hybrid transmission

A hybrid transmission technology, applied in the field of hybrid transmissions and vehicle transmissions, can solve the problems that the pure electric mode cannot realize the full working conditions of the whole vehicle, and achieve the effect of increasing fuel economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

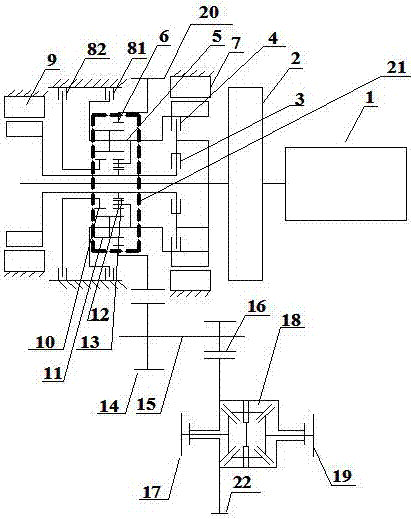

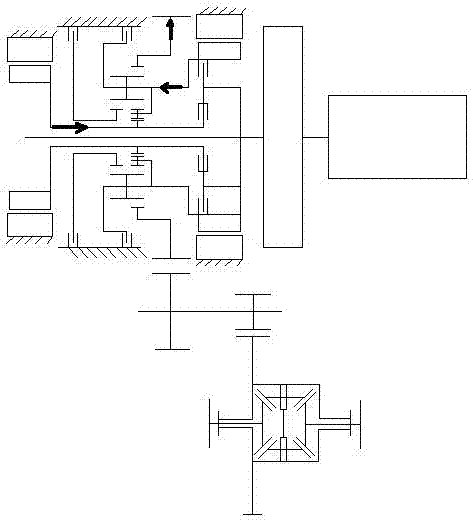

[0060] Embodiment 1 A hybrid transmission

[0061] refer to figure 1 , this embodiment includes an internal combustion engine 1, a torque damper 2, a Ravina planetary system 21, a differential assembly 18, and also includes an outer ring gear 20 with the Ravina planetary system 21, an outer differential assembly Gear 22 meshes with the countershaft gear train. The input shaft is connected with the internal combustion engine through a torque damper.

[0062] The countershaft gear train is arranged between the Ravenna planetary system 21 and the differential assembly 18 .

[0063] The planet carrier 5 of the Ravenna planetary system 21 is connected with the input shaft through the first clutch 4 .

[0064] The Ravina planetary system 21 includes a front sun gear 13 , a rear sun gear 10 , a long planet gear 11 , a short planet gear 12 , and a planet carrier 5 . The inner hub of the first clutch 4 is connected with the outer hub of the second clutch 3 , and the outer hub of th...

Embodiment 2

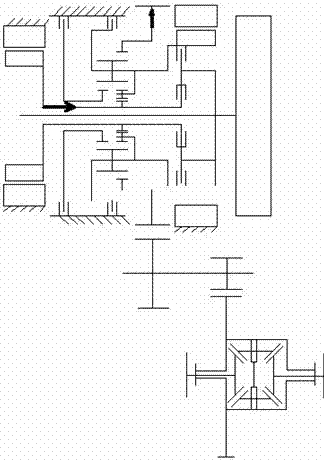

[0103] Embodiment 2 A hybrid transmission

[0104] The structure diagram of this embodiment is shown in Figure 8 , the only difference in structure from Embodiment 1 is that this embodiment does not include the second clutch 3 .

[0105] The structure of other parts of this embodiment is the same as that of Embodiment 1.

[0106] Compared with Embodiment 1, this embodiment can also realize all the functions of the pure electric working condition in Example 1 after removing the second clutch 3. Although it does not have the functions of climbing steep slopes and rapid acceleration in hybrid working conditions, it can pass Although optimizing the motor power cannot meet the driving requirements of a full-featured SUV, it can meet the driving requirements of an ordinary car.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com