Patents

Literature

30results about How to "Meet the force" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

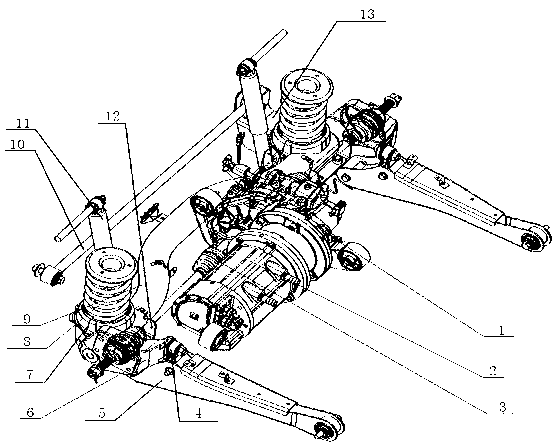

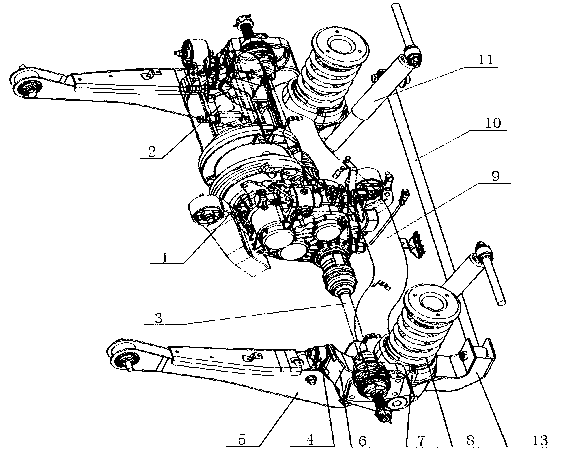

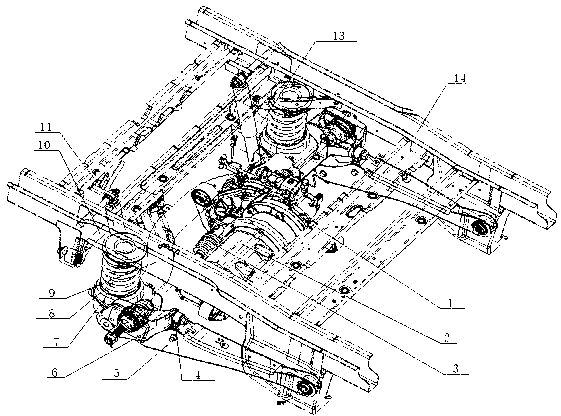

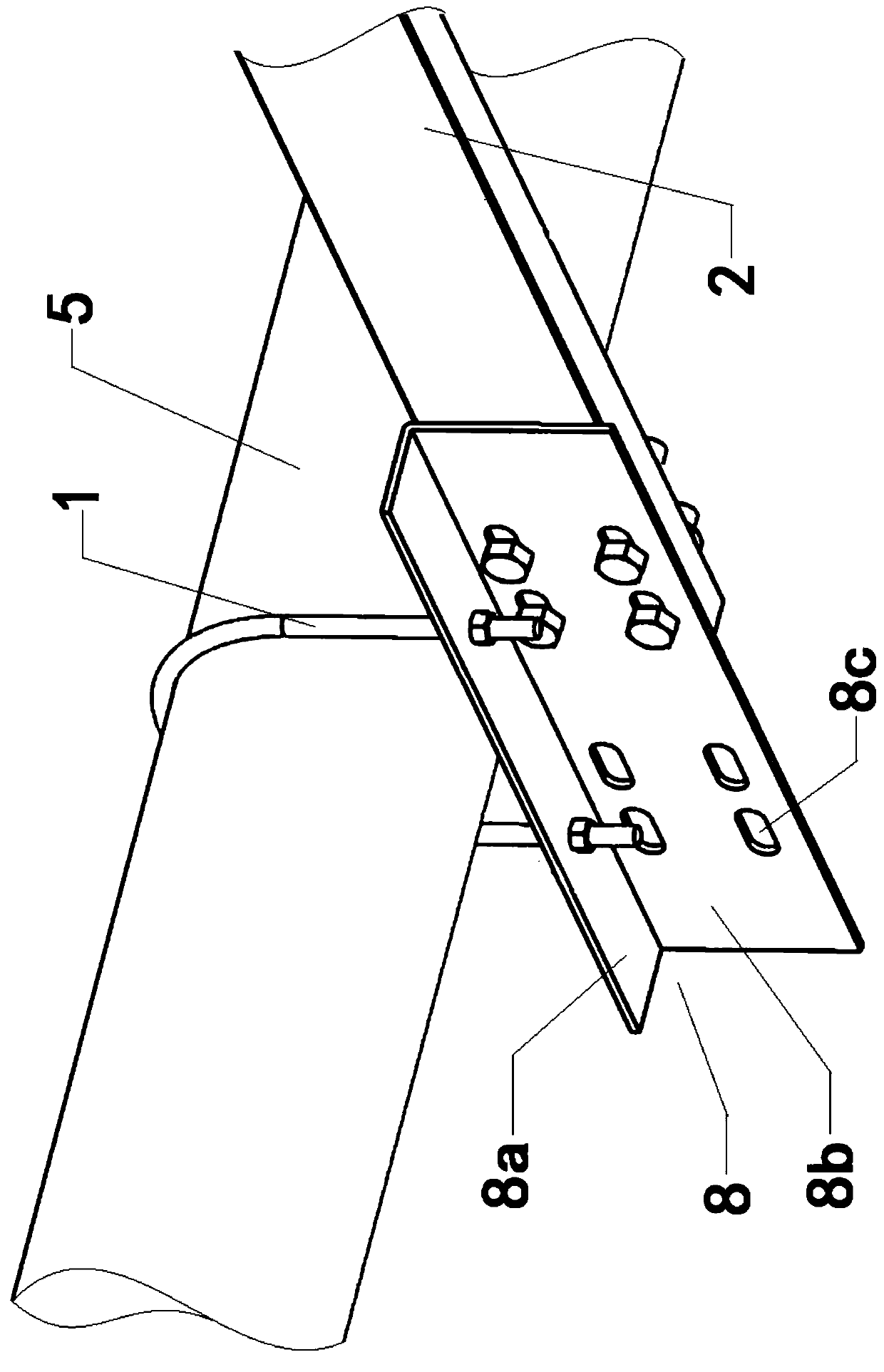

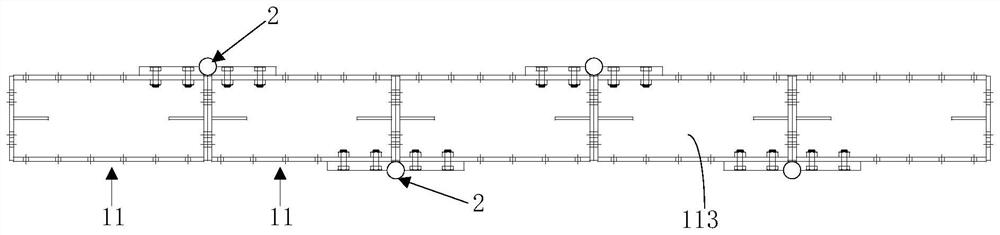

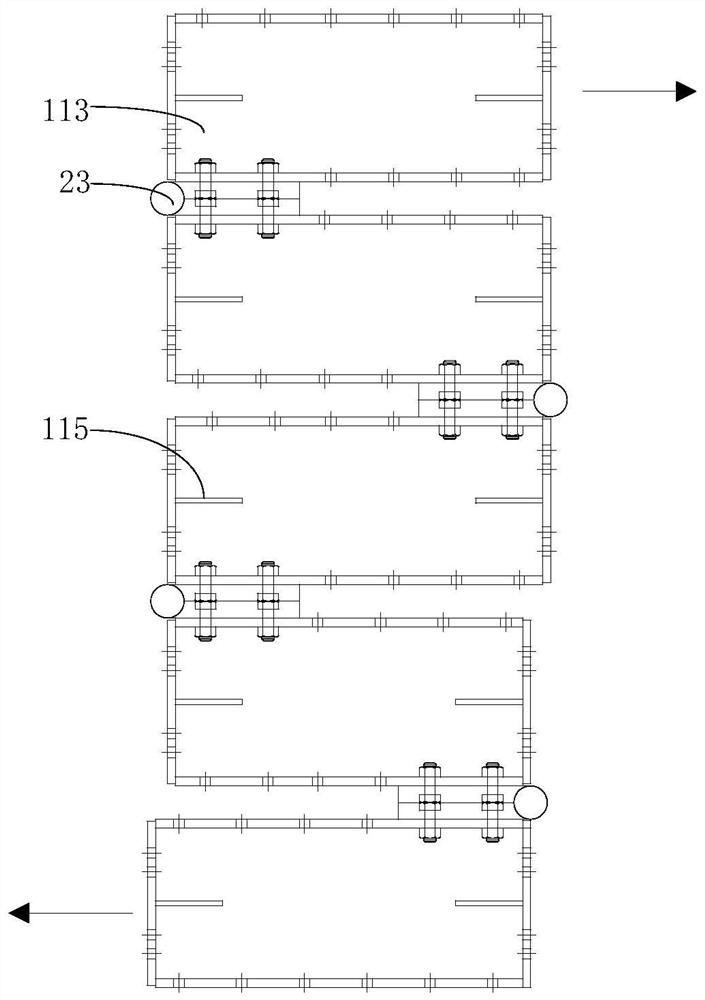

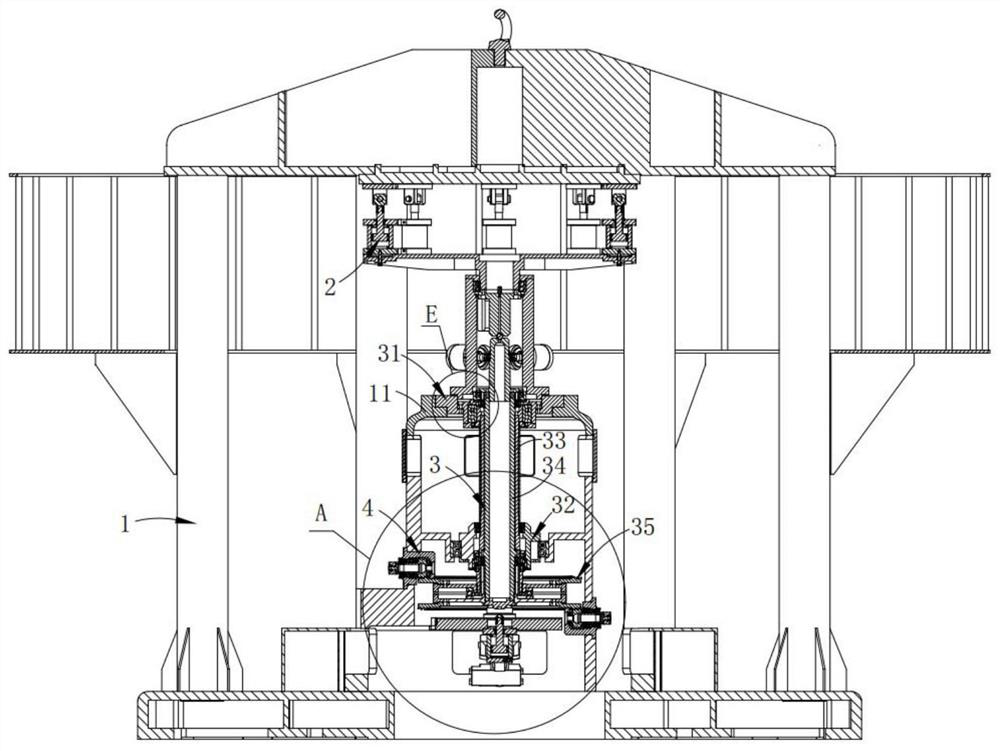

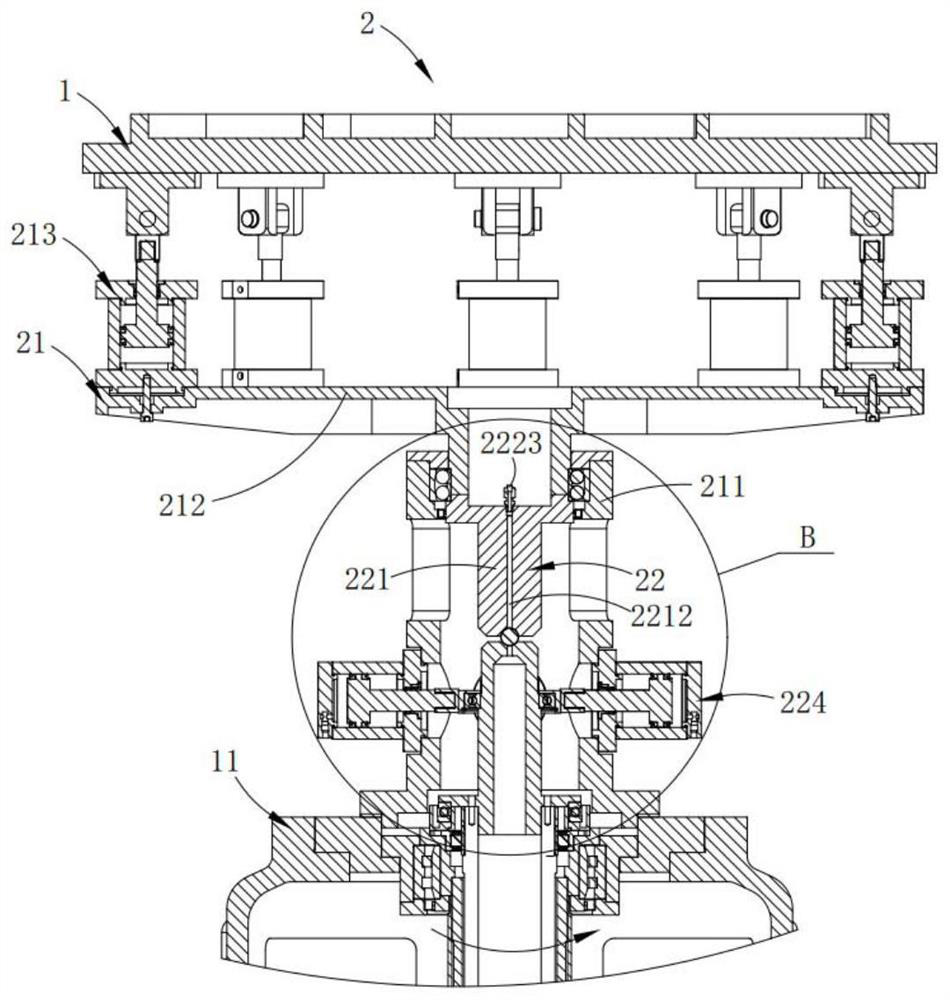

Rear-arranged rear-drive type three connection rod rear suspension frame rear axle structure for motor

ActiveCN103231626AGuaranteed space layout requirementsHigh strengthResilient suspensionsAxle unitsSingle supportDrive shaft

The invention relates to a rear-arranged rear-drive type three connection rod rear suspension frame rear axle structure for a motor. The structure comprises pivot journals, a motor, a speed changer, a driving shaft, a shock absorber, a pipe beam, a lower vertical arm and a push force rod. The pipe beam is 'n'-shaped, the middle portion of the pipe beam protrudes backwards, and a push force rod support and a single support are connected at the positions of the pipe beam close to the left end and the right end respectively in a welding mode. A semicircular groove recessed downwards is respectively arranged at one end of the push force rod support and the single support, and two ends of the pipe beam are embedded in the semicircular grooves in a welding mode. A spring seat is respectively arranged at one end of the push force support and the single support. The push force rod support is formed by welding two metal plates in a splicing mode, and the spring seats are arranged backward in a deviated mode relative to the axis position of the pipe beam. By means of arrangement and optimization of a traditional back axle and a similar bending pipe beam back axle structure, space arrangement requirements of the motor, the driving shaft and elastic elements can be met, and the requirements for stress transfer and strength can be met.

