Patents

Literature

132results about How to "Realize the recycling function" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for preparing sewage treatment adsorbent by edible fungi residues

ActiveCN104107684AAvoid pollutionSolve problems such as pollutionOther chemical processesWater/sewage treatment by sorptionSuspended particlesSorbent

The invention relates to a method for preparing a sewage treatment adsorbent, and particularly relates to a method for preparing a sewage treatment adsorbent by edible fungi residues. The method comprises the steps of with the edible fungi residues as raw materials, crushing the raw materials, carrying out microwave-assisted alkali process degradation, washing, formaldehyde modification, washing, and drying. The sewage treatment adsorbent prepared by adopting the method not only solves the problem of waste of a fungi residue resource, and also can be used for adsorbing and settling suspended particles, organic dye, heavy metal ions and the like in the earlier-stage processing of sewage, thereby realizing a function of recycling the edible fungi residues.

Owner:NANJIANG HONGXIN BIOTECH

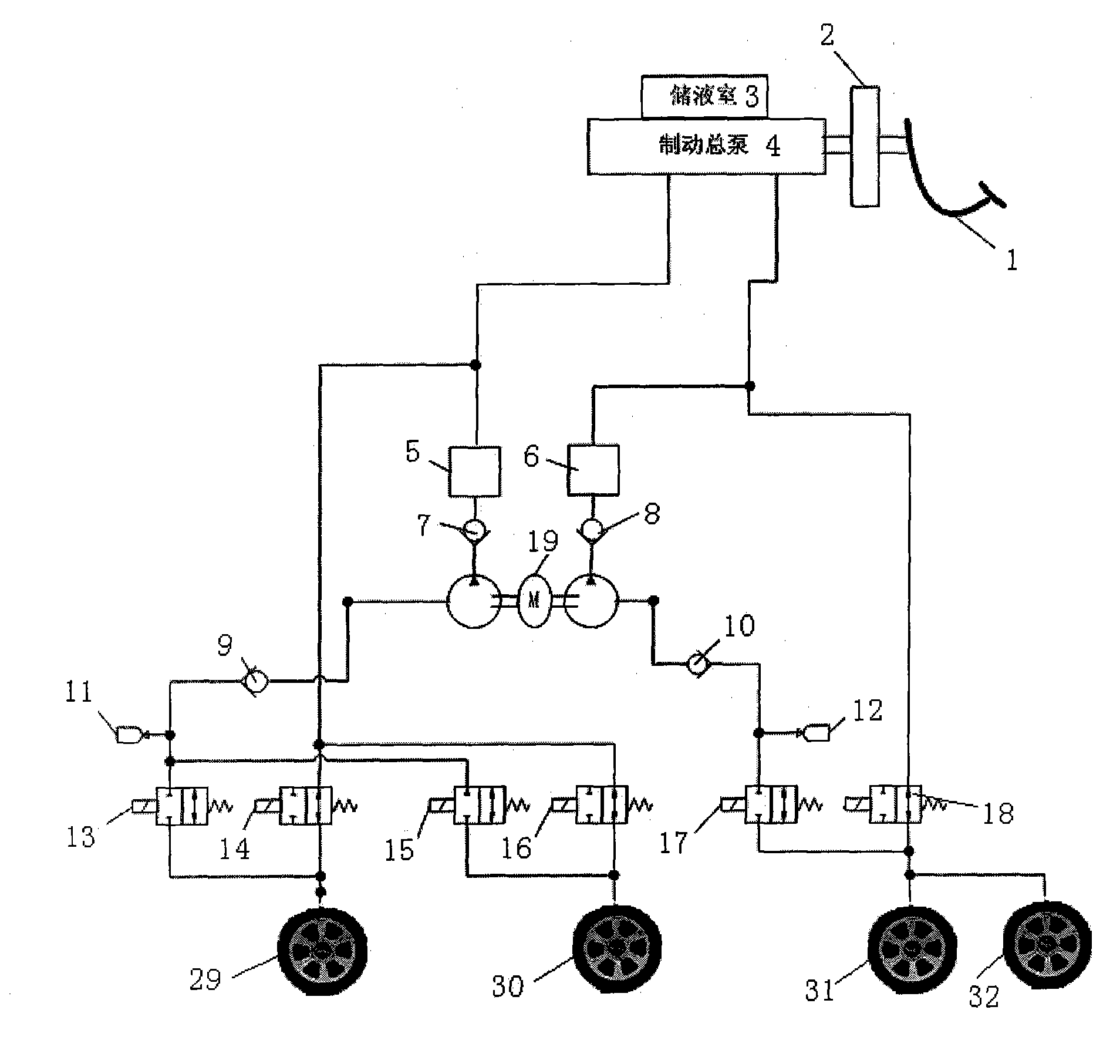

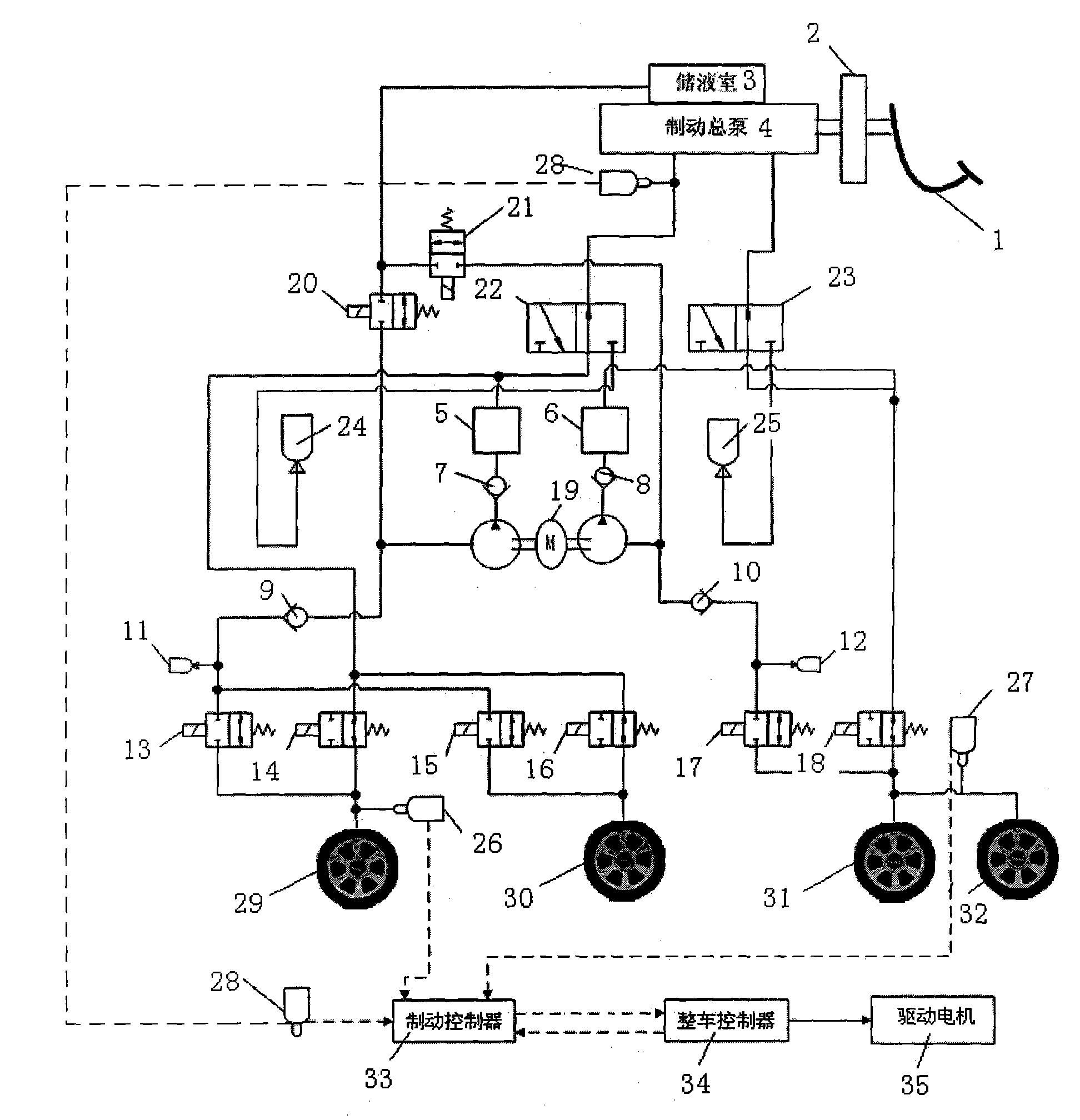

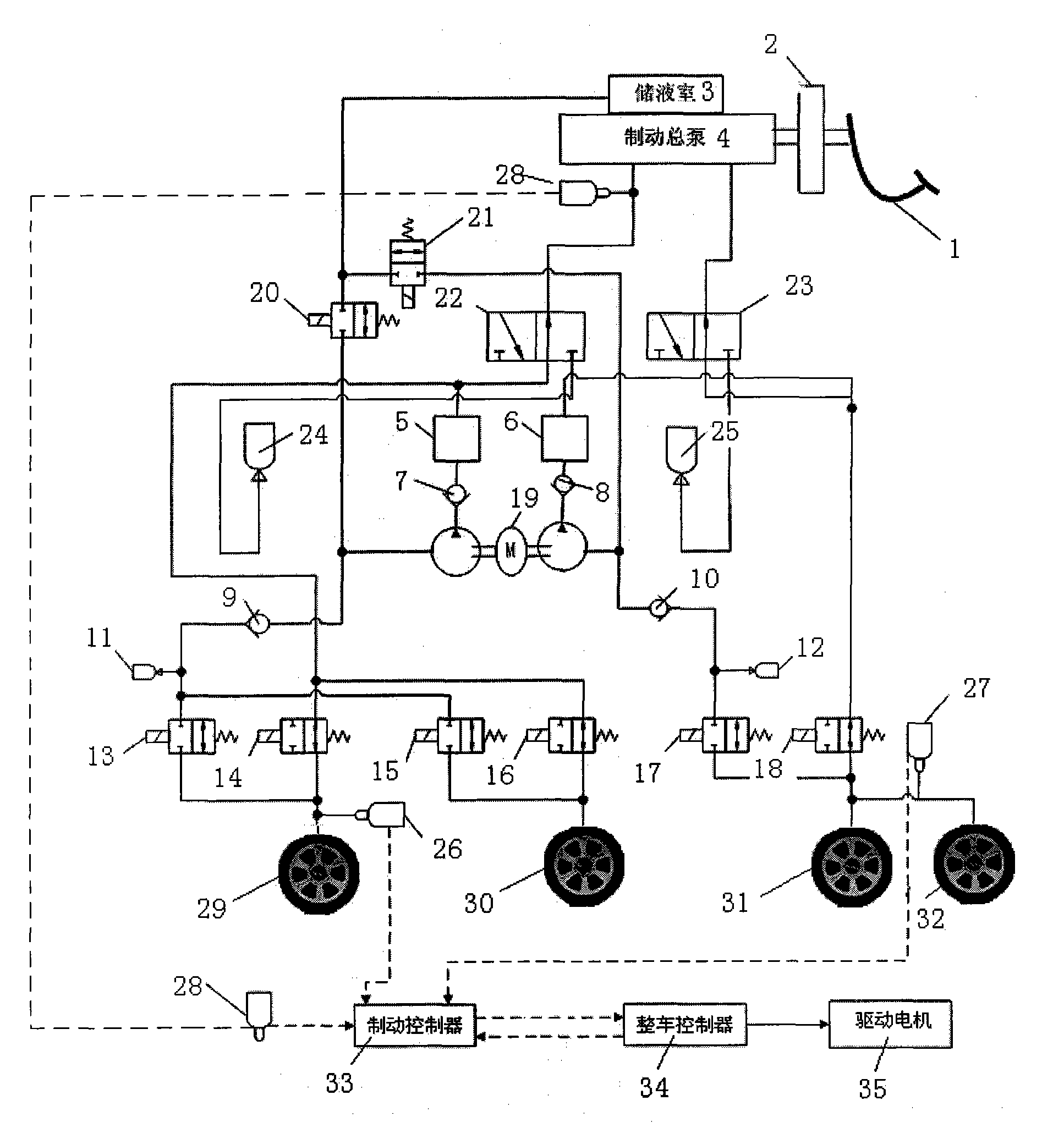

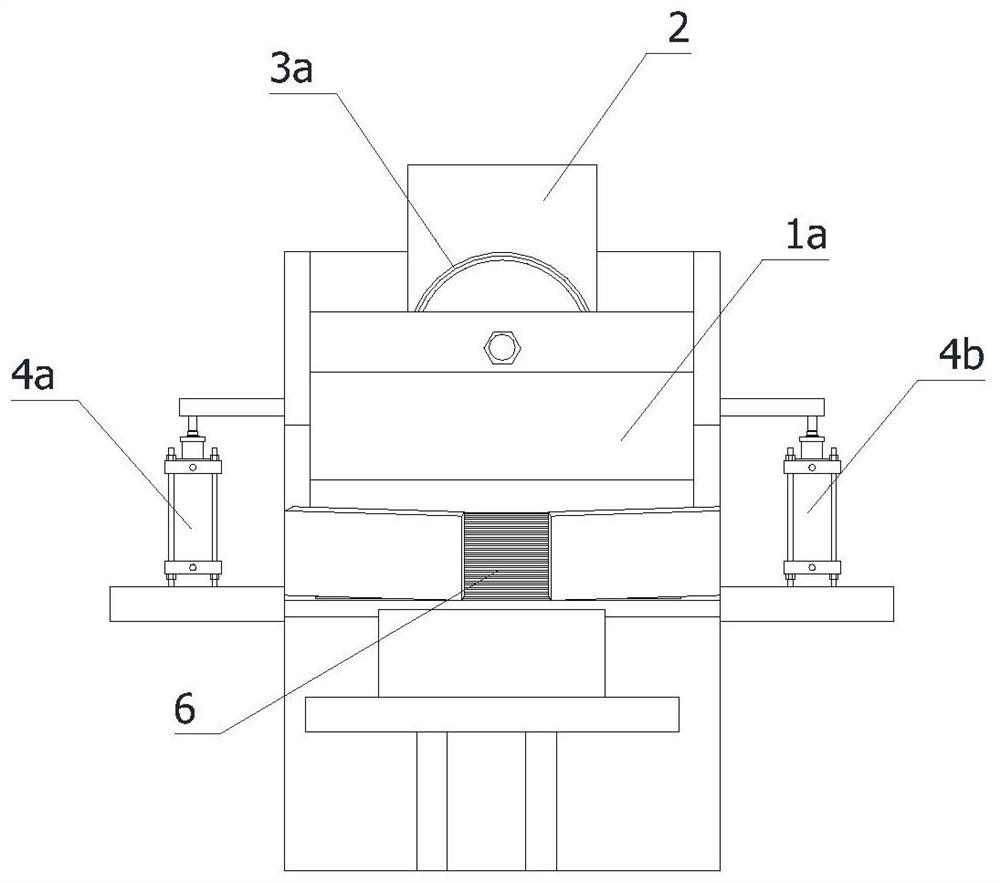

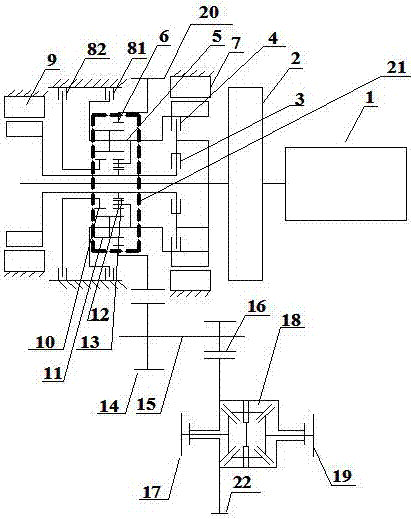

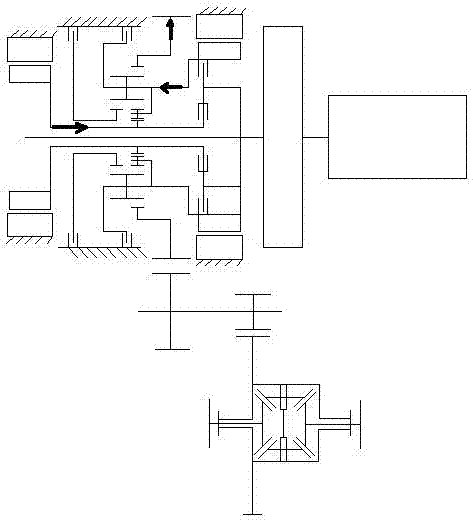

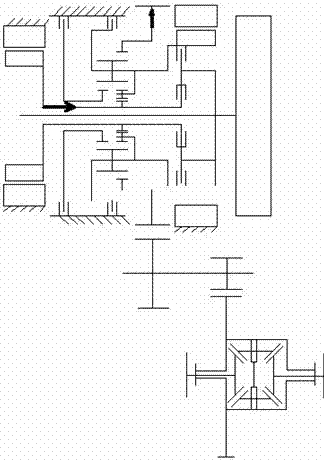

Hydraulic braking system of four-wheel driven electric vehicle

ActiveCN101941430AWith recycling functionRealize the recycling functionBraking action transmissionDriving safetyDriving range

The invention discloses a hydraulic braking system of a four-wheel driven electric vehicle. Based on the conventional hydraulic braking system, the system has the following characteristics that: 1, a selector valve and a master cylinder brake pressure sensor are arranged in front of a high-pressure damper on a brake pipeline led out of a master brake pump, a pipeline is connected from an outlet of the selector valve, and a medium pressure energy accumulator is arranged; another selector valve is arranged in front of the high-pressure damper on another brake pipeline, a pipeline is connected from the outlet of the selector valve, and a medium pressure energy accumulator is arranged; 2, two pipelines are led out of a liquid storage chamber and communicated with two one-way valves, and a switching electromagnetic valve is arranged on the pipeline; and 3, a wheel cylinder brake pressure sensor is connected at a left front wheel cylinder and a right rear wheel cylinder respectively. The system can ensure the same feeling of brake pedal as that of the conventional hydraulic braking system; the braking energy recovery efficiency reaches the maximum; and an ABS function can also be realized; and the driving safety is ensured and the driving range of an electrically-propelled vehicle is widened.

