Flotation pulp magnetizer

A magnetizer and suspension stirring technology, applied in flotation, solid separation and other directions, can solve the problems of complex structure, waste of water resources, reduce the output of medium metamorphic coal, etc., and achieve the effect of improving the flotation effect and increasing the amount of contact.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

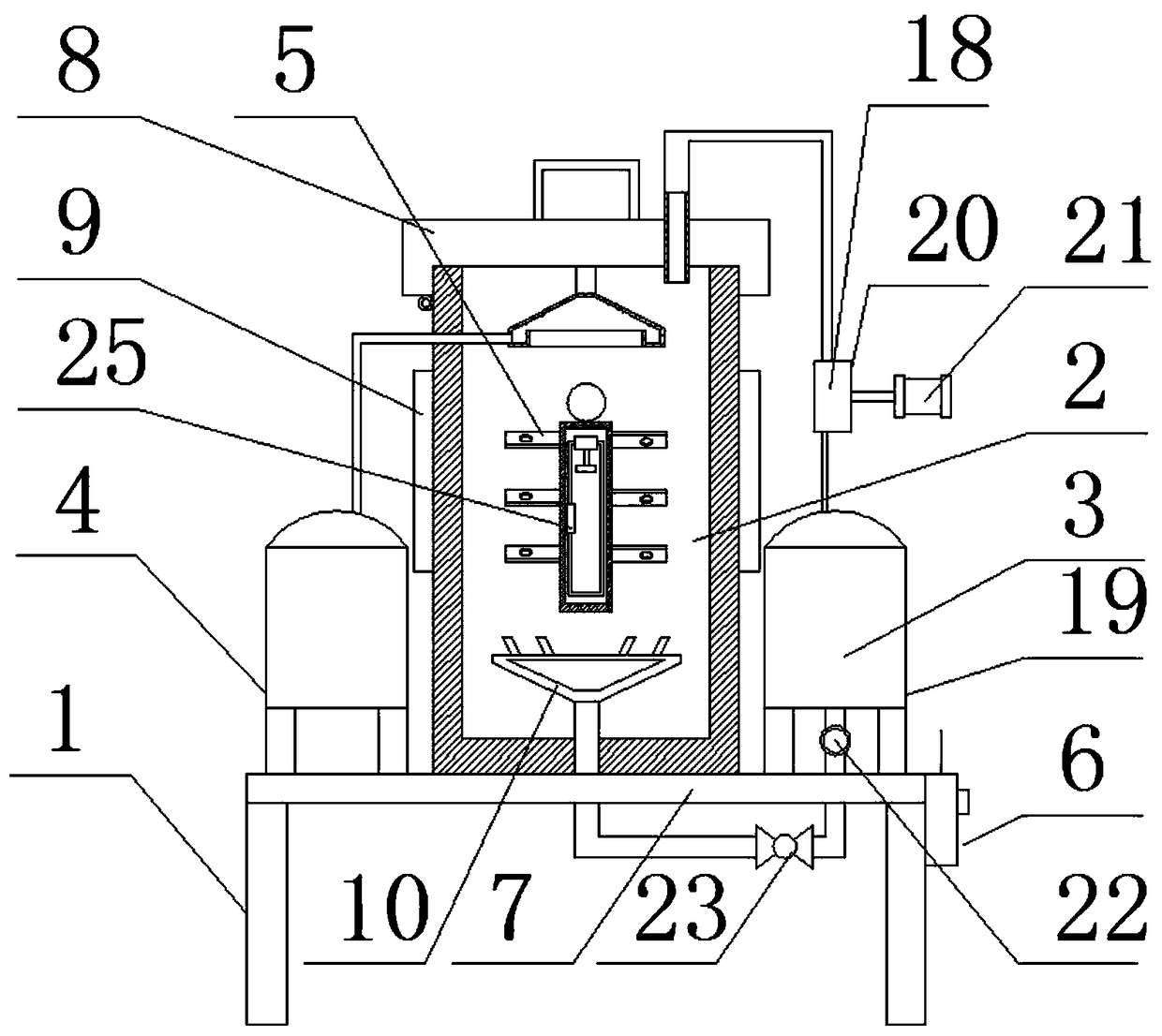

[0024] As a preferred embodiment of the present invention, the air inlet of the vacuum pump 21 is connected to one end of the air passage 17 through a pipeline, and the air outlet of the vacuum pump 21 is connected to the air storage tank 19 through a pipeline.

