Cambered surface assembly type mounting device for special-shaped plate

An installation device and prefabricated technology, which is applied to building components, buildings, ceilings, etc., can solve the problems of inability to meet the installation requirements of laminated sheet-type spherical art shapes, high requirements for production workers' installation skills, and large labor and material resources. , to achieve the effect of reducing fixed marks, satisfying stress, saving manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with specific embodiment, content of the present invention is described in further detail:

[0022] The problem to be solved by the present invention is to provide a special-shaped arc-shaped installation device with high working efficiency and low consumption cost.

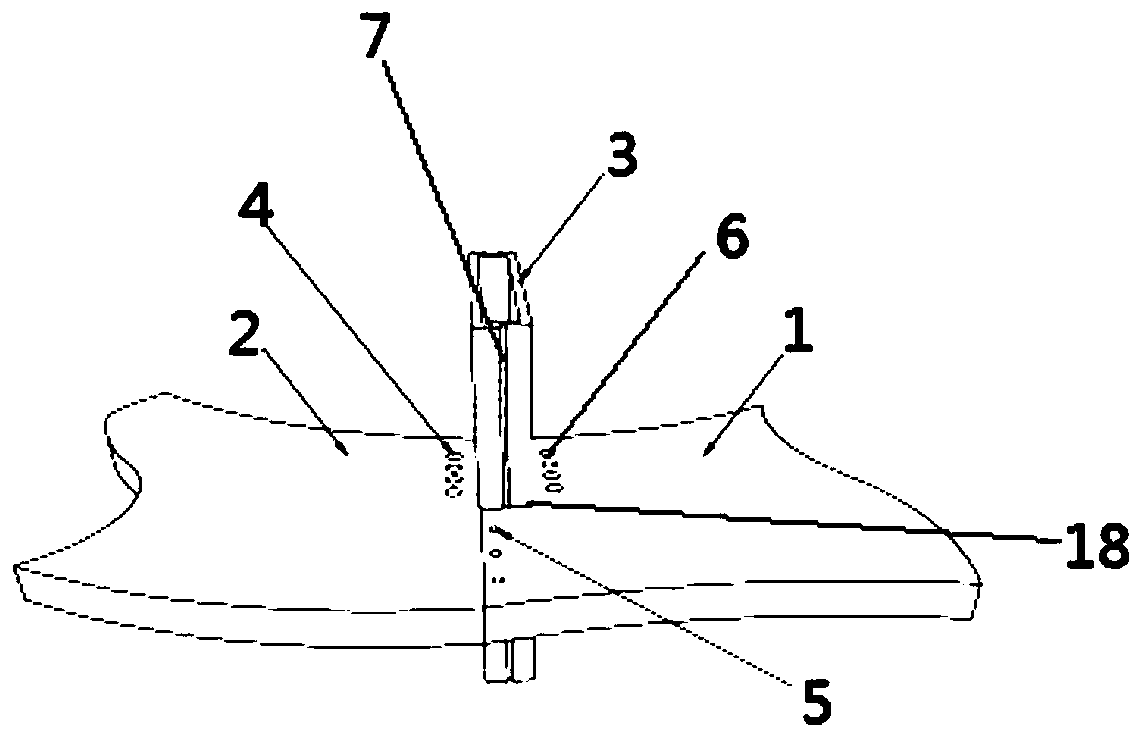