Owner:SUZHOU AUTO TECH

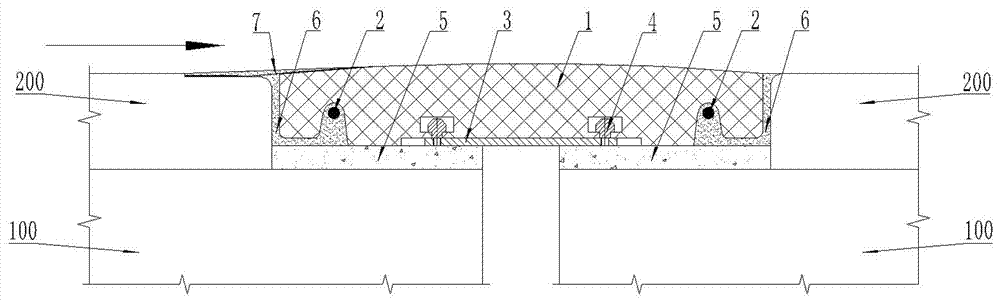

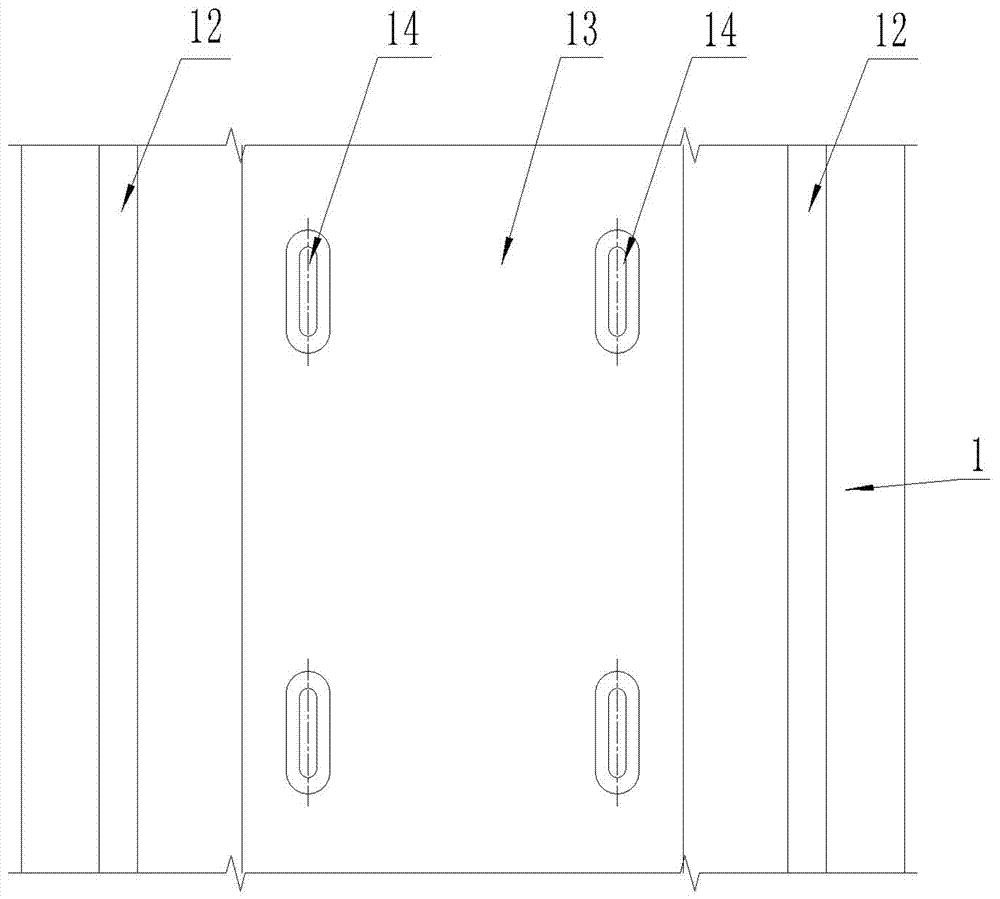

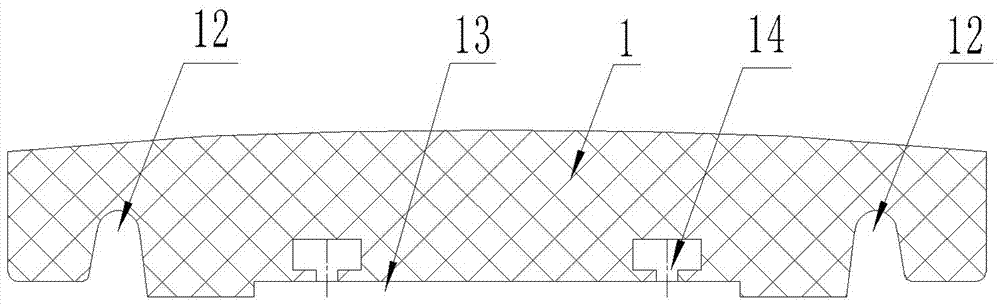

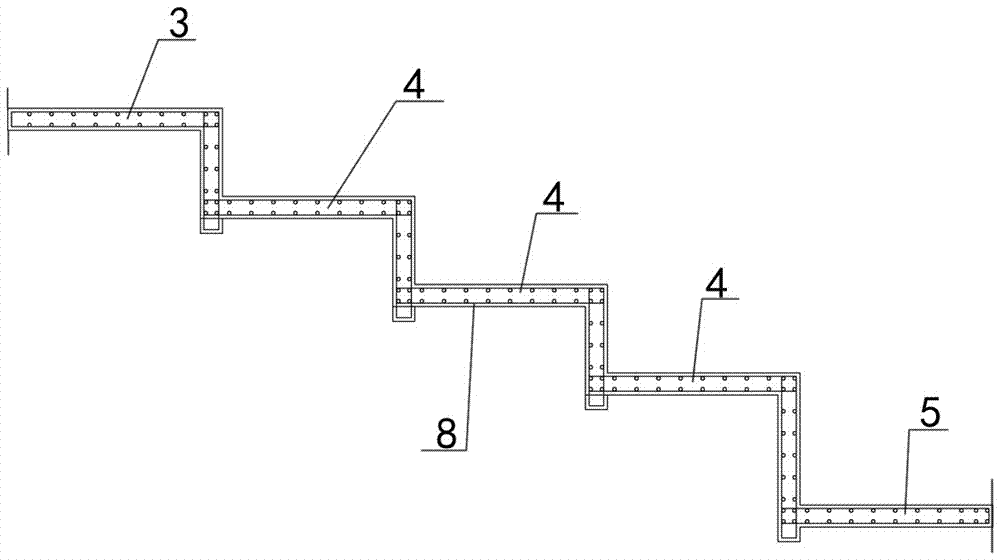

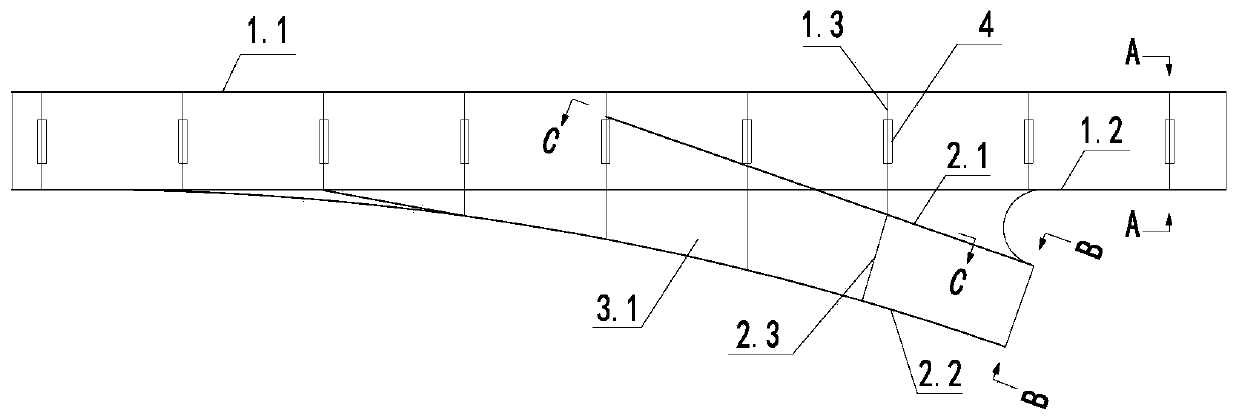

A combined type seamless expansion joint structure used for bridge pavement structures

ActiveCN106906716AEffective bondingMeet the forceClimate change adaptationPaving detailsFiberArchitectural engineering

A combined type seamless expansion joint structure used for bridge pavement structures is disclosed. The expansion joint structure includes a straddle steel plate spanning an expansion joint, and an elastic telescoping component between two pavement structures. The bottom surface of the straddle steel plate is provided with a self-leveling mortar base layer paved on two sides of the top surface of the expansion joint. The elastic telescoping component covers the straddle steel plate and the self-leveling mortar base layer. Bottom two sides of the elastic telescoping component are provided with two mounting slots longitudinally. Fiber rods are disposed in the mounting slots. Anchoring adhesion seams are between the elastic telescoping component and the pavement structures. The anchoring adhesion seam and the mounting slot which are at same side are communicated through a connecting slot in the bottom surface of the elastic telescoping component. The anchoring adhesion seams, the mounting slots and the connecting slots are filled with flexible structural glue. The expansion joint structure has low-temperature toughness, a characteristic of high-speed deformation resilience under heavy loads and a simple structure, and is convenient to construct.

Owner:东莞瑞固工程材料科技有限公司

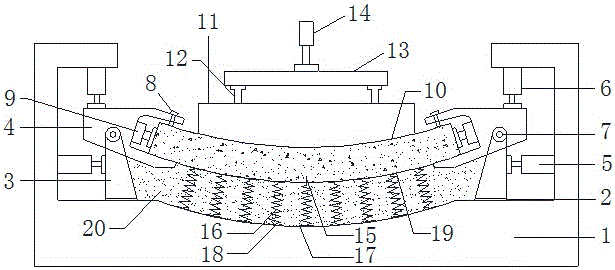

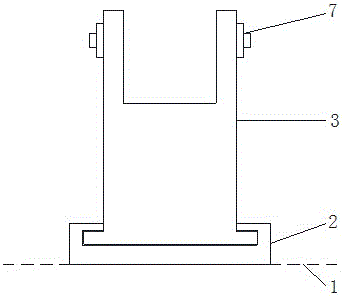

Railway tunnel bottom structure dynamic force model testing device and method

ActiveCN106053234ASimple structureEasy to operateAnalysing solids using sonic/ultrasonic/infrasonic wavesPreparing sample for investigationRailway tunnelEngineering

The invention discloses a railway tunnel bottom structure dynamic force model testing device and method. The device comprises a base, a base surrounding rock simulation structure, a tunnel bottom simulation structure, a static force loading device and a dynamic force loading device. The device can simulate static-dynamic load coupling effect of an invert arch structure, can simulate base surrounding rock condition and structure existing damage and can truly simulate actual service environment and stress characteristic of the invert arch structure. The railway tunnel bottom structure dynamic force model testing device and method has the advantages that the device is simple in structure and simple and convenient to operate.