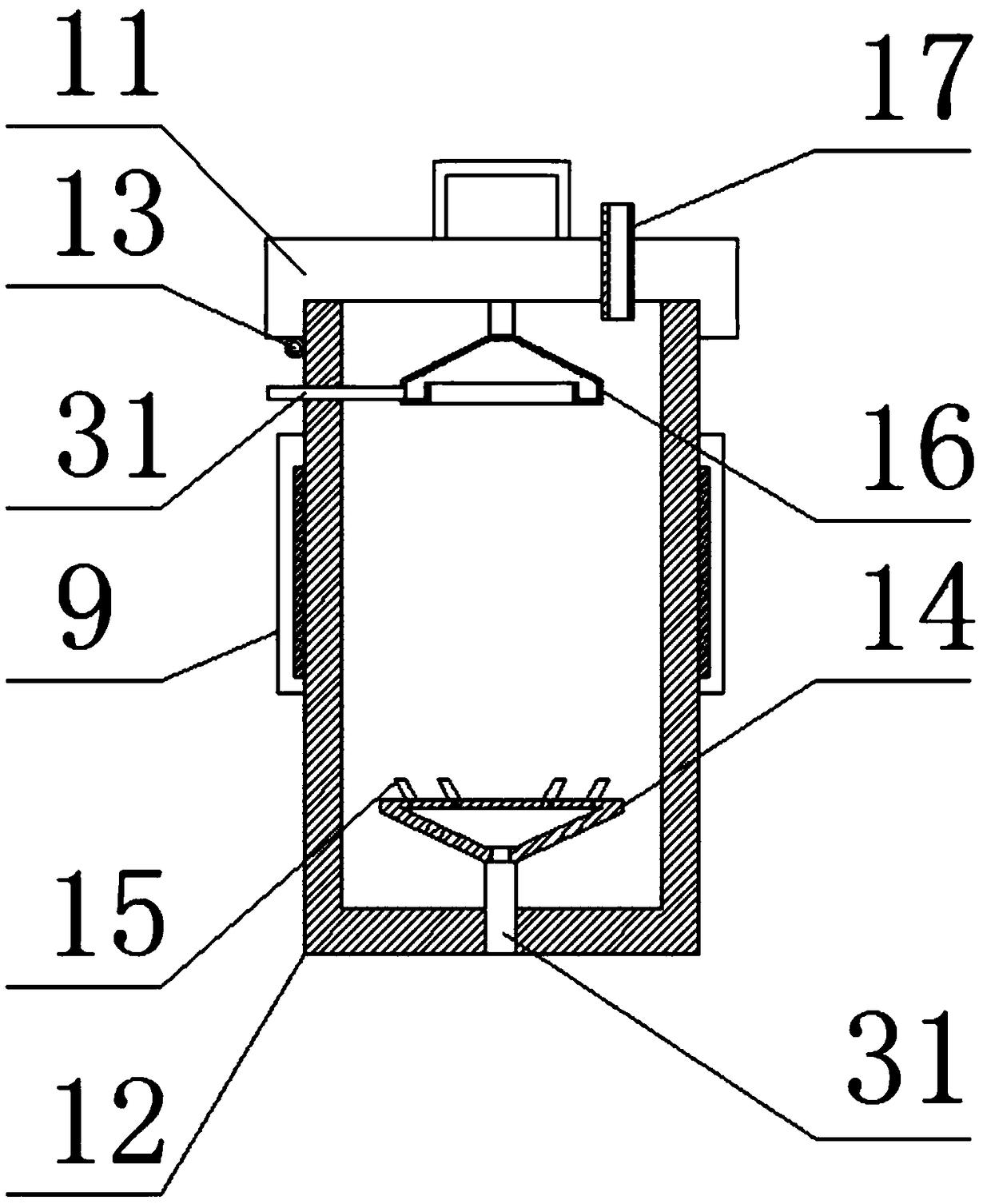

[0025] As a preferred embodiment of the present invention, the magnetizing sleeve 9 is provided with a magnetized iron core and a magnetized coil.