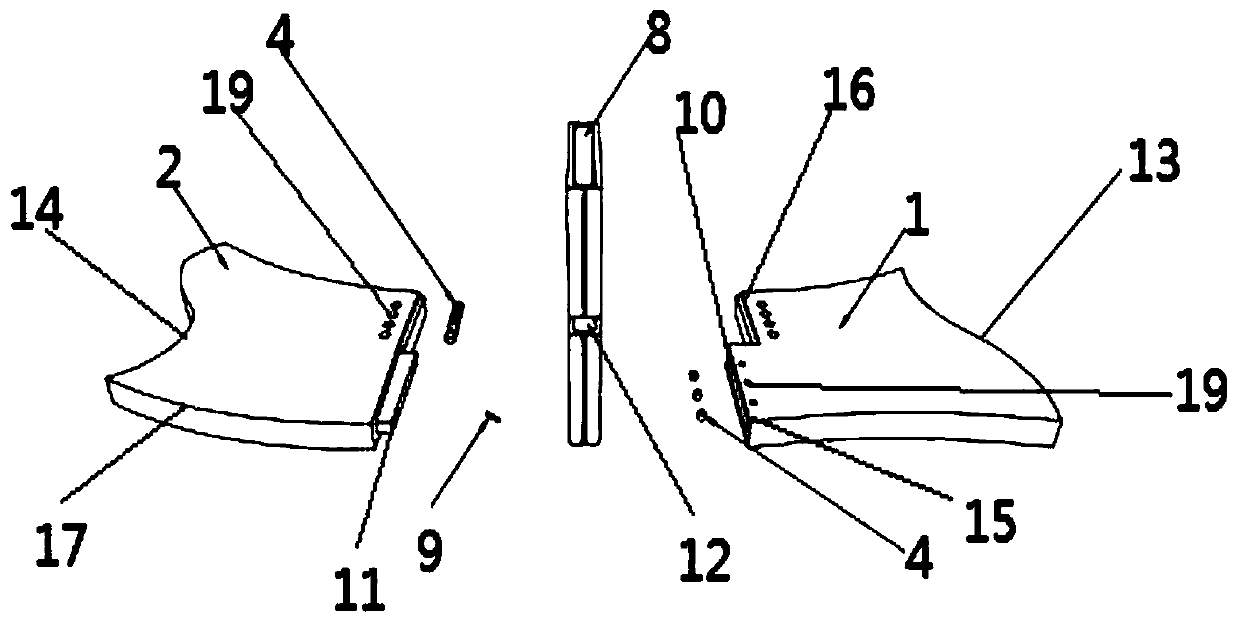

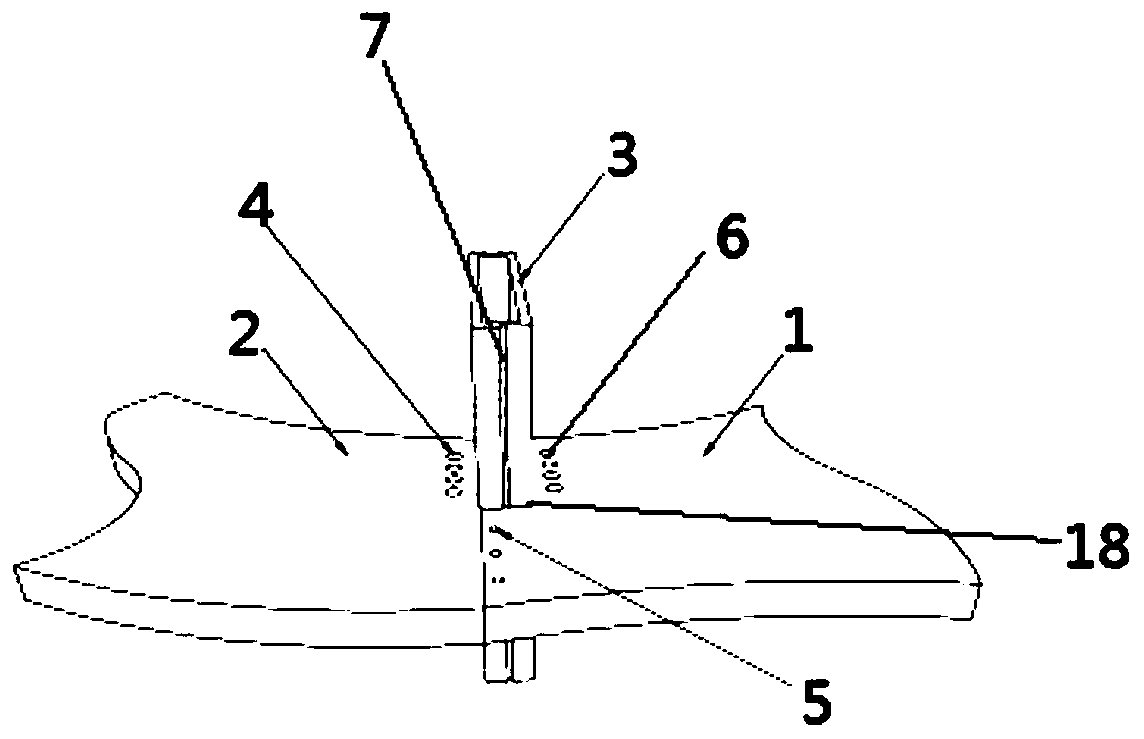

[0023] In order to ensure high work efficiency during use, the present invention relates to a special-shaped arc surface assembled installation device, including:

[0024] Horizontal special-shaped mortise joint set plate 1, horizontal special-shaped tenon joint insert plate 2, wooden tenon cover 4, and arc-shaped skeleton 3;

[0025] A connection groove 10 is provided on the transverse profiled tenon joint plate 1; a connecting block 11 is provided on the transverse tenon joint plate 2; 11 is inserted into the connection groove 10 and connected and fixed; the arc-shaped skeleton 3 is provided with a riding buckle 12 in the middle; The mortise joint set plate 1 and the transverse spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com