Owner:KUNMING UNIV OF SCI & TECH

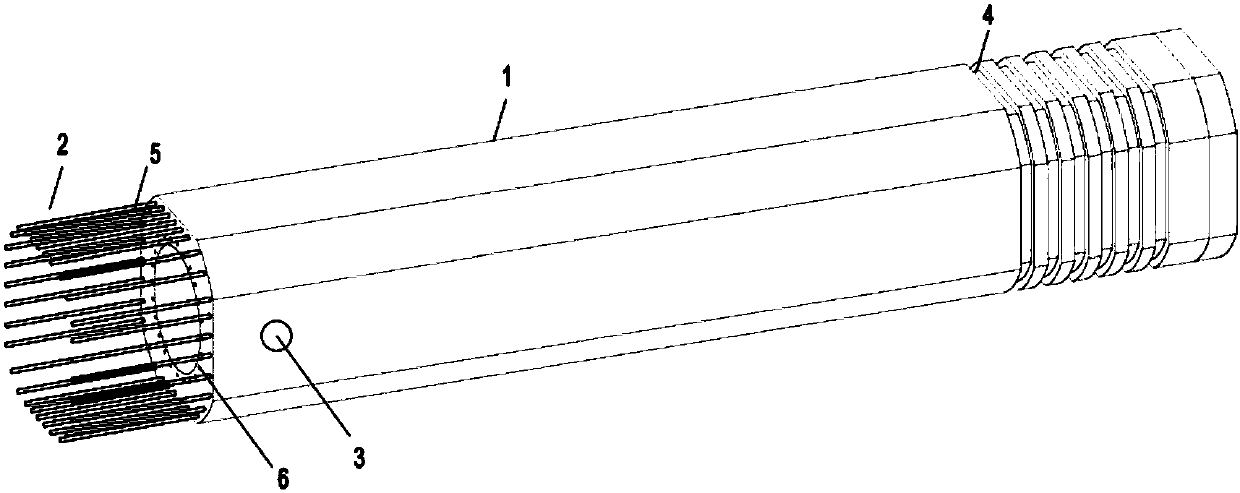

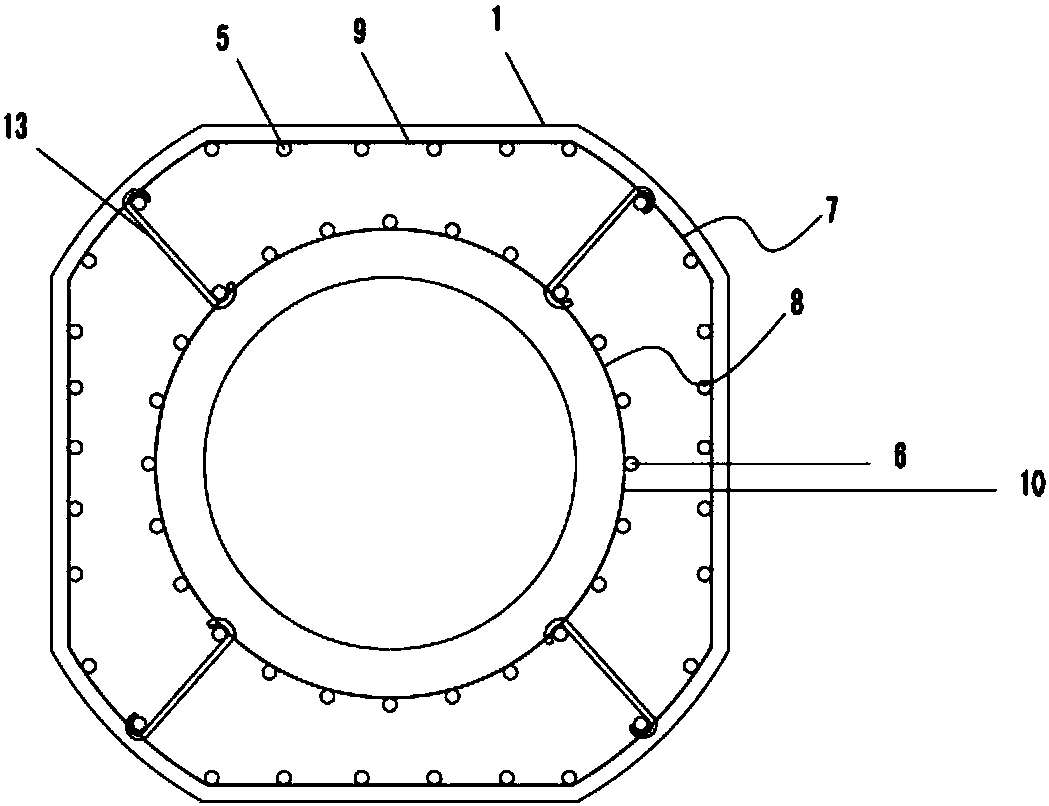

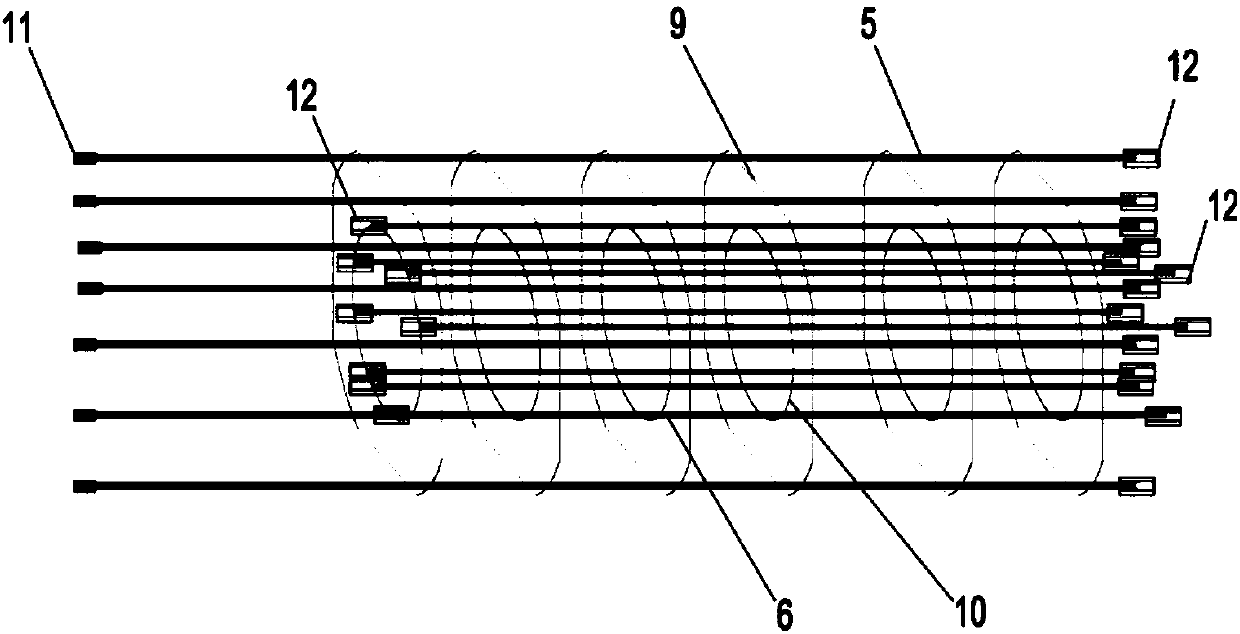

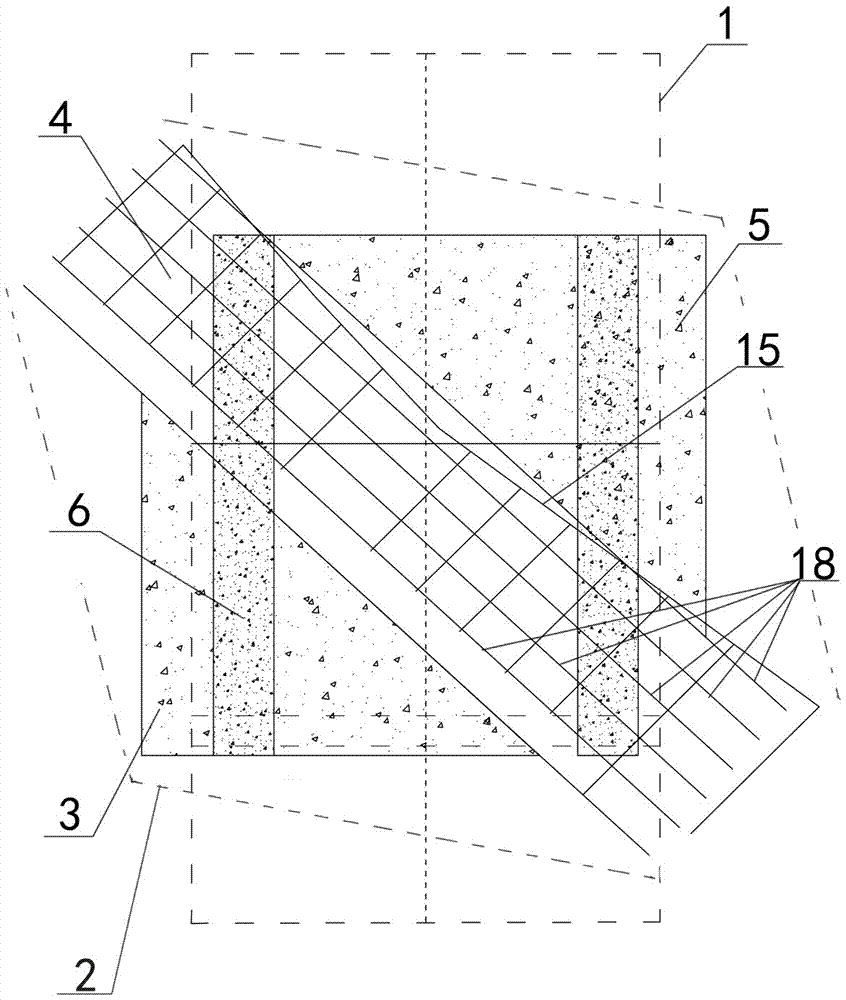

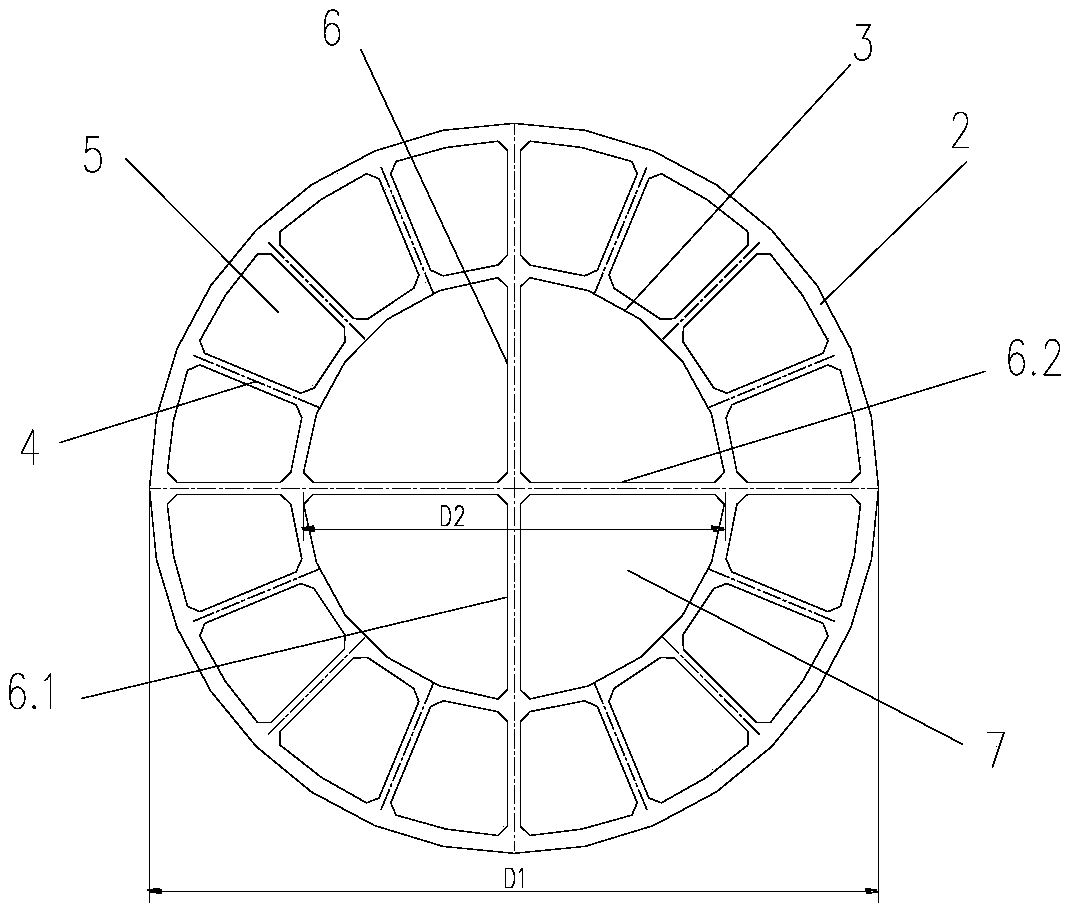

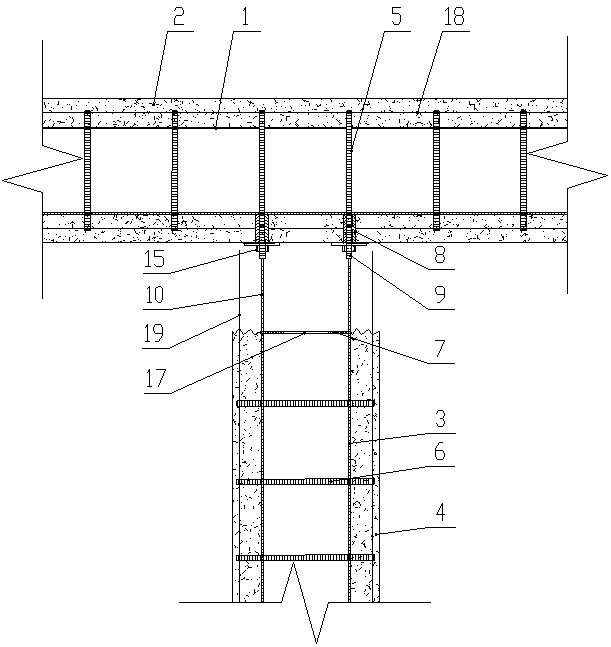

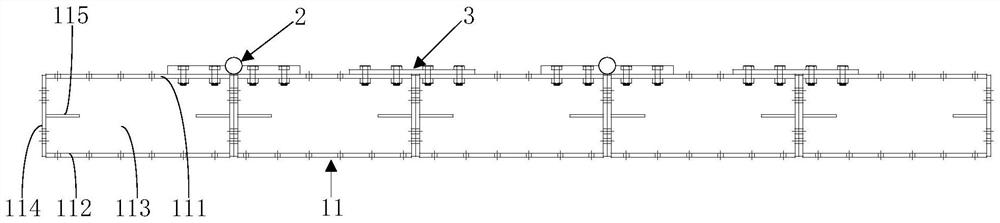

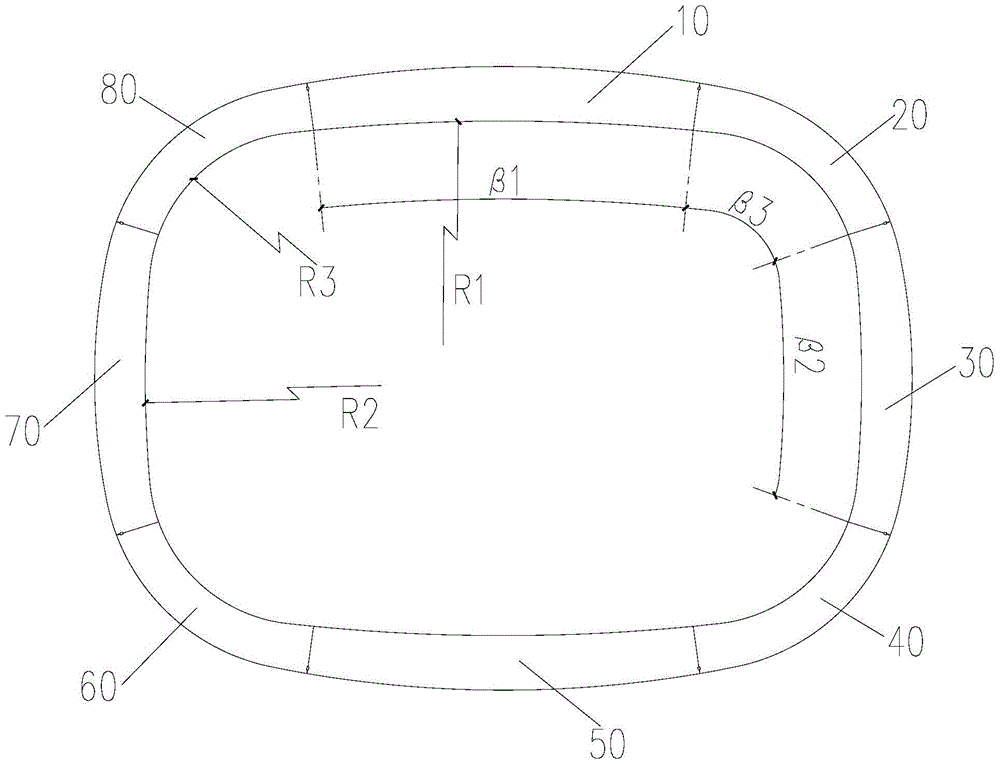

Prefabricated high-strength concrete pier as well as forming mold and manufacturing method of prefabricated high-strength concrete pier

PendingCN107932700AShorten the construction periodReduce on-site manpower and construction costsMouldsMould auxillary partsRebarHigh strength concrete

The invention discloses a prefabricated high-strength concrete pier as well as a forming mold and a manufacturing method of the prefabricated high-strength concrete pier. The pier comprises a pier body, steel framework cages and a hoisting hole; the outer contour shape of the cross section of the pier body is formed by combination of more than four straight sections and more than four circular arcsections; all circular arc sections are positioned at the same circumference; the outer surface of the bottom end of the pier body is provided with a concave-convex groove section; the hoisting holeis annularly arranged along the circumference of the pier body and penetrates through the pier body; two or more than two steel framework cage layers are arranged inside the pier body; the outermost steel framework cage layer is heteromorphic; a main reinforcement of the outermost steel framework cage layer is arranged at the inner side of a hooping reinforcement; the head end of the main reinforcement is provided with screw threads; the tail end of the main reinforcement is provided with a sleeve with an internal thread; the rest steel framework cage layers are circular, each main reinforcement thereof is arranged at the outer side of the corresponding hooping reinforcement, and the head end and the tail end of each main reinforcement are each provided with one sleeve with the internal thread; and the two adjacent steel framework cage layers are connected by a connecting part. The prefabricated concrete pier disclosed by the invention has the advantages of excellent mechanical properties, high concrete strength grade, simple and convenient production process, and so on.

Owner:JIANHUA CONSTR MATERIALS (CHINA) CO LTD

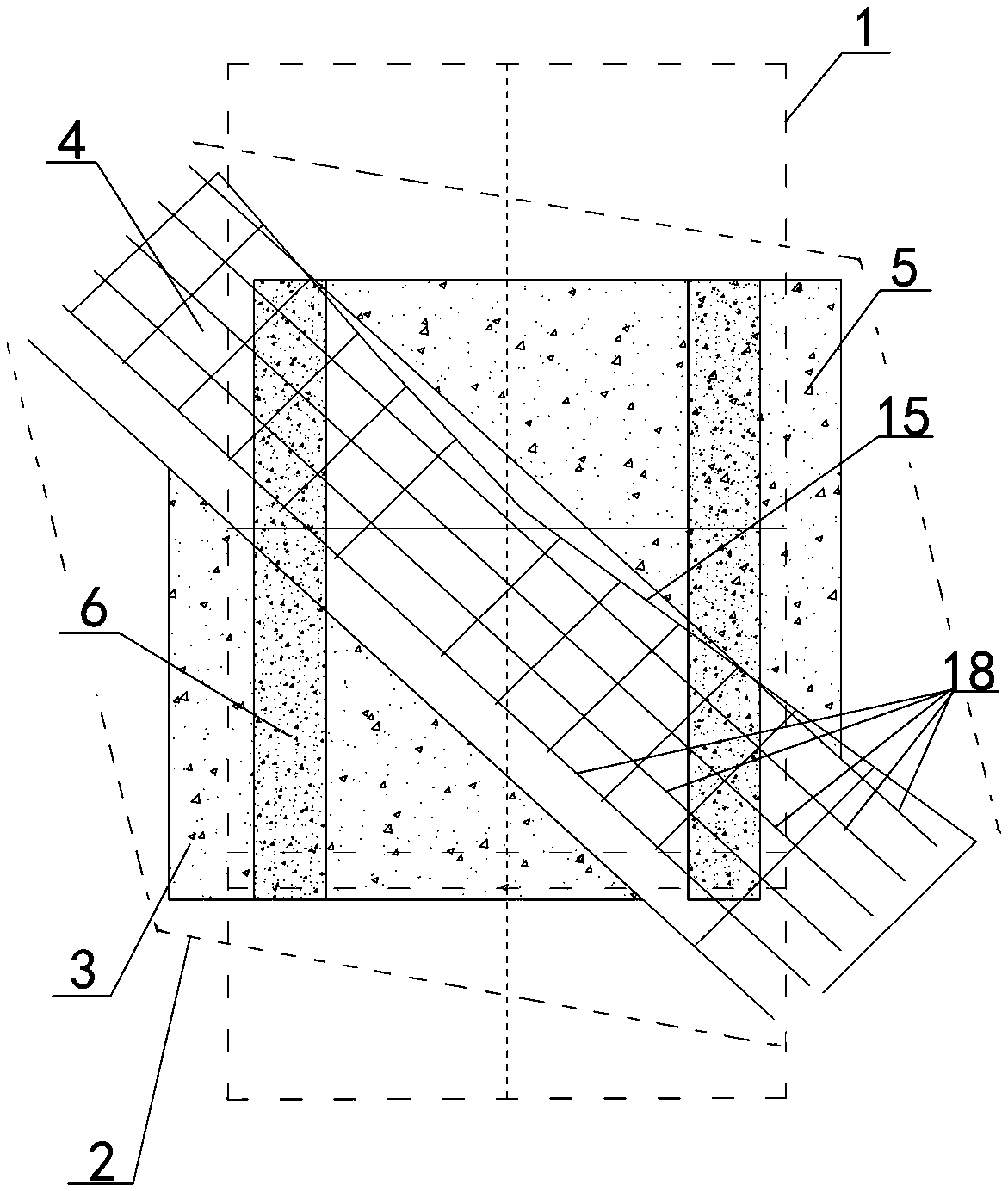

Core tube inverse superimposed underground diaphragm wall and construction method thereof

