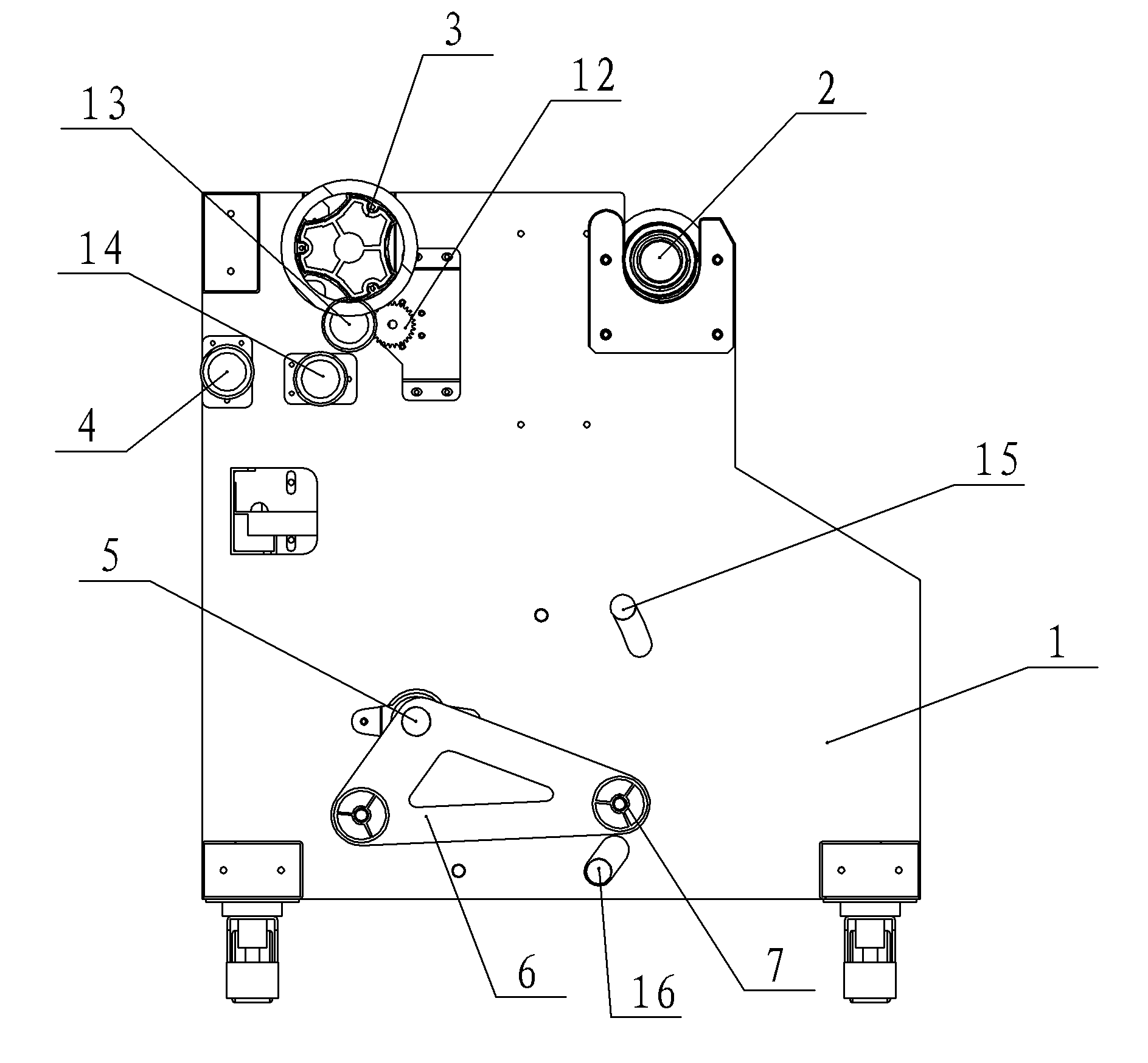

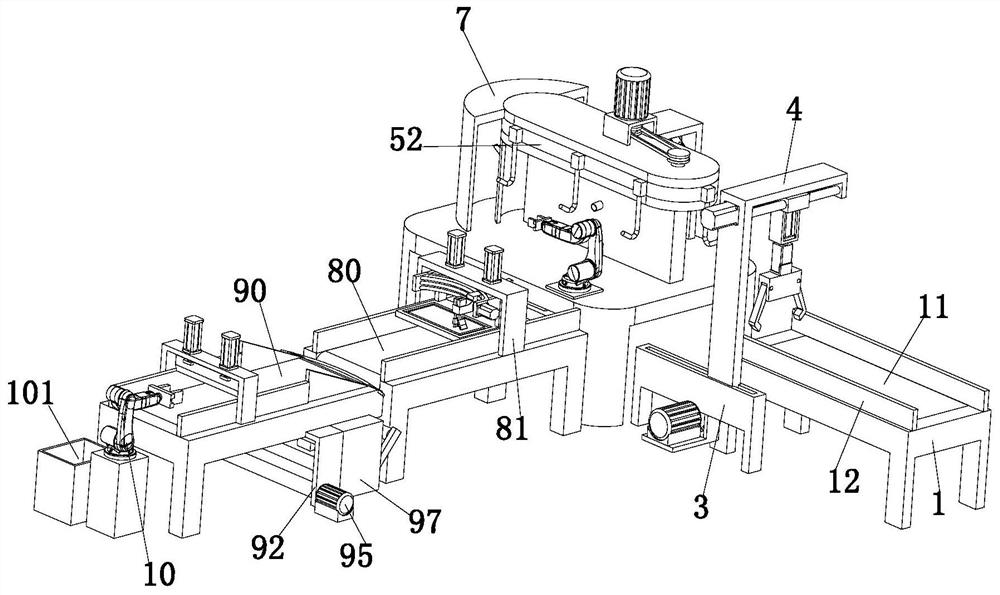

Automatic threading equipment for venetian blind slats

PendingCN110924836ARealize automatic unwindingRealize a high degree of automationDoor/window protective devicesMetal working apparatusGear wheelElectric machinery

The invention discloses automatic threading equipment for venetian blind slats in the field of venetian blind slat machining equipment. The automatic threading equipment for the venetian blind slats comprises a threading device, a plurality of threading assemblies are arranged on the threading device, in the threading assemblies, sliding servo motors drive motor rotating gears to rotate, so that threading sliding blocks slide along a left sliding rail and a right sliding rail, a lifting servo motor drives lifting supporting plates to slide up and down through a lifting shaft, a lifting gear and a lifting rack sequentially, string shifting air cylinders are connected with string shifting blocks and drive the string shifting blocks to slide left and right, the blind slats are located on theupper sides of the lifting supporting plates and the upper sides of the string shifting blocks, and a ladder rope is hung on blind slat supporting frames after passing by the string shifting blocks. According to the automatic threading equipment for the venetian blind slats, automatic unwinding, arc pressing, punching, slicing and ladder rope penetrating processes of the blind slats can be achieved, meanwhile, the draw rope penetrating process can be achieved in a manually and automatically cooperated mode, so that the highly automatic process of the venetian blind production is realized, thelabor cost is greatly saved, and meanwhile, the production efficiency and the machining precision are improved.

Owner:汉狮光动科技(广东)有限公司

Unwinding feeding frame for glass fiber tape

PendingCN113799410AQuick changeIncrease productivityArticle deliveryWebs handlingGlass fiberMechanical engineering