Owner:TSINGHUA UNIV

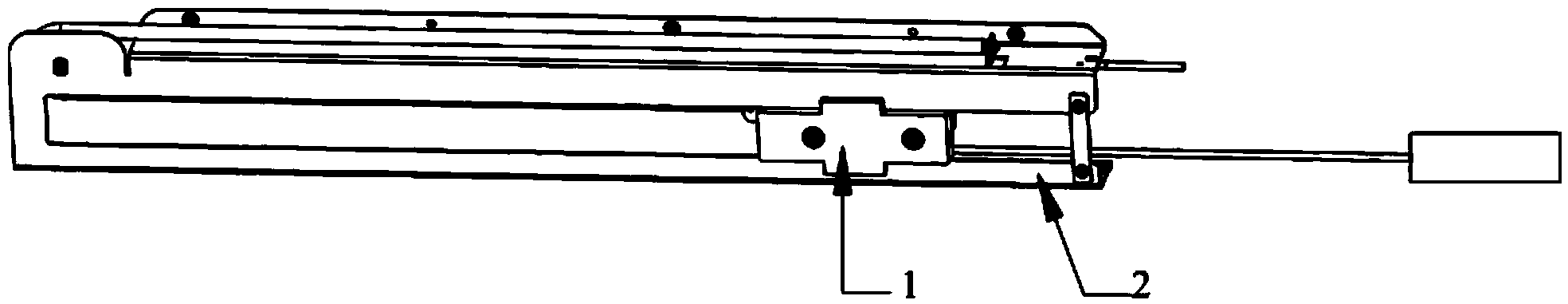

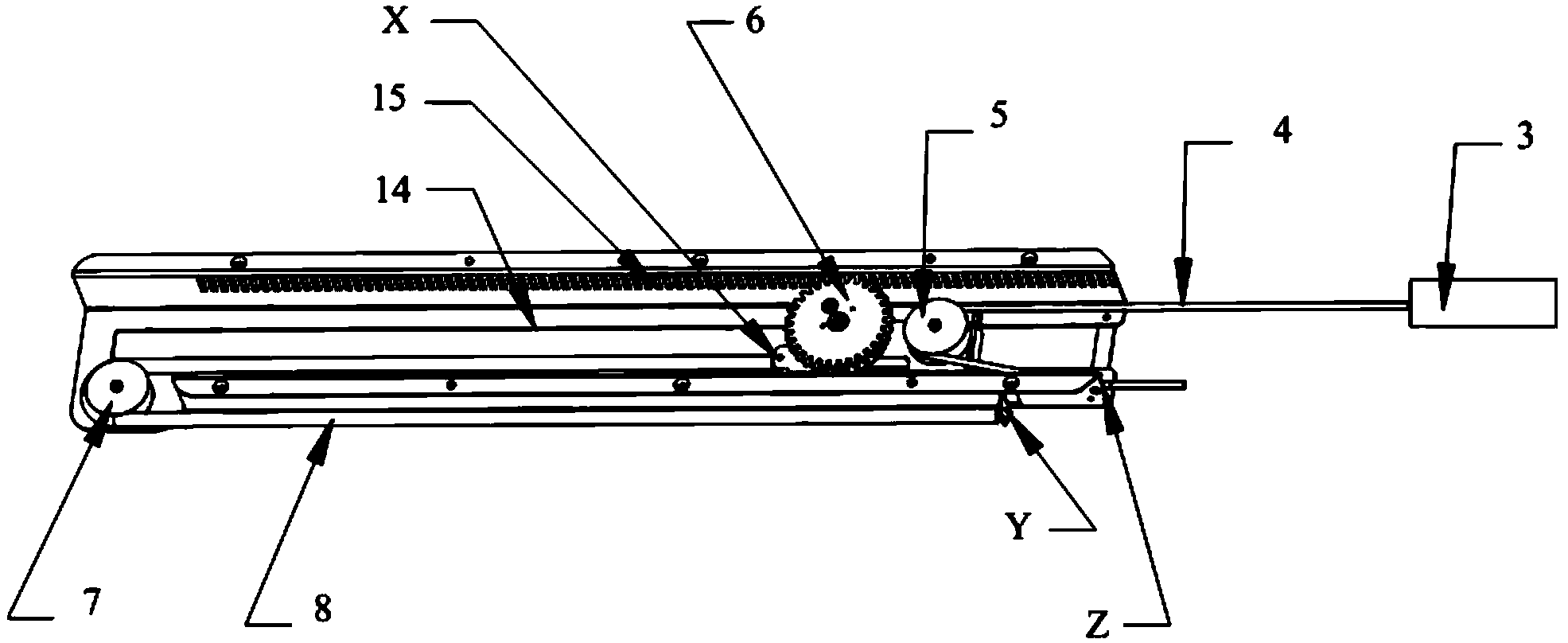

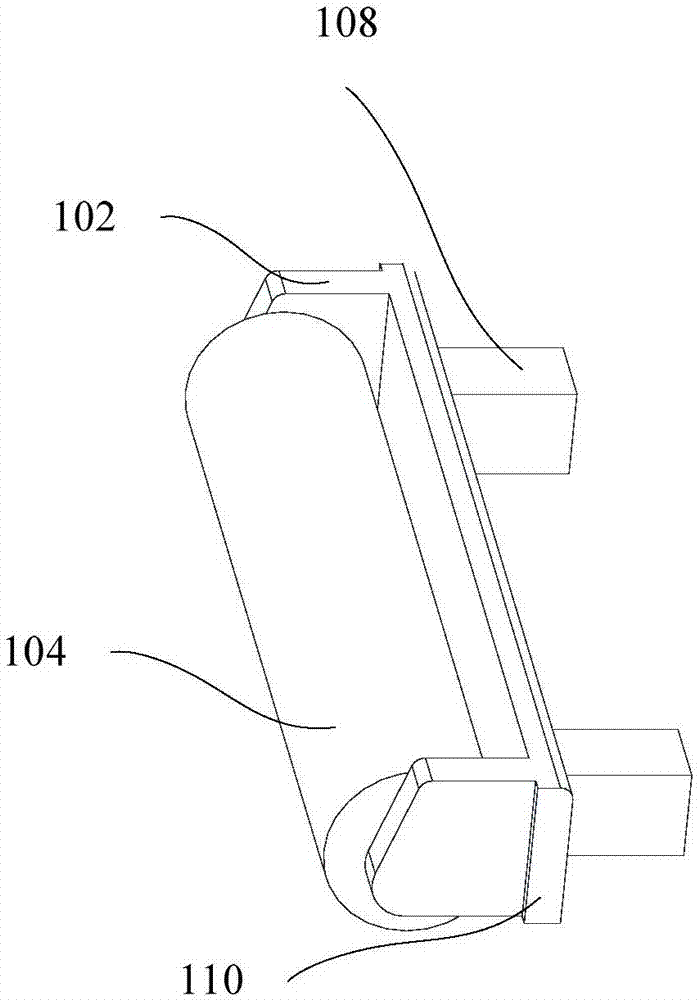

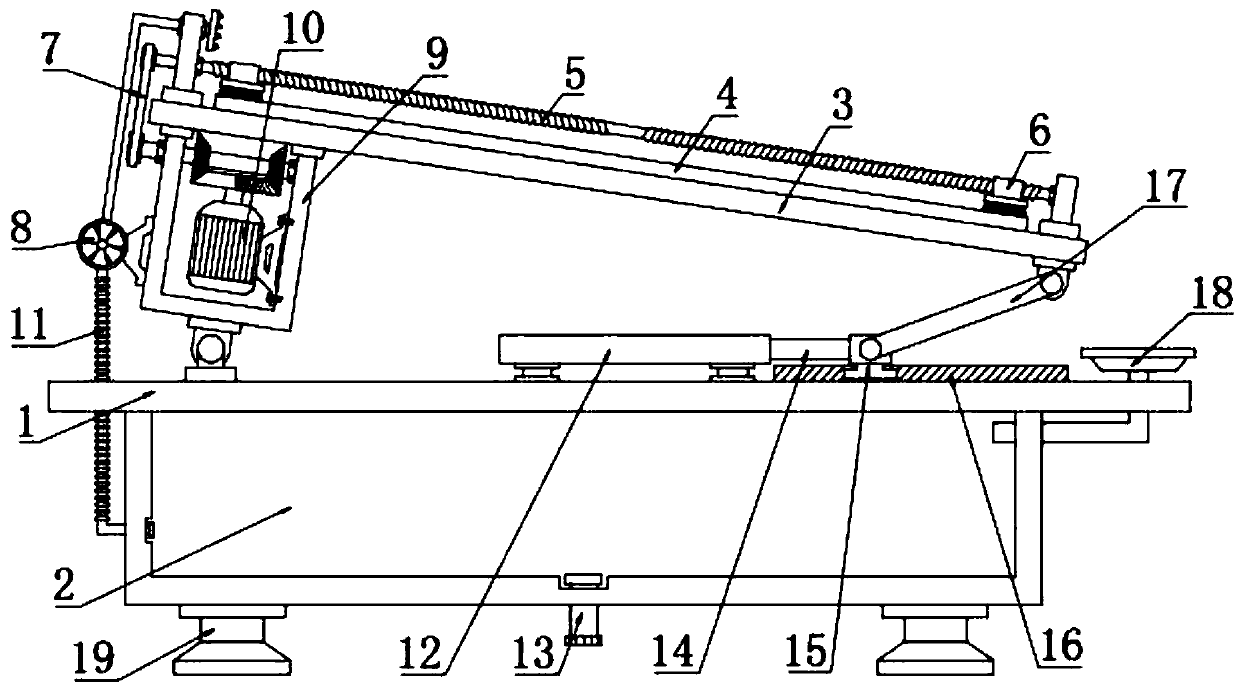

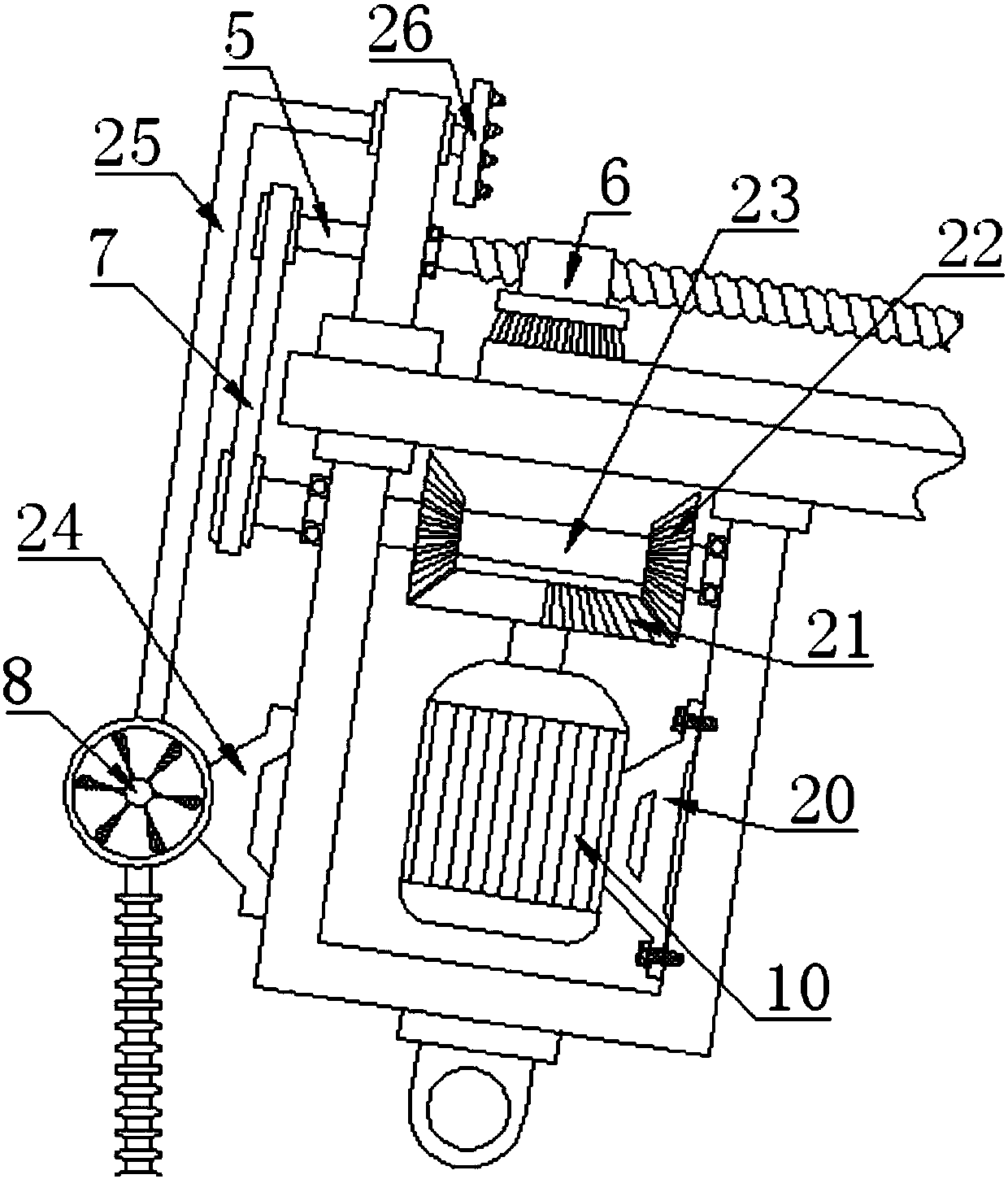

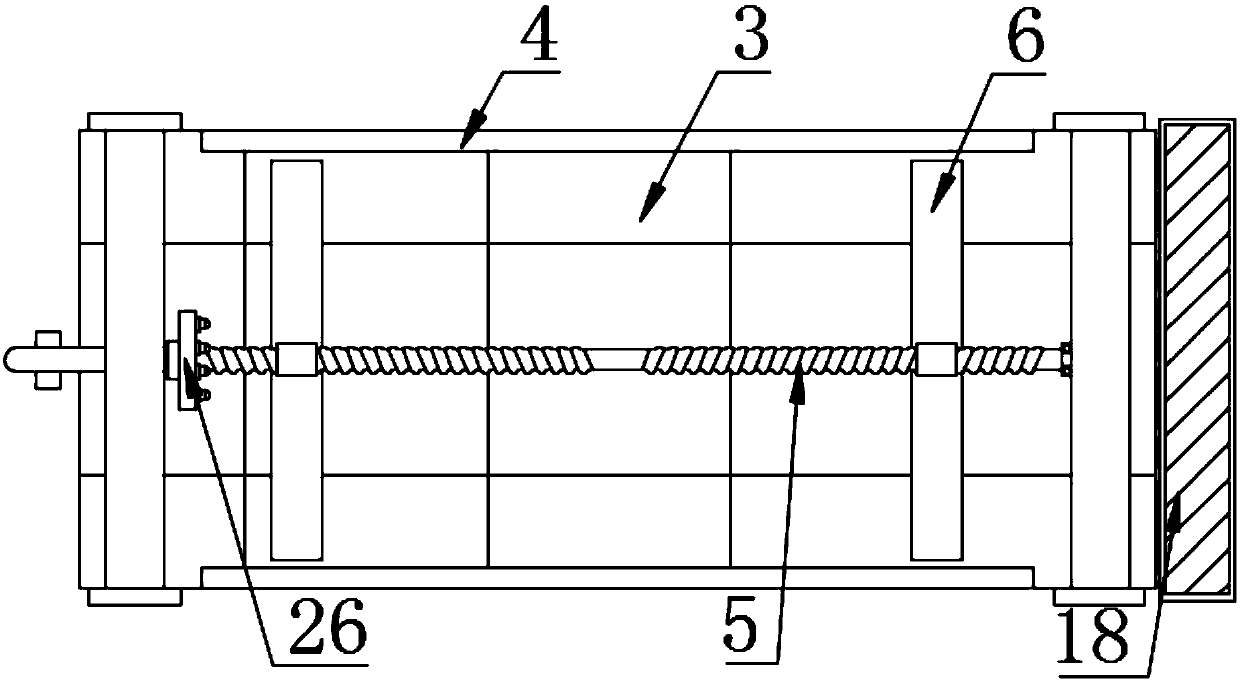

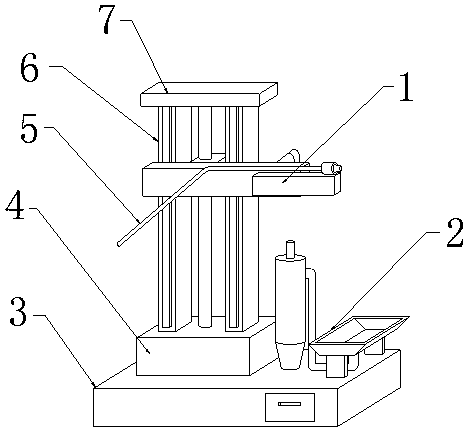

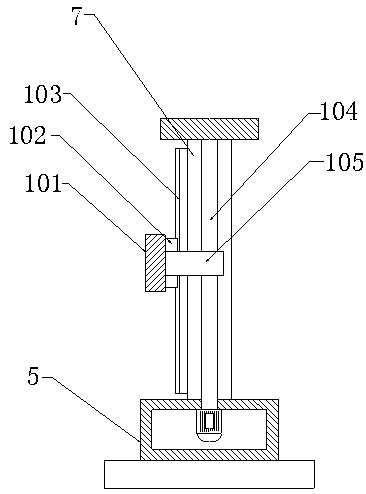

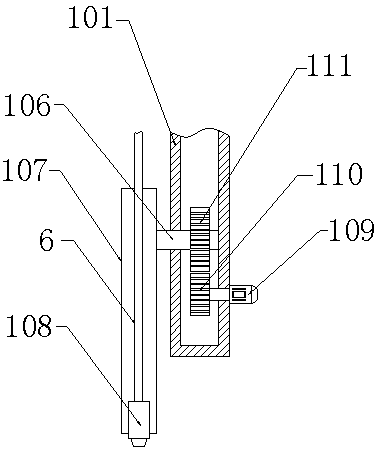

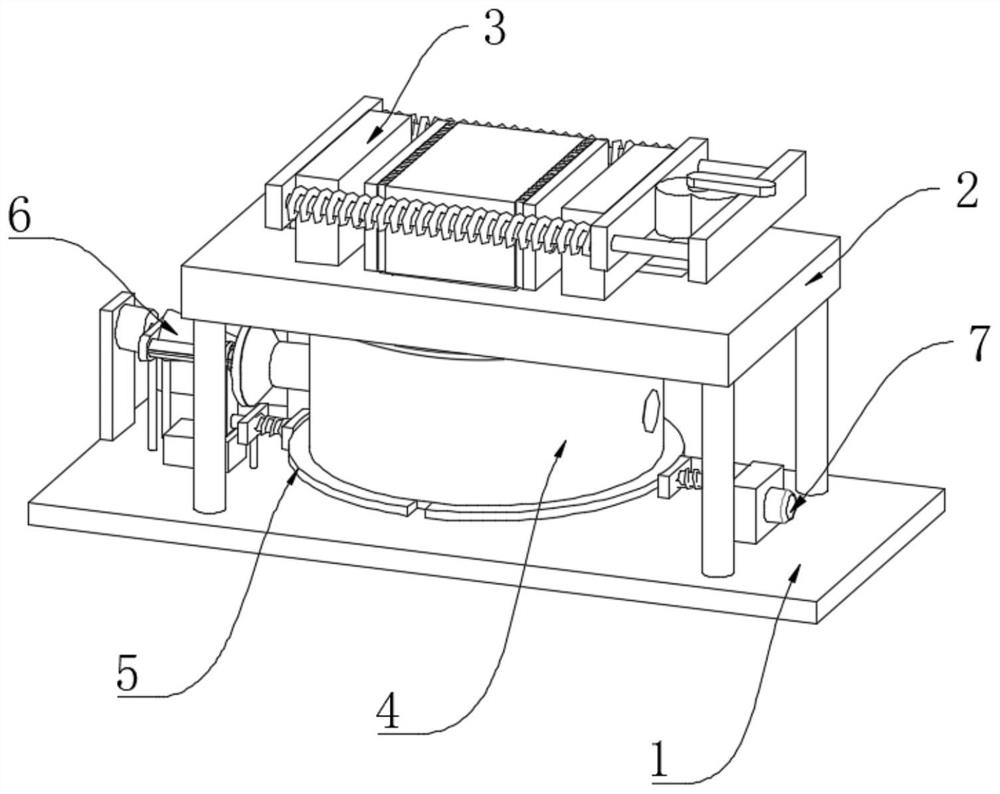

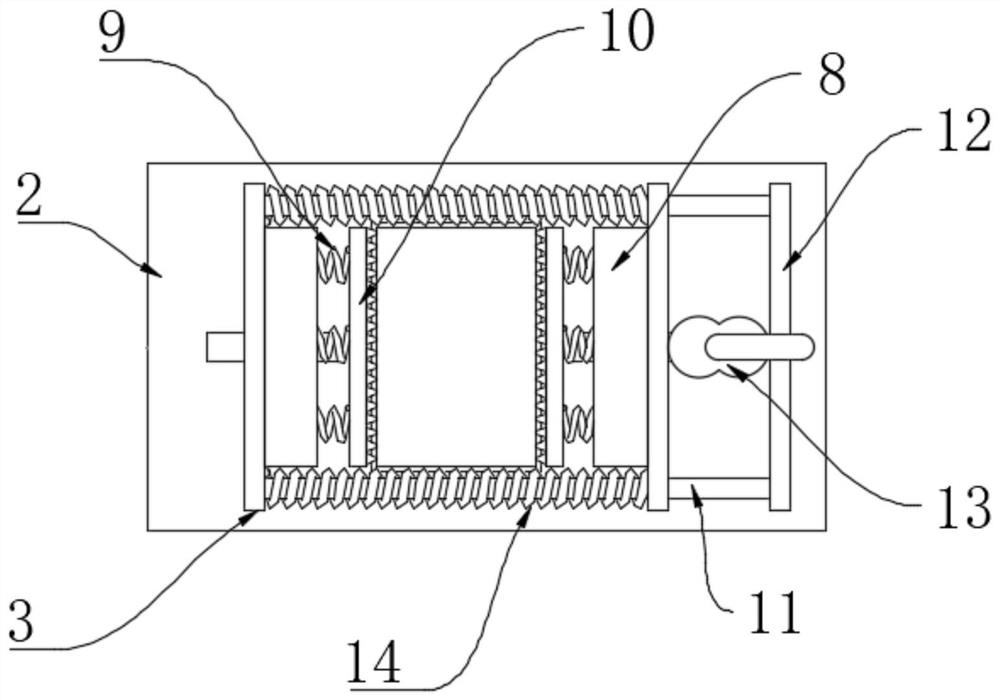

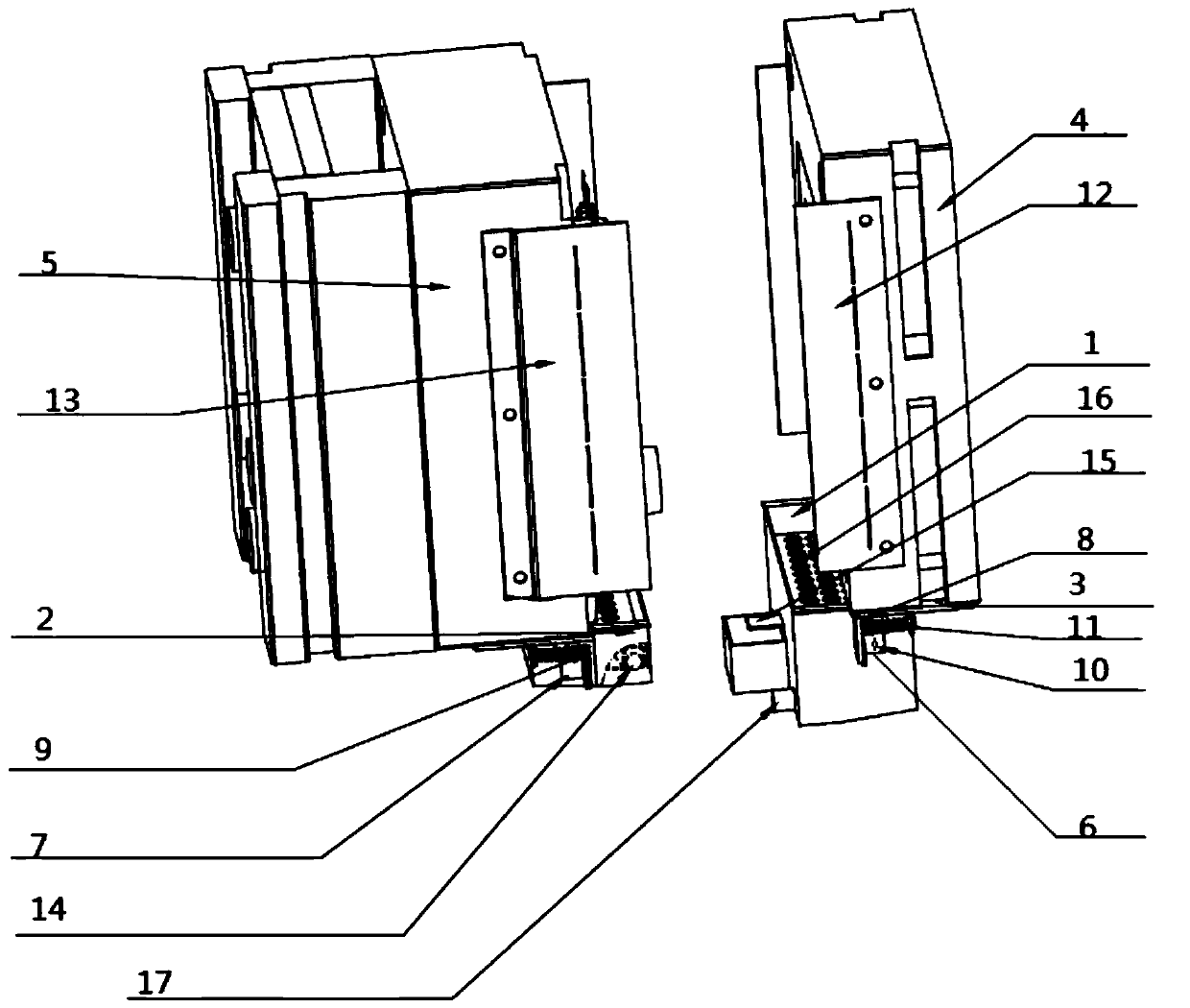

Telephone wire take-up device

ActiveCN103873623AAchieve rotationRealize the recycling functionTelephone set constructionsLocking mechanismSelf locking

The embodiment of the invention discloses a telephone wire take-up device. The telephone wire take-up device is used for achieving the pay-off function and the take-up function on a telephone wire, enables operation to be smooth, improves user experience and avoids call distortion caused by application of an electric brush due to the fact that the electric bush is not needed. The telephone wire take-up device comprises a sliding block 1, a machine frame 2, a microphone 3, a telephone wire 4, an idler wheel A5, a rotation self-locking mechanism 6, an idler wheel B7 and an extension spring 8. The rotation self-locking mechanism is composed of a base 9, a gear shell 10, a shifting sheet 11, an elastic sheet A12 and an elastic sheet A13.

Owner:GRG BAKING EQUIP CO LTD

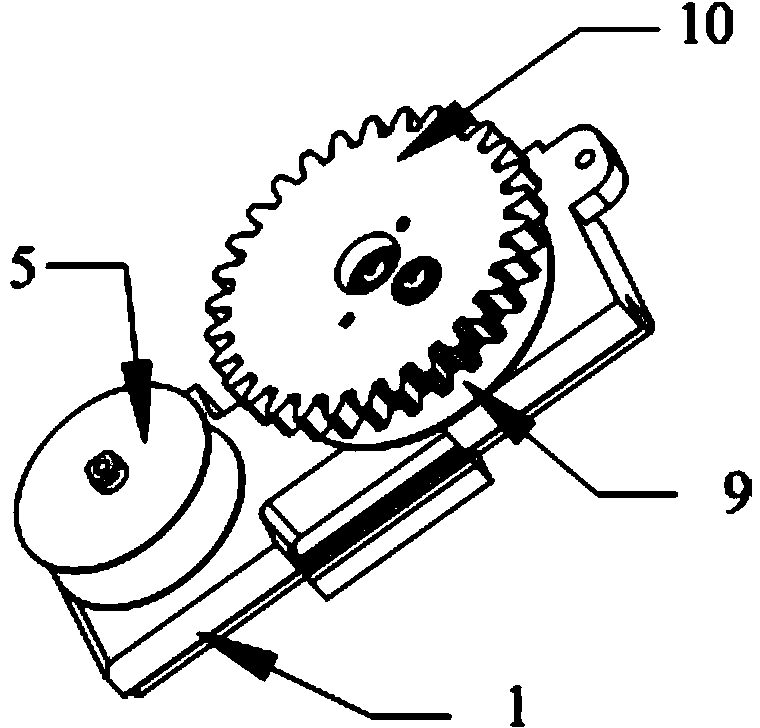

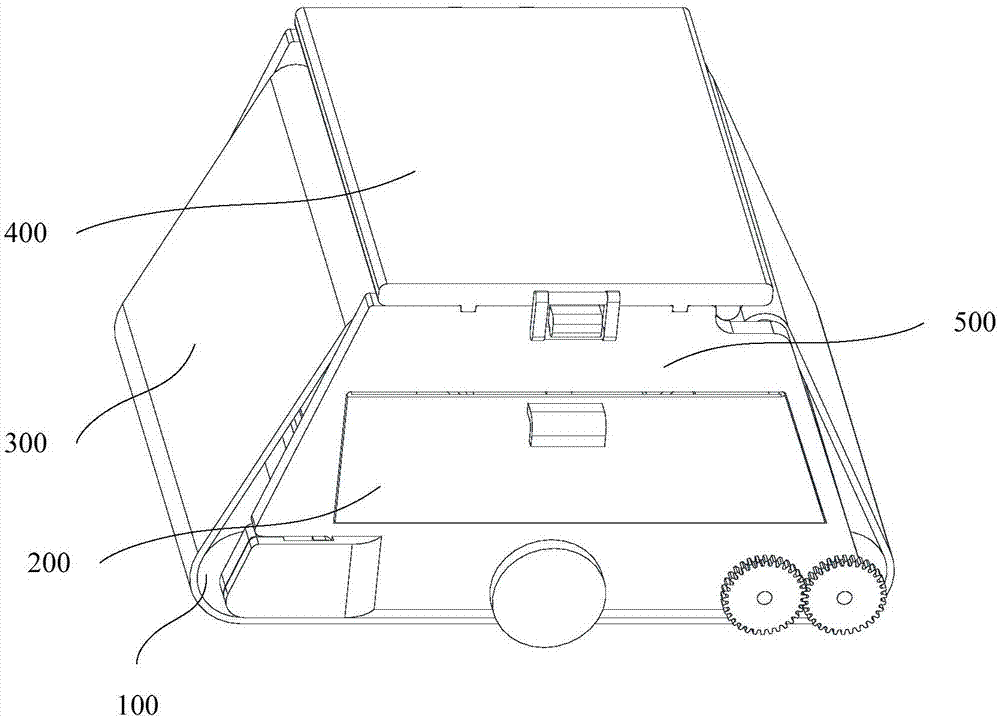

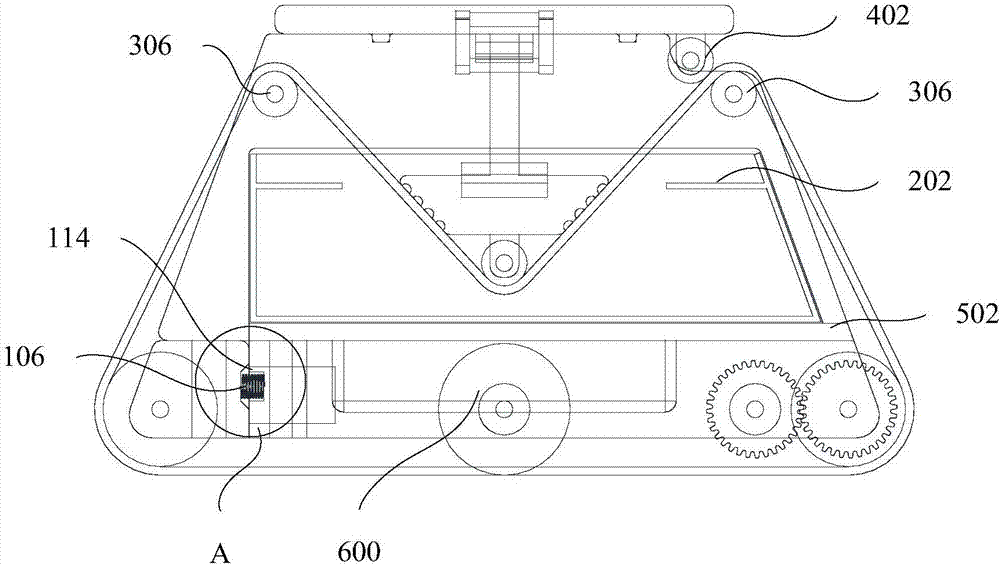

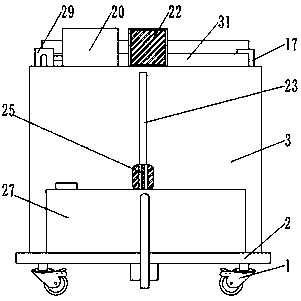

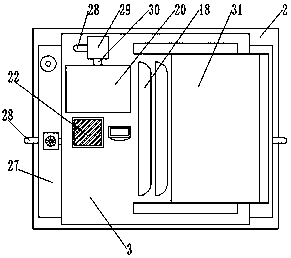

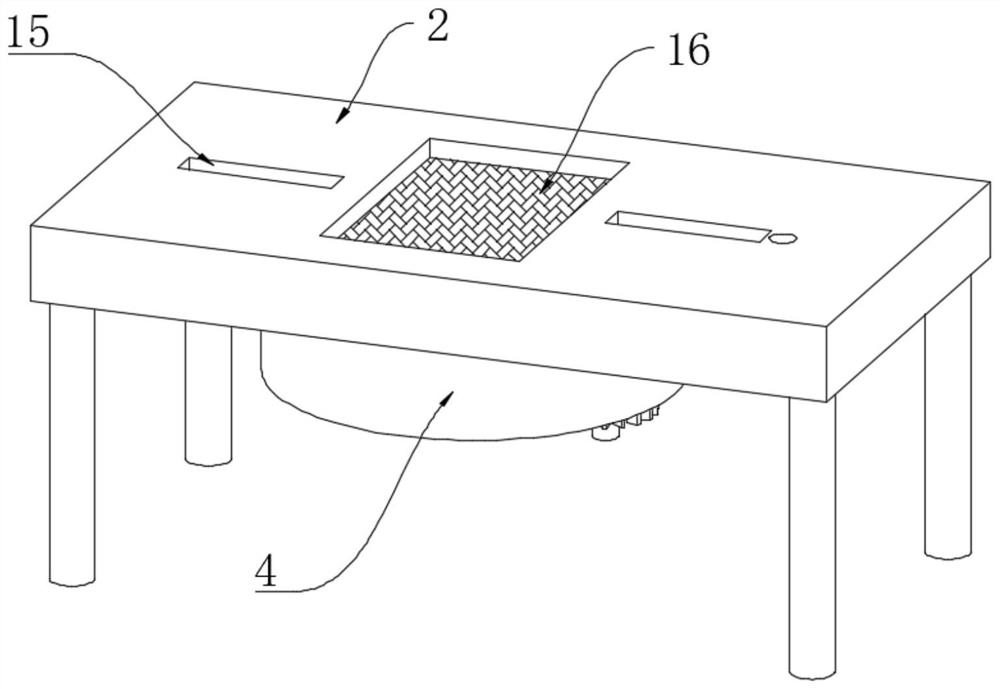

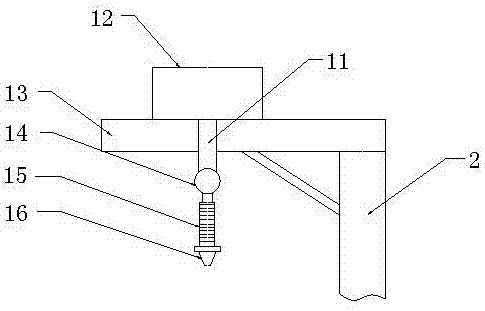

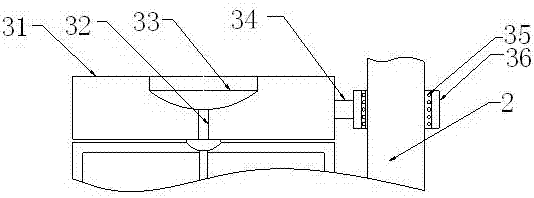

Floor-mopping cloth tensioning mechanism and floor mopping machine

InactiveCN107348913AAchieve tensionIncrease frictionCarpet cleanersFloor cleanersReciprocating motionTextile

The invention provides a floor-mopping cloth tensioning mechanism and a floor mopping machine. The floor-mopping cloth tensioning mechanism is applied to the floor mopping machine. The floor mopping machine includes floor mopping cloth and a machine body, the floor-mopping cloth tensioning mechanism is arranged on the machine body, and the floor-mopping cloth tensioning mechanism and the machine body are both sleeved with the floor mopping cloth; the floor-mopping cloth tensioning mechanism includes a fixing frame, a tensioning wheel and an elastic part, wherein the fixing frame is arranged on the machine body and can do reciprocating motion, the tensioning wheel is mounted on the fixing frame and can rotate around the fixing frame, and the elastic part is arranged on the machine body and faces one side of the fixing frame; under a working condition, the fixing frame compresses the elastic part, the floor mopping cloth is subjected to counter-acting force of the elastic part on the fixing frame and keeps tensioned. By the adoption of the floor-mopping cloth tensioning mechanism, the floor mopping cloth can have enough tensioning force, it is ensured that enough friction is generated between the floor mopping cloth and the floor, and the cleaning effect of the floor mopping machine is improved; meanwhile, even though slightly shaped or lengthened, the floor mopping cloth can be compensated through the floor-mopping cloth tensioning mechanism so that normal word cannot be influenced, and the user experience is improved.

Owner:GUANGDONG MIDEA KITCHEN APPLIANCES MFG CO LTD +1

Energy-saving power generation assembly with heat dissipation and dust removal functions

InactiveCN110165983AGuaranteed cleanlinessExtended service lifePhotovoltaic supportsSolar heating energyHydraulic cylinderEngineering

The invention discloses an energy-saving power generation assembly with heat dissipation and dust removal functions. A water tank is fixedly connected to the lower portion of a transverse plate, and supporting legs are fixedly connected to the two sides of the lower end of the water tank respectively. A liquid discharging pipe is arranged at the lower end of the middle of the water tank. A solar panel is arranged above the transverse plate, wherein the lower end of the right side of the solar panel is rotatably connected with the upper end of a connecting rod, and the lower end of the connecting rod is rotatably connected with a sliding block. The sliding block is slidably connected with a guide rail, and the guide rail is fixedly connected with the right side of the transverse plate. Thepower generation assembly drives the solar panel to swing to adjust the inclination angle through an oil pressure in the hydraulic cylinder. Meanwhile, a liquid suction pump continuously sprays waterto the surface of the solar panel, a forward and reverse bidirectional lead screw drives a cleaning brush to move left and right to brush the solar panel, thereby guaranteeing the cleanliness of the solar panel, prolonging the service life of the solar panel, and achieving the rainwater collection and water liquid recycling functions under the action of a stopping plate and a water receiving hopper.