ActiveCN105275013ASolve the lack of carrying capacityImprove integrityArtificial islandsUnderwater structuresSlurry wallCarrying capacity

The invention discloses a core tube inverse superimposed underground diaphragm wall. The core tube inverse superimposed underground diaphragm wall comprises a core tube underground diaphragm wall body below a raft top elevation and a core tube underground diaphragm wall body above the raft top elevation. The underground diaphragm wall body below the raft top elevation comprises first advance width sections and first follow-up width sections. The underground diaphragm wall body above the raft top elevation comprises second advance width sections, second follow-up width sections, connecting beams, post-pouring gap sections arranged at the connecting positions of the second advance width sections and the second follow-up width sections and the connecting positions of the width sections and the connecting beams, and outer lining walls arranged at the outer sides of the width sections and the post-pouring gap sections. Wall body lacing wires and stirrups are pre-embedded in the two side edges of steel reinforcement cages of the second advance width sections and the second follow-up width sections respectively. Box irons are pre-embedded in the end portions of the two sides of the second advance width sections and the second follow-up width sections, and the box irons stretch into the underground diaphragm wall body below the raft top elevation. The invention further discloses a construction method for the core tube inverse superimposed underground diaphragm wall. According to the core tube inverse superimposed underground diaphragm wall, the outer lining walls are arranged additionally on the two sides of the underground diaphragm wall body above the raft top elevation, and the problem that an existing underground diaphragm wall is insufficient in carrying capacity is solved; in addition, two different underground diaphragm wall connecting modes are adopted, so that not only are requirements for stressing and constructing met, but also the shear performance of the underground diaphragm wall is guaranteed.

Owner:CHINA ARCHITECTURE DESIGN & RES GRP CO LTD

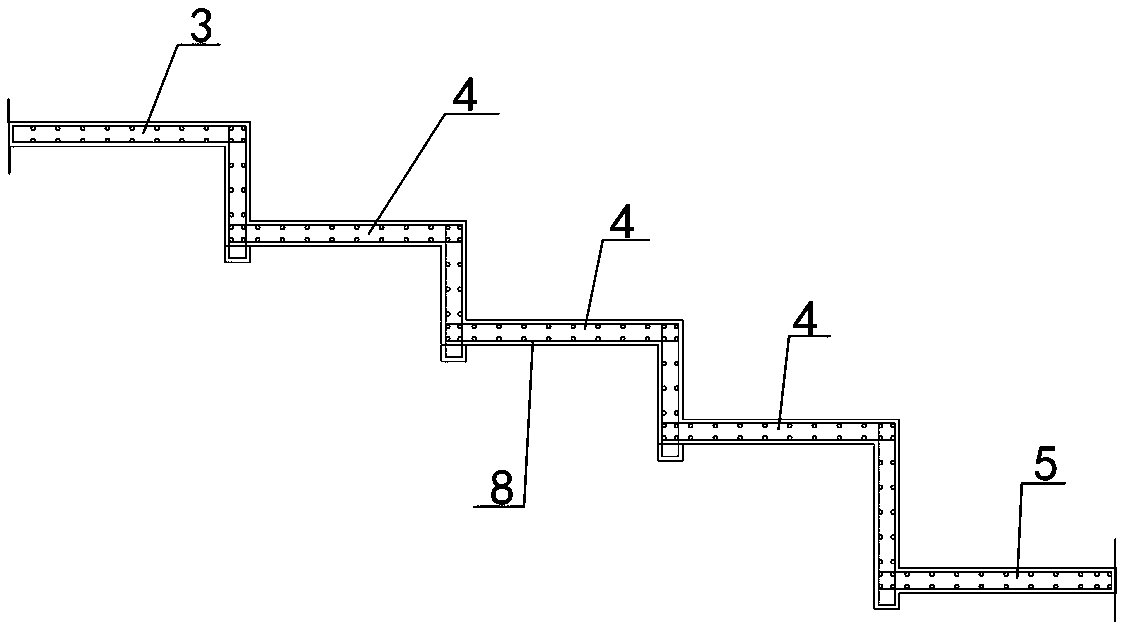

Combined construction method of cable-stayed bridge main beam and counterweight structure system of construction method

ActiveCN106917358AHeavy loadEasy to useCable-stayed bridgeBridge erection/assemblyFalseworkCable stayed

The invention provides a combined construction method of a cable-stayed bridge main beam and a counterweight foundation structure system of the construction method. The construction method comprises the following steps: designing a scaffold foundation, designing an excavation slope and step height of a dam at an edge slope region, designing the counterweight structure system of an nth block to a (n+m)th block of a mid-span, excavating the dam, wholly pouring the scaffold foundation and a counterweight foundation, carrying out symmetrical construction on a side-span and the mid-span of a main beam block by block by adopting a construction method for pouring by adopting a symmetrical hanging basket cantilever at two sides, and constructing an nth block to a (n+m)th block of the side-span and the like. The counterweight system provided by the invention comprises the scaffold foundation and the counterweight structure system. A combined construction technology of a main beam front-support-point hanging basket cantilever pouring method and a bracket cast-in-place method is adopted and two technologies are combined together, so that a side-span main beam which cannot meet hanging basket cantilever pouring is constructed; meanwhile, a mid-span main beam and the side-span main beam are symmetrically constructed and a stress state of a cable-stayed bridge is wholly met; a working period is shortened and the construction cost is reduced.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP

