Recirculating loop for fuel cell

A fuel cell stack, recycling technology, applied in fuel cells, fuel cell additives, circuits, etc., can solve problems such as huge

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

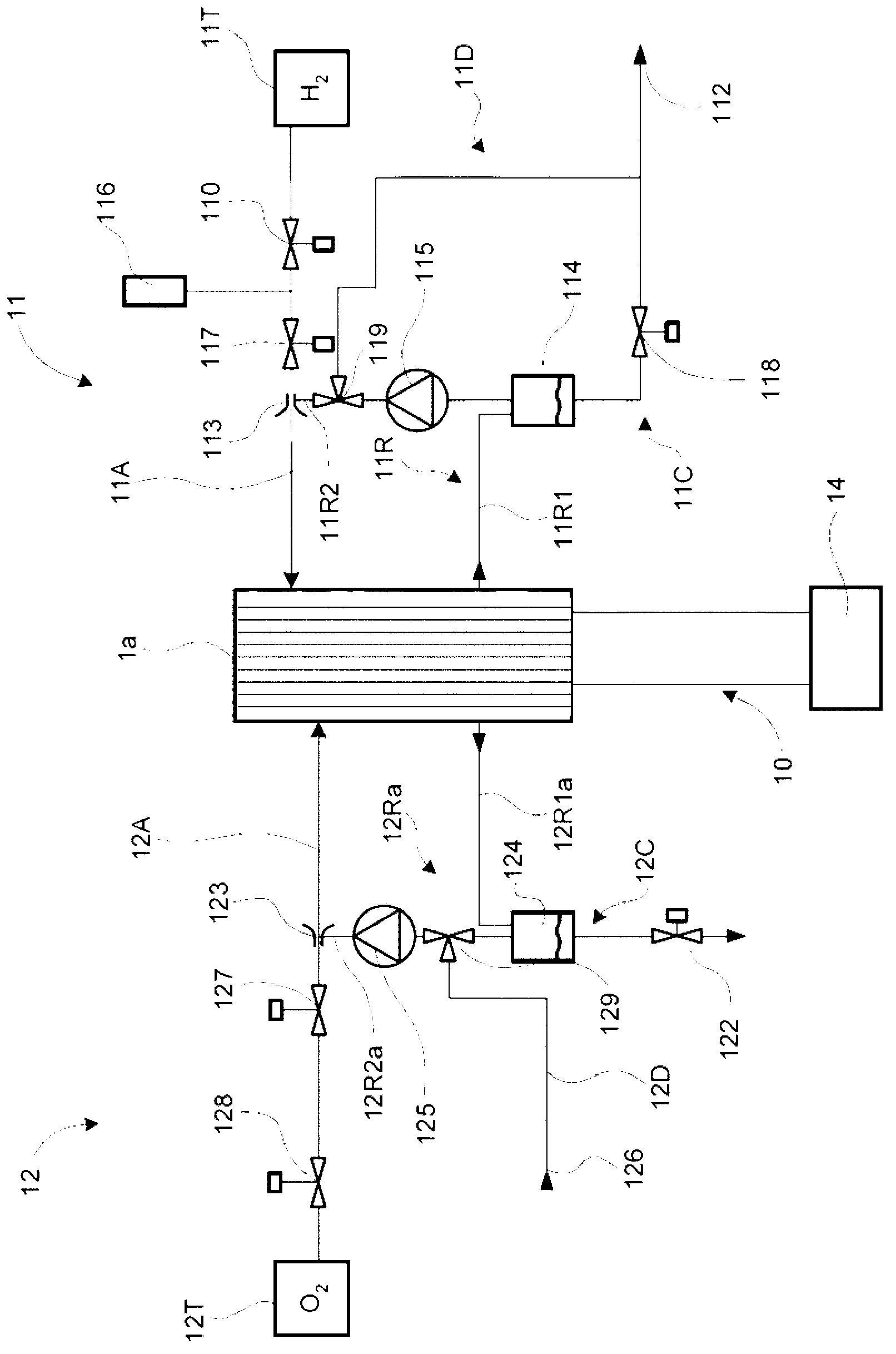

[0021] figure 1 A fuel cell stack 1 a of the type having an electrolyte in the form of a polymer membrane is shown (ie of the PEFC (polymer electrolyte fuel cell) or PEM (proton exchange membrane) type). The fuel cell stack 1 a is supplied with two gases, a fuel (hydrogen stored or generated on board the vehicle) and an oxidant (in this example, pure oxygen), whose gas is supplied to the electrodes of the electrochemical cells. The power loader 14 is connected to the fuel cell stack 1 a through the power line 10 . To simplify things, figure 1 Only gas line parts are shown for understanding the invention.

[0022] Description of the anode circuit:

[0023] show on figure 1 The arrangement in includes a fuel gas supply line 11 on the anode side. Pure hydrogen (H 2 ) tank 11T is visible, the pure hydrogen (H 2 ) tank 11T is connected to the inlet of the anode circuit of the fuel cell stack 1a by a supply line passing through the shut-off valve 110, then through the press...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com