Owner:苏州晨霞美合智能科技有限公司

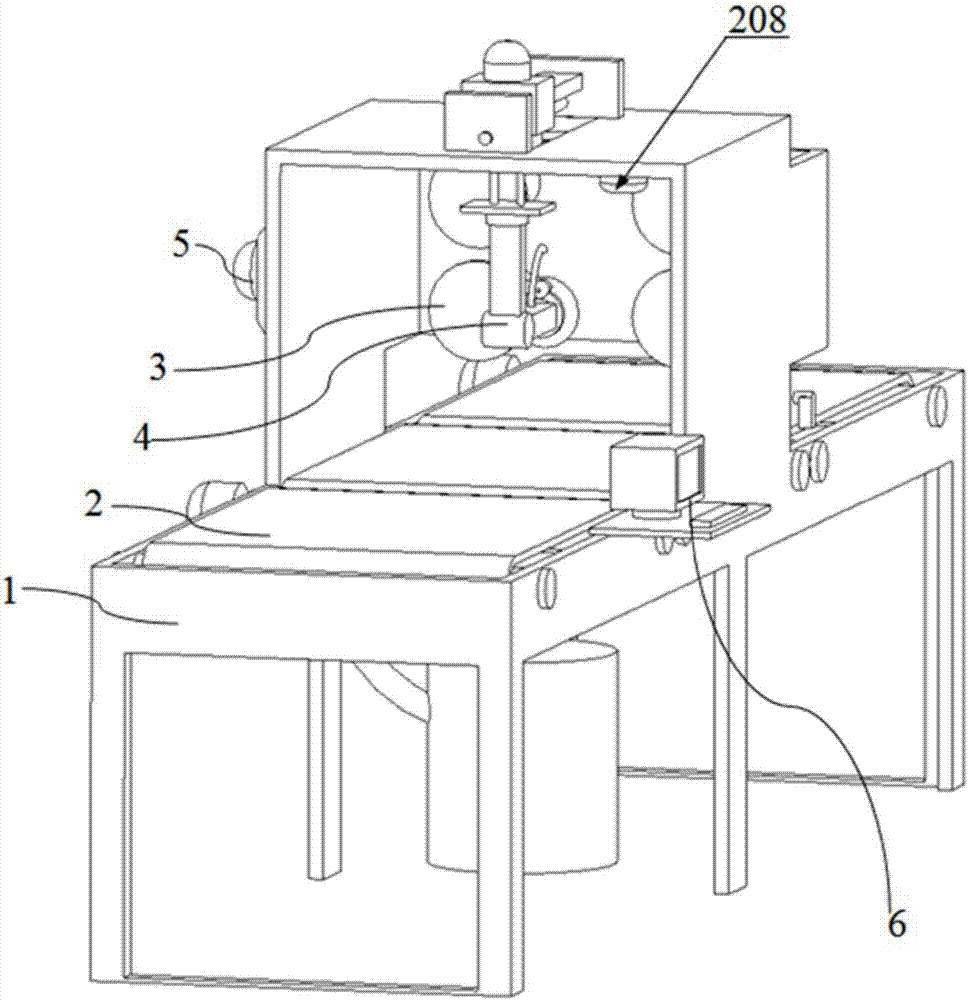

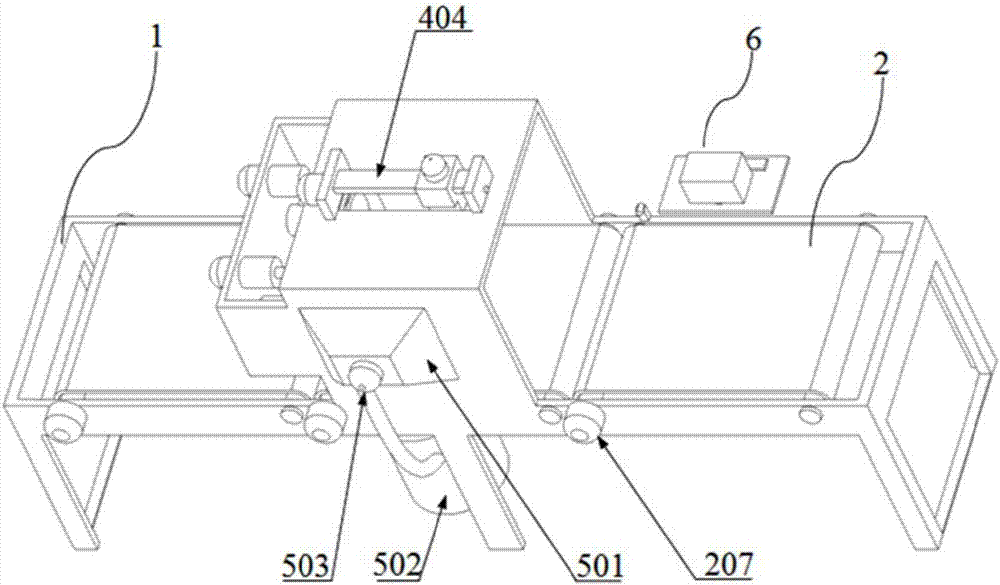

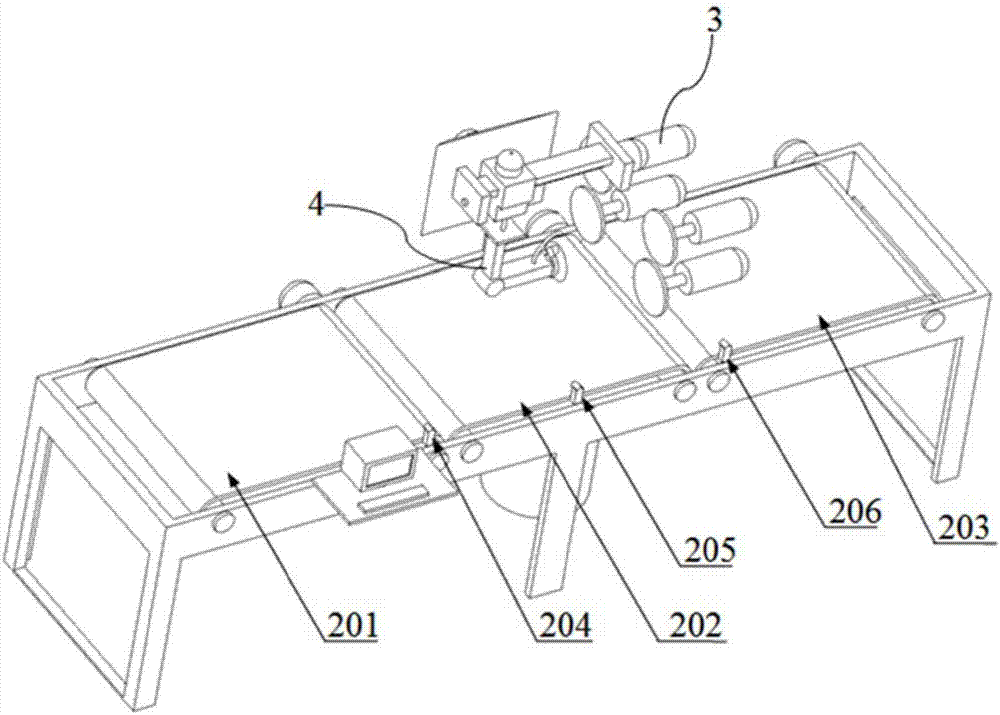

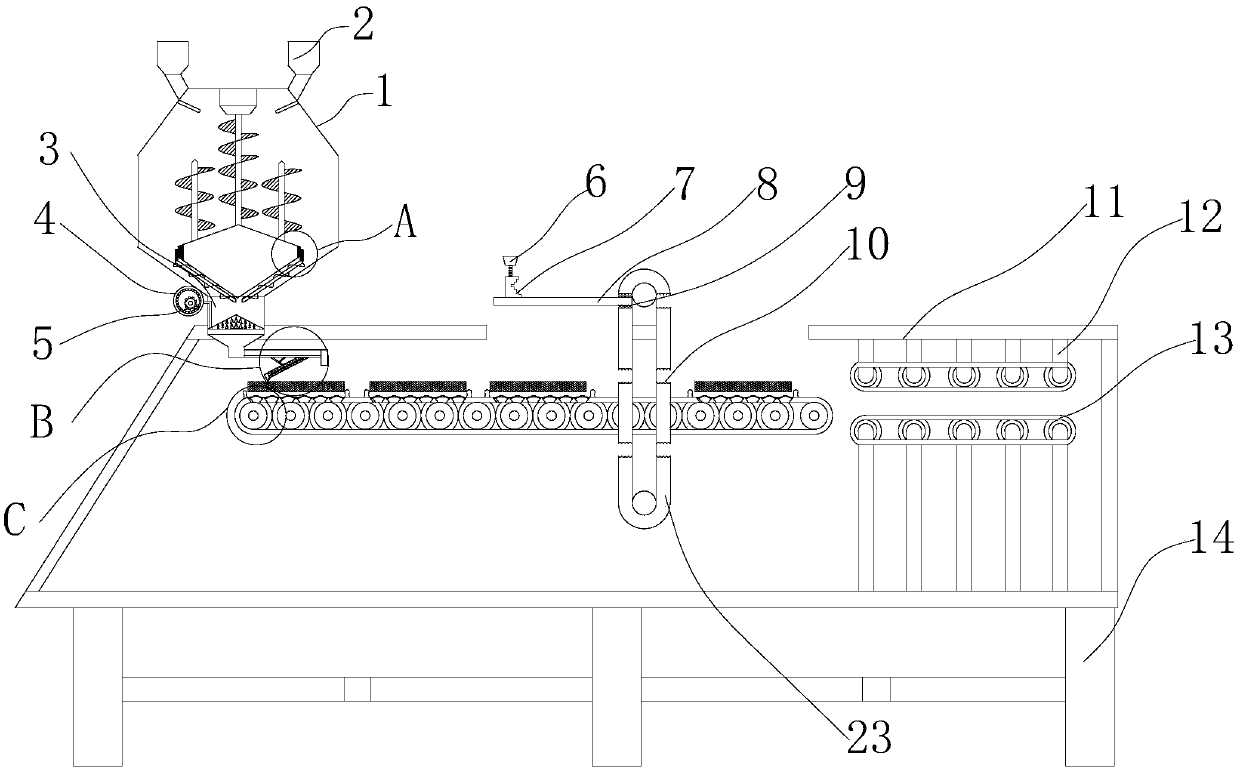

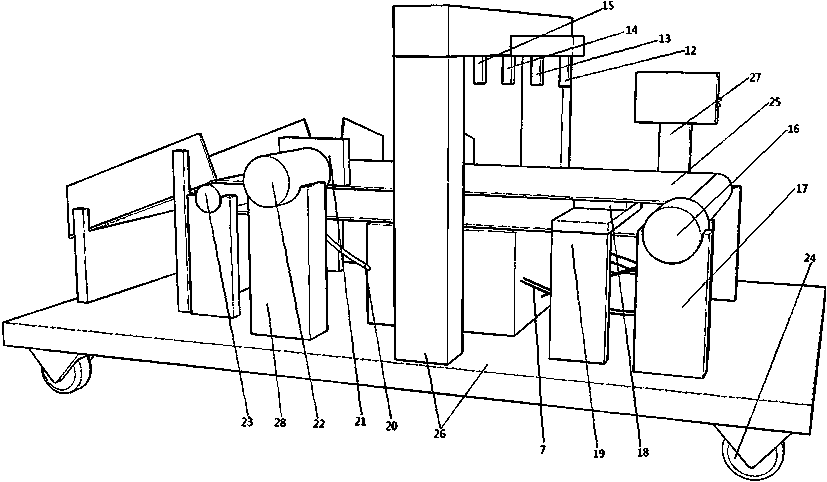

Automatic board grinding system for circuit board resistance welding and board grinding method

PendingCN107263285AThe grinding method is simpleEasy to operateEdge grinding machinesGrinding feed controlProduction lineControl system

The invention discloses an automatic board grinding system for circuit board resistance welding. The automatic board grinding system comprises a conveying rack, a conveying mechanism, a polishing mechanism, a grabbing mechanism, a recycling mechanism and a control mechanism, wherein the conveying mechanism, the polishing mechanism, the grabbing mechanism and the recycling mechanism are arranged at the top of the conveying rack; and the control mechanism controls the system to work. The conveying mechanism is divided into three sections, and each section of the conveying mechanism is provided with a sensor. The polishing mechanism and the recycling mechanism are arranged on the side wall of a fixed support. The grabbing mechanism is movably arranged on the top edge of the fixed support. A grabbing camera is installed on the inner wall of the fixed support. A polishing camera is installed at the end of the grabbing mechanism. All the sensors and the cameras are in circuit connection with the control mechanism. The invention discloses an automatic board grinding method for circuit board resistance welding. The automatic board grinding system for circuit board resistance welding is reasonable in structural arrangement, the efficiency of a board grinding production line is improved, and the board grinding effect for meeting different precision requirements is achieved; due to arrangement of the recycling mechanism, the recycling function on abrasive materials is achieved, and cleanliness and environmental protection are realized; and operation is easy and the degree of automation is high.

Owner:信丰迅捷兴电路科技有限公司

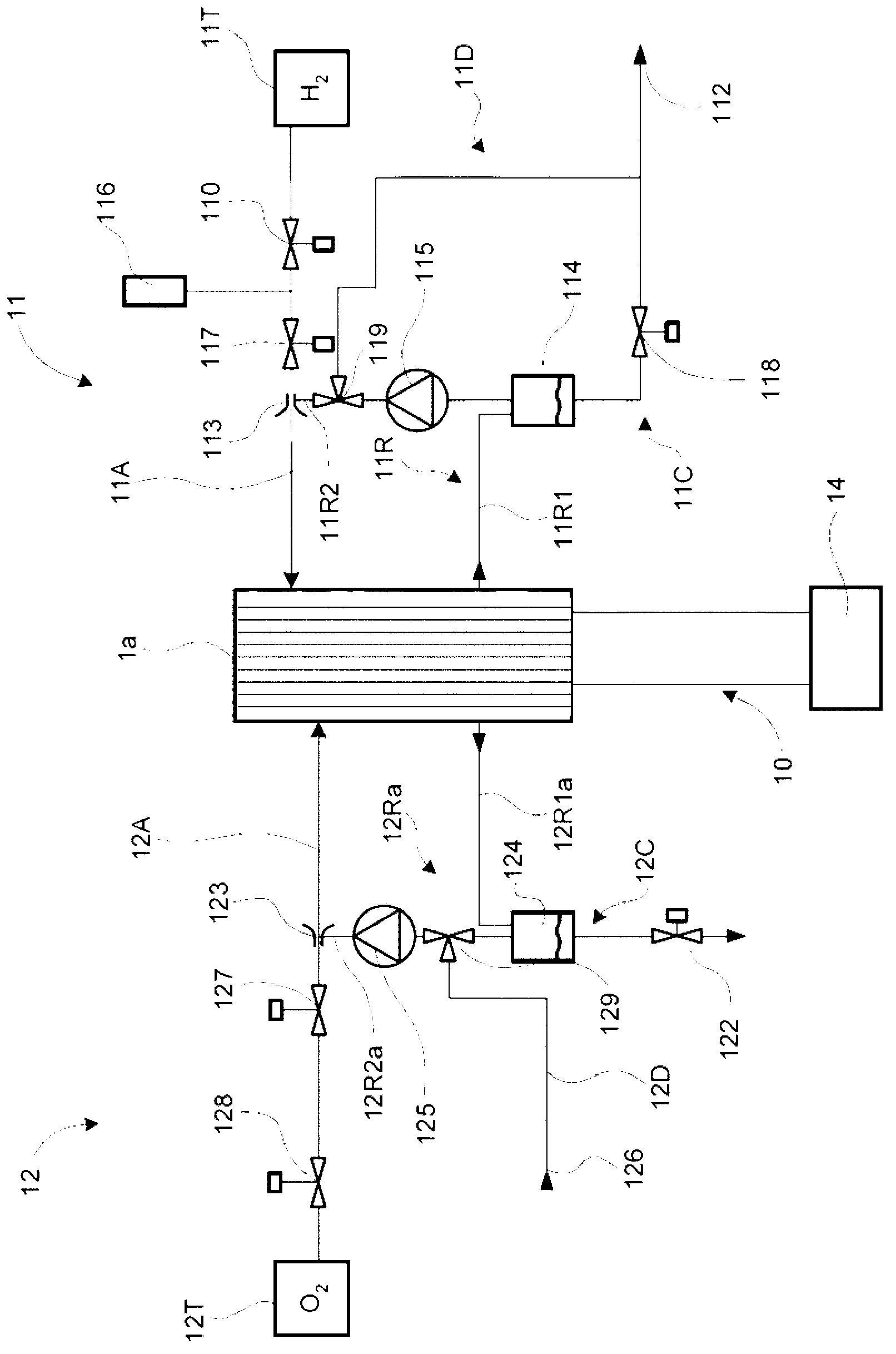

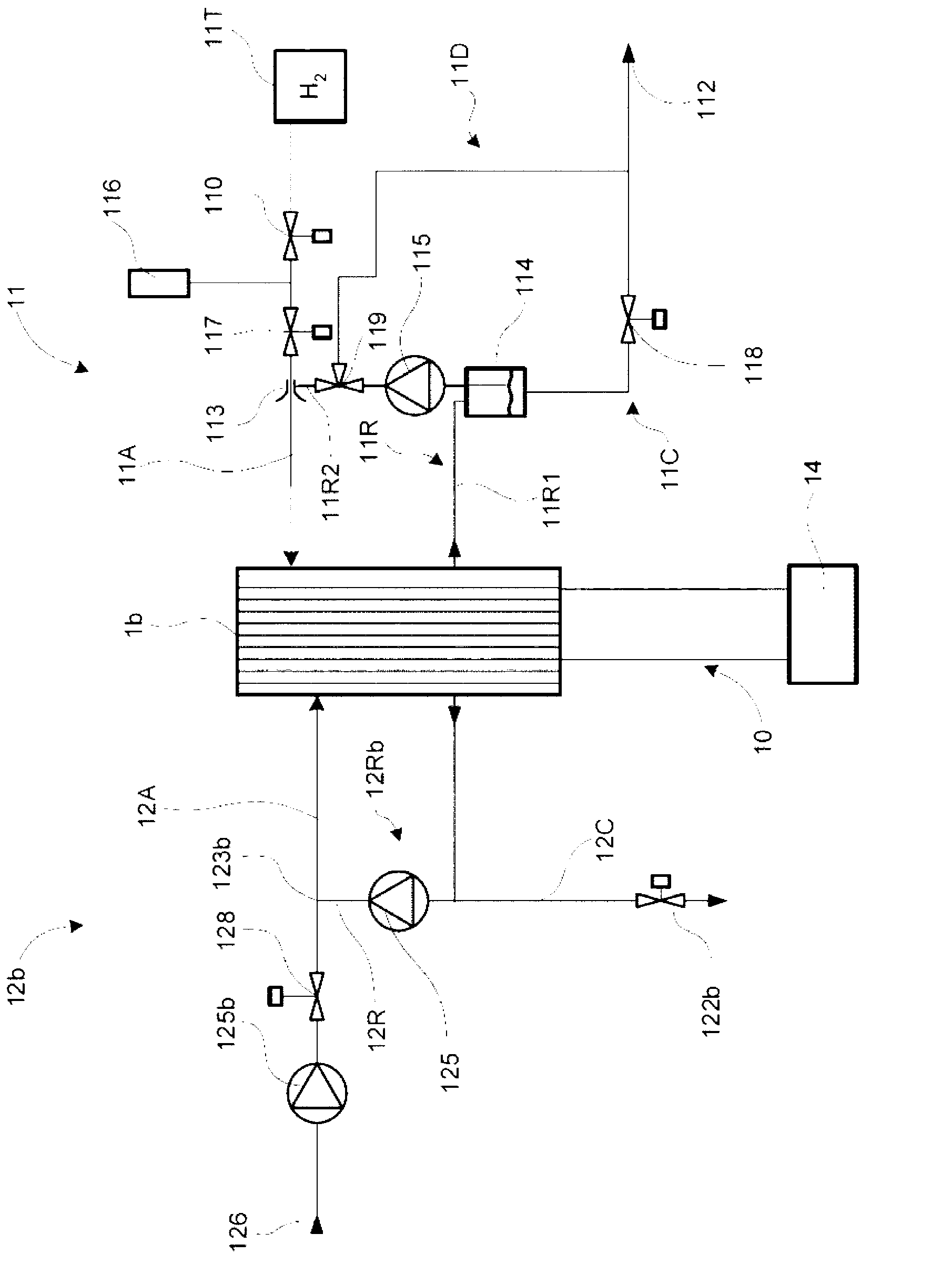

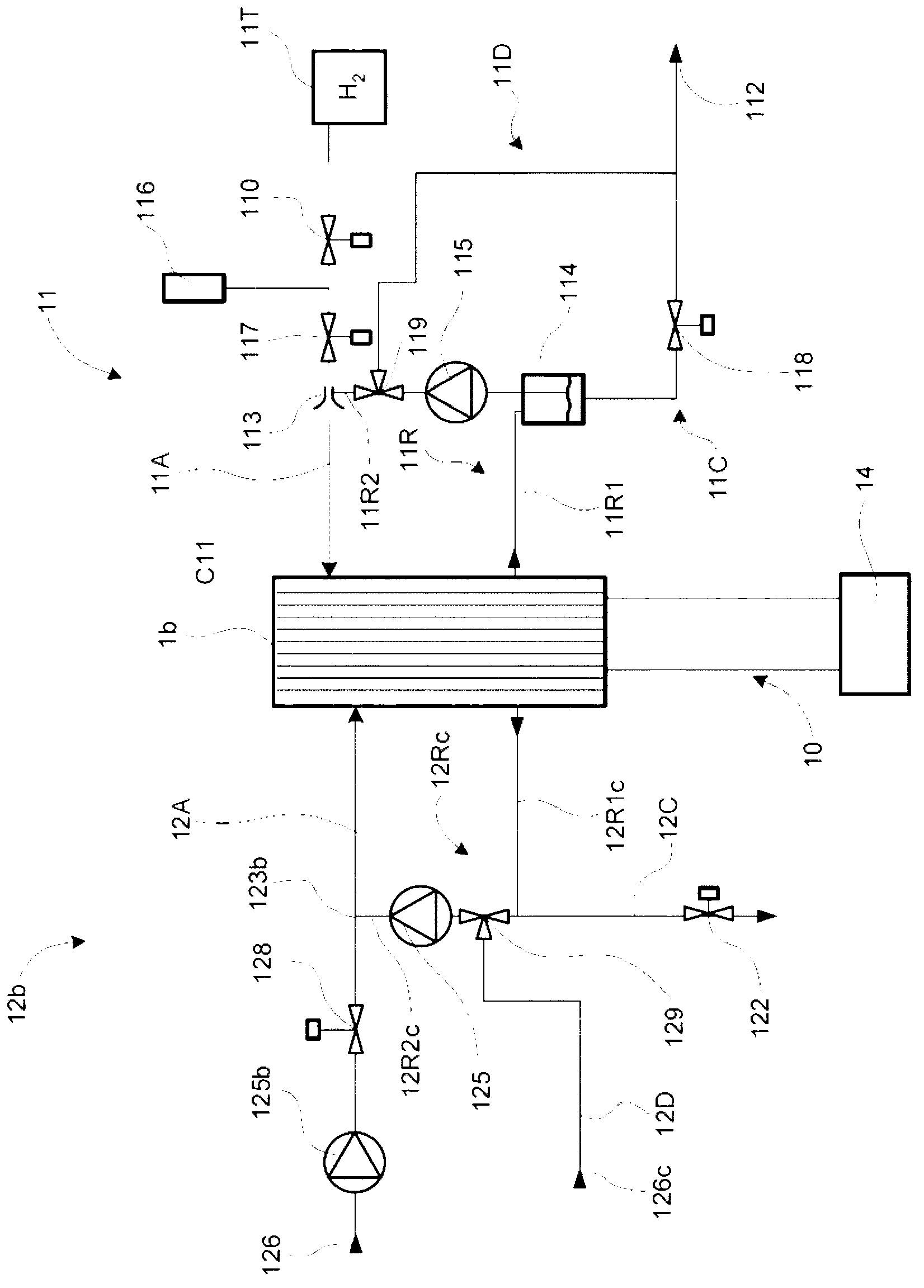

Recirculating loop for fuel cell

ActiveCN103348522AImplement extractionRealize the recycling functionFuel cell auxillariesFuel cellsEngineering

The invention relates to a recirculating loop (11R or 12Ra) for a gas circuit of a fuel cell (1a), which recirculating loop forms a connection duct beginning at the outlet of one of the two anode or cathode circuits of the fuel cell stack (1) and terminating on one of the two supply circuits, either on the fuel-gas supply duct (11A) or on the oxidant-gas supply duct (12A). The recirculating loop recirculates the gas contained in the anode or cathode circuits of the fuel cell, said recirculating loop comprising a pump (115 or 125) for recirculating said gas. The recirculating loop comprises a multi-way valve (119 or 129) that divides the loop into a first section (11R1 or 12R1) and a second section (11R2a or 12R2a), said multi-way valve having: a first stable operating position which establishes continuity between the first and second sections of the loop; and a second stable operating position which simultaneously interrupts the continuity between the first and second sections of the recirculating loop and brings said recirculating loop into contact with the atmosphere, by moving the multi-way valve.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

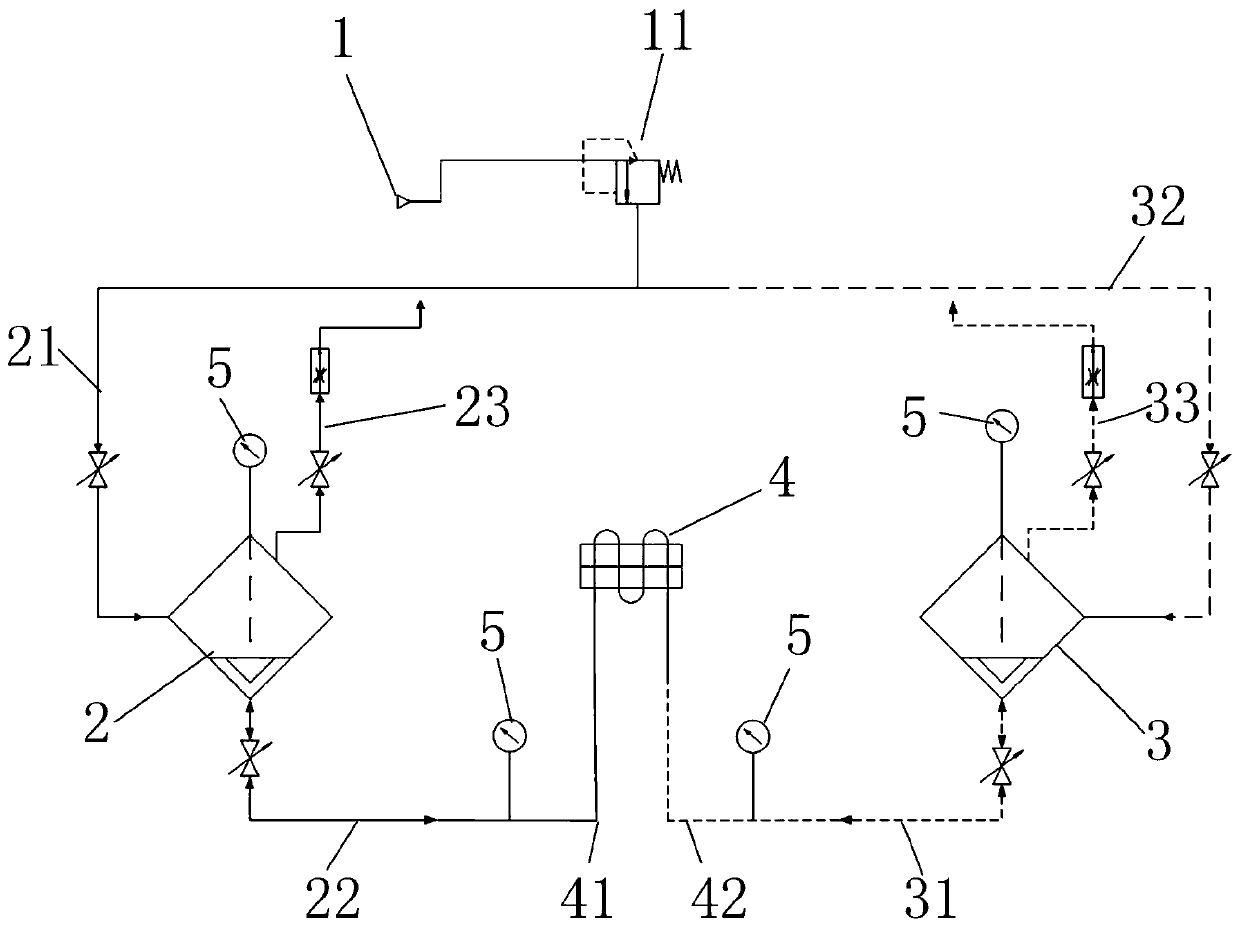

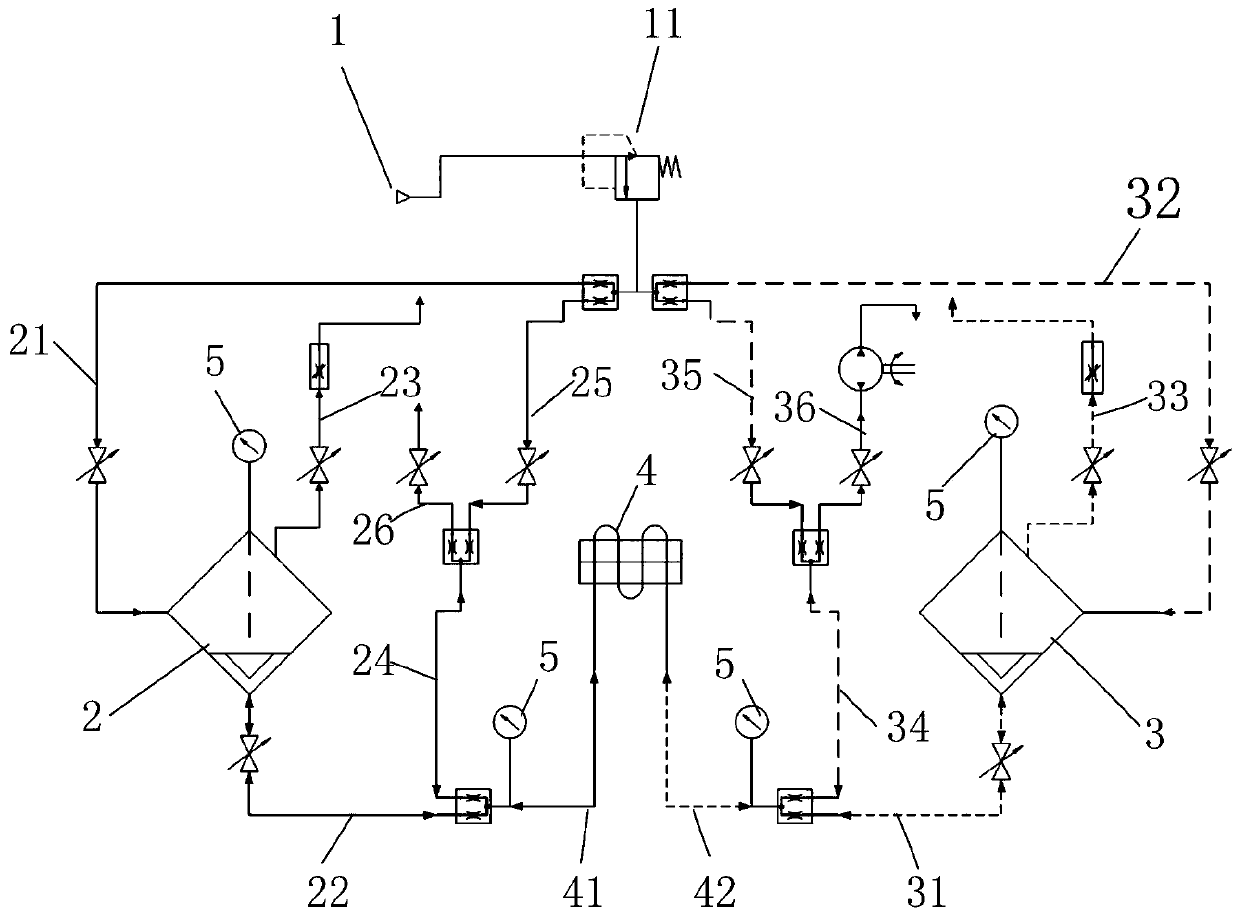

Multifunctional circulating cleaning system

PendingCN110420926ASolving Recycling ProblemsEasy to storeCleaning using liquidsVapor–liquid separatorSolenoid valve

The invention discloses a multifunctional circulating cleaning system used for two-way cleaning of a part to be cleaned. The multifunctional circulating cleaning system comprises a gas source, a firstgas-liquid separator for storing cleaning agents, a second gas-liquid separator for storing the cleaning agents, a first exhaust pipeline, a second exhaust pipeline, a pressure detecting device, a plurality of pipelines for connecting the components, solenoid valves arranged on the pipelines and controllers arranged on the pipelines. The gas source is used as power, the multiple pipelines and thesolenoid valves are used in cooperation to realize the reciprocating cycle type automatic cleaning process, the operation is simple, thorough cleaning can be achieved, batch cleaning work can be done, the problem of recycling of the cleaning agents is solved, the cleaning cost is effectively reduced, and the free-liquid residual cleaning is truly achieved.