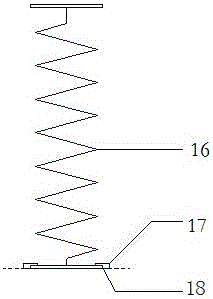

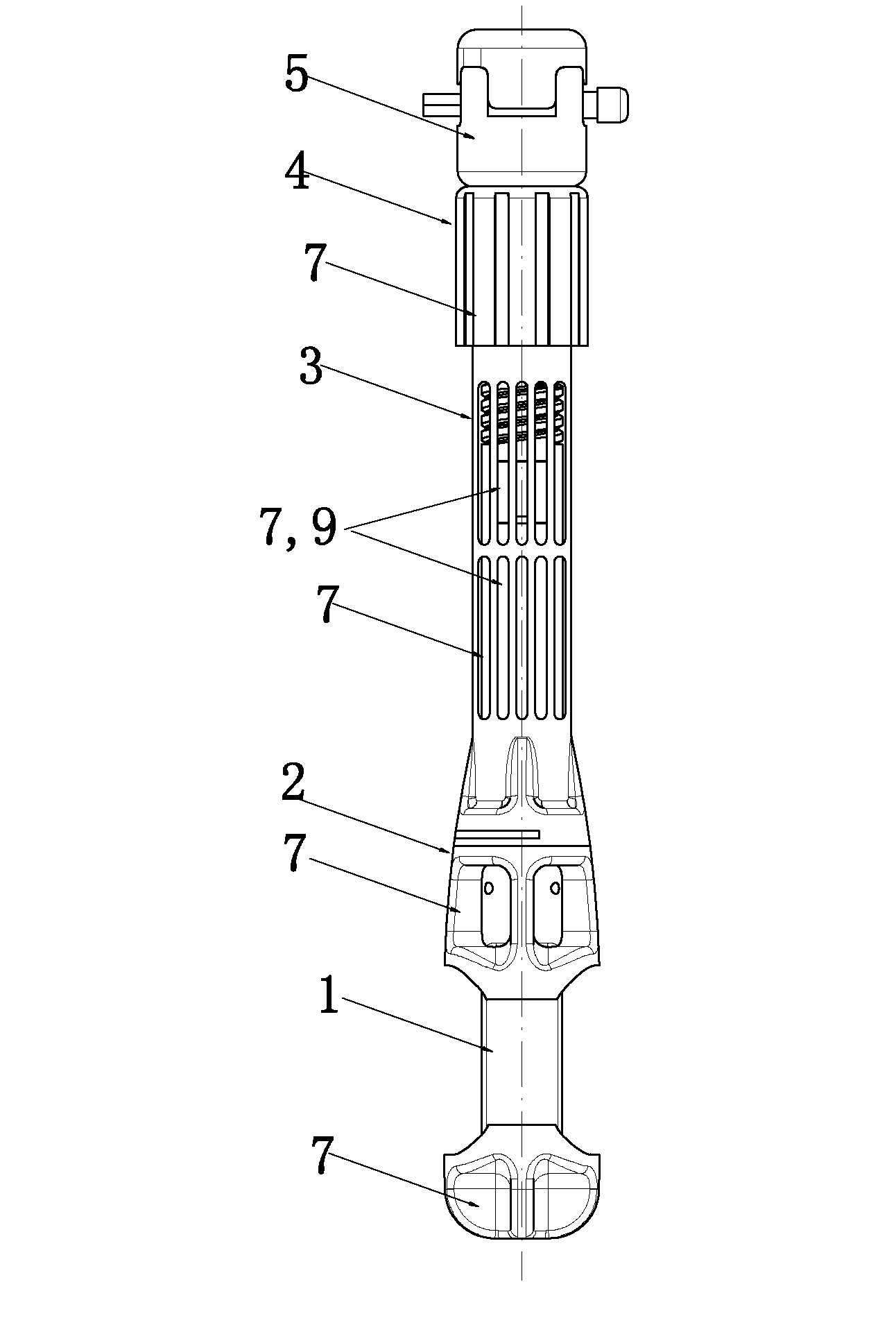

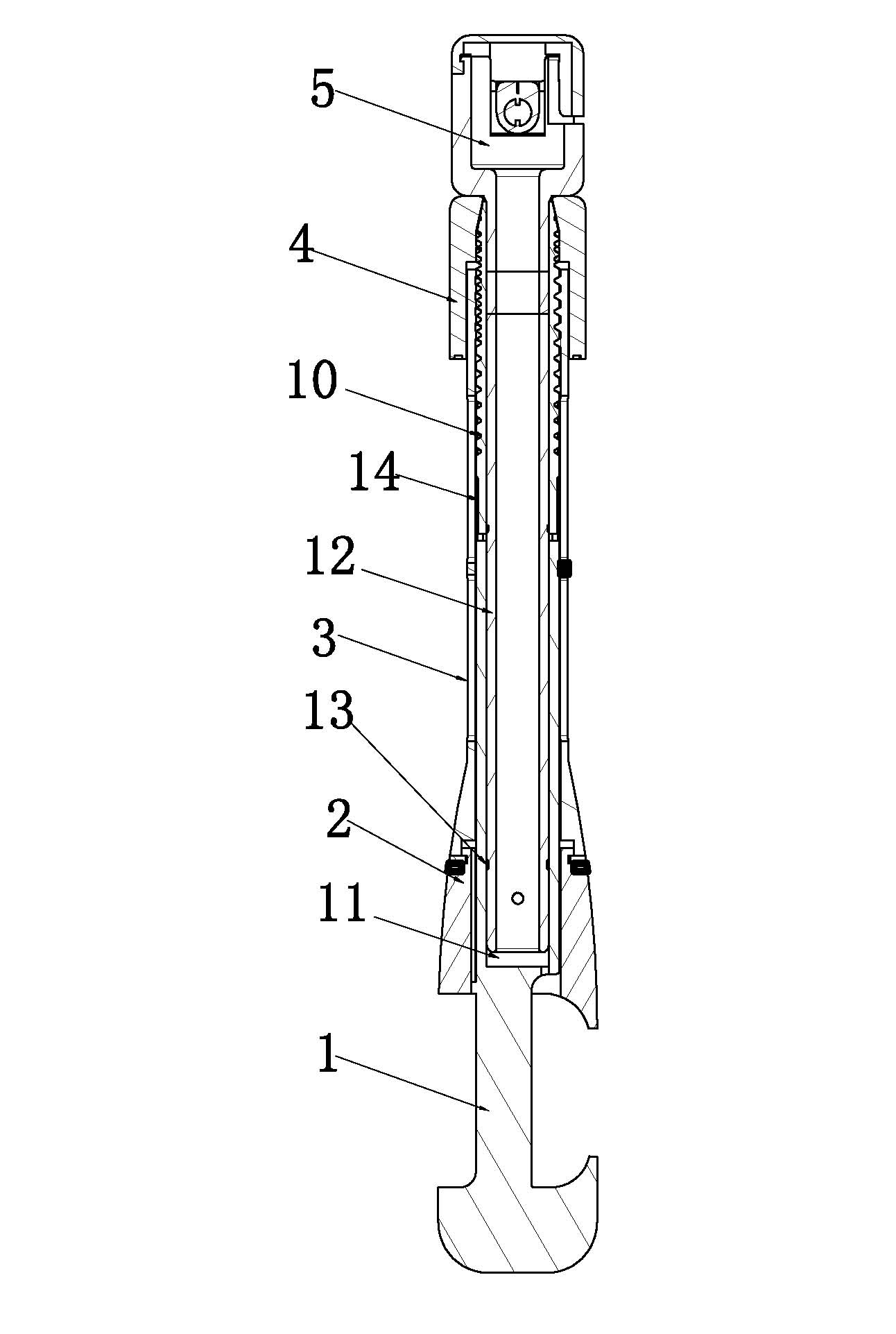

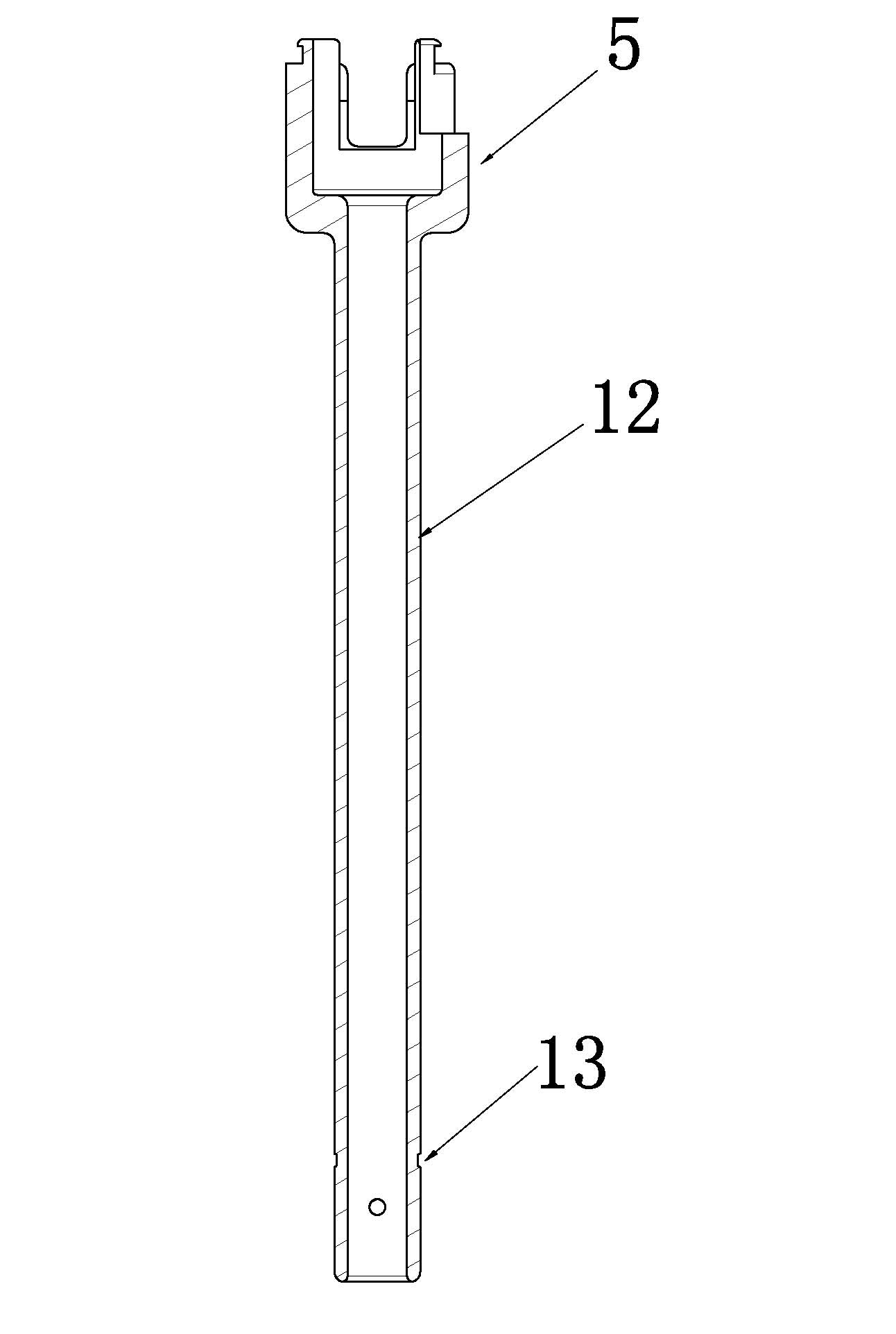

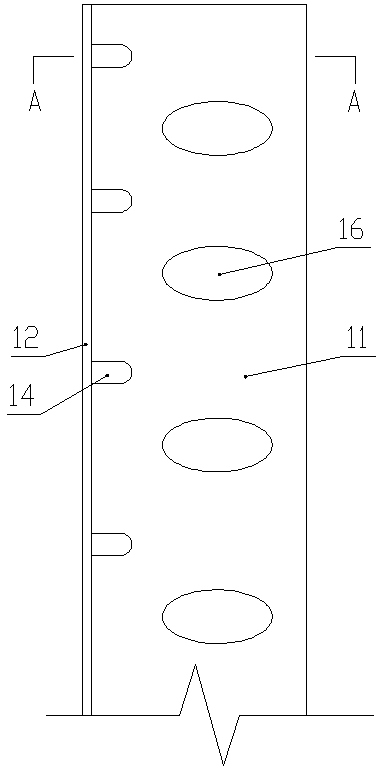

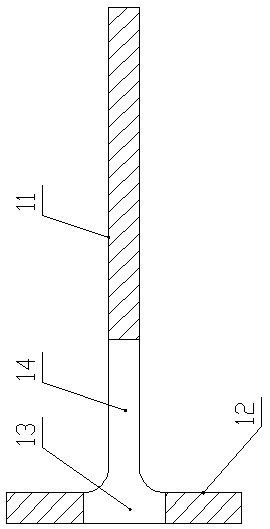

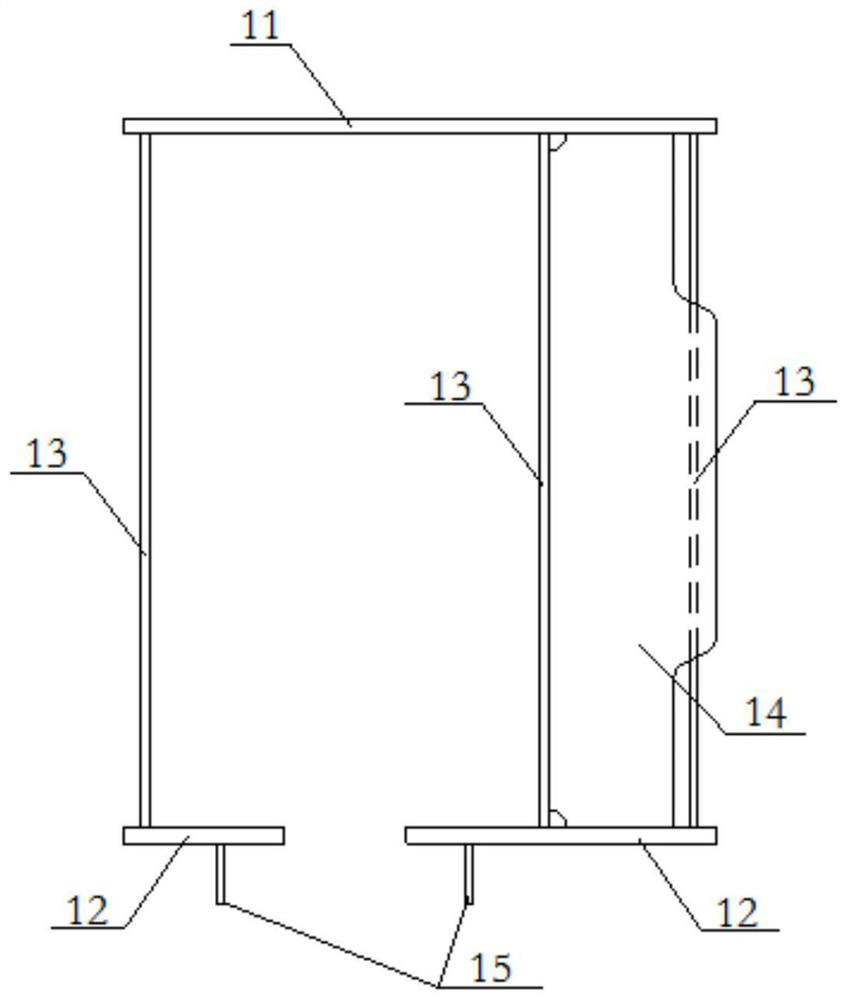

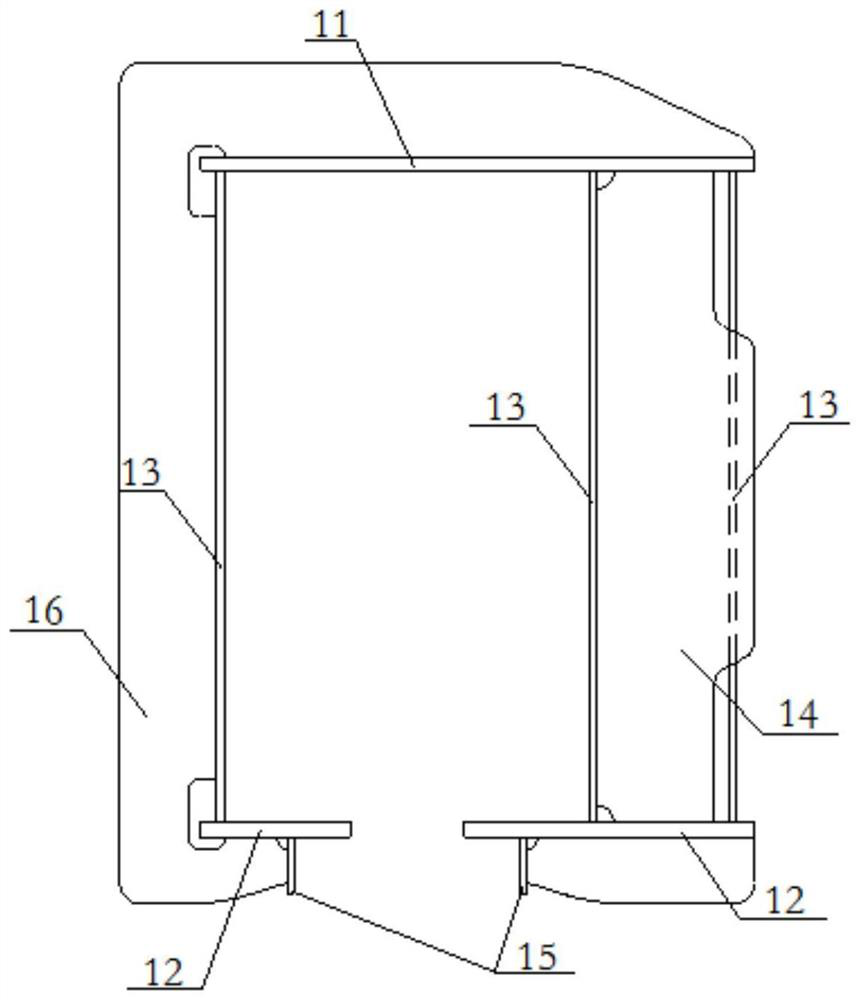

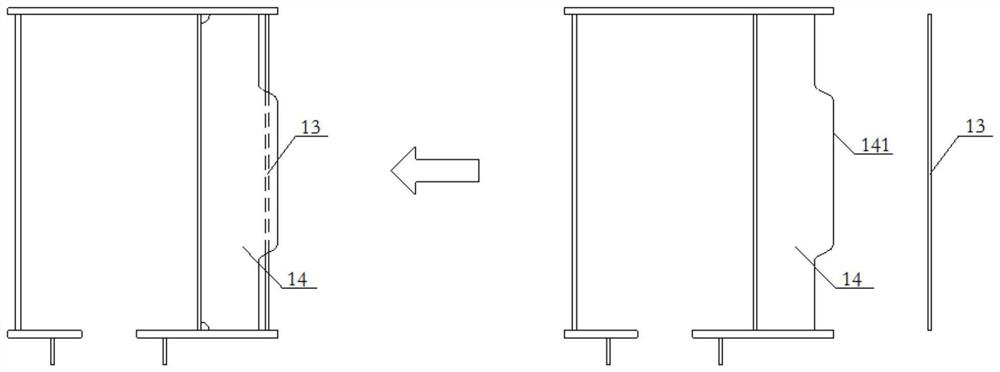

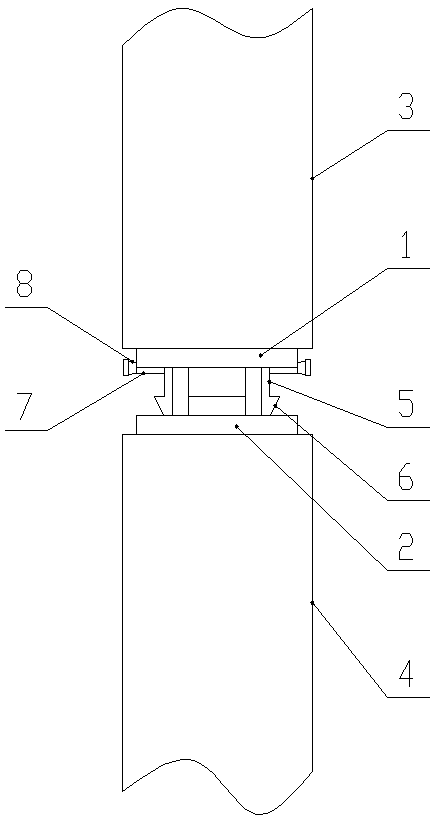

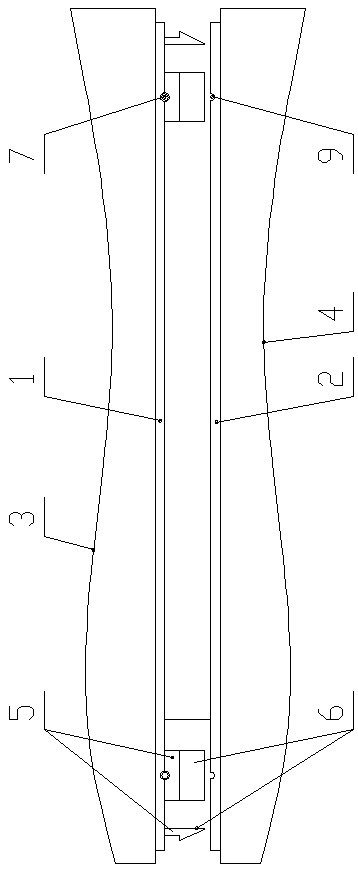

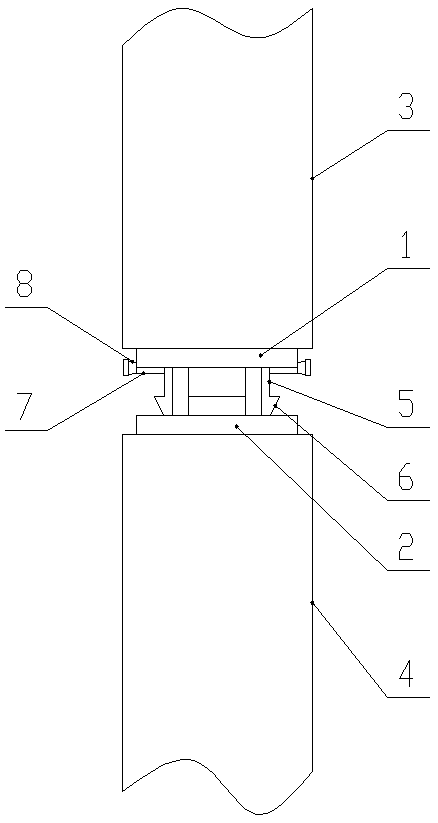

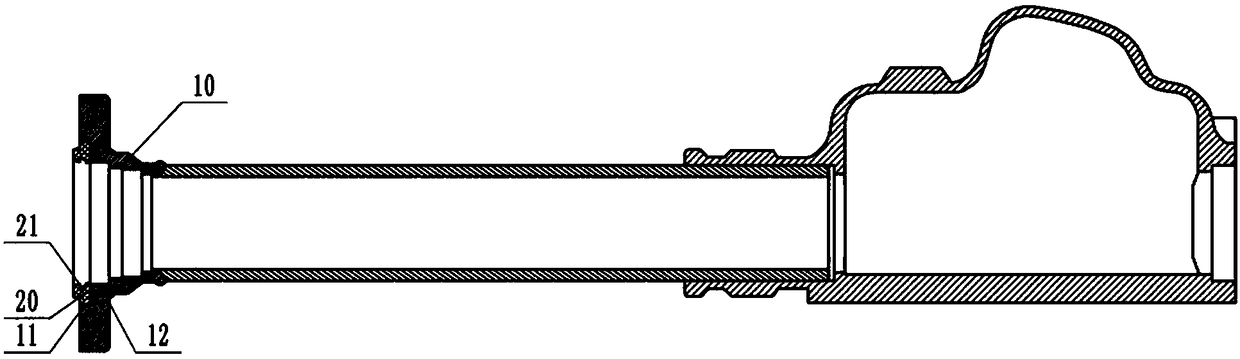

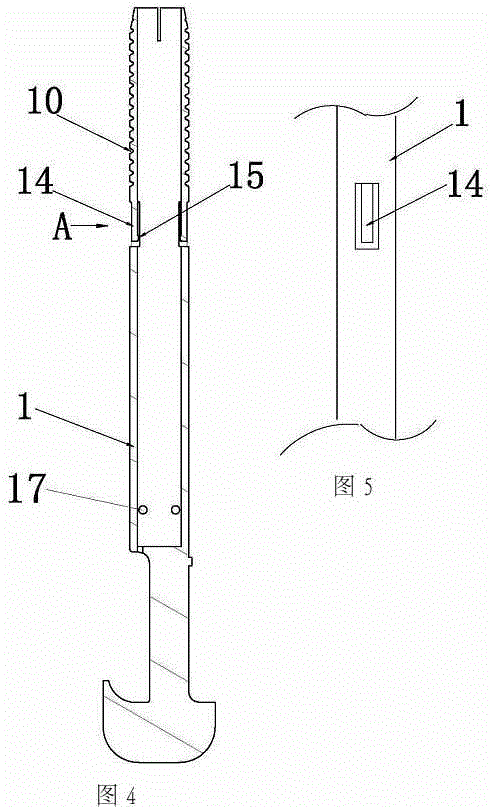

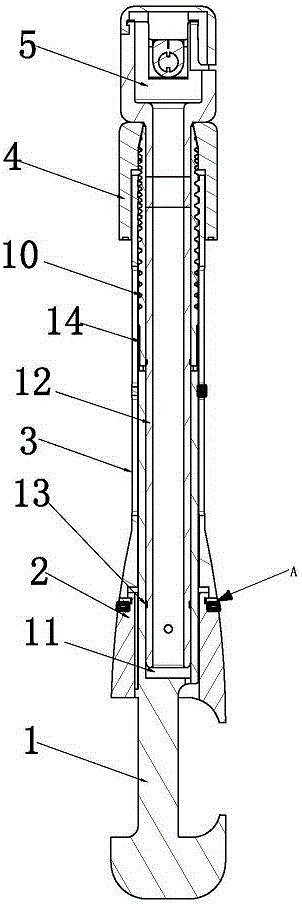

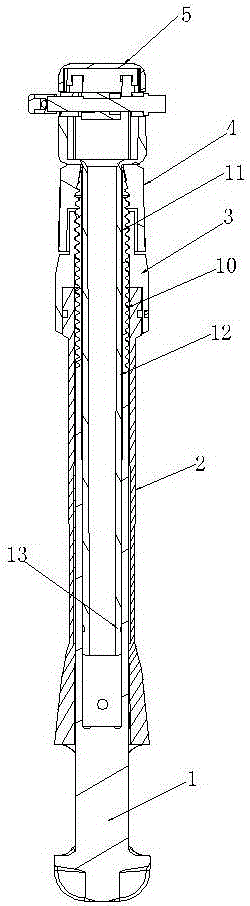

Medical surgical soft tissue dilator

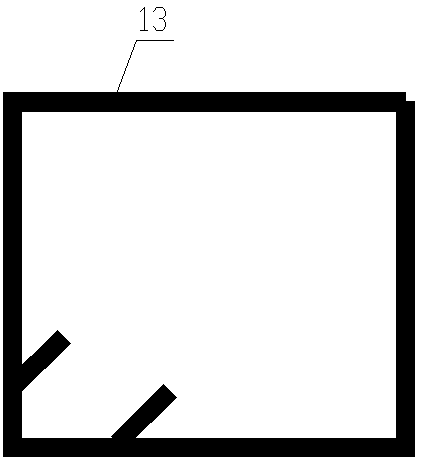

A medical surgical soft tissue dilator comprises a main rod (1), a locking sleeve (2), a locking operating rod (3), a belt winding device locking sleeve (4), a belt winding device (5) and a hook plate (6). A half dovetail groove which matches with a surgical bedside is arranged at the lower end of the main rod (1), another half dovetail groove capable of vertically moving is arranged at the lower end of the locking sleeve (2), the locking operating rod (3) is provided with inner threads matching with outer threads at the upper end of the main rod (1), an inner screw hole which matches with the outer threads of the