Shot blasting cleaning equipment for water pump shell manufacturing and using method of shot blasting cleaning equipment

A shot blasting cleaning and casing technology, which is applied in the direction of manufacturing tools, metal processing equipment, used abrasive processing devices, etc., can solve the problems of inconvenient adjustment of the clamping angle and poor adaptability of shot blasting, etc., to achieve improved shot blasting Quality, the effect of realizing the cleaning function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

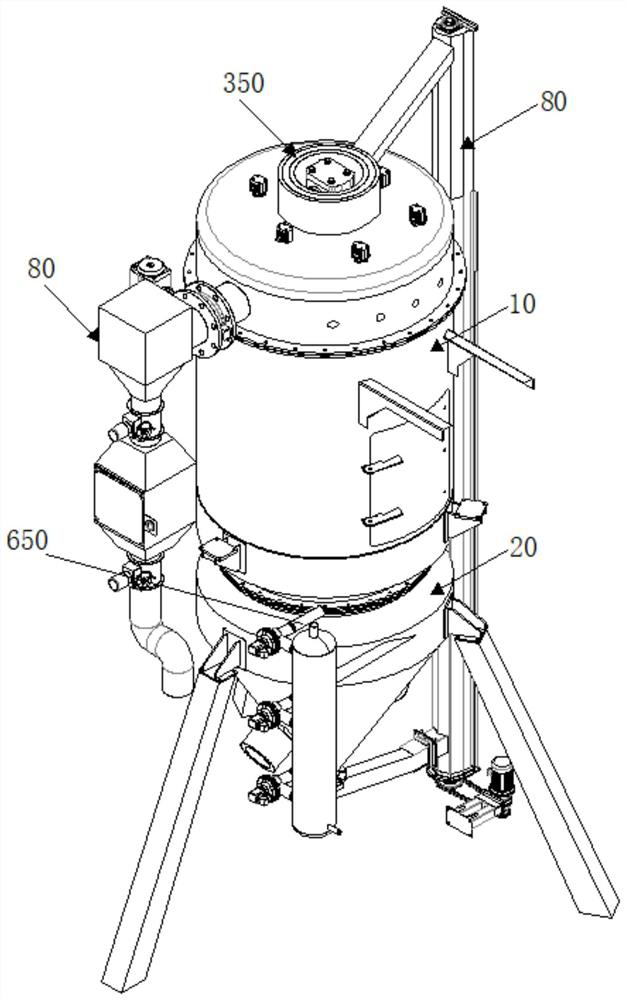

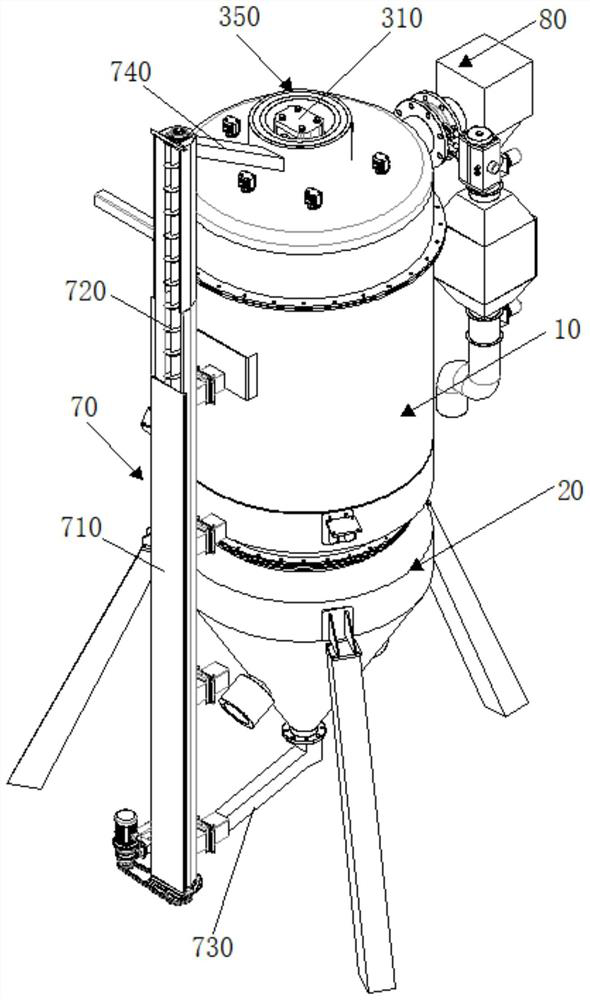

[0051] refer to Figure 1-8 , a kind of shot blasting cleaning equipment for the manufacture of water pump casings, comprising an upper tank body 10 and a lower tank body 20 which are connected to each other and provided with hatch doors, and also includes,

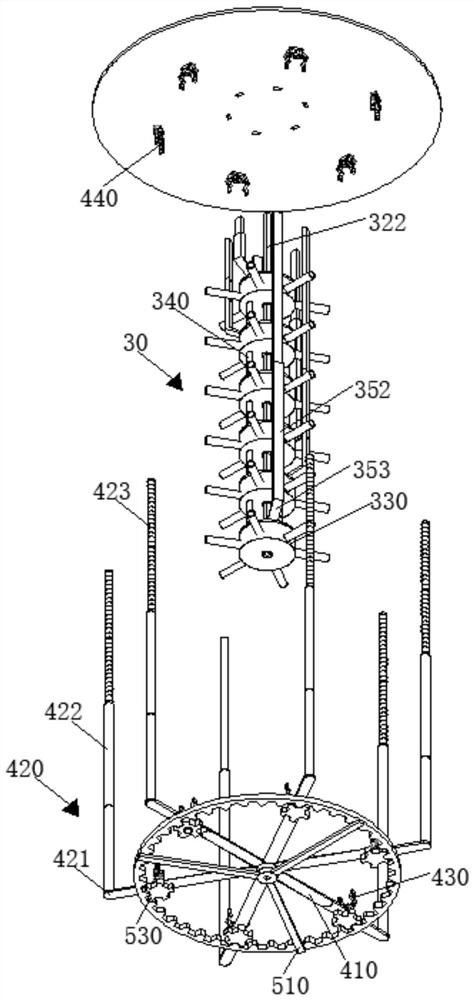

[0052] The shot blasting mechanism 30 is arranged in the cavity of the upper tank body 10. The shot blasting mechanism 30 includes a driving motor 310 installed on the top of the upper tank body 10, and the cross section that is installed at the output end of the driving motor 310 and extends to the inner cavity of the upper tank body 10 is Rectangular drive shaft 320, slidingly connected to the shot blasting part 330 that is equidistantly distributed on the outer wall of drive shaft 320, the adjusting rod 340 that is connected to the automatic telescopic reset between adjacent shot blasting parts 330, and the shot that communicates with shot blasting part 330 Material supply part 350;

[0053] The clamping mechanism 40 ...

Embodiment 2

[0067] refer to Figure 3-5 , a kind of shot blasting cleaning equipment for the manufacture of water pump shells, which is basically the same as that of Embodiment 1. Further, the rotation adjustment mechanism 50 includes a connecting frame 510 that is rotatably connected to the bottom of the mounting frame 410, and a tooth mounted on the connecting frame 510. The ring 520 and the gear 530 that is installed on the mounting bracket 410 and meshed with the gear ring 520 through the rotating shaft, the rotating shaft on the gear 530 passes through the mounting bracket 410 and is fixedly connected with the lower mounting seat 431, and the middle part of the connecting frame 510 is provided with a drive shaft 320 The matching square groove, while the driving shaft 320 drives the shot-separating wheel 333 to realize the shot blasting function, drives the gear ring 520 to rotate, and then drives the gear 530 meshing with it to rotate, and then drives the lower clamping part 430 to ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com