Owner:蒋书印

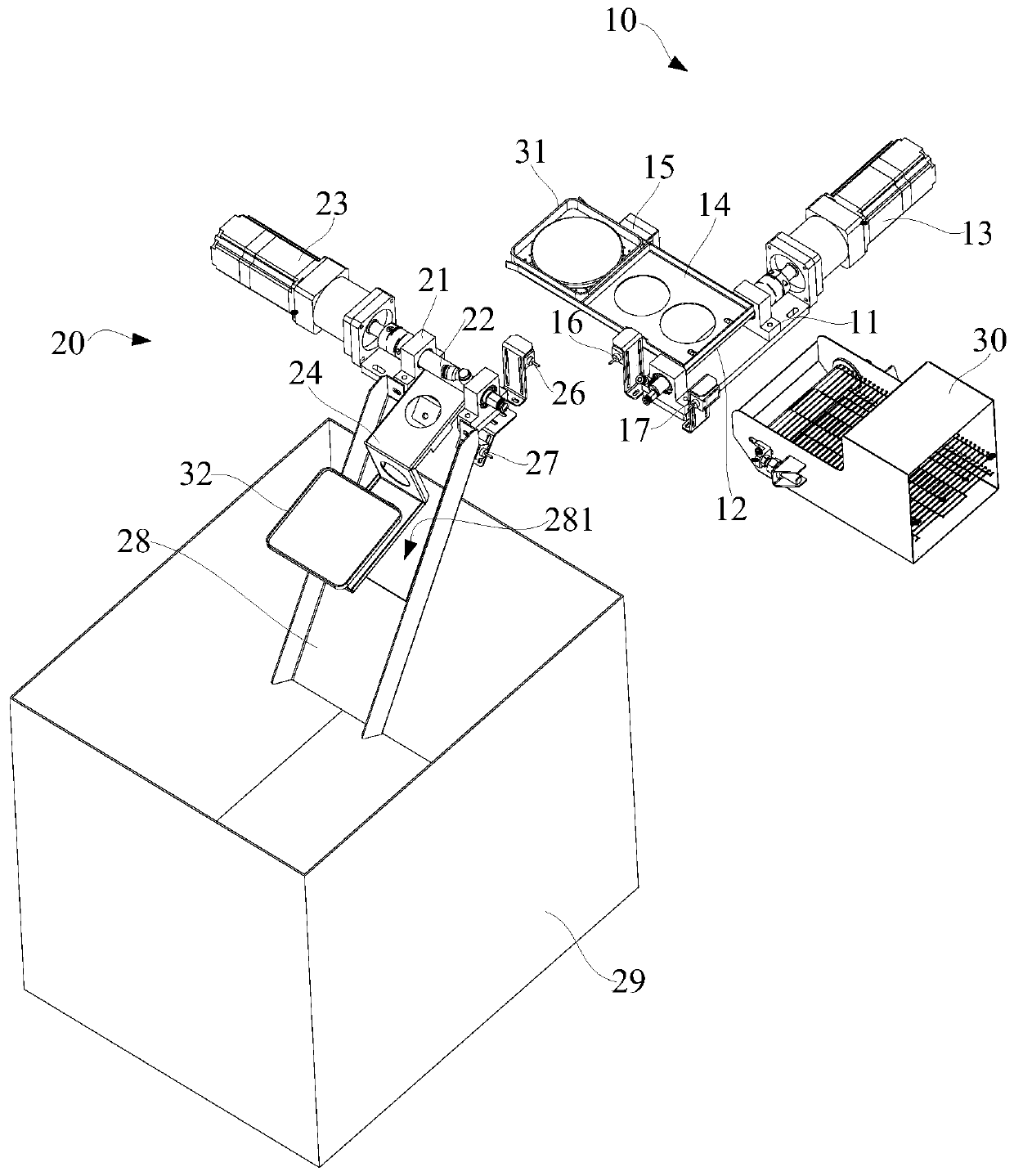

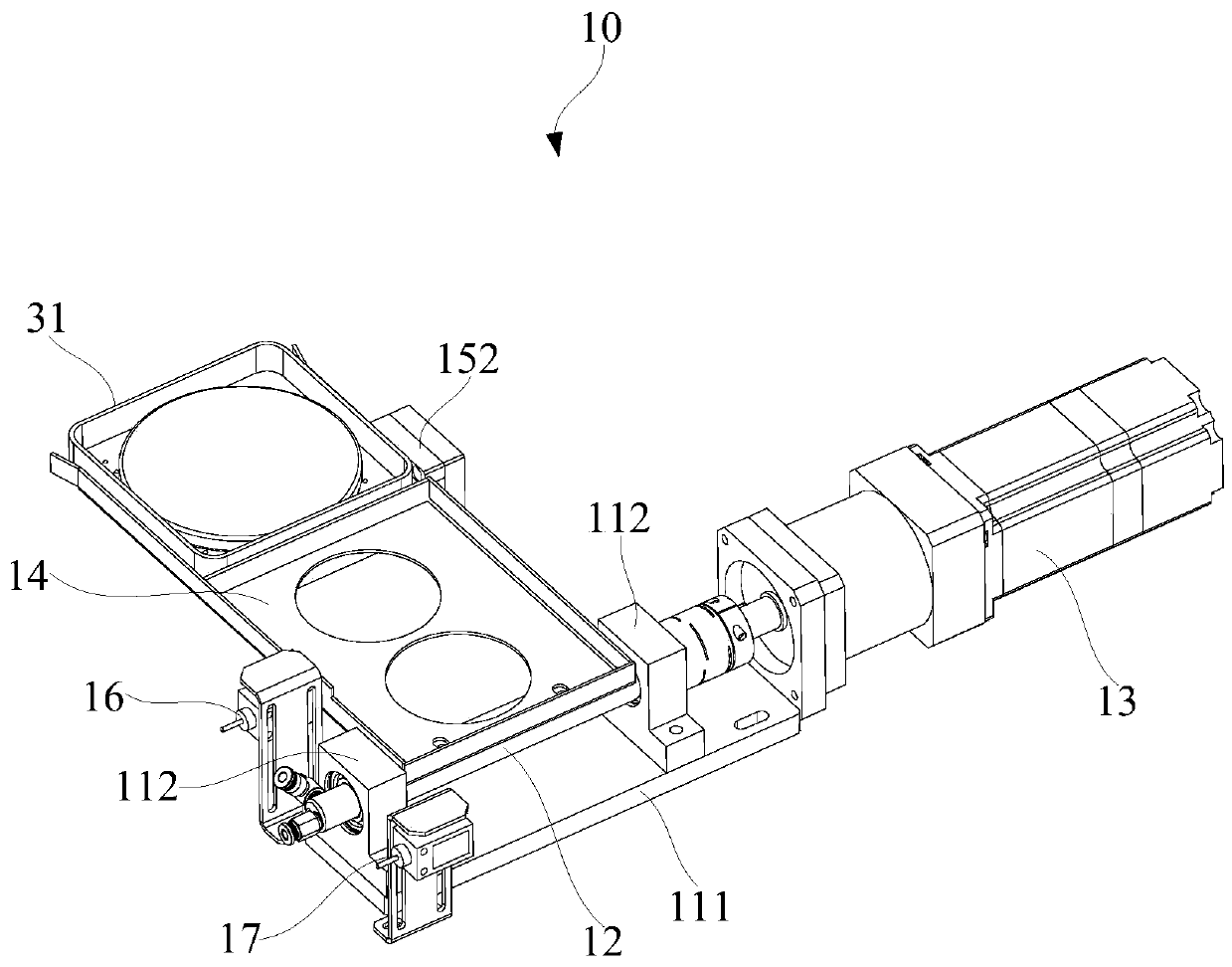

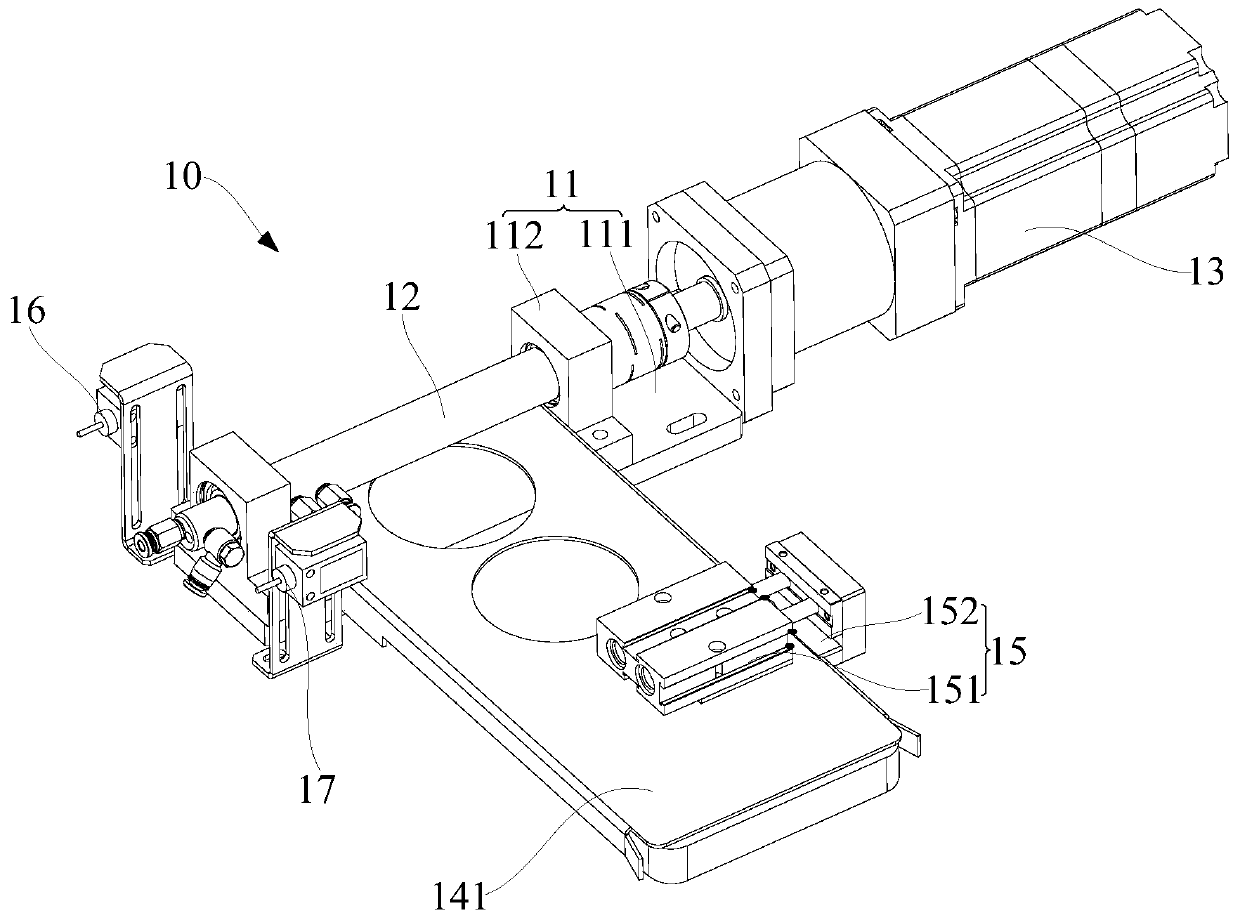

Feeding mechanism and feeding method

InactiveCN111345674AImprove feeding efficiencyRealize the recycling functionCooking vesselsReciprocating motionControl engineering

The invention relates to a feeding mechanism and a feeding method, and relates to the technical field of automatic cooking. The feeding mechanism comprises a feeding module and a recovery module. Thefeeding module comprises a first driving assembly, a first overturning support and a locking structure, the first driving assembly is used for driving the first overturning support to overturn back and forth between a material receiving station and a feeding station, and the locking structure is used for releasably locking materials on the first overturning support; the recovery module comprises asecond driving assembly and a transfer assembly; the second driving assembly is used for driving the transferring assembly to reciprocate between a picking station and a recovery station, and when the transferring assembly moves to the picking station, the transferring assembly can execute picking operation from the material receiving station and execute releasing operation at the recovery station. The feeding mechanism can well solve the problem that automatic feeding of materials which are loose in tissue and soft in texture is difficult.

Owner:GUANGDONG ATHENE ROBOTIC TECH CO LTD

Pesticide spraying device for corn disease and pest control

ActiveCN114097753AEasy dischargeAvoid inadequate mixingSpraying apparatusInsect catchers and killersAgricultural scienceSprayer

The invention relates to the technical field of corn disease and pest control, and discloses a pesticide spraying device for corn disease and pest control. A first fixing block extrudes a reset spring and slides on the surface of a limiting strip, so that the problems that manual pesticide spraying operation is mostly carried out by workers, the labor intensity is high, the spraying efficiency is low, meanwhile, the corn plants cannot be uniformly sprayed, and the labor intensity is high are solved. Therefore, many plants cannot obtain reasonable pesticide spraying, and normal growth of the corn plants is influenced; the front face and the back face of a corn leaf are sprayed with pesticide at the same time through the double-face pesticide spraying device, the problems that an existing electric sprayer cannot conduct pesticide spraying on the front face and the back face of the leaf at the same time, consequently, the working efficiency is reduced, and during independent use, a switch valve is used for blocking conveying of pesticide liquid in a short pipe, and independent pesticide spraying can be conducted are avoided.

Owner:唐山市食品药品综合检验检测中心

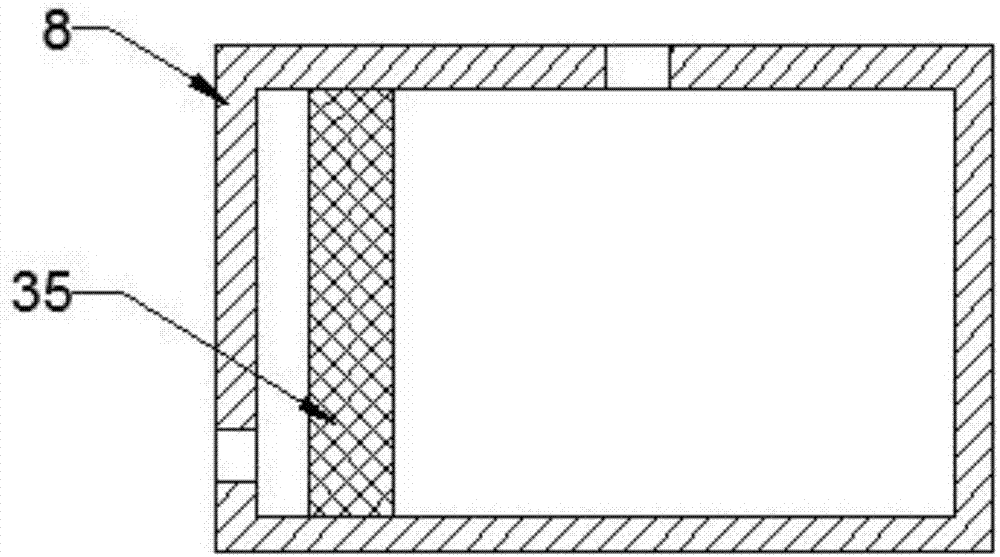

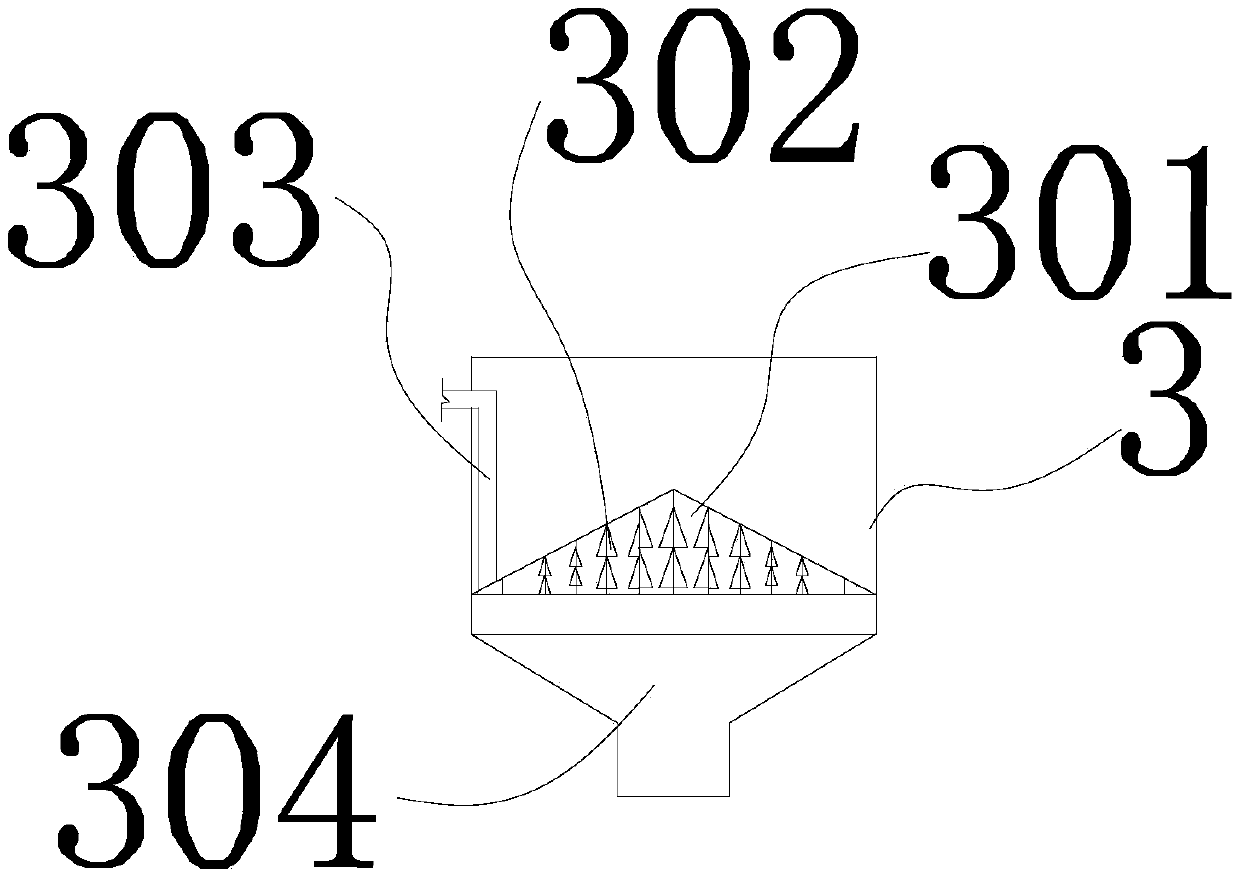

Waste water circulating type remaining concrete recovering and processing device

InactiveCN107351259AEasy to cleanEasy outflowDischarging apparatusWater/sewage treatmentHydraulic cylinderBristle

The invention provides a waste water circulating type remaining concrete recovering and processing device and belongs to the field of remaining concrete recovering. The upper end of a supporting column is provided with a carrier plate through a hinge, and the lower end of the right side of the carrier plate is connected with a hydraulic cylinder through a hinge. The right end of a water pump is connected with a filter through a water inlet pipe, and the left end of the water pump is connected with the right side of a washing vessel through the water inlet pipe. A hydraulic telescopic column is fixedly arranged on the upper face of the supporting plate, and a transverse plate is fixedly arranged at the upper end of the hydraulic telescopic column. A scrubbing device is fixedly arranged at the lower end of a walking trolley. A waste water purifying device is fixedly arranged below a sundry collection box. According to the waste water circulating type remaining concrete recovering and processing device, the inner sides of side wall scrubbing plates are arranged on the two sides of a telescopic rod through springs, iron bristles are arranged on the side wall scrubbing plates, and the function of conveniently cleaning away the residual cement paste with relatively-high viscosity is achieved. The waste water circulating type remaining concrete recovering and processing device has the beneficial effects of being simple in structure, high in practicality and good in recovering and processing effect.

Owner:ZHENGZHOU AIMOFU INFORMATION TECH CO LTD

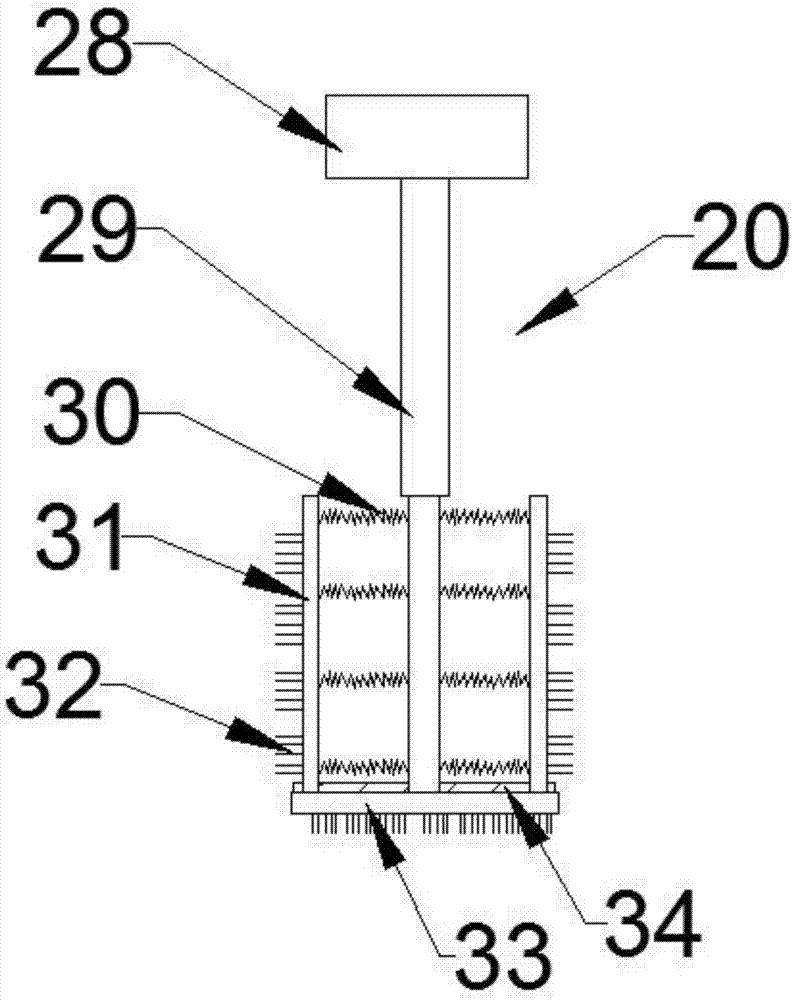

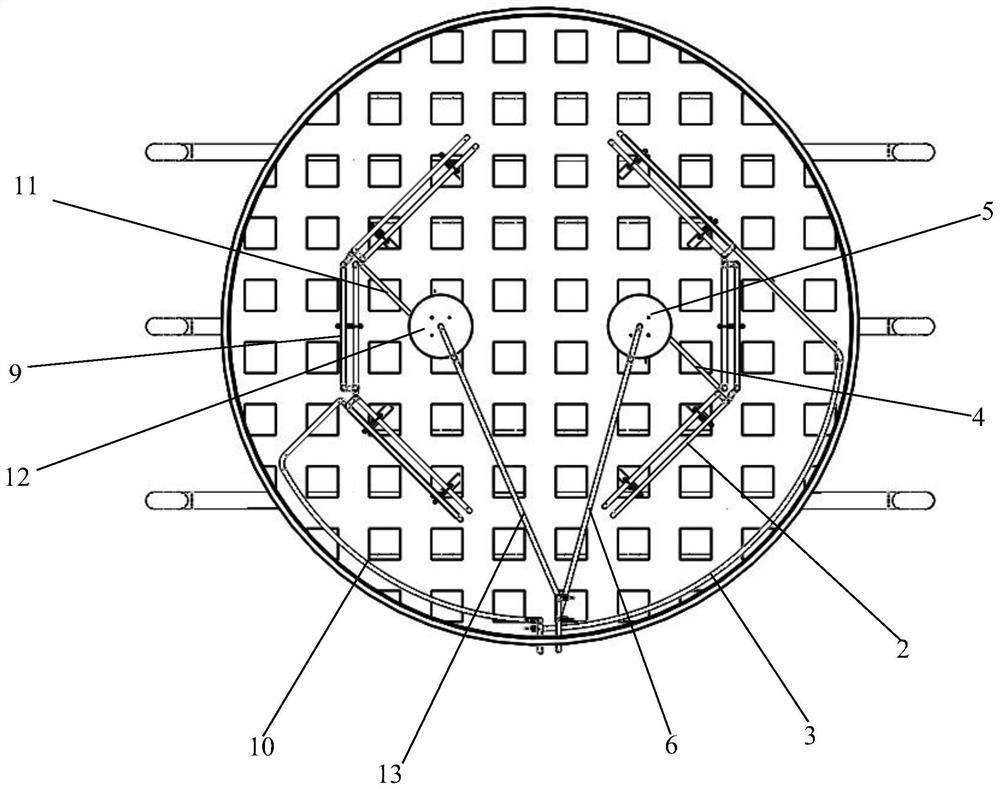

Multi-degree of freedom power spraying manipulator

InactiveCN108745727AQuickly adjust spray heightQuickly adjust the spray angleSpraying apparatusSpiral bladeMulti degree of freedom

The invention provides a multi-degree of freedom power spraying manipulator. The multi-degree of freedom power spraying manipulator comprises a conveying pipe, a vertical frame, a top plate, an angleadjusting mechanism and a powder recycling mechanism. The conveying pipe is disposed on the left side surface of a powder spraying head; the vertical frame is fixed to the upper end surface of a carrying table; the top plate is fixed to the upper end surface of the vertical frame through bolts; the angle adjusting mechanism is disposed on the front side surface of the vertical frame and comprisesa supporting arm, a linear sliding block, a linear sliding rail, a longitudinal screw rod, a nut seat, a rotating shaft, an adjusting arm, the powder spraying head, a driving motor, a first gear and asecond gear; and the powder recycling mechanism is disposed on the right portion of the upper end surface of a base and comprises a support, an air intake hood, an air guiding pipe, a high-pressure fan, an exhausting pipe, a conical barrel, spiral blades, a collecting box, a guiding block and a guiding groove. Compared with the prior art, the multi-degree of freedom power spraying manipulator hasthe following beneficial effects that the function of rapidly adjusting the spraying height and angle is achieved, and the function of recycling powder in air is achieved.