upper end of the main rod (1) is arranged at the upper end of the belt winding device locking sleeve (4), the lower end of the belt winding device locking sleeve (4) is covered at the upper end of the locking operating rod (3), the lower end of the belt winding device (5) is inserted in an inserting hole at the upper end of the main rod (1), the height of the belt winding device (5) is adjustable, and a belt winding box is disposed at the upper end of the belt winding device (5) and connected with the hook plate (6). The medical surgical soft tissue dilator is characterized in that a limiting groove (13) is arranged on an inserting rod (12) at the lower end of the belt winding device (5), and an elastic jaw (14) is arranged on the main rod (1) and provided with a one-way check bump (15) which is inserted into the limiting groove (13). Structural strength is guaranteed, simultaneously, utilization quantity of materials is greatly reduced, and the medical surgical soft tissue dilator has the advantages of high strength, light weight and convenience in operation and use.

Owner:JIANGSU HAIZE MEDICAL TECH DEV

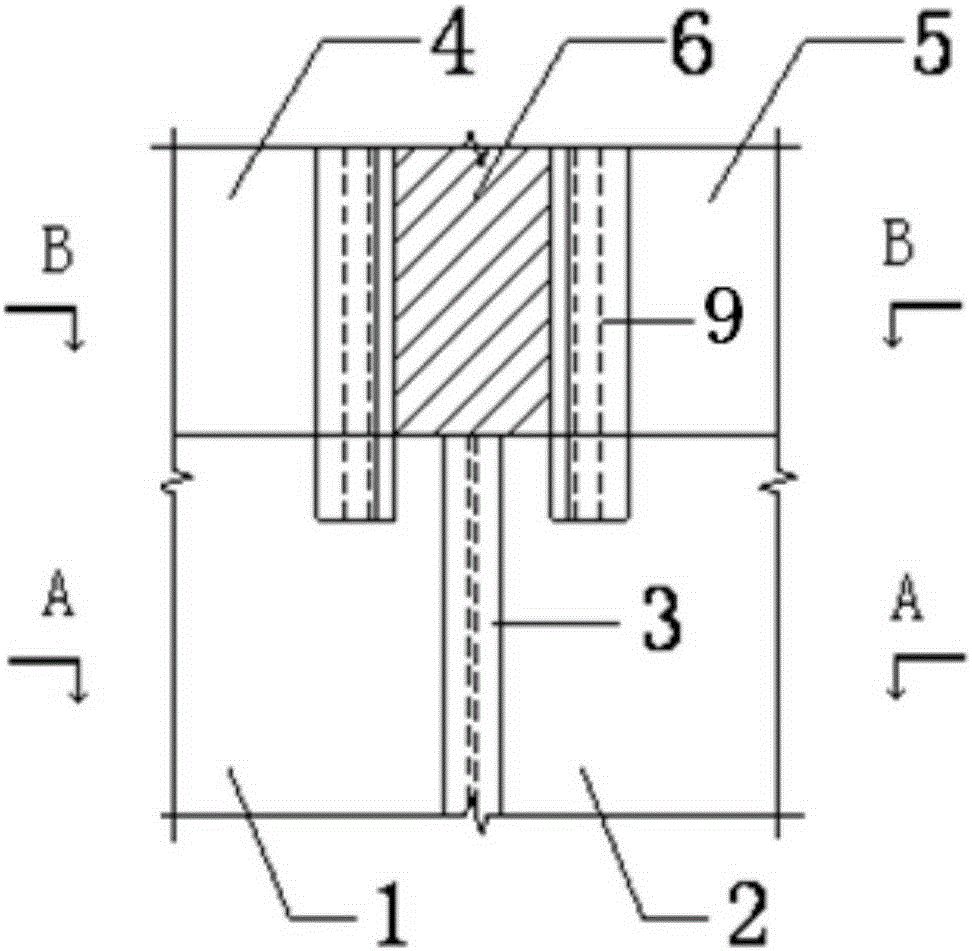

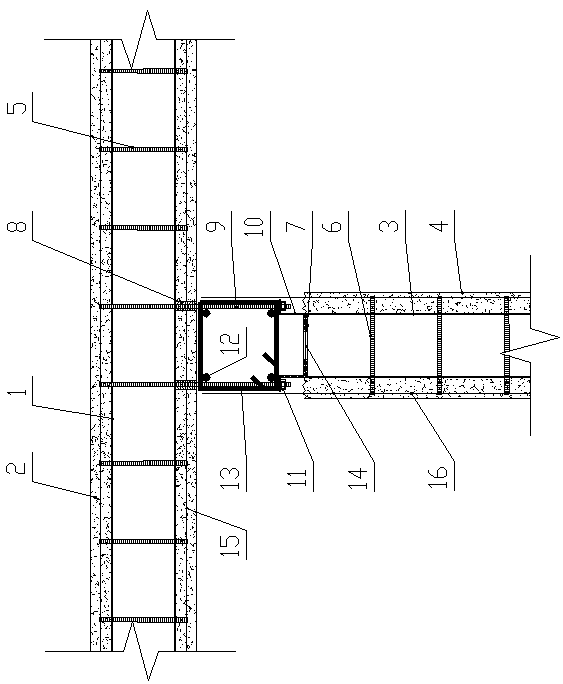

Joint treatment method for fabricated building wall

InactiveCN108316508AGuaranteed compactnessComponent form is reasonableWallsPre embeddingBuilding construction

