Waste old clothes automatic sorting cyclic regeneration system

A recycling and automatic sorting technology, which is applied in the direction of sorting and solid waste removal, can solve the problems of resource waste, environmental pollution, and inability to record data, and achieve the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following are preferred embodiments of the present invention, but the protection scope of the present invention is not limited thereby.

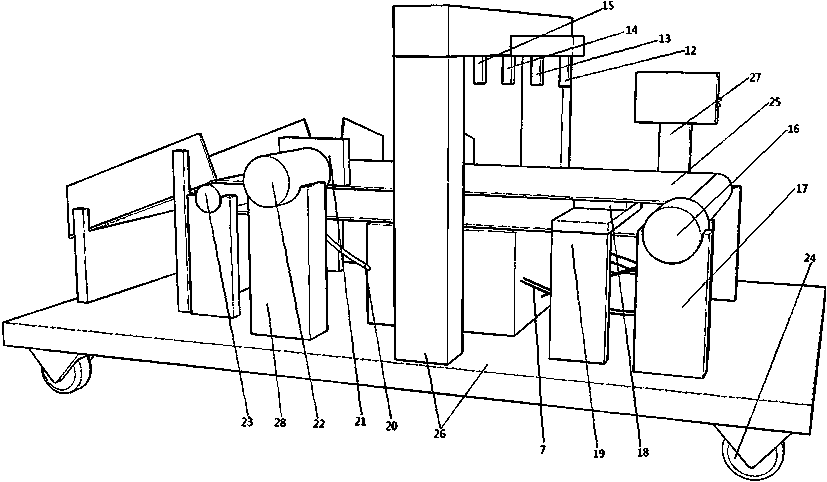

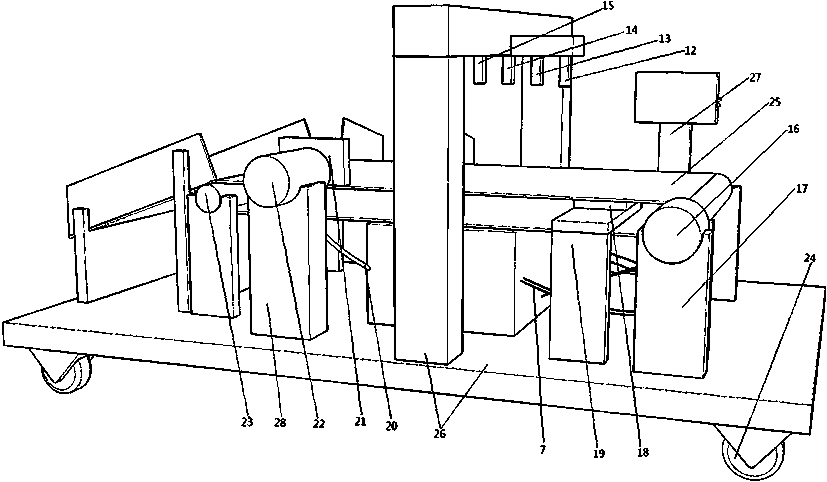

[0019] As shown in the figure, an automatic sorting and recycling system for discarded old clothes includes a controller 1, a belt main shaft 5, a belt shaft support plate 6, a sliding groove 11 for second-type clothes, a belt 25, a detection frame 26, and a hydraulic cylinder Frame 28; It is characterized in that: described detection frame 26 is made up of base plate and inverted " U " frame, and the top of detection frame 26 bottom plates is equipped with four symmetrical belt shaft support plates 6, support groove plate 9, motor frame 17, Pressure sensor support frame 19, controller support plate 27, hydraulic cylinder frame 28, four self-locking wheels 24 are installed on the bottom four corners of the bottom plate of the detection frame 26; belt shaft support plates 6 are symmetrically installed respectively The main shaft 5 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com