Owner:中山市恒易盈实业有限公司

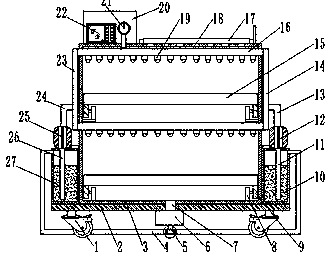

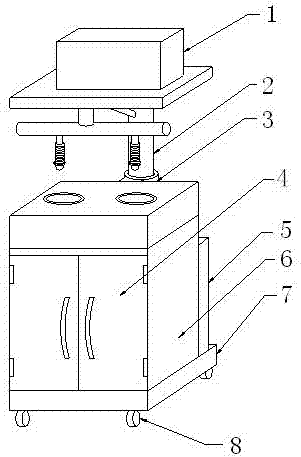

Seedling cultivation device for agricultural planting

InactiveCN109526481ARealize the recycling functionReduce resource consumptionClimate change adaptationGreenhouse cultivationAgricultural scienceSeedling

The invention belongs to the technical field of agricultural planting and especially provides a seedling cultivation device for agricultural planting. In the prior art, a seedling cultivation device cannot effectively recycle the materials, consumed in the cultivation process, which causes waste of a large quantity of resources and cannot satisfy requirements. According to the scheme, the seedlingcultivation device includes a bottom plate. Universal wheels are connected to four corners of the outer wall on the bottom of the bottom plate through bolts. A box body is connected to the outer wallof one side, far away from the universal wheels, of the bottom plate through bolts. A first water tank and a second water tank are successively connected to the outer wall of one side, far away fromthe universal wheels, of the bottom plate through bolts. The device has material recycling function, so that consumption on resources is reduced during use of the device, and the internal environmentof the box body reaches the standard being most proper to growth of seedlings. The device effectively increases growth rate of the seedlings in the box body, and an operator can conveniently replace the cultured seedlings on a planting plate, thereby effectively increasing cultivation efficiency on the seedlings.

Owner:六安科创教育信息咨询有限公司

Anti-interference electronic communication filtering equipment and using method thereof

InactiveCN113784586ARealize the limit functionRealize demolition workAlarmsModifications using liquid coolingEngineeringDrive motor

The invention relates to the technical field of data communication, and discloses anti-interference electronic communication filtering equipment and a using method thereof. The anti-interference electronic communication filtering equipment comprises a mounting base, wherein a supporting platform is fixedly connected to the top of the mounting base, a heat absorption layer used for absorbing heat energy of a filter is arranged in the middle of the upper surface of the supporting platform, the temperature of the surface of the filter is absorbed through the heat absorption layer, heat is transmitted to an inner cavity of a liquid storage cavity through a heat conduction column, when a baffle moves outwards, an arc-shaped plate is pushed to synchronously move outwards so as to push spring telescopic rods to move outwards, the spring telescopic rod on the left side pushes a movable frame to synchronously move leftwards when moving leftwards at the moment, then a friction wheel is pushed to slide leftwards on the outer wall of a spline shaft, as the linear speed of the left end of a friction roller is greater than that of the right end of the friction roller, the rotating speed of the friction wheel is increased, and the rotating speed of fan blades is further driven to be increased. Meanwhile, when the movable frame moves leftwards, the resistance value of an adjusting resistor line can be lowered, the power of a driving motor is increased, and the cooling rate is increased.

Owner:瑞安市黄林水电有限公司

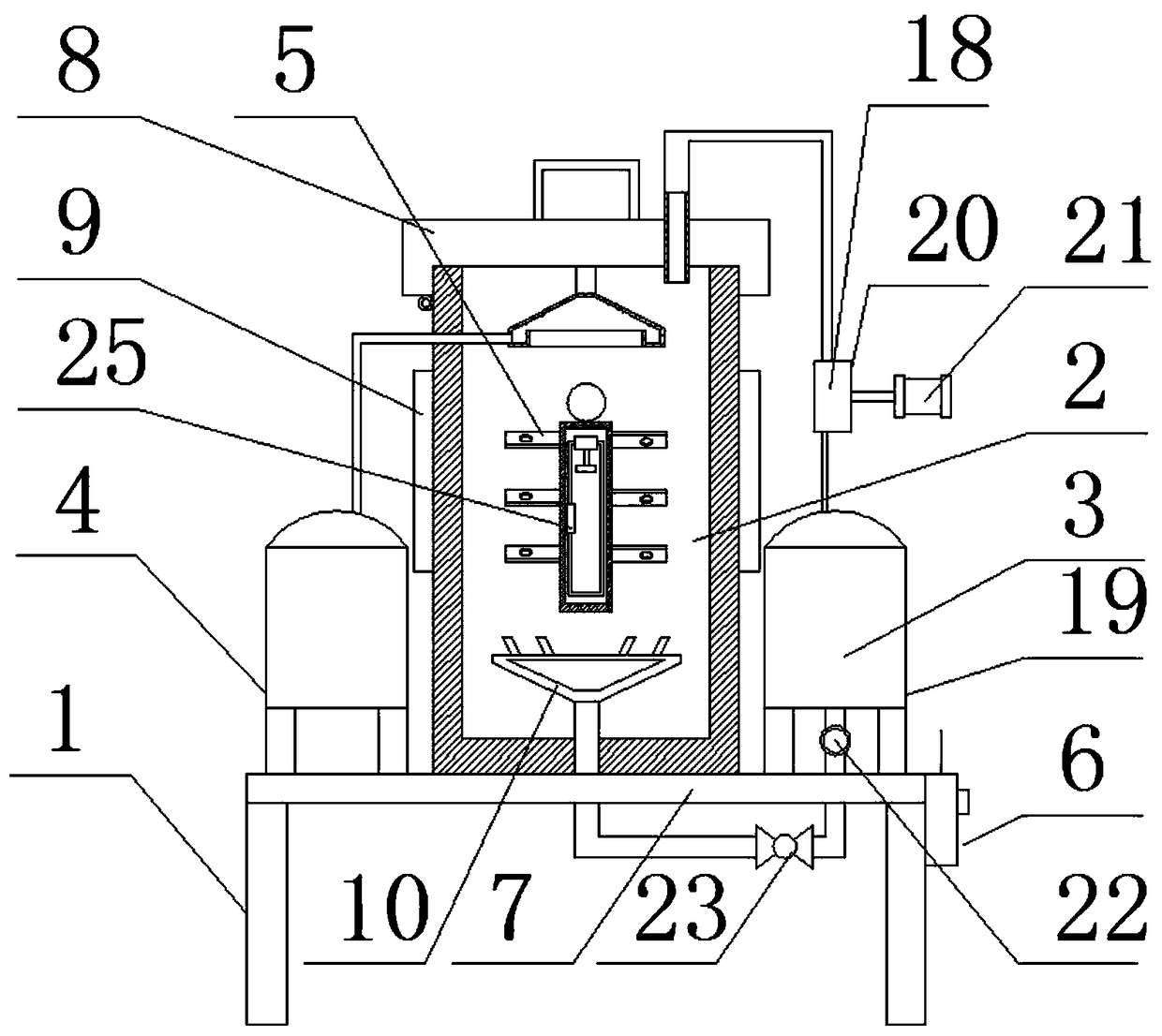

Flotation pulp magnetizer

The invention discloses a flotation pulp magnetizer which comprises a support frame body, a magnetizer body, a vacuum-pumping system, a distilling water storage tank, an air bag suspension stirring device and a control electric box, wherein a support plate is arranged on the support frame body, and the magnetizer body is arranged on the support plate; the vacuum-pumping system is arranged on one side of the magnetizer body and is connected with the support plate, and the distilling water storage tank is arranged on the other side of the magnetizer body and is connected with the support plate;the air bag suspension stirring device is arranged in the inner part of the magnetizer body, and the control electric box is arranged on one side of the support plate; and the magnetizer body comprises a magnetization tank, a magnetization sleeve and an eddy current oxygen exhauster, and the magnetization tank comprises an end cover and a tank body. According to the flotation pulp magnetizer, theair bag suspension stirring device is arranged in the tank body, a magnetic field is generated in the tank body through the magnetization sleeve at the outer part of the tank body, and a conducting loop is arranged in the air bag suspension stirring device in the tank body. The principle of electromagnetic induction is utilized, the air bag suspension stirring device rotates and crushes ores, andthe contact density of magnetized water and the ores is increased.

Owner:内蒙古广利隆能源股份有限公司

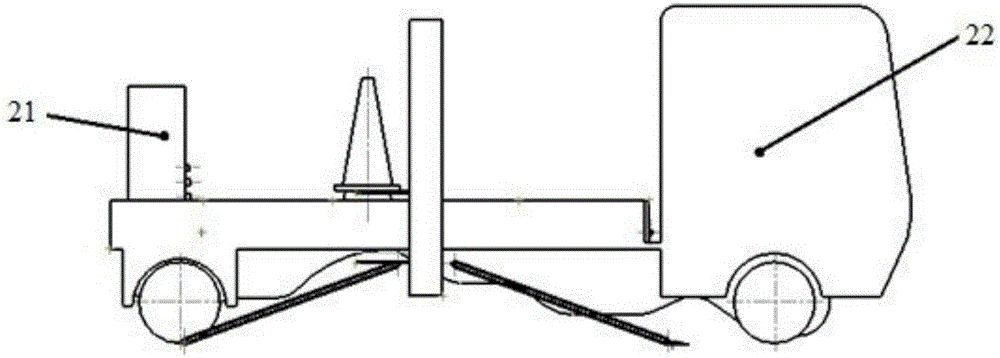

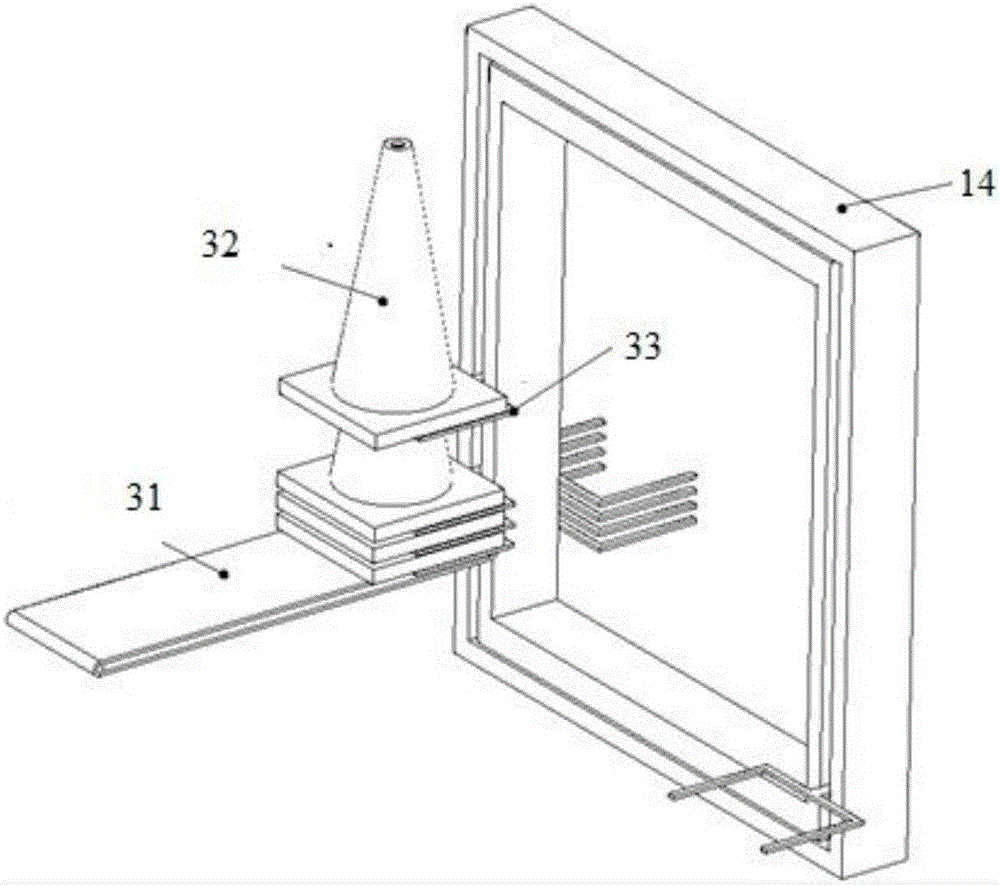

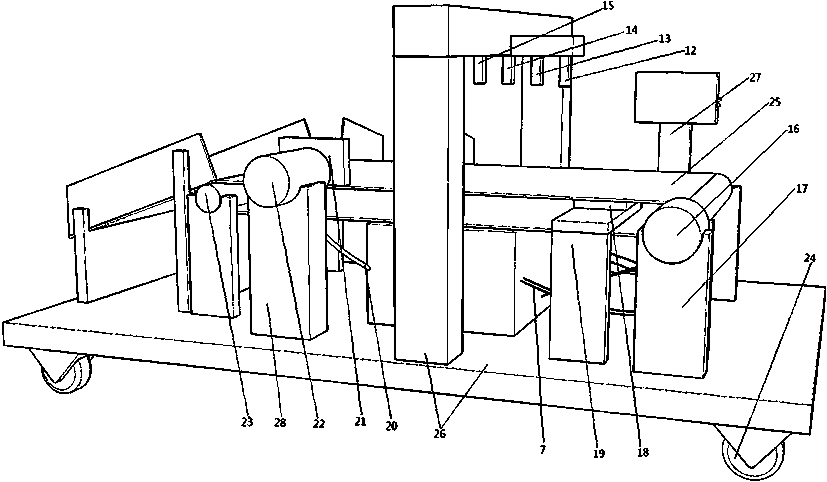

Gantry-type road cone automatically deploying and retracting device

The present invention relates to a gantry-type road cone automatically deploying and retracting device. The gantry-type road cone automatically deploying and retracting device comprises a conveying device, a transporting device and a ground-connected conveying and placing device, wherein the transporting device also comprises push plates and a conveying crawler belt, and the push plates are installed on side baffles of a vehicle body while the conveying crawler belt is installed on a flat board of the vehicle body; the transporting device also comprises a track and support forks, and the support forks can move along the track; and the ground-connected conveying and placing device comprises a road cone deploying and retracting crawler belt forming a certain angle with the ground, and a micro poking and shoveling component. Manual replacement and recycling of the road cones during road maintenance is replaced, and full automation of road cone placement and recycling is realized. Risks of road operation are reduced, and personal safety of workers during working is raised. The road working efficiency is raised, and time is saved. Through constant-speed advancement of the vehicle and constant-speed movements of the device, equal-distance placement of the road cones is realized, and the aim of controlling distance among the road cones can be achieved by changing travelling speed of the vehicle.

Owner:SHANGHAI DIANJI UNIV

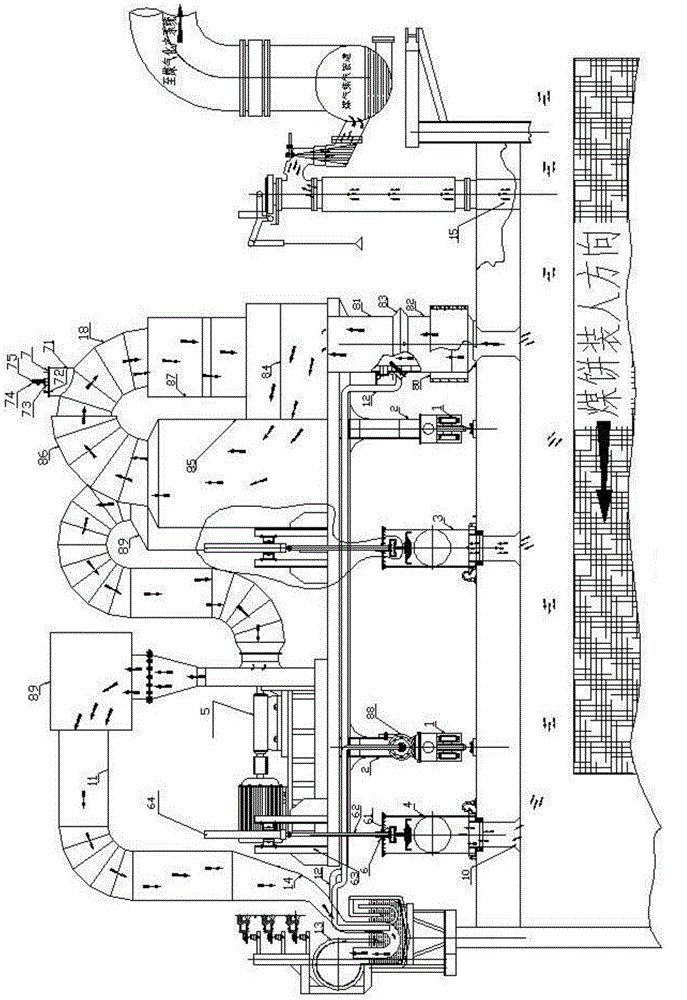

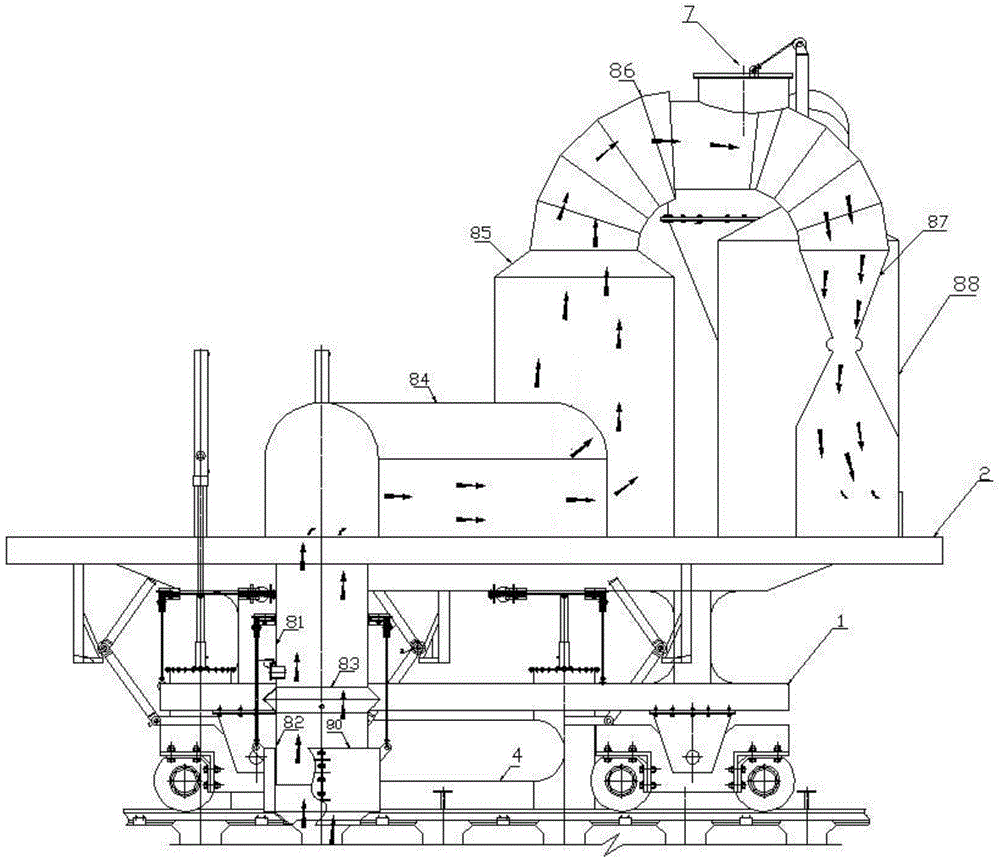

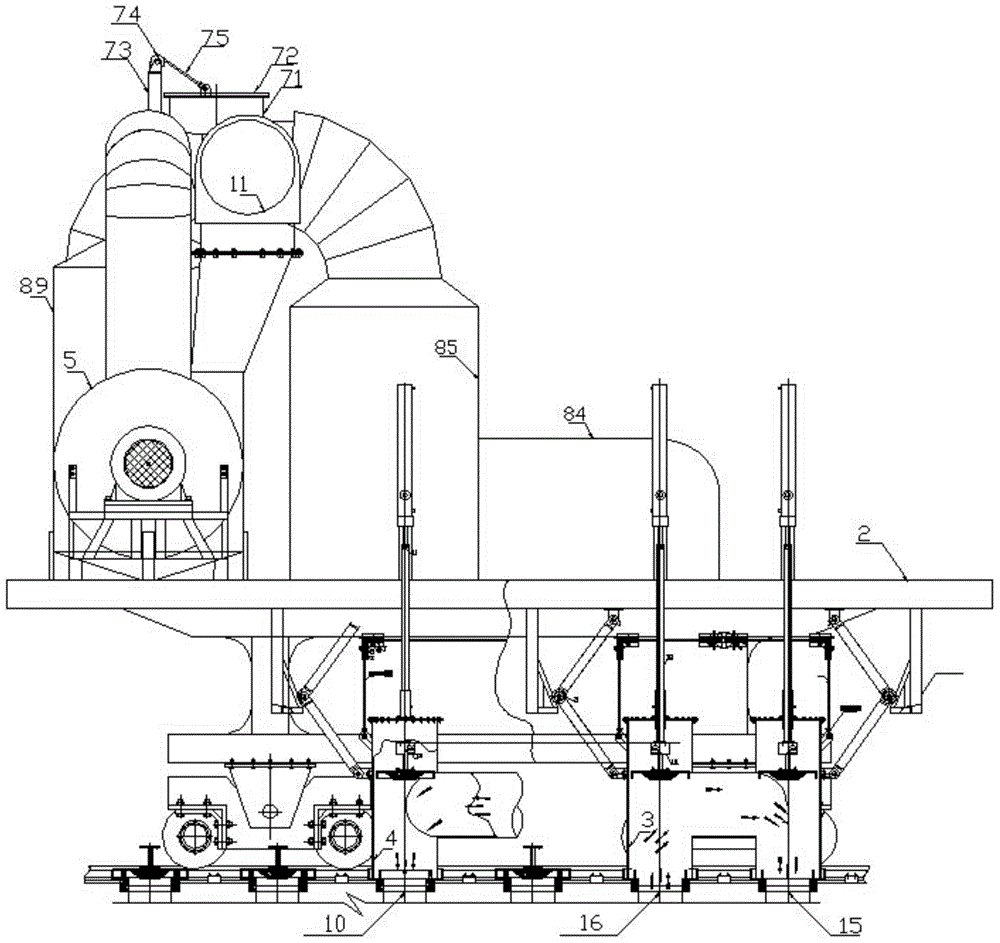

Multifunctional external-adsorption gas smoke guide and recovery and combustion smoke elimination and dust removal vehicle

ActiveCN104388104AMeet the requirements of new emission standardsIt has the function of recovering raw gas from coal loadingCoke oven safety devicesOven incrustations prevention/removalCombustionCarbonization

The invention belongs to the technical field of coking of coking furnaces, relates to a multifunctional external-adsorption gas smoke guide and recovery and combustion smoke elimination and dust removal vehicle and aims to provide the multifunctional external-adsorption gas smoke guide and recovery and combustion smoke elimination and dust removal vehicle which inherits the functions of combustion smoke guide and high-pressure ammonia water injected N<-1> and N<+2> smoke guide and is capable of meeting the requirements for deep processing and recycling of energy and energy saving, low in cost and operation cost as well as good in economic and environment-friendly effects. The adopted technical scheme is as follows: a traveling device is arranged at the bottom of a frame body; both a movable adsorption guide pipe and a fixed adsorption guide pipe are arranged on the frame body; the movable adsorption guide pipe is inserted to the fixed adsorption guide pipe; the fixed adsorption guide pipe is communicated with a smoke inlet of a carbonization chamber; a gas inlet of a combustion smoke elimination and dust removal system is communicated with a second smoke outlet formed in the top of a coal storage and carbonization chamber; and a smoke outlet of the combustion smoke elimination and dust removal system is communicated with a dust removing and collecting pipeline arranged at the top of the furnace. The multifunctional external-adsorption gas smoke guide and recovery and combustion smoke elimination and dust removal vehicle can be widely applied to the field of cokes.