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

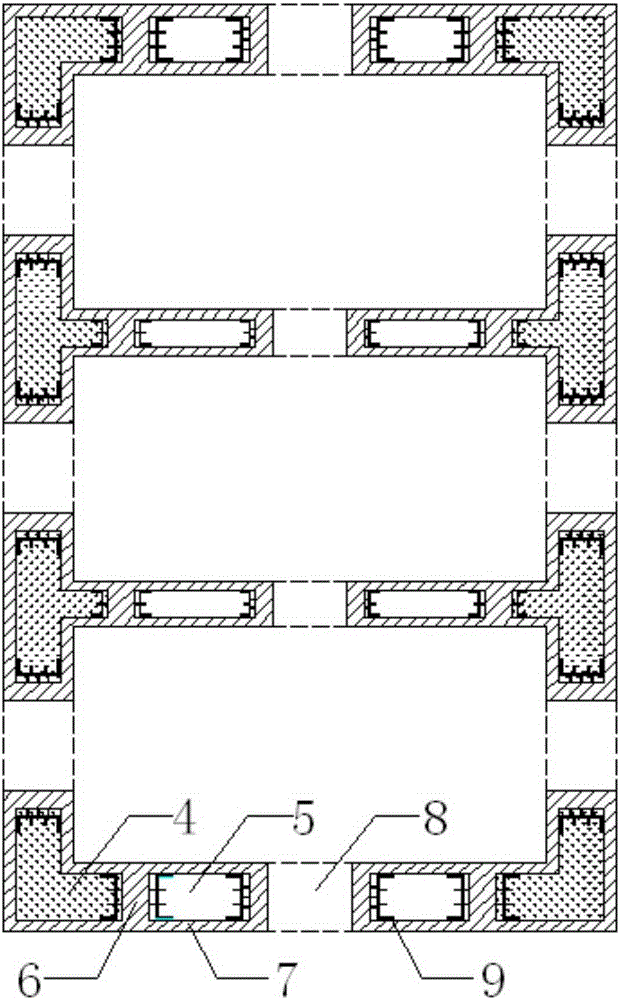

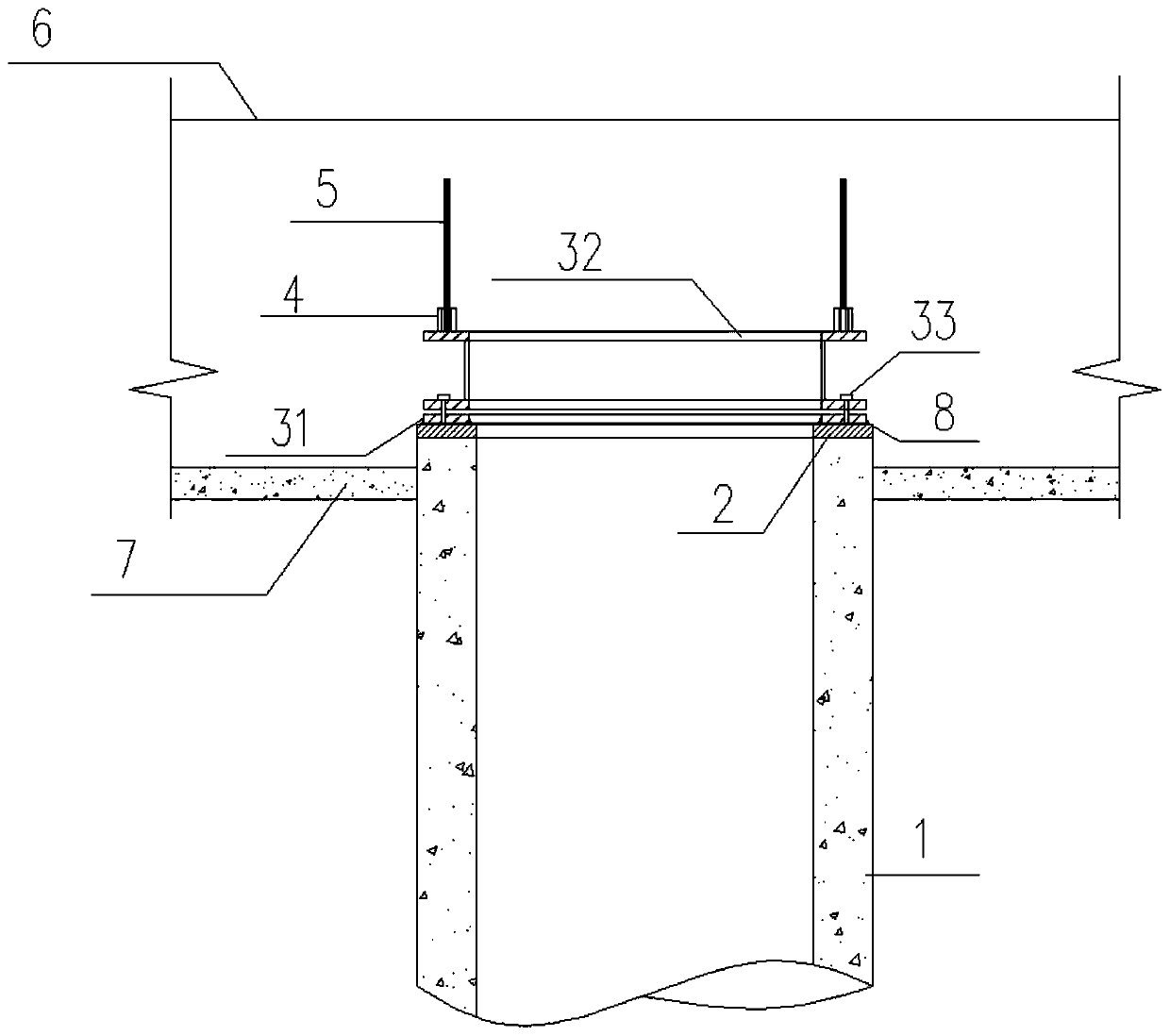

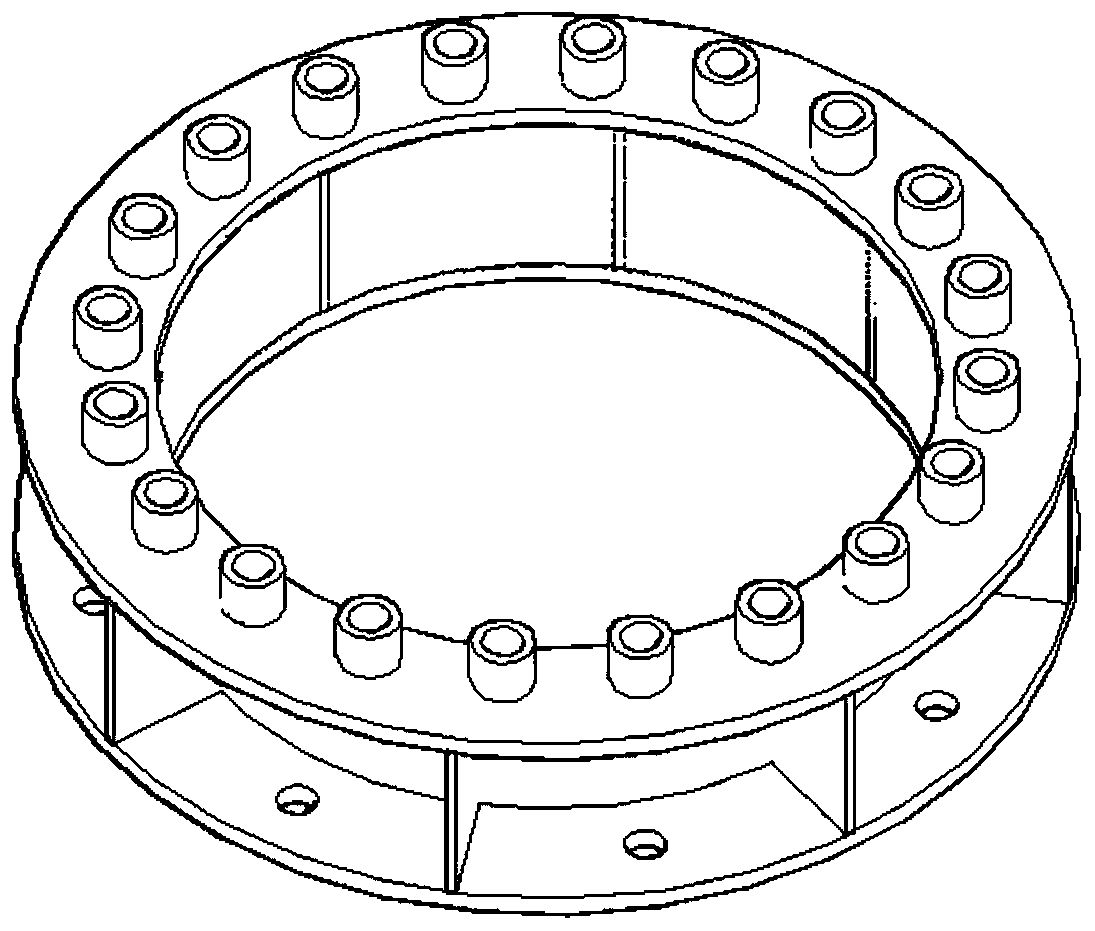

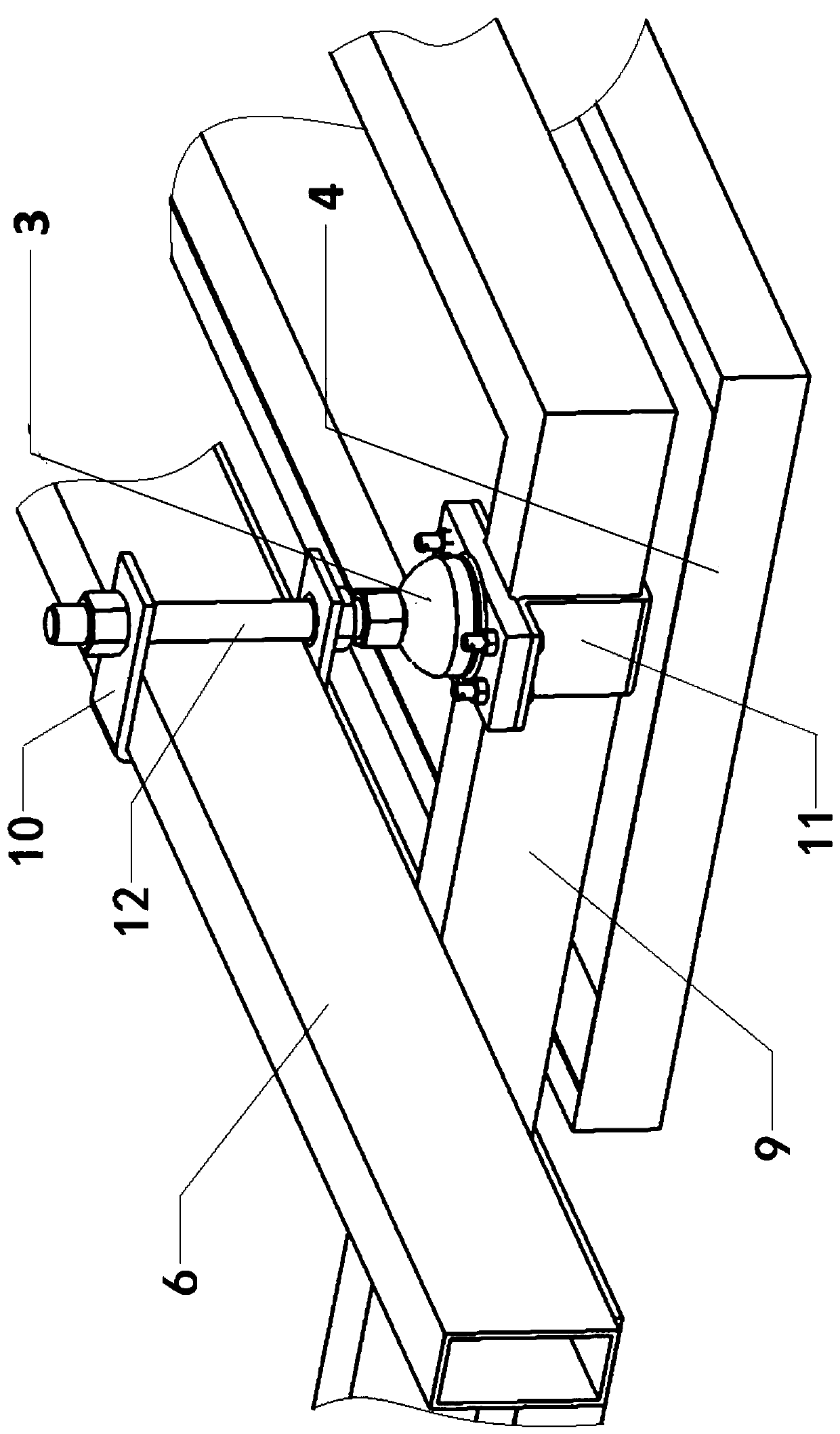

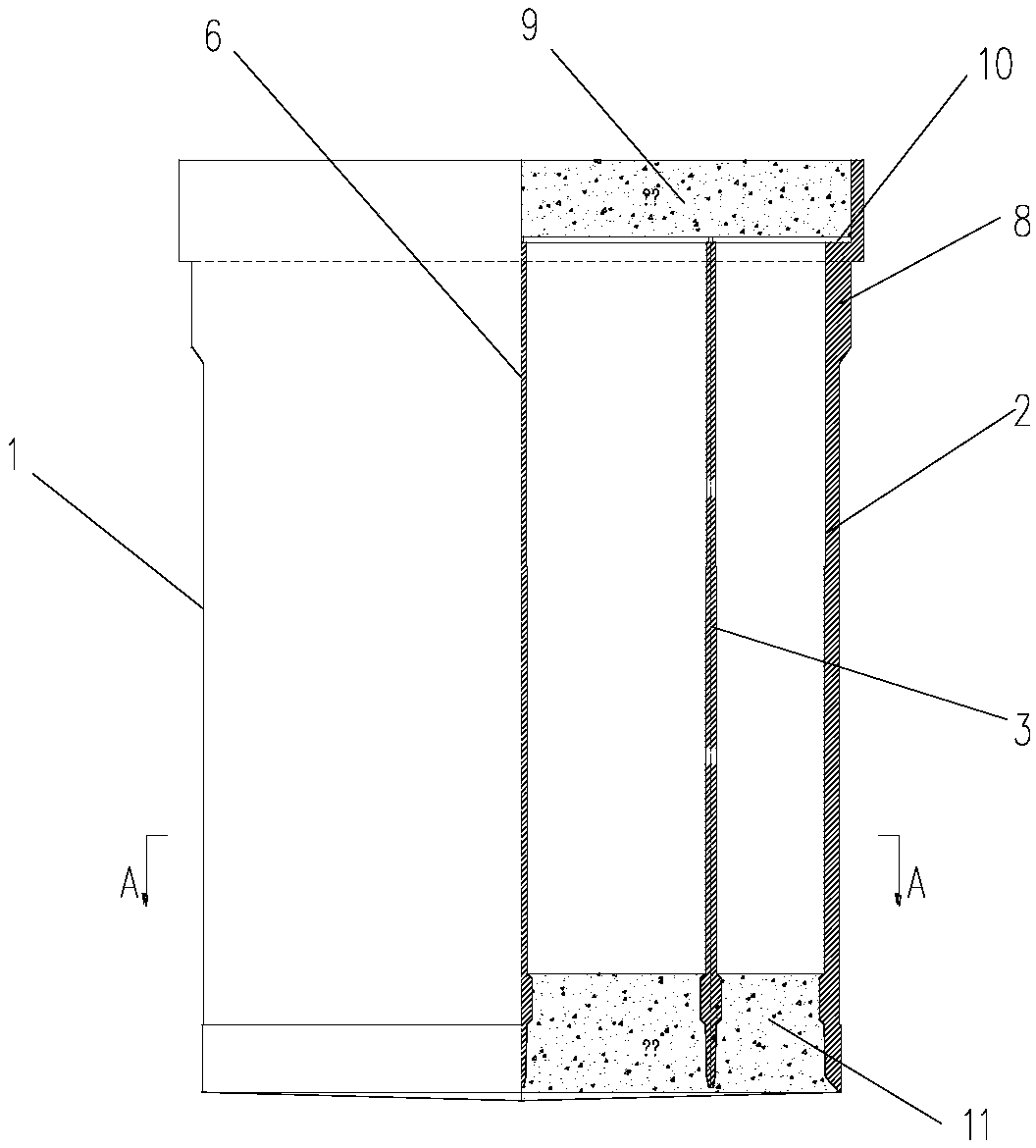

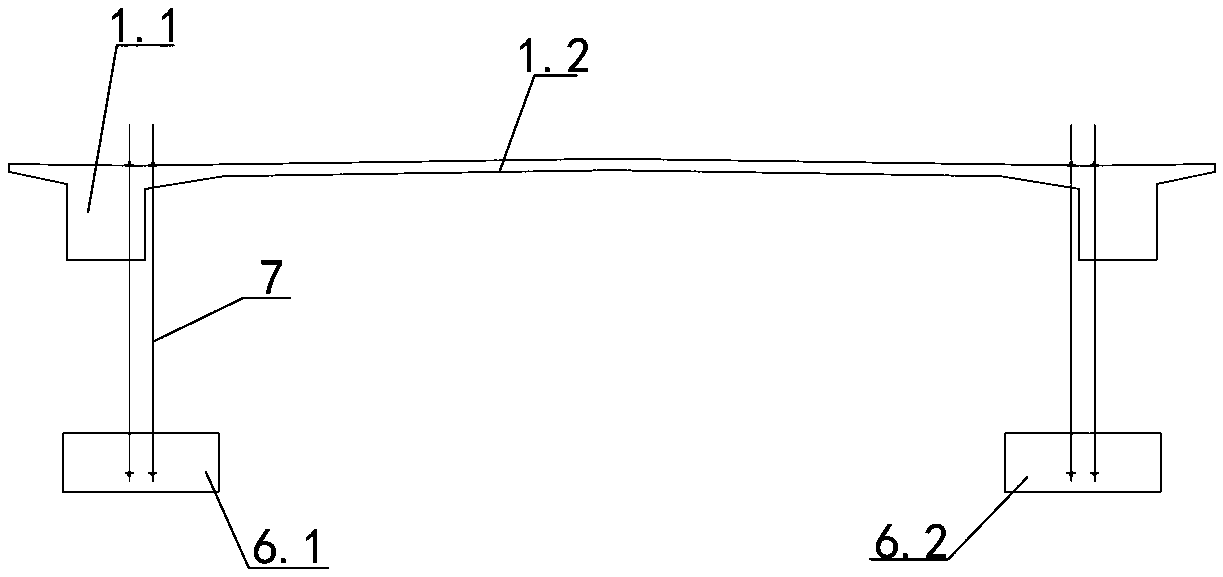

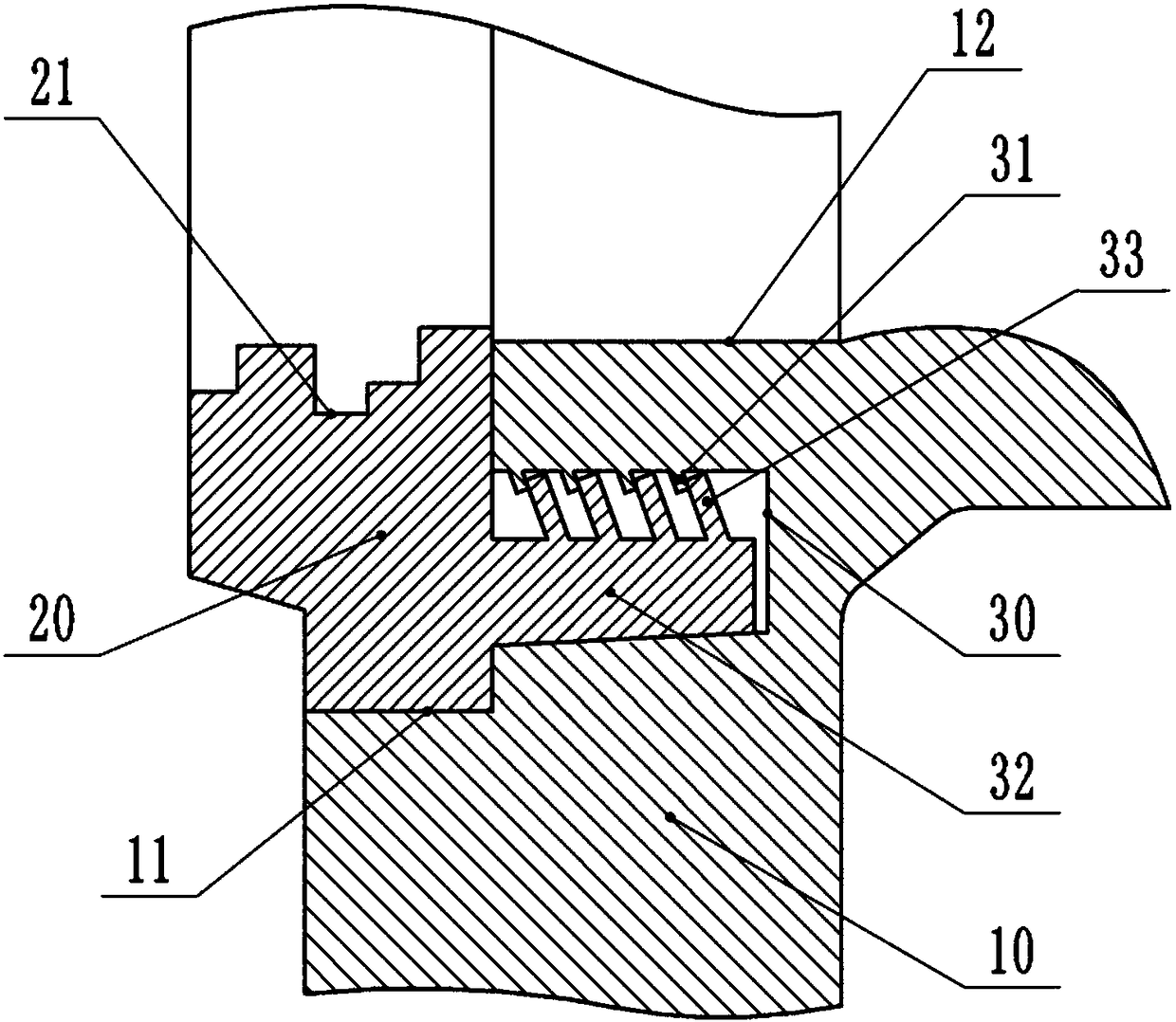

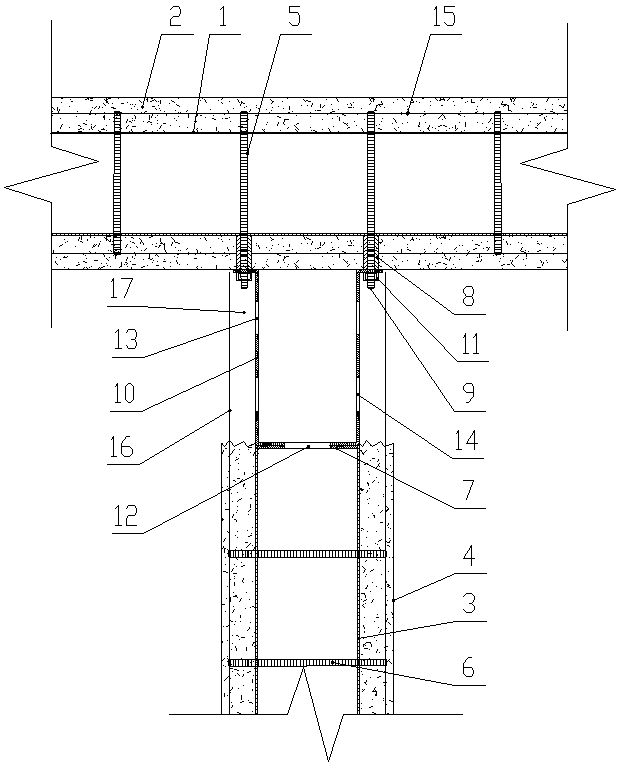

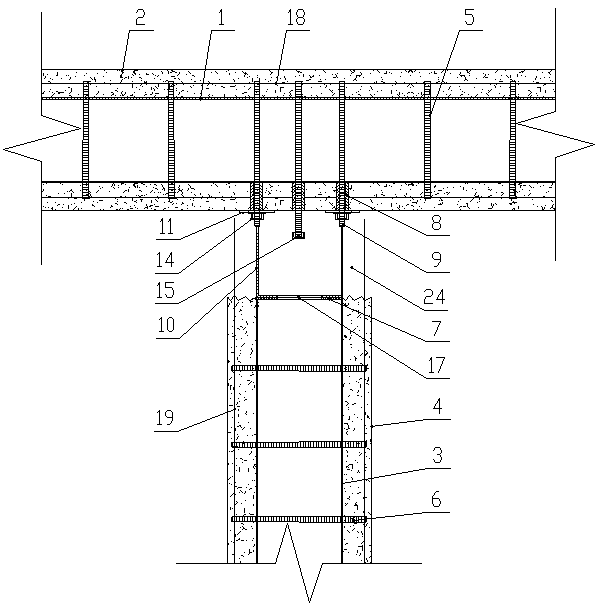

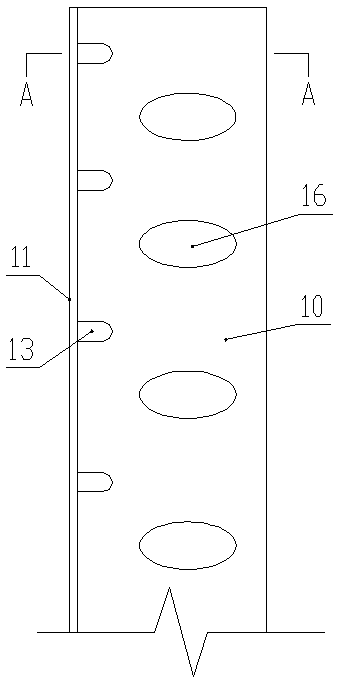

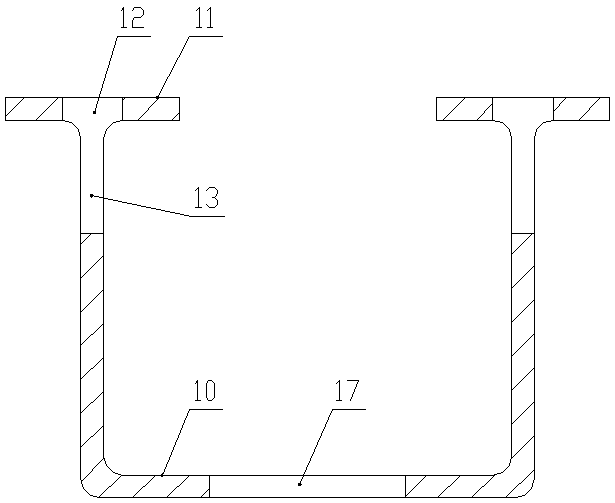

Connecting structure of railway bridge pipe pile and bearing platform, foundation structure and construction method

PendingCN109778894AGuaranteed integrityImprove connection strengthFoundation engineeringHorizontal forceEngineering

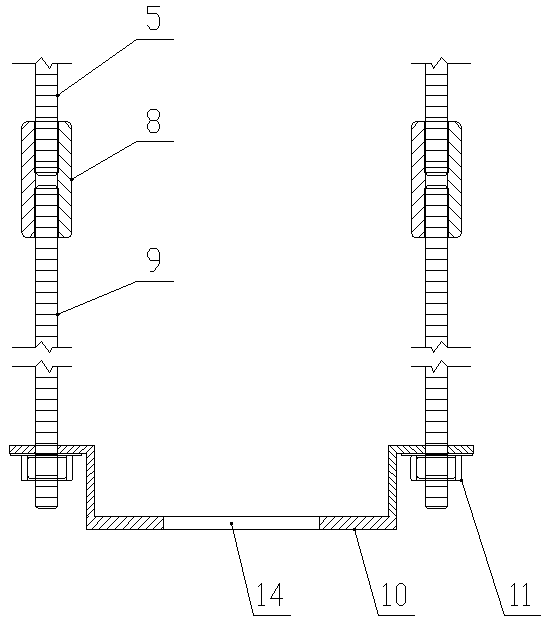

The invention discloses a connection structure of a railway bridge large-diameter pipe pile and a bearing platform. The connection structure is characterized by comprising a first flange plate (31), asecond flange plate (32) with preset steel sleeves (4), and an anchoring steel bar (5). The first flange plate (31) is welded and fixed on an end plate (2) at the top end of a tubular pile (1). A plurality of steel sleeves (4) are fixedly connected to the top surface of the second flange plate (32) in the circumferential direction. An anchoring steel bar (5) is fixedly connected in each steel sleeve (4). A bearing platform (6) is poured at the top of the pipe pile (1), and the whole first flange plate (31), the second flange plate (32), the steel sleeves (4), the anchoring steel bar (5) and one part of the top of the pipe pile (1) are connected with one another and embedded into the bearing platform. The connection mode ensures the integrity of the connection between the pile and the bearing platform, the horizontal force on the top of the pile can be better transmitted to the whole pile body, and the continuity of the stress is ensured.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

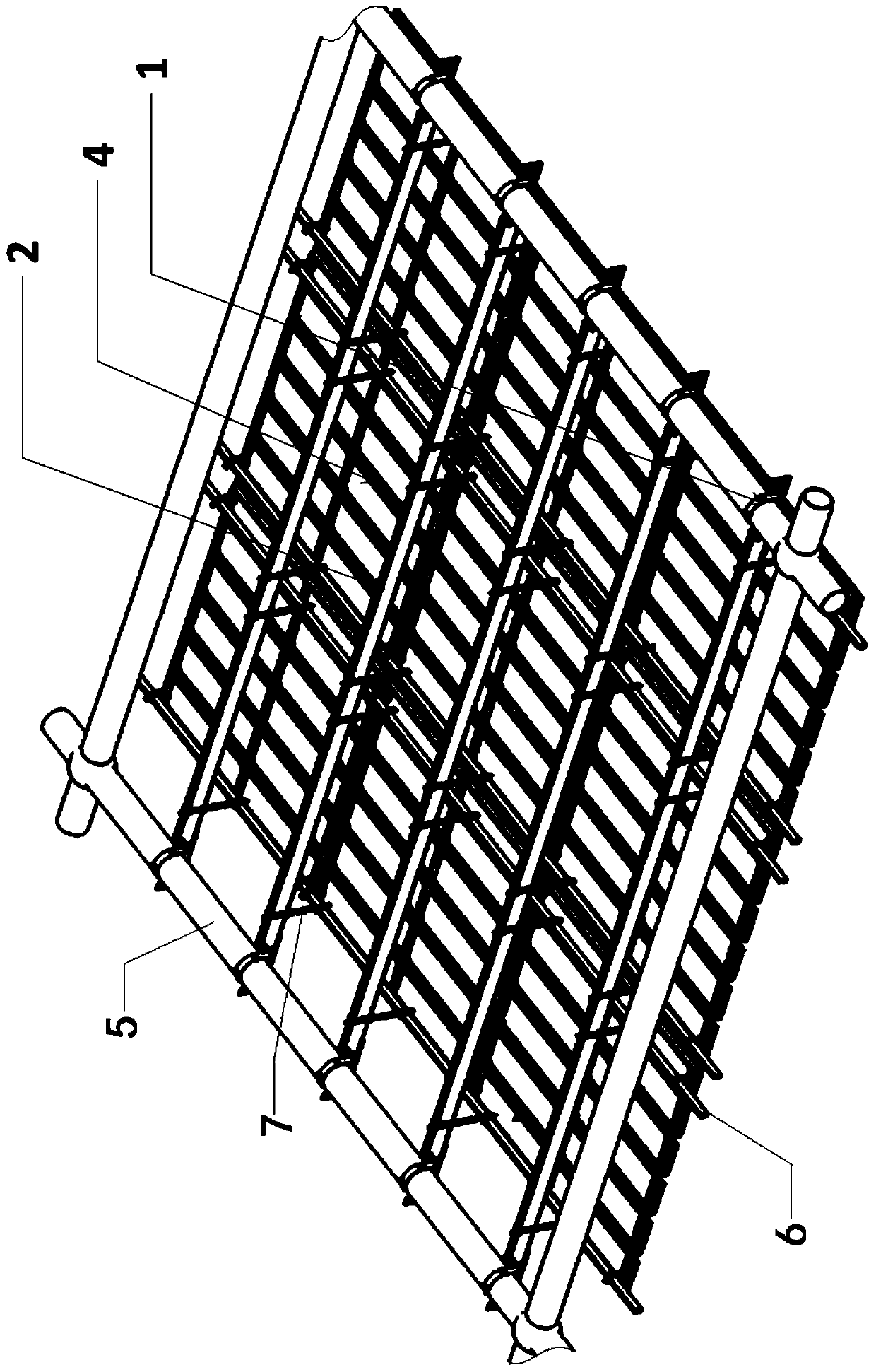

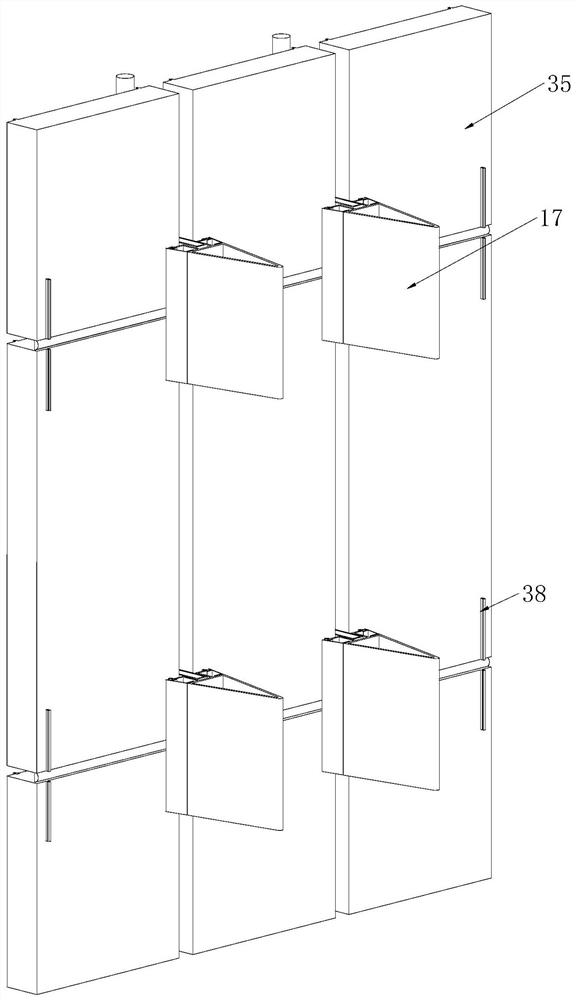

Double-curved-surface aluminium plate suspended ceiling structure

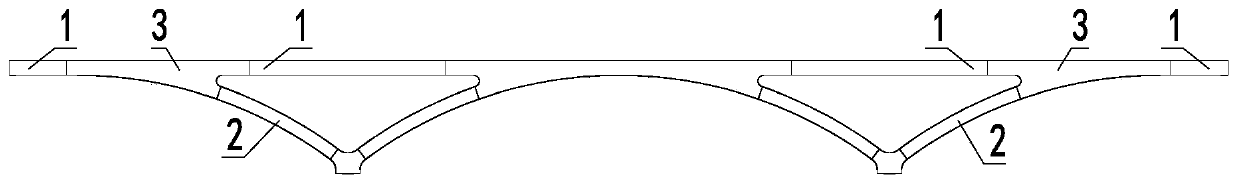