[0026] As a preferred embodiment of the present invention, the bottom of the distilled water storage tank 4 is provided with a foot, the top of the distilled water storage tank 4 is provided with a water inlet hole, and one side of the tank body 12 is provided with a water pipe 31. Both ends of the water pipe 31 are connected to the water inlet hole and the condensate drainage cover 16 through pipelines.

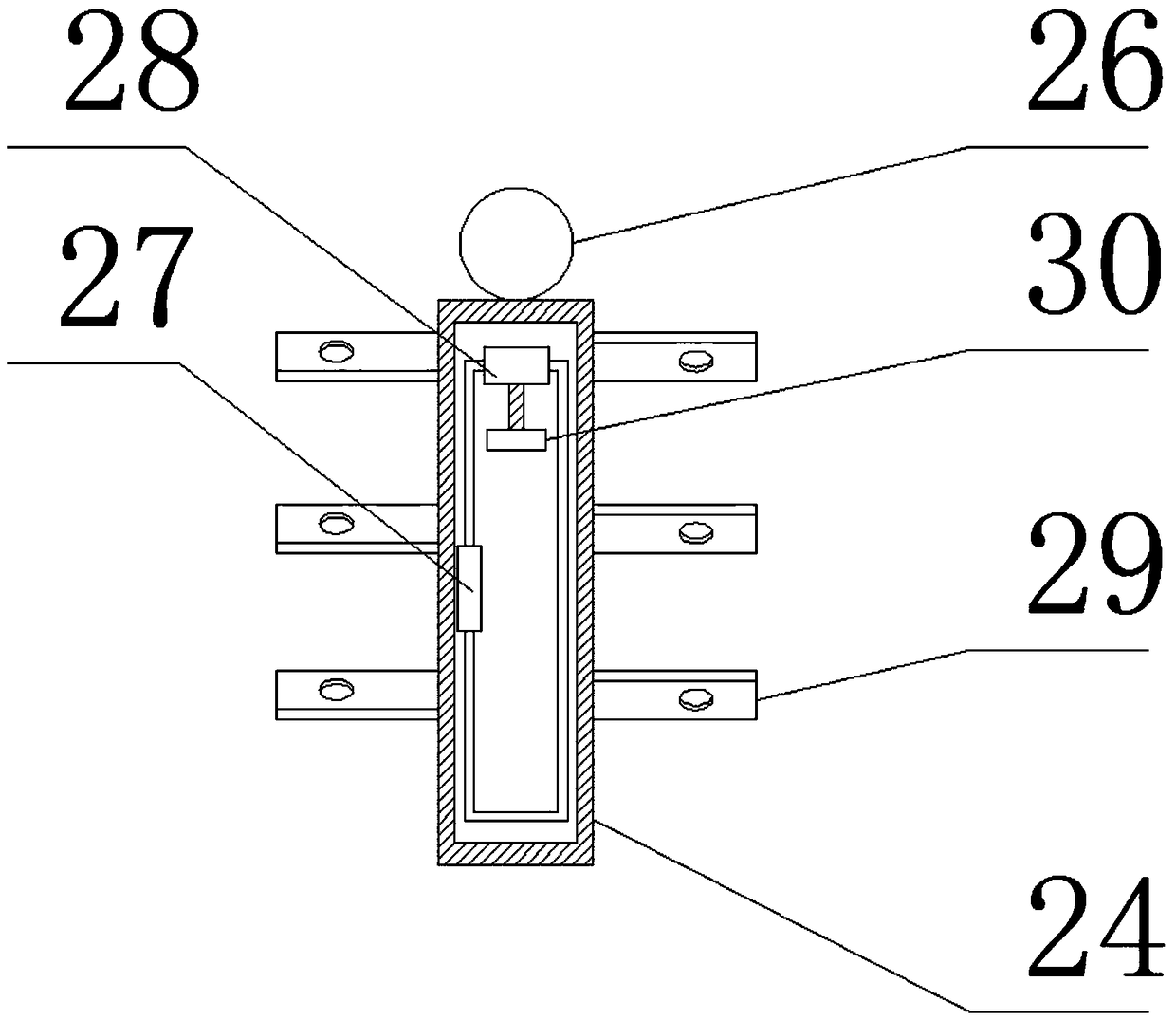

[0027] As a preferred embodiment of the present invention, buffer holes are provided on the crushing blades 29 .

[0028] As a preferred embodiment of the present inve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com