Owner:刘瑞军

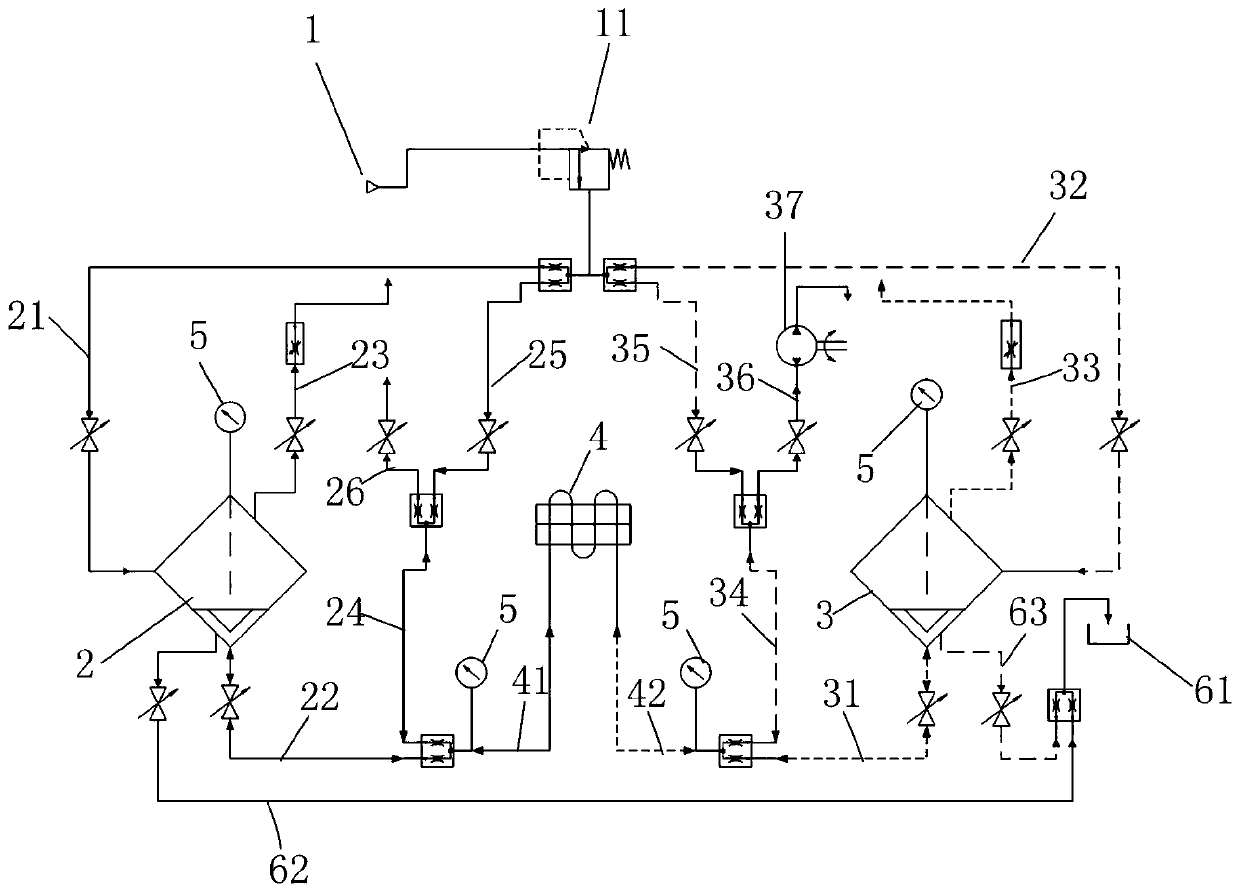

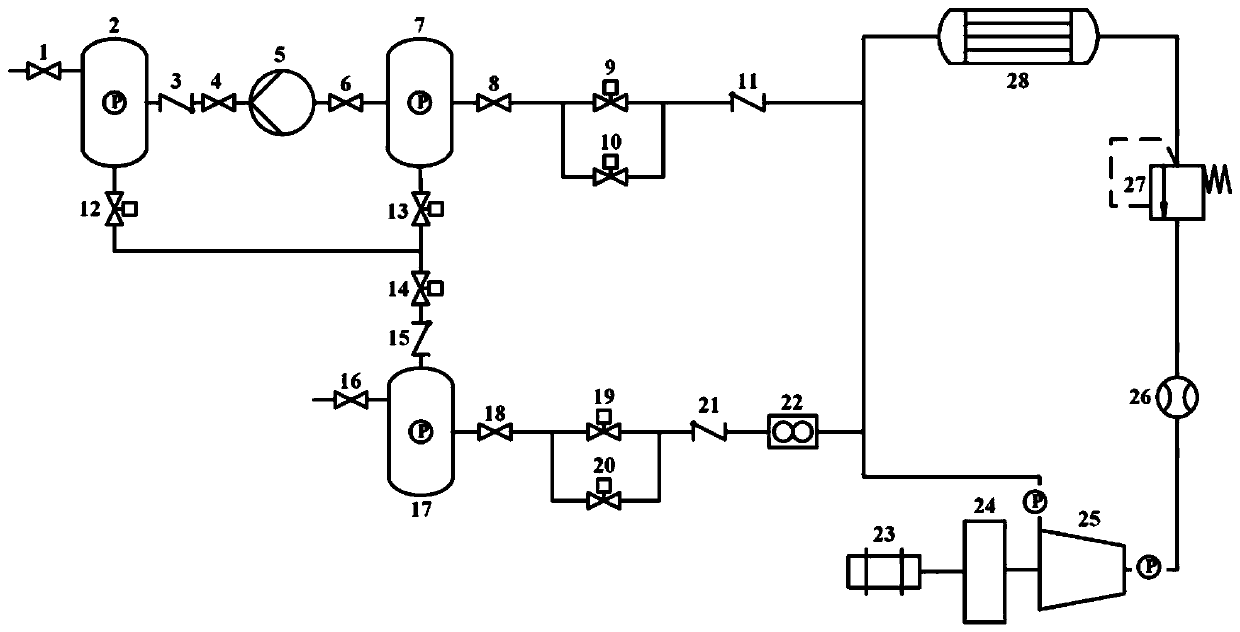

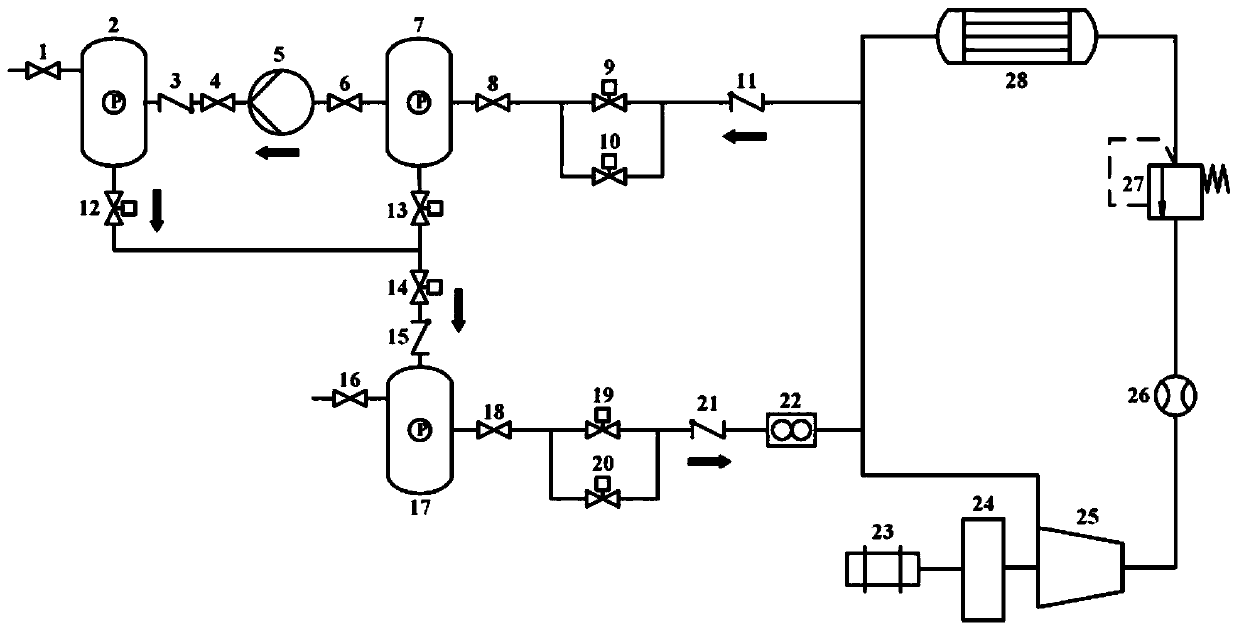

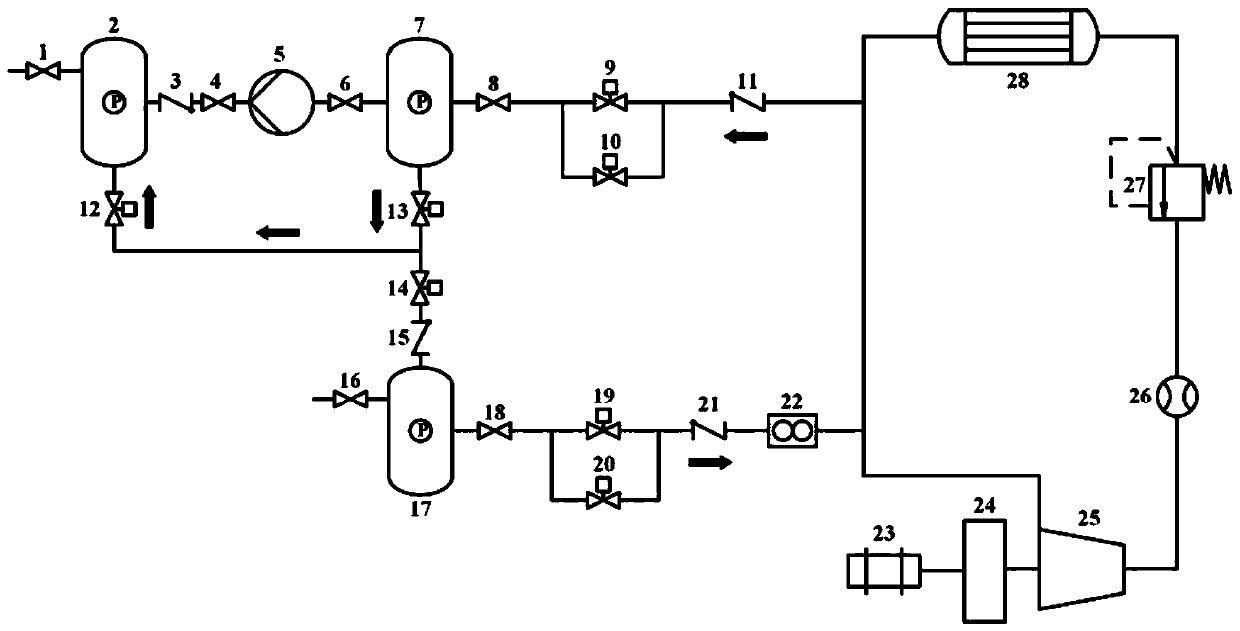

Air source device for compressor closed type experiment system and control method thereof

ActiveCN110793800AImprove test resultsRealize the recycling functionStructural/machines measurementThermodynamicsNitrogen gas

The invention discloses an air source device for a compressor closed type experiment system and a control method of the air source device. The air source device comprises an air supplementing unit, anair discharging unit and a pressure stabilizing unit. According to the air source device, the self-circulation of a working medium can be completed through the pressure stabilizing unit (including apressure stabilizing tank, a compressor and other components), the recycling function of the working medium can be achieved, and the testing capacity of the compressor closed type experiment system iseffectively expanded. According to the air source device, the air supplementing unit and the air discharging unit are arranged such that the air supplementing and discharging of the compressor closedtype experiment system can be achieved, the rapid surge relief of a tested compressor can be realized by dynamically monitoring the outlet pressure fluctuation of the tested compressor and operatinga main vent valve. The air source device disclosed by the invention belongs to the related technical field of centrifugal or axial flow compressor testing, is suitable for stable working media such asair, carbon dioxide, nitrogen and the like, and is also suitable for inflammable, explosive and corrosive working media such as hydrogen gas, ammonia gas and the like.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