The invention discloses an unwinding feeding frame for a glass fiber tape. The unwinding feeding frame is detachably and fixedly connected to a notch of an epoxy impregnating tank. The unwinding feeding frame sequentially comprises an unwinding device, an impregnating conveying device, a tape scraping conveying device and a discharging conveying device along the glass fiber tape. The unwinding device, the impregnating conveying device, the tape scraping conveying device and the discharging conveying device are fixedly connected through side rods correspondingly matched with the tank walls on the two sides of the epoxy impregnating tank. A plurality of vertical rods are evenly and fixedly connected to the bottoms of the side rods. The bottoms of the outer side walls of the vertical rods are fixedly connected with flanges A. Flanges B are arranged at notches of the tank walls on the two sides of the epoxy impregnating tank. Locking devices used for locking and fixing the flanges A and the flanges B are arranged on the tank walls on the two sides of the epoxy impregnating tank. According to the structure, the unwinding feeding frame for the glass fiber tape achieves automatic unwinding, impregnating, tape scraping and gathering discharging of the glass fiber tape, and it is guaranteed that the discharged glass fiber tape can be automatically wound around an epoxy glass tube.

Owner:盐城品冠高压电气有限公司

Automatic bending and wire-wrapping process for copper sheet shielding layer of mutual inductor

InactiveCN112216498ATo achieve the purpose of deliveryEasy to cutTransformersTransformers/inductances coils/windings/connectionsStructural engineeringInductor

The invention discloses an automatic bending and wire wrapping process for a copper sheet shielding layer of a mutual inductor, and belongs to the field of mutual inductor processing. The process comprises the following steps: 1, automatically unwinding a copper sheet; 2, automatically cutting the copper sheet; 3, automatically bending the two sides of the copper sheet; 4, mounting a lead at the bent part of the copper sheet; 5, transversely and longitudinally flattening the copper sheet to wrap the lead; 6, cutting off redundant leads in the copper sheet; 7, automatically laying off. The method is ingenious in process design and smooth in procedure connection, the purpose of automatically machining the copper sheet shielding layer of the mutual inductor is achieved, manual operation for bending the covered wire is not needed, one person can be responsible for one production line, the yield and the productivity are greatly improved, and the method has remarkable economic value.

Owner:王伟林

An anti-winding collection device for cables

The invention discloses a cable anti-winding collecting device comprising a base; the top portion of the base is connected with an anti-winding device through a sliding groove in a sliding mode; one side of the top portion of the base is fixedly connected with a rotating support; the end face of the rotating support is provided with a collecting roller in a sleeving mode; one side of the collecting roller is rotatably connected with a handle; the anti-winding device comprises a sliding rail; the surface of the sliding rail is connected with the sliding groove in a sliding mode; the top portionof the sliding rail is fixedly connected with a supporting arc; two sides of the supporting arc are both fixedly connected with fixed supports; and the surfaces of the fixed supports are provided with spring-back sliding grooves. The invention relates to the technical field of cable machinery tool. According to the cable anti-winding collecting device, the anti-winding device straightens the winding inner diameter of a cable insulation layer by squeezing, the winding degree of the cable is relieved, balls can effectively defuse extrusion force on the cable surface, the cable is prevented fromirreversibly deforming and causing damage, the collecting operation is more smooth by the balls, and effort is saved.

Owner:温州拓远电气有限公司

Telescopic winding device capable of continuously rotating

PendingCN114249184ARealize the tension functionRealize the recycling functionCoil springContinuous rotation

The invention discloses a winding device capable of telescoping and continuously rotating, and belongs to the technical field of corrugated pipe application. The device comprises a corrugated pipe, a storage box and at least three tensioning wheels, wherein the corrugated pipe is connected with an action arm; a top cover of the storage box is provided with a storage hole, and one end of the corrugated pipe penetrates through the storage hole, extends out of the storage box and is connected with an external action arm through a flange; the top cover of the storage box is provided with a pin shaft which is parallel to the top cover and is used for mounting the tensioning wheel; the tensioning wheel rotates along a pin shaft penetrating through a central shaft of the tensioning wheel, and a coil spring is arranged between the tensioning wheel and the pin shaft; each tensioning wheel is tightly attached to the portion, exposed out of the containing hole, of the corrugated pipe. According to the winding device, winding on occasions with continuous rotation and telescopic movement can be achieved at the same time.

Owner:NO 54 INST OF CHINA ELECTRONICS SCI & TECH GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com