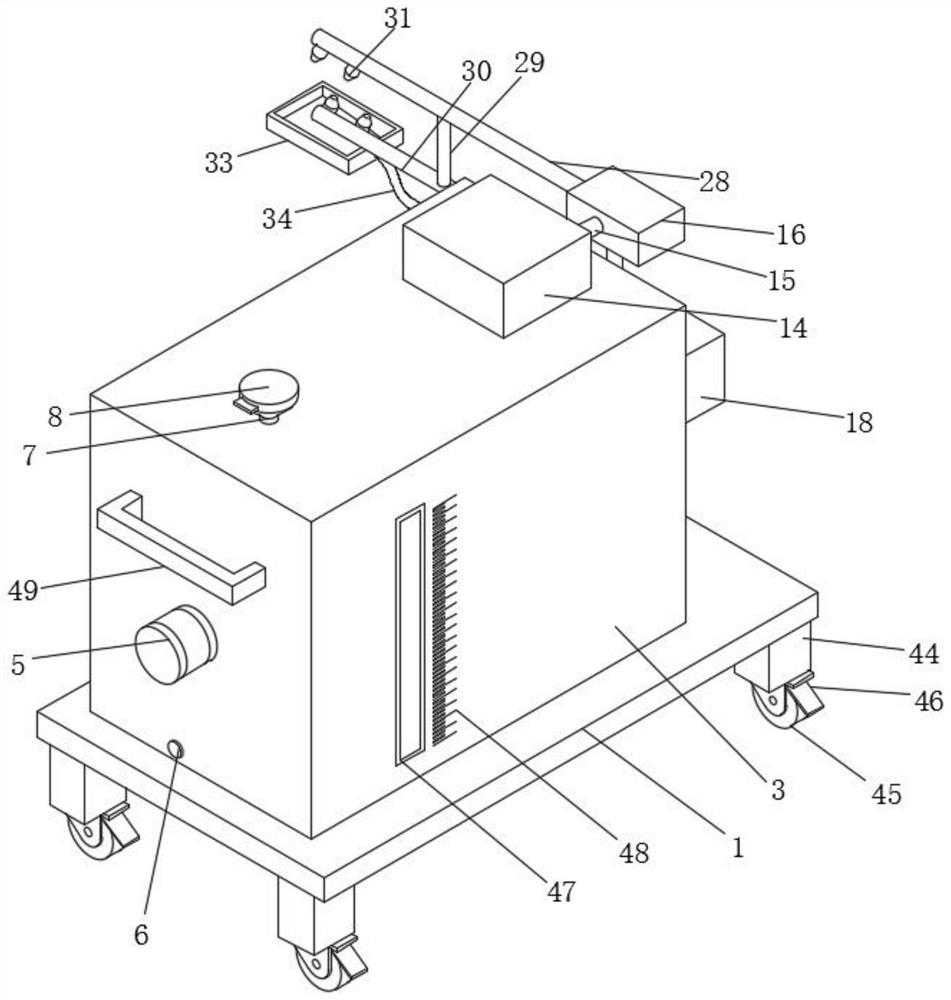

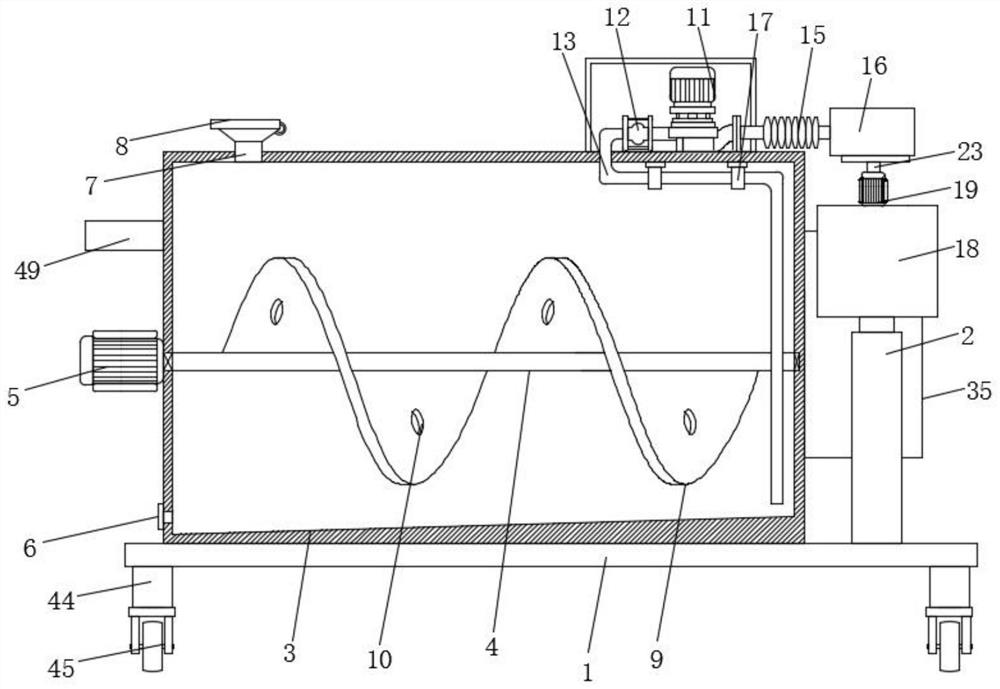

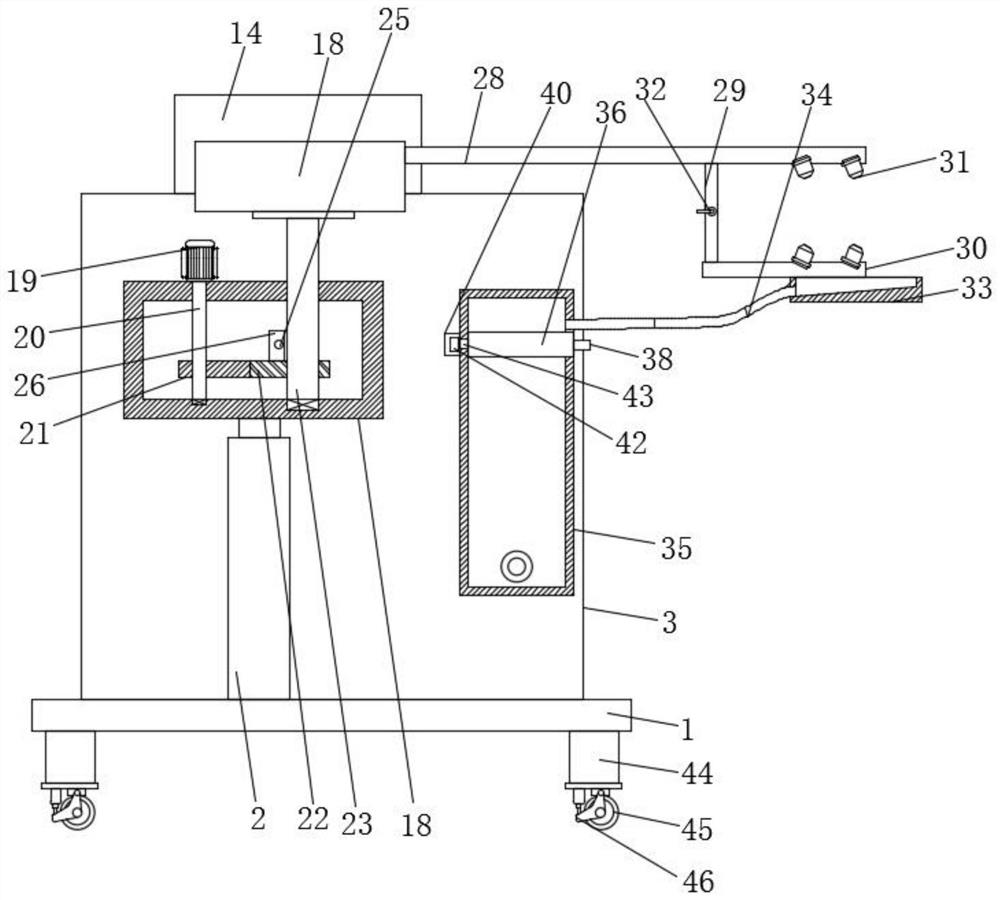

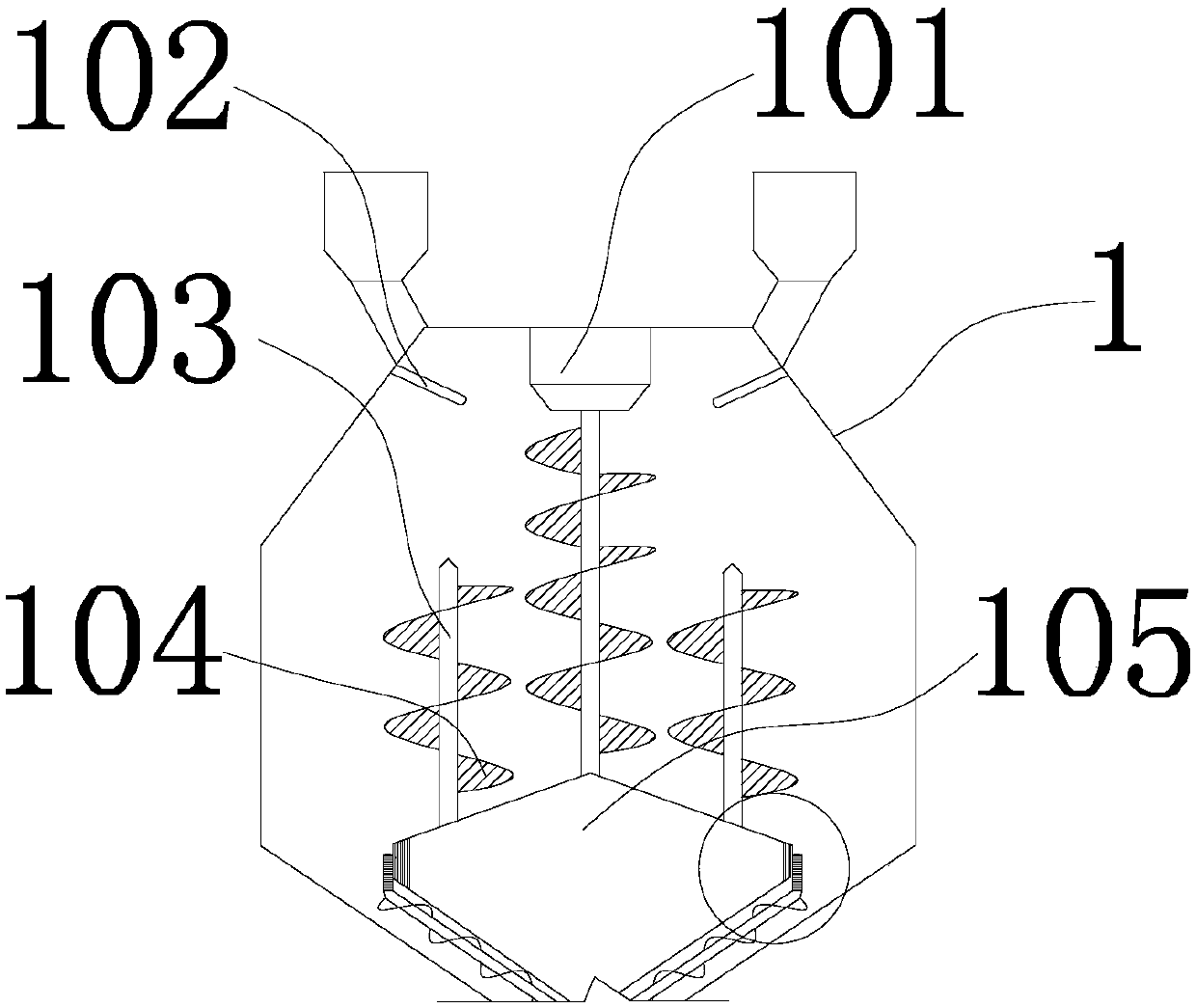

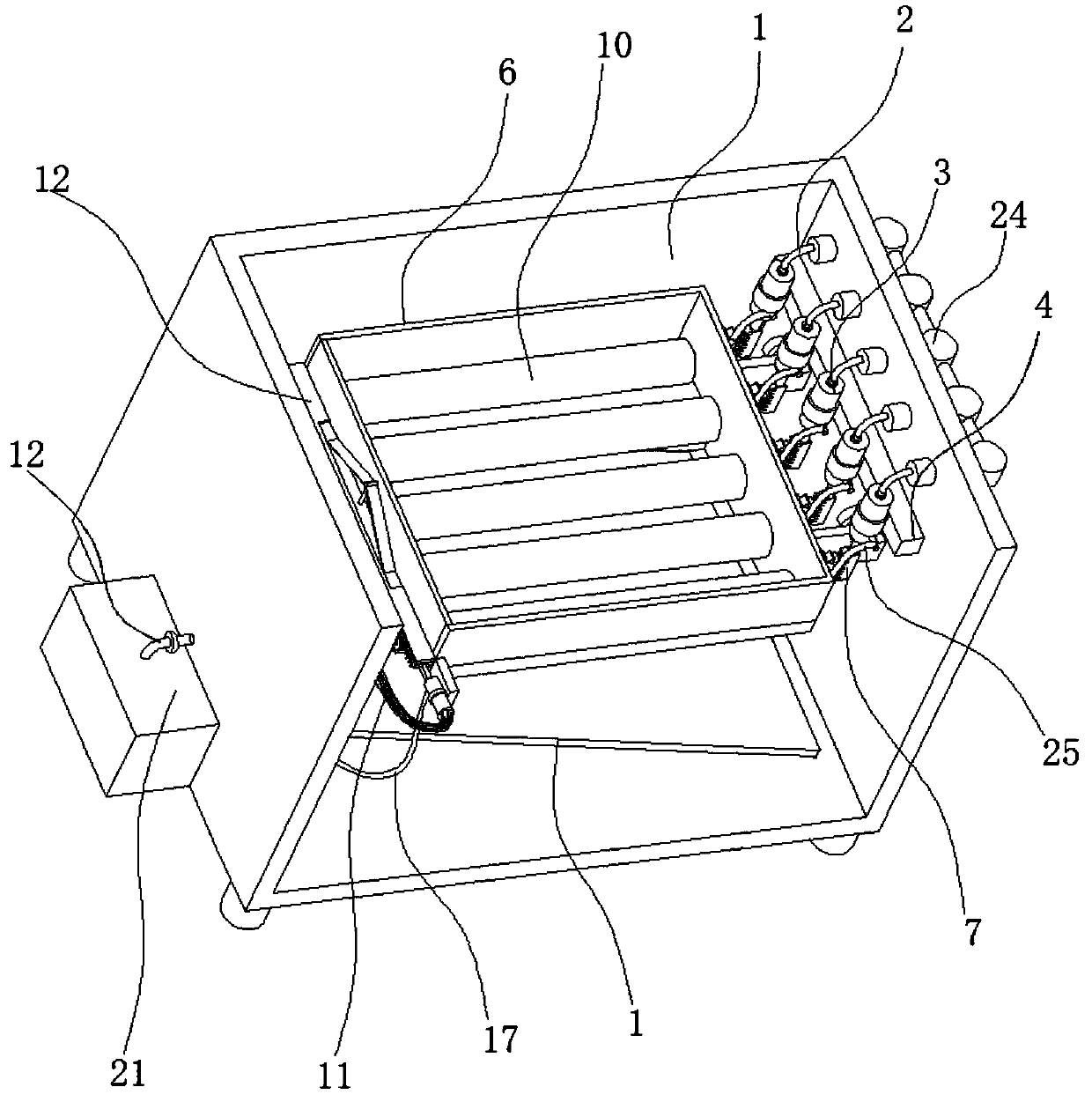

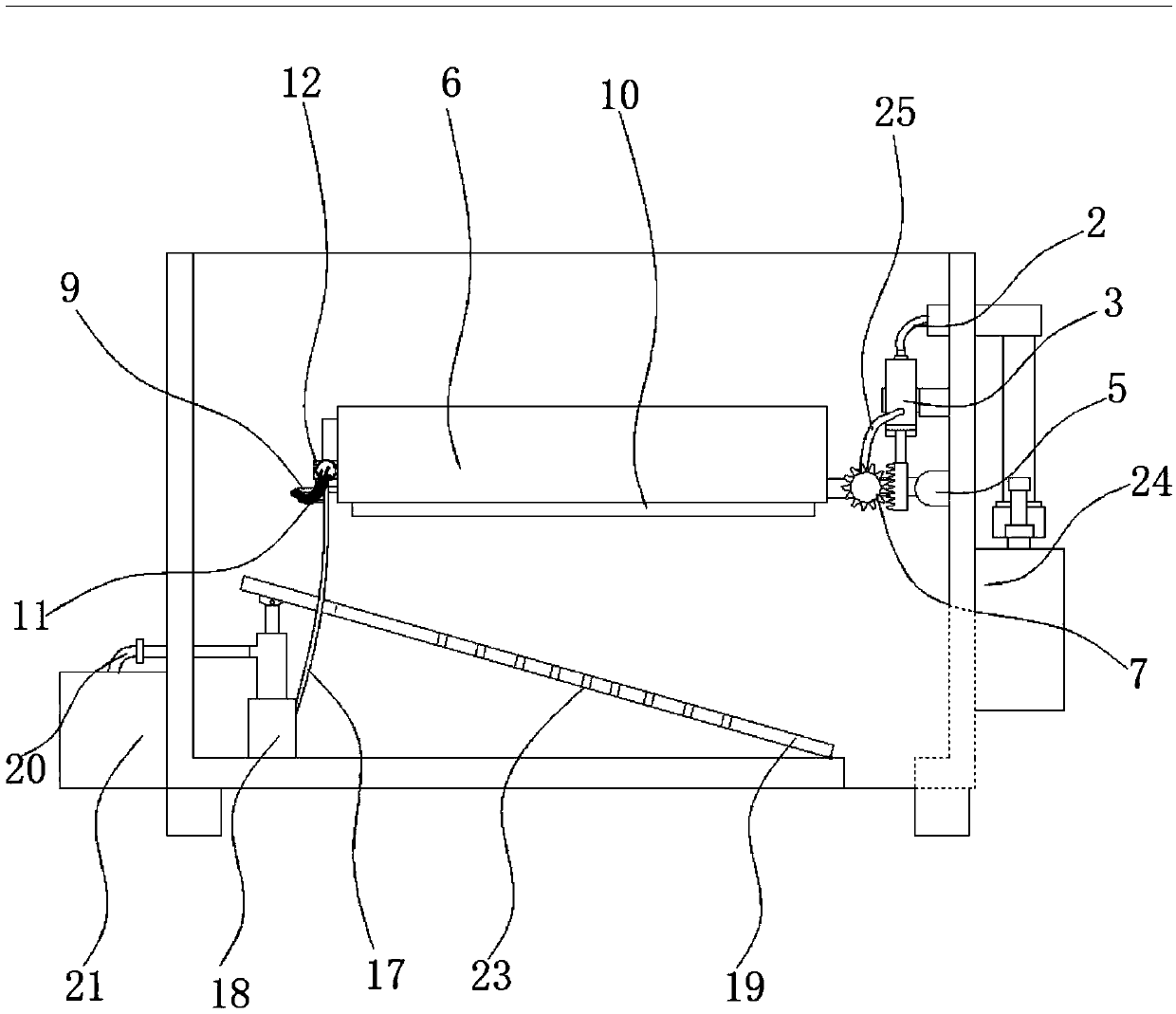

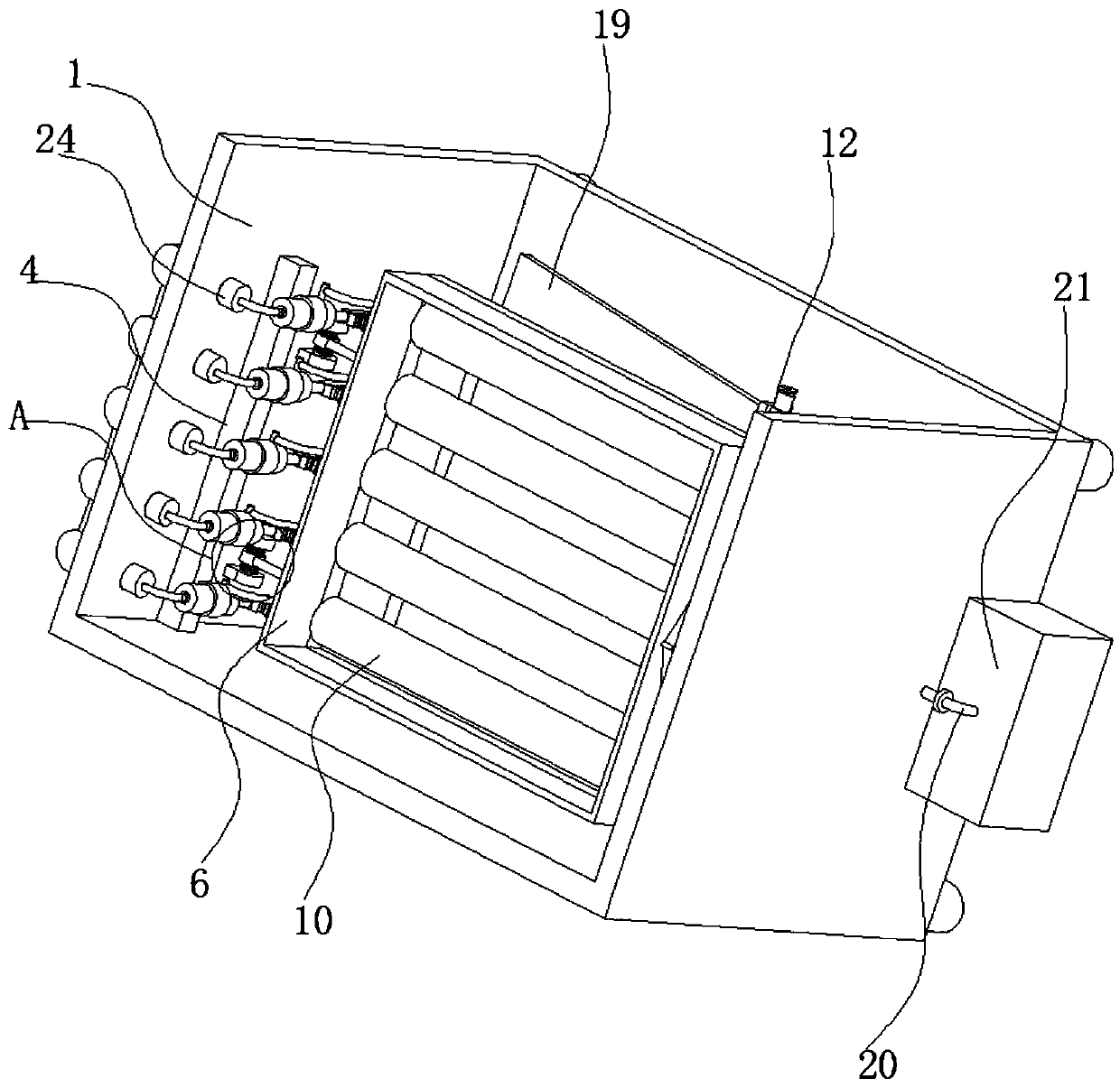

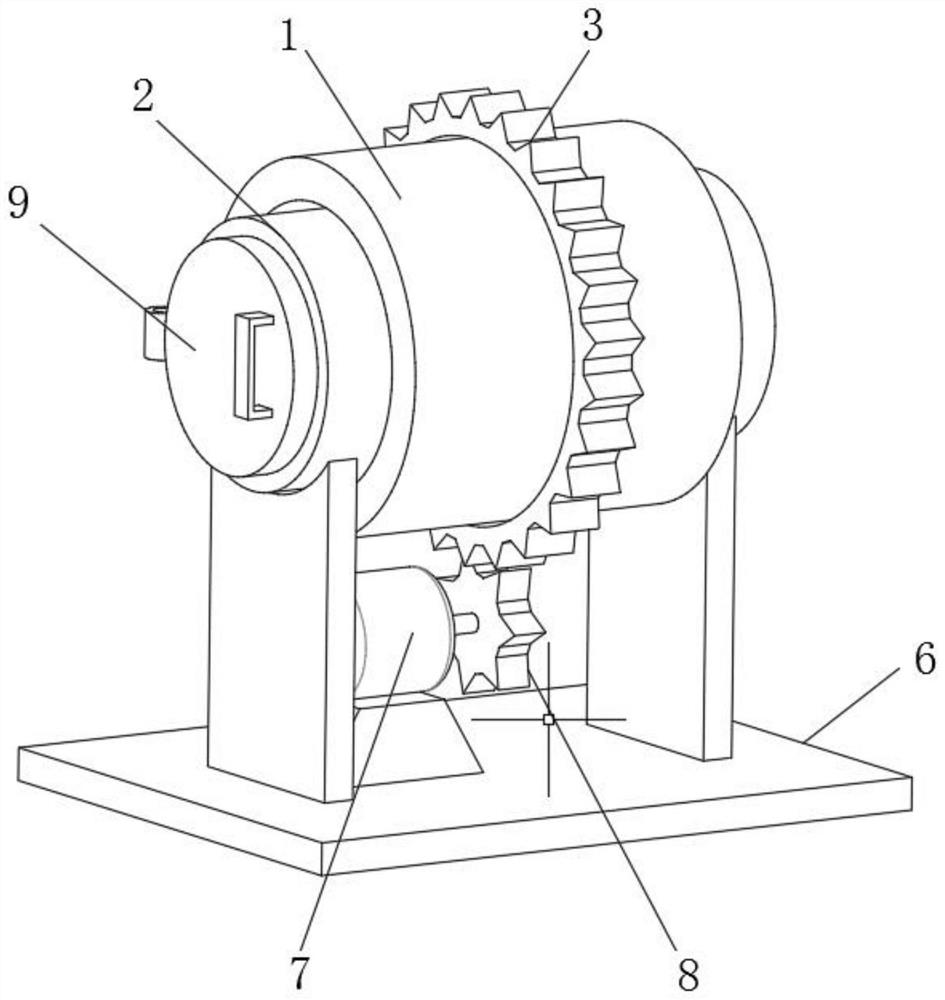

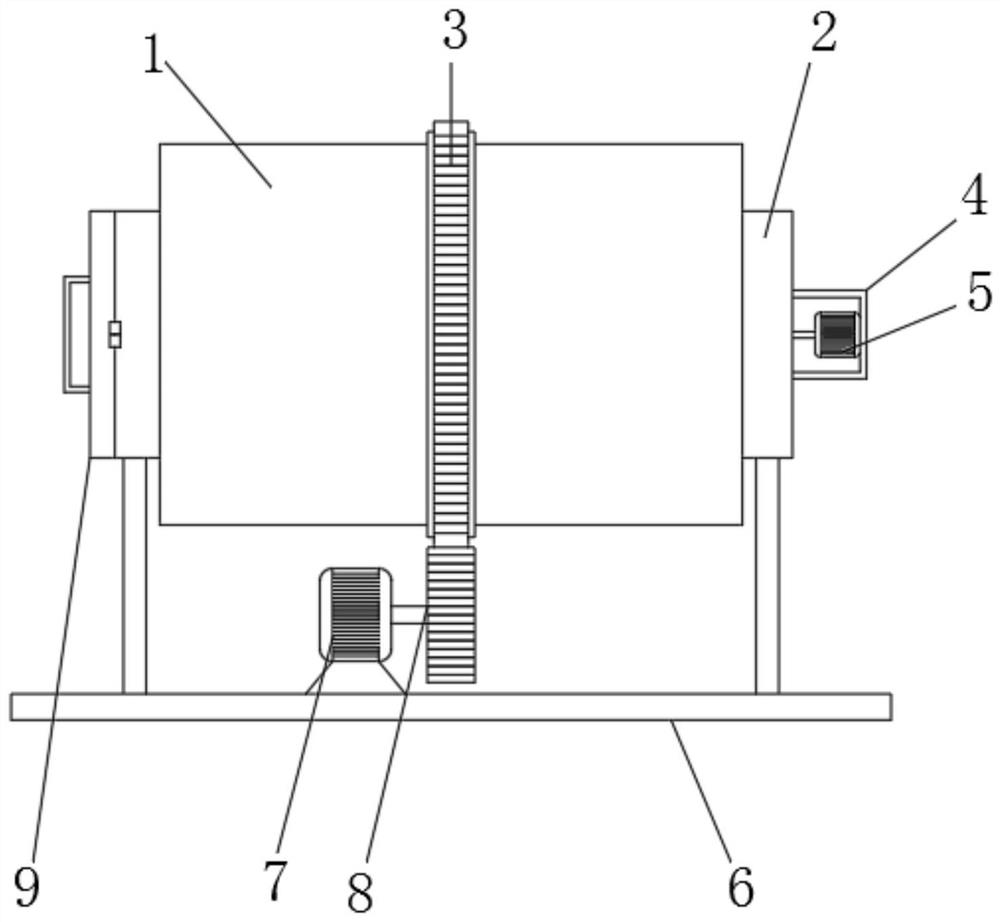

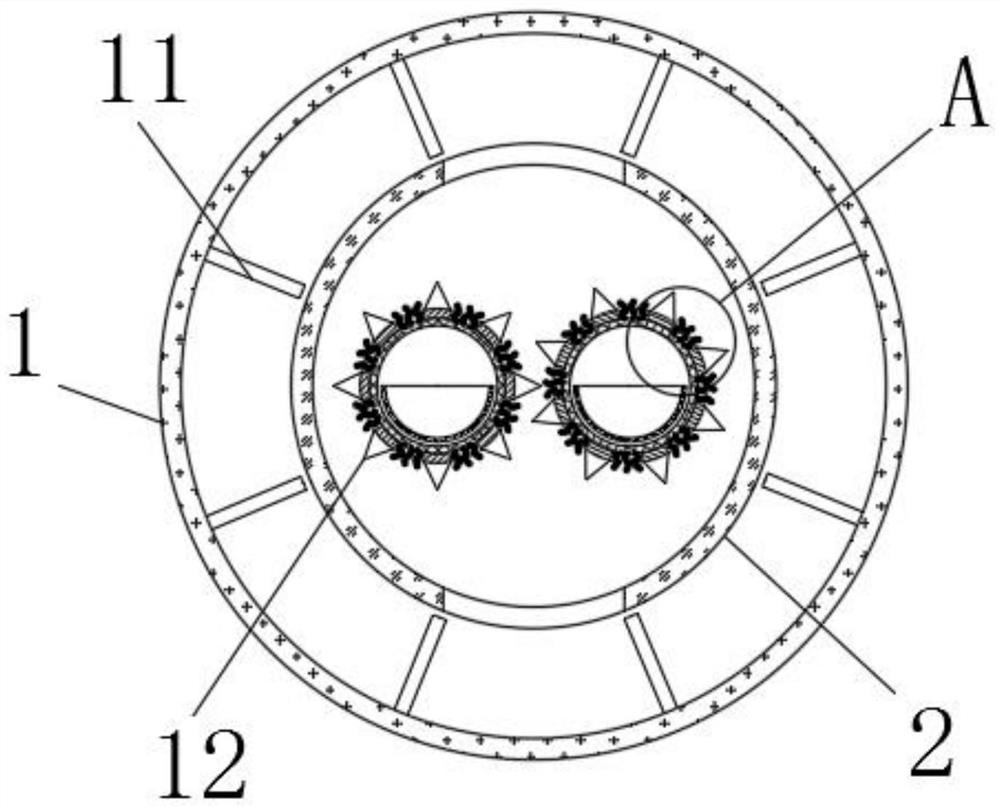

Plywood processing device integrating stirring and gluing

ActiveCN109675767AExtend the mixing timeImprove the mixing effectLiquid surface applicatorsMaterial gluingDrive motorEngineering

The invention provides a plywood processing device integrating stirring and gluing. The plywood processing device comprises a stirring mechanism, a discharge mechanism, a gluing mechanism and a laminating mechanism. The plywood processing device is characterized in that the stirring mechanism is positioned above the discharge mechanism; the gluing mechanism is positioned below the discharge mechanism; the laminating mechanism is positioned at one side of the gluing mechanism; the stirring mechanism comprises a mixing box, a charge tank and a drive motor; and the charge tank is connected to thetwo sides above the mixing box in a penetrating mode. The plywood processing device is equipped with a stirring rod; the stirring rod, a rotary disc and a spiral pushing rod toothed slot are arranged, and the stirring rod rotates to drive a grid to rotate, so that added glue can be stirred and mixed very well; and meanwhile, the stirring rod can stir glue which is dropped into the stirring rod back and forth on an inclined position above the rotary disc as the stirring rod is arranged in an inclined mode above the rotary disc, so that stirring effect is improved, and therefore, the plywood processing device brings especially important effect in use of plywood processing producing.

Owner:嘉善安顺木业股份有限公司

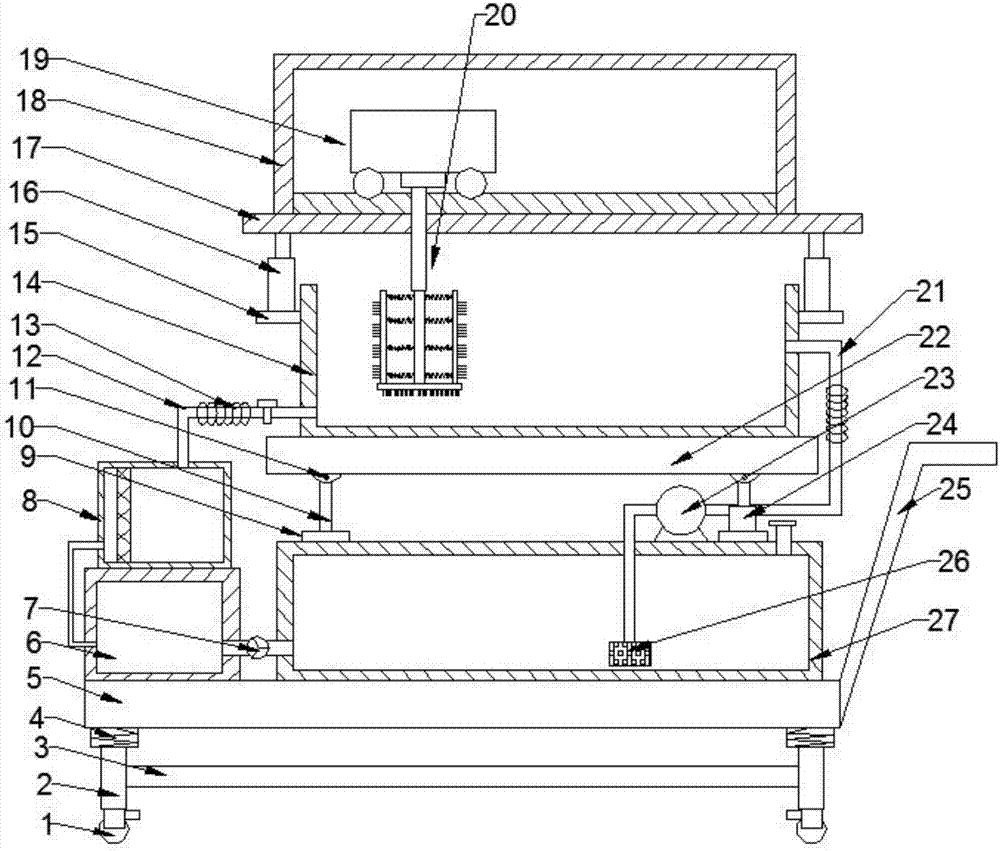

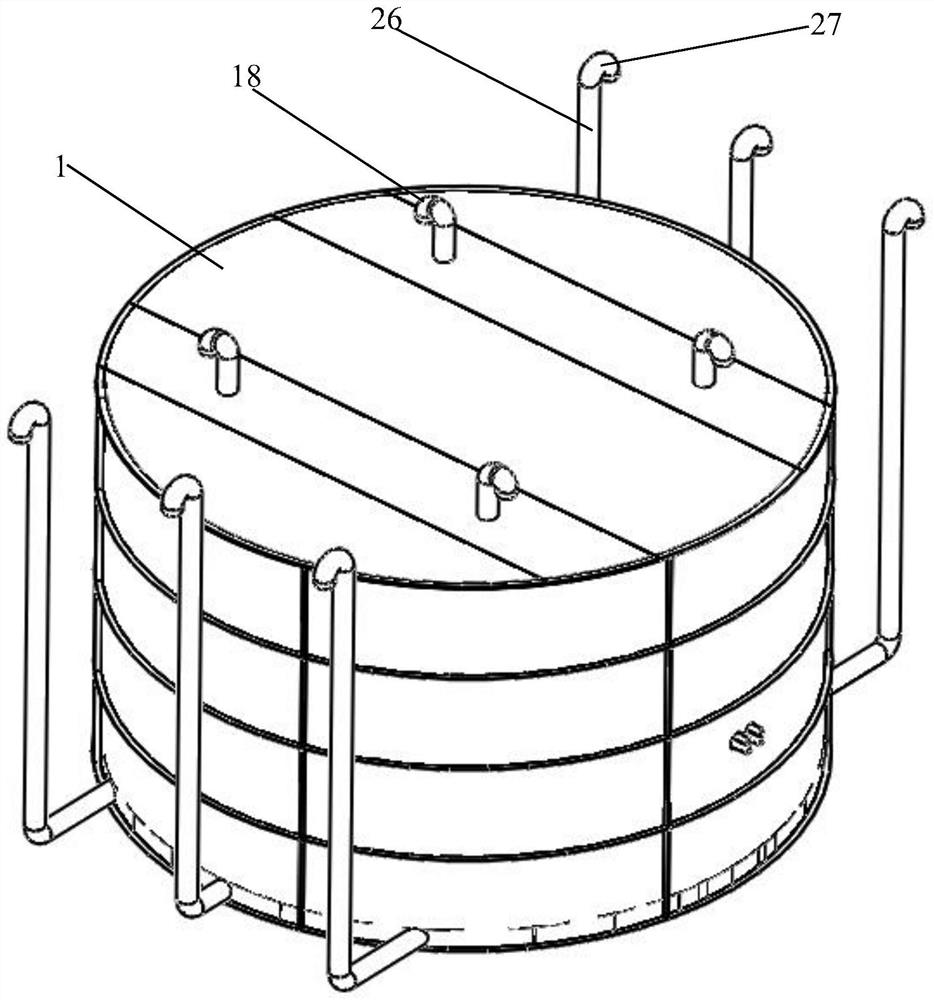

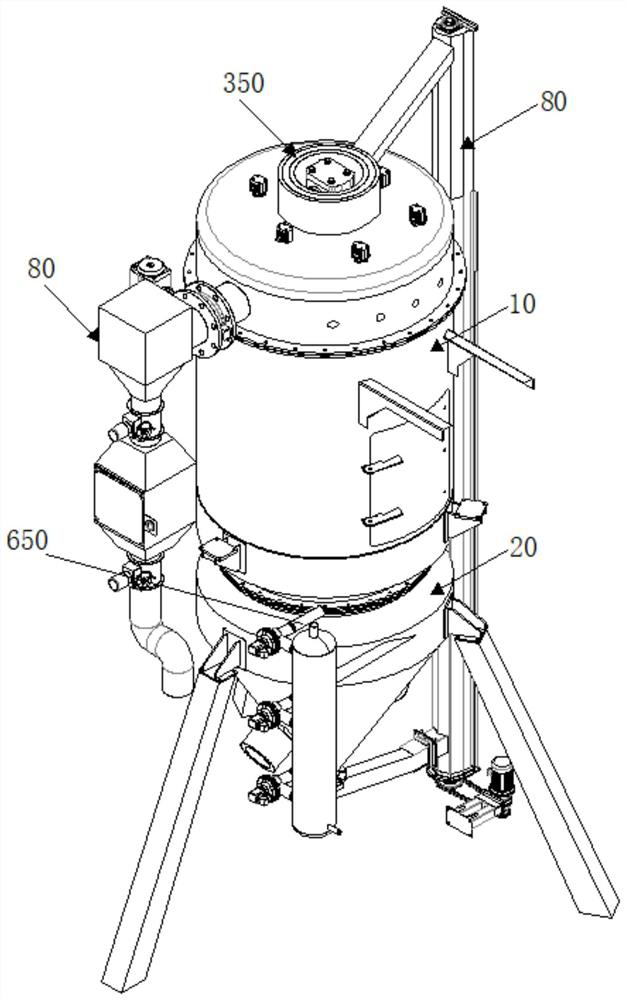

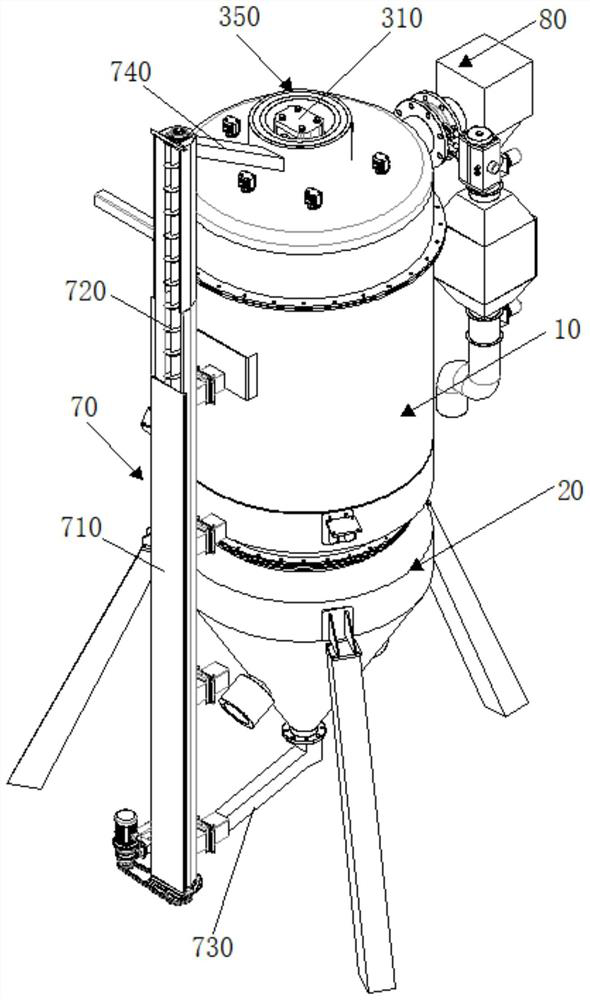

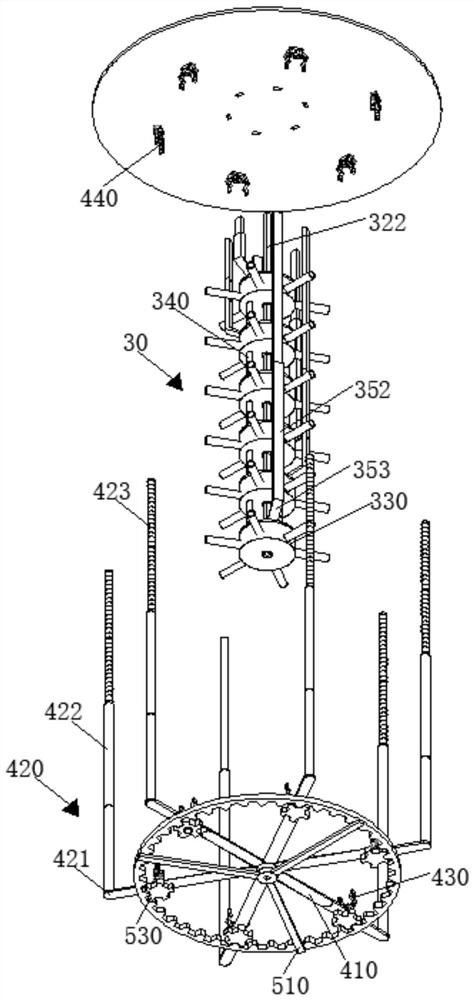

Aerobic fermentation heat recycling equipment for coupling agricultural and forestry waste and breeding excrement

PendingCN114149895AEasy to collectPromote fermentationBioreactor/fermenter combinationsBiological substance pretreatmentsEnvironmental engineeringFermentation

The invention discloses agricultural and forestry waste coupled breeding manure aerobic fermentation heat recycling equipment. The equipment comprises a fermentation tank; the first heat exchanger is arranged in the fermentation tank, a water inlet of the first heat exchanger is connected with a first water inlet pipe, and a water outlet of the first heat exchanger is connected with a first water outlet pipe; the first heat storage water tank is arranged in the fermentation tank, a water inlet of the first heat storage water tank is communicated with a pipe opening, away from the first heat exchanger, of the first water outlet pipe, a water outlet of the first heat storage water tank is connected with a second water outlet pipe, and a pipe opening, away from the first heat storage water tank, of the second water outlet pipe extends out of the fermentation tank; the heat utilization system is positioned outside the fermentation tank and is connected with the first water inlet pipe and the second water outlet pipe through a first pipeline. The first heat exchanger and the first heat storage water tank of the heat recovery equipment are both positioned in the fermentation tank, so that heat can be recovered and stored to the greatest extent, and the heat recovery equipment is convenient to mount, popularize and use.

Owner:HARBIN INST OF TECH

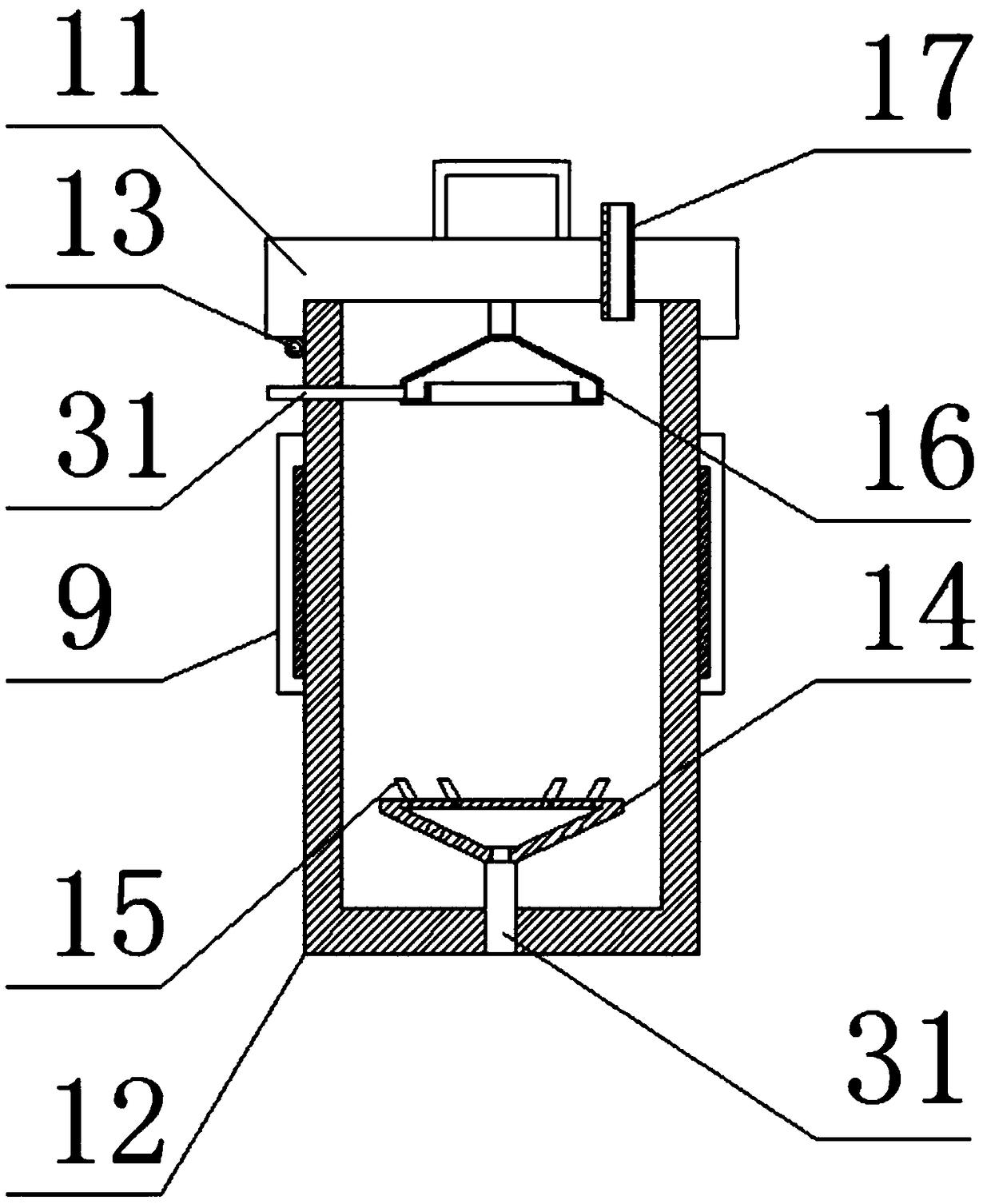

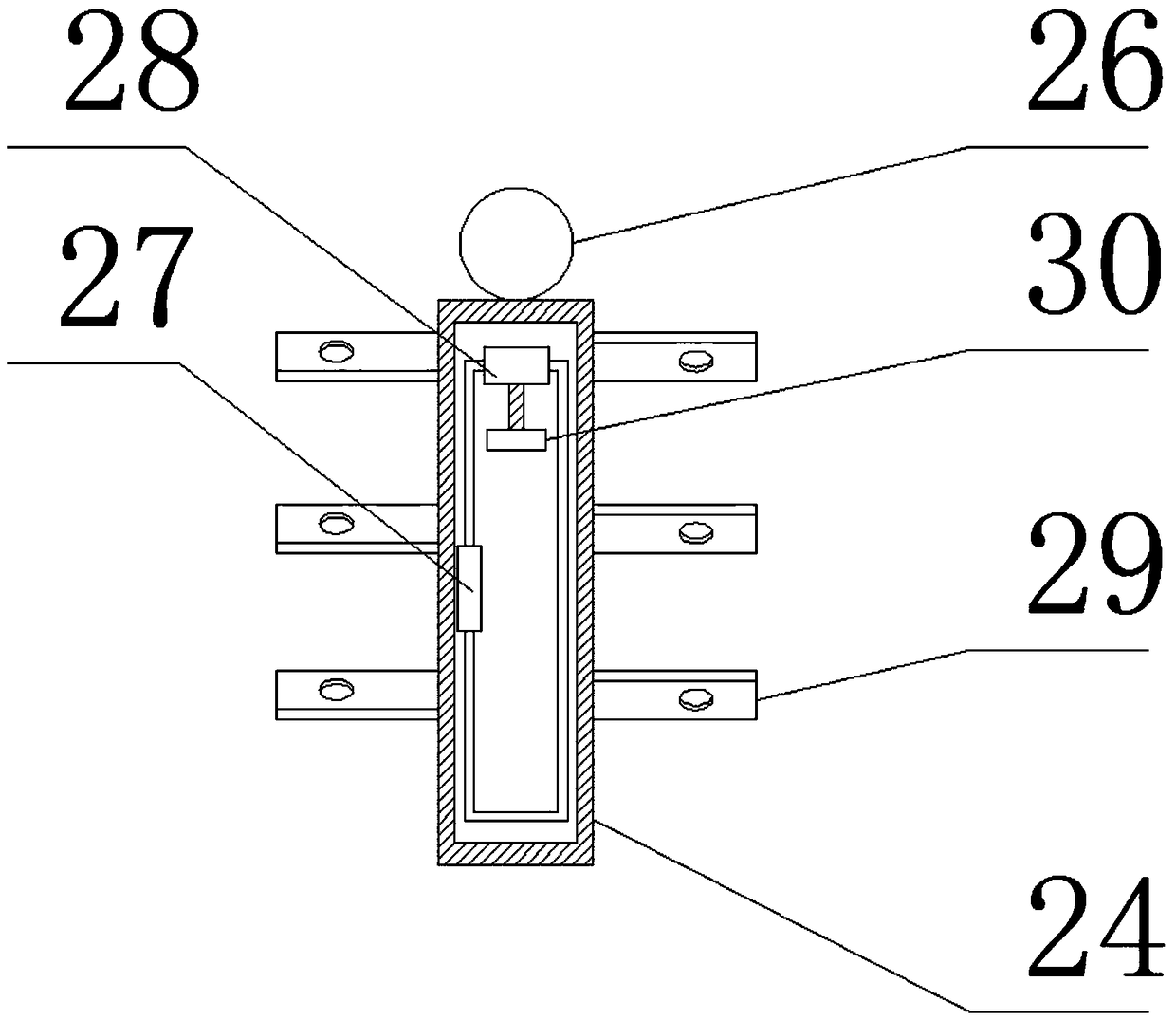

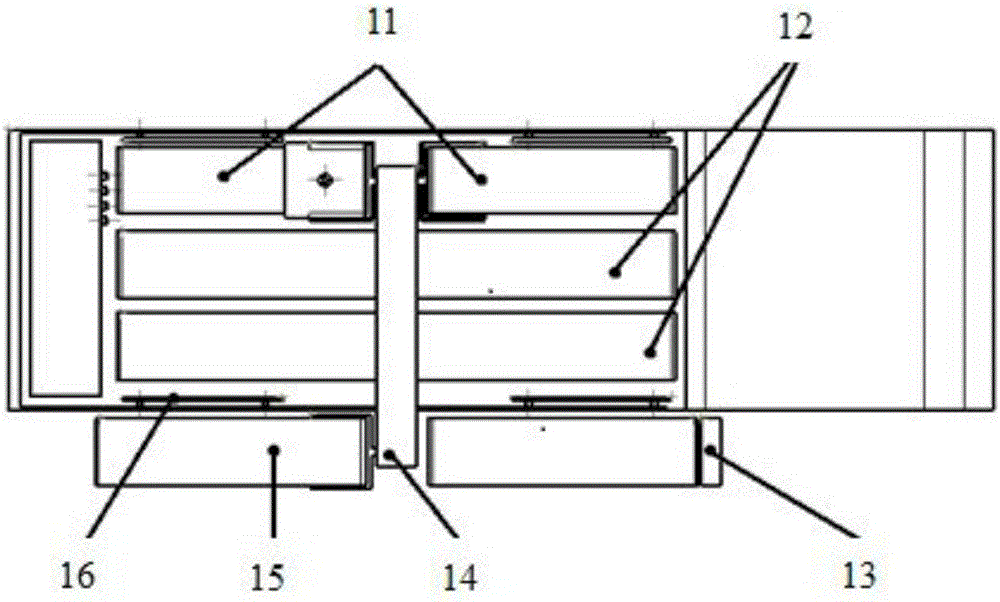

Drying device for pipe parts

ActiveCN109654833AAvoid damageHelp shake offDrying gas arrangementsDrying chambers/containersElectricityHeat transmission

The invention discloses a drying device for pipe parts, and belongs to the technical field of processing of mechanical parts. The drying device for the pipe parts comprises a box body and an electricheating steam generation mechanism, wherein the electric heating steam generation mechanism is connected to the outer side wall of the box body, an air outlet of the electric heating steam generationmechanism is connected with a first driving assembly through a first connecting hose, a fixed part and a movable connecting part are connected to the longitudinal inner side wall of the box body in the vertical direction, and the end, away from the inner side wall of the box body, of the movable connecting part is connected with a fixed frame. According to the drying device for the pipe parts, vapor is used for heat transmission and drying, so that the problem of damage to the machine pipe parts caused by high temperature is effectively solved; the fixed frame is driven to vibrate through steam while drying is carried out so that water drops adhered to the surfaces of the pipe parts can be rapidly reduced, and the drying efficiency is improved; and meanwhile, a drying cylinder is driven torotate while the fixed frame is driven to vibrate through the steam, so that the contact area between the drying cylinder and the pipe parts is increased, and the drying uniformity is improved.

Owner:福建泉州市剑井贸易有限公司

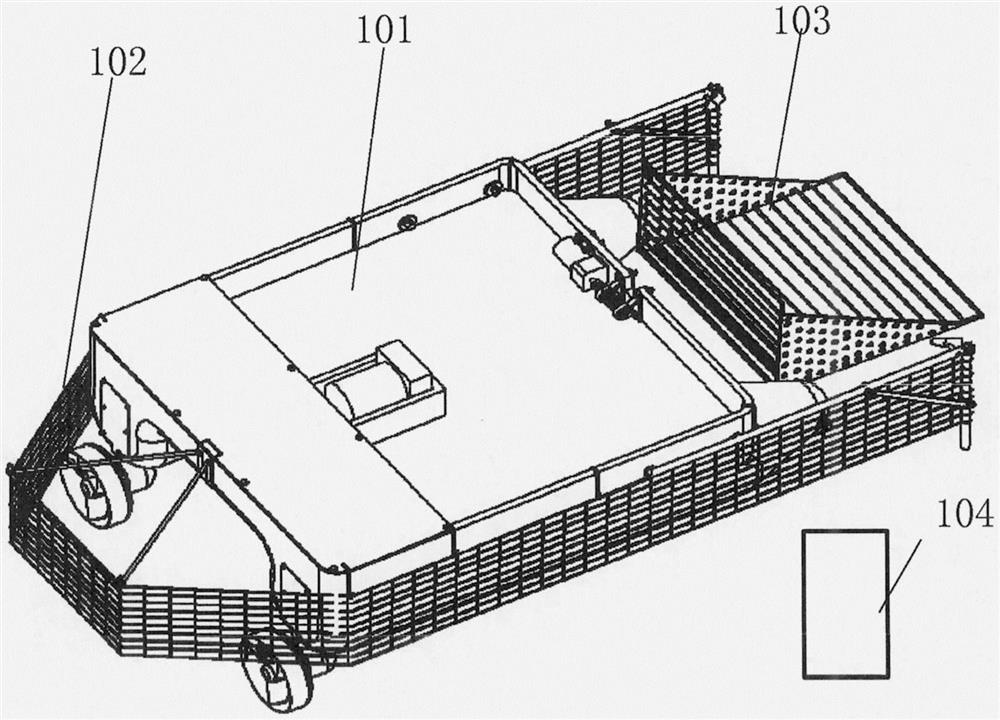

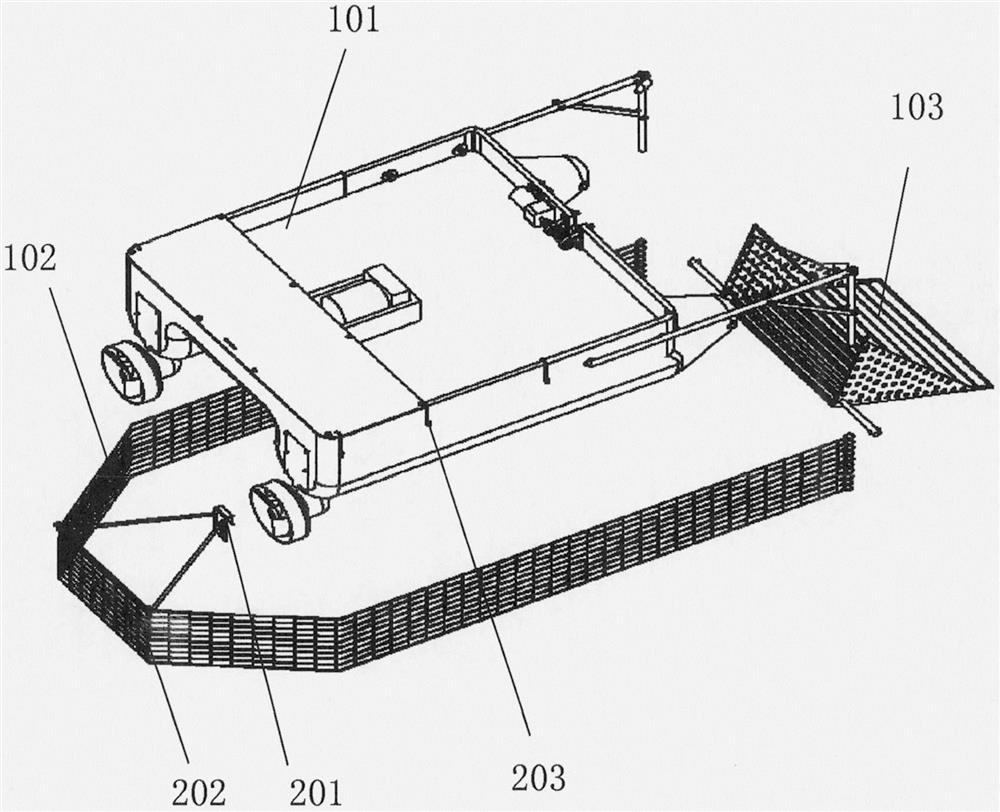

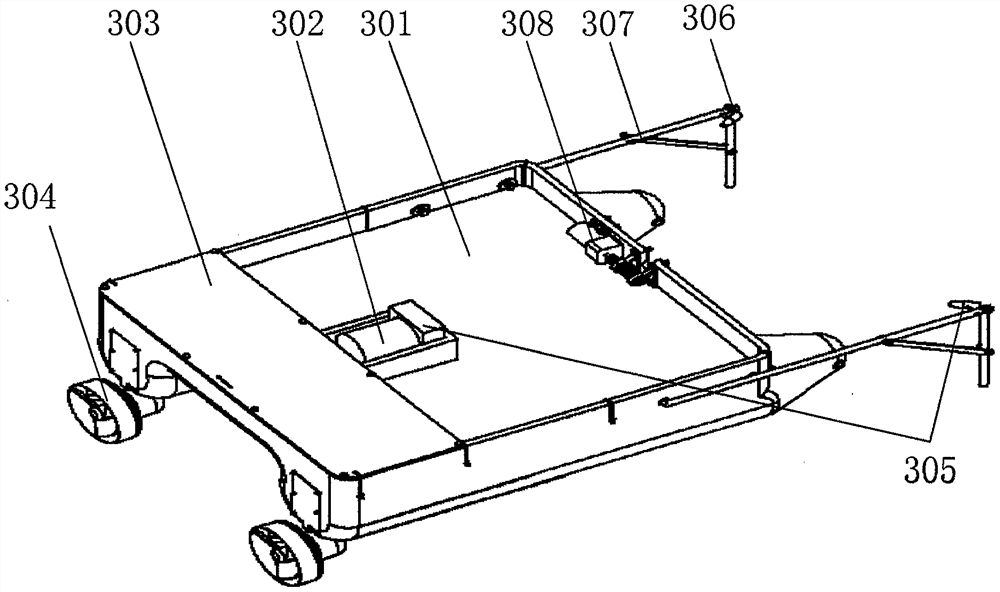

Portable garbage cleaning ship suitable for south-to-north water diversion channel

PendingCN112027003ARealize the recycling functionReduce pollutionWater cleaningNon-magnetic metal hullsSplit pinControl system

The invention relates to a portable garbage cleaning ship suitable for a south-to-north water diversion channel, which consists of a control system, a basic ship body module, a light floating object collecting module and a heavy floating object collecting module, and is detachable and easy to assemble. The basic ship body module comprises a ship body, a power supply device, a driving device, a jetflow guide device, a purse seine supporting rod and a heavy floating object collection driving device; the light floating object collecting module comprises a purse net, a purse net support and a purse net hook. The heavy floating object collecting module comprises a bucket, a steel sleeve, a connecting pin shaft and a cotter pin. The portable garbage cleaning ship realizes the function of automatically cleaning and recycling garbage in the south-to-north water diversion channel, has the advantages of easiness in disassembly and assembly, light weight, convenience in transportation, automaticpower storage, route planning and automatic garbage recycling, and can greatly reduce water environment pollution, reduce manual operation and reduce cost.

Owner:河北水利电力学院

Waste old clothes automatic sorting cyclic regeneration system

InactiveCN108043747ARealize the recycling functionReduce labor intensitySolid waste disposalSortingHydraulic cylinderLife quality

The invention relates to a waste old clothes automatic sorting cyclic regeneration system. The waste old clothes automatic sorting cyclic regeneration system comprises a controller, a display screen,a first sort of clothes sliding out tank, a second sort of clothes sliding out tank, a moisture detector, a clothes worn degree detector, a clothes color detector, a counter, a motor, a pressure sensor, a second-level hydraulic cylinder, self-locking wheels and a belt. The waste old clothes automatic sorting cyclic regeneration system can detect waste old clothes in an all-round mode and record data through installation of the moisture detector, the clothes worn degree detector, the clothes color detector and the counter, wherein modern society life quality and waste degree can be objectivelyreflected by recording the clothes data. The second-level hydraulic cylinder is mounted on the device so that the waste old clothes can be sorted fully automatically. In addition, the controller is mounted on the device, highly mechanical automation is achieved, the labor intensity of working personnel is relieved, the display screen is mounted on the controller, people can record the detected data better, the self-locking wheels are mounted on the system so that the system can move, and the system achieves the cyclic regeneration function of waste old clothes.

Owner:杭州新天元织造有限公司

Drawer type demoulding water cycle use device

ActiveCN110681843AEasy to operateExtended service lifeMultistage water/sewage treatmentWater cyclingManufacturing engineering

The invention relates to a drawer type demoulding water cycle use device, and relates to the field of casting. The drawer type demoulding water cycle use device comprises a fixed mould drawer type recovery plate, a movable mould drawer type recovery plate and a slide rail mechanism, wherein the fixed mould drawer type recovery plate is arranged on the bottom part of a fixed mould through the sliderail mechanism and slides relative to the fixed mould; when the fixed mould drawer type recovery plate slides to one end of the slide rail mechanism, an upper plate surface of the fixed mould drawertype recovery plate is located right under a mould surface of the fixed mould; when the fixed mould drawer type recovery plate slides to the other end of the slide rail mechanism, the upper plate surface of the fixed mould drawer type recovery plate gets away from the right lower part of the mould surface of the fixed mould; and a cooperative relationship of the movable mould drawer type recoveryplate and a movable mould is the same as a cooperative relationship of the fixed mould drawer type recovery plate and the fixed mould. The device is convenient to operate, and a positional relationship of each recovery plate and the corresponding mould surface can be adjusted according to the process condition of the corresponding mould surface, so that a demoulding water recycle function can be realized, meanwhile, castings are further prevented from frequently falling to hit a device body, and the service life is prolonged.

Owner:顺景园精密铸造(深圳)有限公司

First aid treatment device for patients of emergency surgery department

InactiveCN107468471AWide range of cleaningEasy to operateHollow article cleaningTreatment involving filtrationEmergency surgeryWater pipe

The invention provides a first aid treatment device for patients in emergency surgery, which includes a water storage tank, a universal water pipe, a rotating seat, a dirt collection plate, a collar, an activated carbon filter, a water pump, a water collecting bucket, a sewage collection box and a treatment box. The water pipe is installed on the lower end surface of the water storage tank, and the water storage tank is installed on the end surface of the support plate. The upper end of the universal water pipe is connected with the connecting water pipe. This design realizes the quick cleaning function of the present invention. The collection plate is installed on the upper end of the rotating seat, and the collar is installed through the bearing and connected to the column. This design realizes the free adjustment of the dirt collection angle. The activated carbon filter is installed in the treatment box, the water pump is installed on the delivery pipe, and the water collection bucket It is installed in the middle of the upper end face of the cabinet, and the sewage collection box is installed in the cabinet. This design realizes the function of sewage recovery and treatment. The invention has reasonable structure, complete functions, easy operation, strong practicability, good stability and high reliability.

Owner:中山市智辉科技服务有限公司

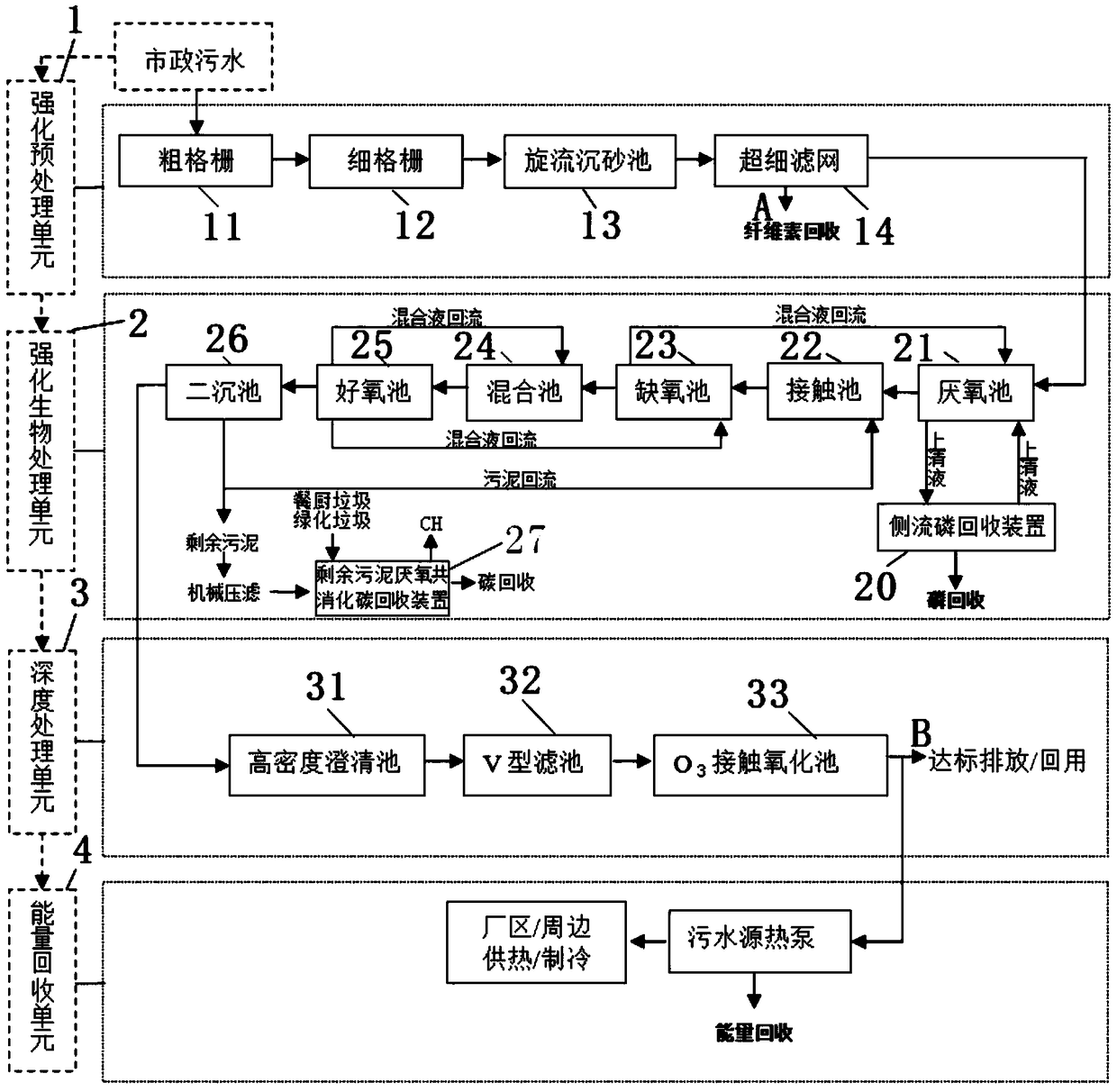

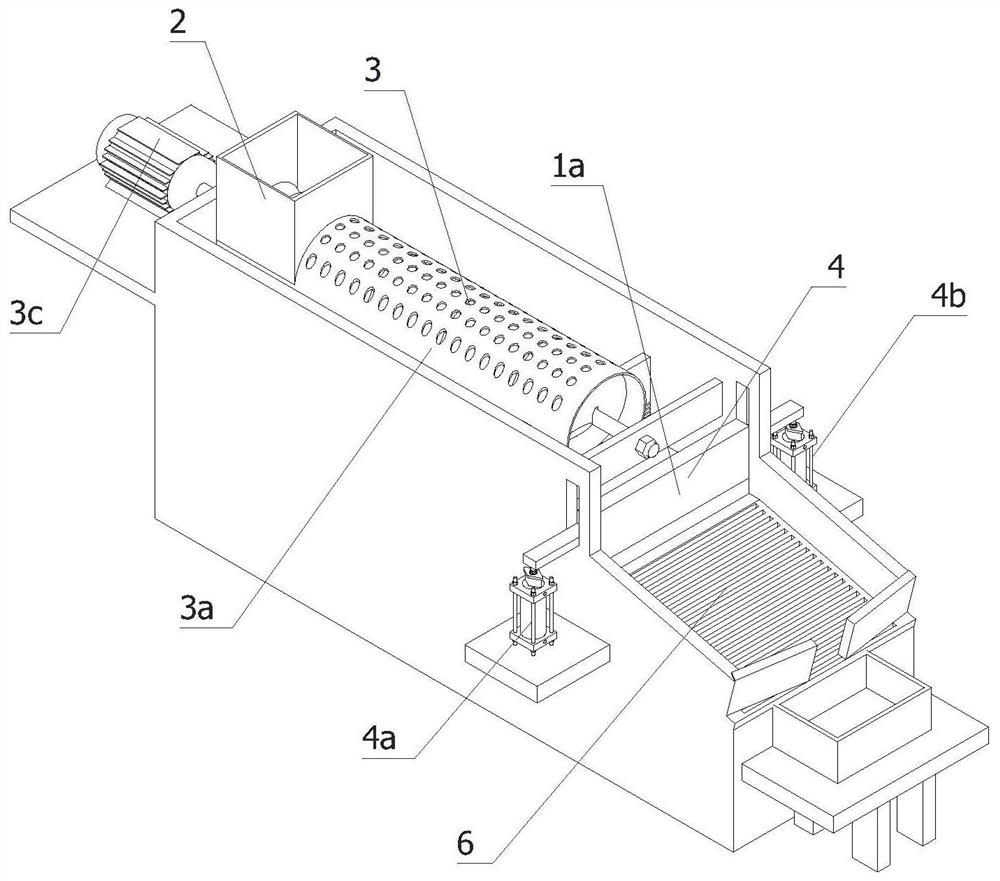

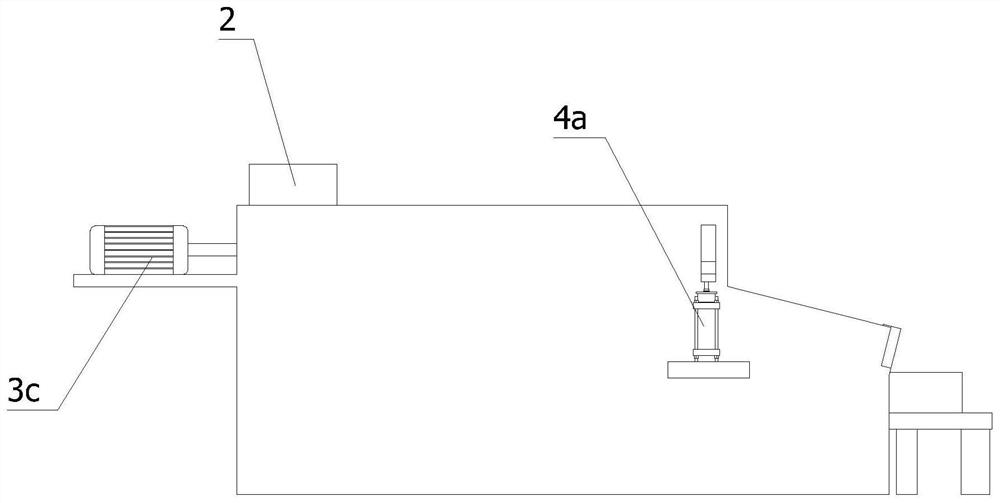

Municipal sewage treatment system and method

ActiveCN109320012ARealize the recycling functionAchieve reductionWater/sewage treatment by centrifugal separationSpecific water treatment objectivesMunicipal sewagePre treatment

The invention discloses a municipal sewage treatment system and method. The municipal sewage treatment system comprises a strengthened pre-treatment unit, a strengthened biological treatment unit, a deep treatment unit and an energy recycling unit, wherein the strengthened pre-treatment unit is internally provided with a cellulose recycling device; the cellulose recycling device is provided with acellulose recycling opening; a municipal sewage inlet is formed in the front end of the strengthened pre-treatment unit and an outlet is formed in the rear end of the strengthened pre-treatment unit;the outlet at the rear end of the strengthened pre-treatment unit is connected with the strengthened biological treatment unit and the deep treatment unit in sequence; the deep treatment unit is provided with an up-to-standard water outlet; the strengthened biological treatment unit is internally provided with a lateral flow phosphorus recycling device; the lateral flow phosphorus recycling device is provided with a phosphorus recycling opening; the strengthened biological treatment unit is provided with a residual sludge outlet; the energy recycling unit is connected with the up-to-standardwater outlet of the deep treatment unit; the energy recycling unit is provided with a resource recycling opening and an energy recycling opening respectively. The system can meet high emission standards and also can be used for recycling resources and energy sources including phosphorus, chemical energy, heat energy, cellulose and the like in sewage.

Owner:GUOZHONG AIHUA TIANJIN MUNICIPAL ENCIRONMENT ENG

Dried fruit cleaning equipment

InactiveCN112293759ARealize the recycling functionEfficient separationClimate change adaptationFood treatmentFiltrationAgricultural engineering

The invention relates to the field of dried fruit cleaning, in particular to dried fruit cleaning equipment. The equipment comprises a rack as well as a cleaning tank, a linear driving mechanism, a feeding mechanism, a draining mechanism and a conveying mechanism which are fixedly mounted on the rack, wherein the cleaning tank is horizontally arranged, and a gate capable of being opened and closedis arranged at one end of the cleaning tank; the linear driving mechanism is used for driving the gate to be opened or closed; the feeding mechanism is arranged at the end, away from the gate, of thecleaning tank and used for filling the cleaning tank with dried fruits needing to be cleaned; the draining mechanism is arranged at the end, away from the cleaning tank, of the gate; and the conveying mechanism is arranged in the cleaning tank and used for driving the dried fruits in the cleaning tank to move from the end, close to the feeding mechanism, of the cleaning tank to the end, close tothe draining mechanism, of the cleaning tank. According to the invention, the function of separating soil from the dried fruits is achieved through the conveying mechanism, the linear driving mechanism, a water circulation mechanism, a filtering mechanism and the draining mechanism; sewage and the soil can be effectively separated through multiple times of filtration of the filtering mechanism; and the purpose of saving water resources is achieved through the water circulation mechanism.

Owner:李栋

hybrid transmission

InactiveCN103057395BRealize functionRealize stepless speed changeGas pressure propulsion mountingPlural diverse prime-mover propulsion mountingElectric machineryElectric cars

The invention discloses a hybrid transmission, which comprises an internal combustion engine, a Ravina planetary system, and a differential gear assembly. The input shaft is connected with the internal combustion engine through a torque damper. Motor, the Ravenna planetary system has a second motor on the front sun gear. The present invention is improved on the basis of the existing 4AT of the Ravina-type planetary structure, so that it has a double EVT structure with a CVT-like continuously variable speed function, which can improve the shifting comfort of the electric working condition, and at the same time It can realize pure electric work under all working conditions of the whole vehicle, so it is especially suitable for plug-in hybrid vehicles. That is to say, all the functions of the electric vehicle can be realized completely by the power of the battery when the battery is not short of power. The present invention can effectively improve fuel economy, reduce fuel consumption, and improve shifting comfort at the same time. The invention is suitable for vehicles with front and front drive and transverse power assembly, and realizes hybrid drive.

Owner:GREAT WALL MOTOR CO LTD

Adjustable ore crusher for iron ore processing and crushing method

ActiveCN113600284AGuarantee sufficiencyPrevent dispersionElectrostatic separation detailsGrain treatmentsMining engineeringElectric machine

The invention discloses an adjustable ore crusher for iron ore processing and a crushing method, and particularly relates to the technical field of ore crushing. A driving motor drives a crushing cylinder to rotate, so that a conveying plate can drive iron ore to move, the iron ore can circularly enter a connecting cylinder to realize the cyclic crushing function of the iron ore, and the crushing sufficiency of the iron ore is ensured. The crushing barrel can rub with a dust removal net in the rotating process, so that dust generated in the iron ore crushing process can be adsorbed by static electricity generated on the surfaces of the dust removal net and fluff, meanwhile, the dust removal net can play a role in screening the iron ore, and the function of recycling the qualified iron ore is achieved. The dust removal net is inflated through an air pump, so that the dust removal net expands, the adhesive force of the dust on the surface of the dust removal net is reduced, the dust is easy to separate, the dust removal net is convenient to clean, and the utilization rate of the crusher is improved.

Owner:安徽省飞宇材料科技有限公司

Shot blasting cleaning equipment for water pump shell manufacturing and using method of shot blasting cleaning equipment

ActiveCN114378722AAchieving Fixture SuitabilitySolve the problem of poor clamping adaptabilityImpeller wheelsRotor bladesDrive shaftElectric machinery

Owner:SHENYANG GREAT PUMP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com