The invention discloses a double-curved-surface aluminium plate suspended ceiling structure. The suspended ceiling structure comprises a hoop, a keel, panels and a three-dimensional adjusting mechanism, wherein the hoop is assembled with a roof truss of a building; the keel is assembled with the hoop, the keel comprises a plurality of main keels arranged in parallel with one another, and further comprises a plurality of secondary keels arranged in parallel with one another, the length direction of the main keels is perpendicular to the length direction of the secondary keels, and framed keels are further arranged on the lower parts of the main keels and the secondary keels; a plurality of panels are fixed to the lower parts of the framed keels; and the three-dimensional adjusting mechanism comprises vertical threaded rods connected with the main keels and the secondary keels, universal joints connected with the framed keels are arranged at the bottoms of the threaded rods, the universal joints are provided with threaded holes assembled with the threaded rods, and the universal joints are provided with the rotation freedom degree of the universal joints and the rotation freedom degree of the threaded rods around the axis of the threaded rods. According to the double-curved-surface aluminium plate suspended ceiling structure, the structural strength is high, on-site welding is eliminated, maintenance and disassembly are convenient, and when the effect of the curved surface top is needed to be created on the overall, the local panel can conveniently fine adjust the height and adaptively change the angle.

Owner:GOLD MANTIS CONSTR DECORATION

Annular open caisson structure

The invention discloses an annular open caisson structure which comprises an open caisson body. The open caisson body comprises an outer ring caisson wall and an inner ring caisson wall, and a plurality of partition walls are arranged between the outer ring caisson wall and the inner ring caisson wall. An annular space formed between the outer ring caisson wall and the inner ring caisson wall is divided into a plurality of independent fan-shaped cavities by the partition walls, and a fan-shaped caisson hole is formed in each fan-shaped cavity. An open caisson adopts an annular cross section, the water flow adaptability is good, the local scour depth is small, and the water flow force and wave force borne by the structure are small. Moreover, the fan-shaped caisson holes are formed in the fan-shaped cavities, so the solid area of the partition walls of the open caisson can be reduced, and taking soil evenly in the sinking process of the open caisson and assisting the sinking of the opencaisson are facilitated.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

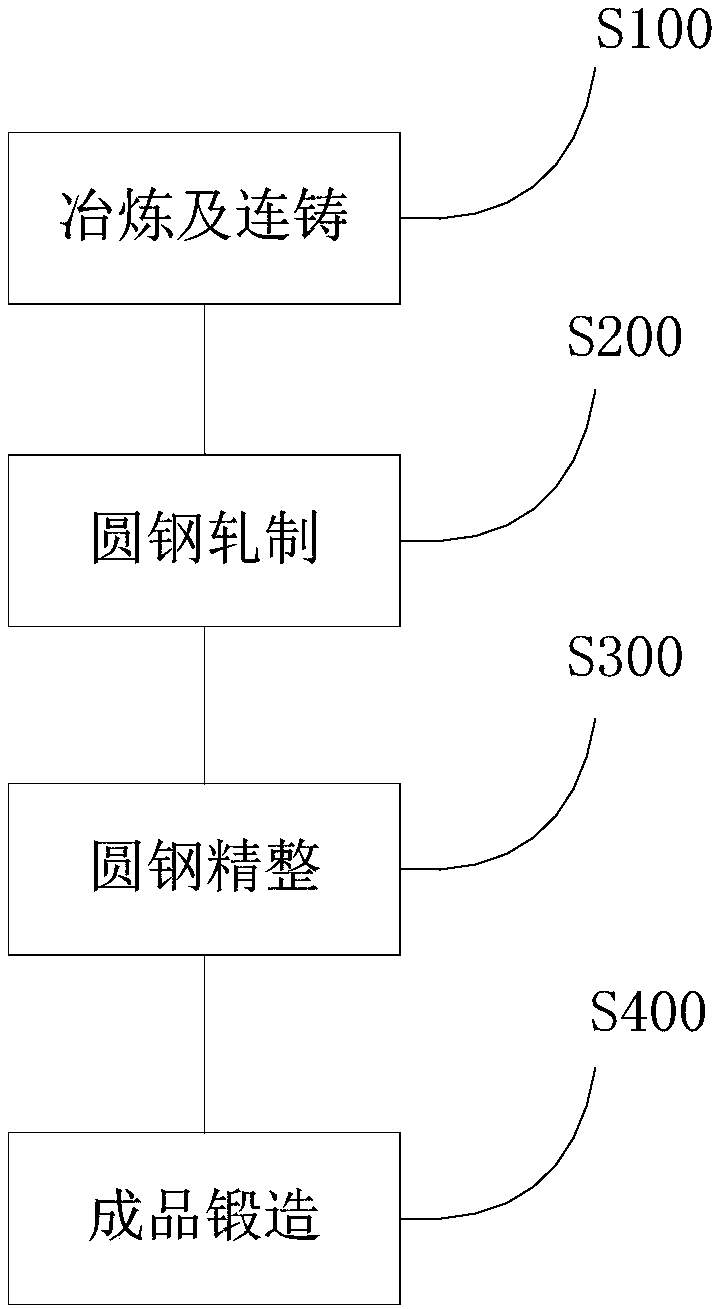

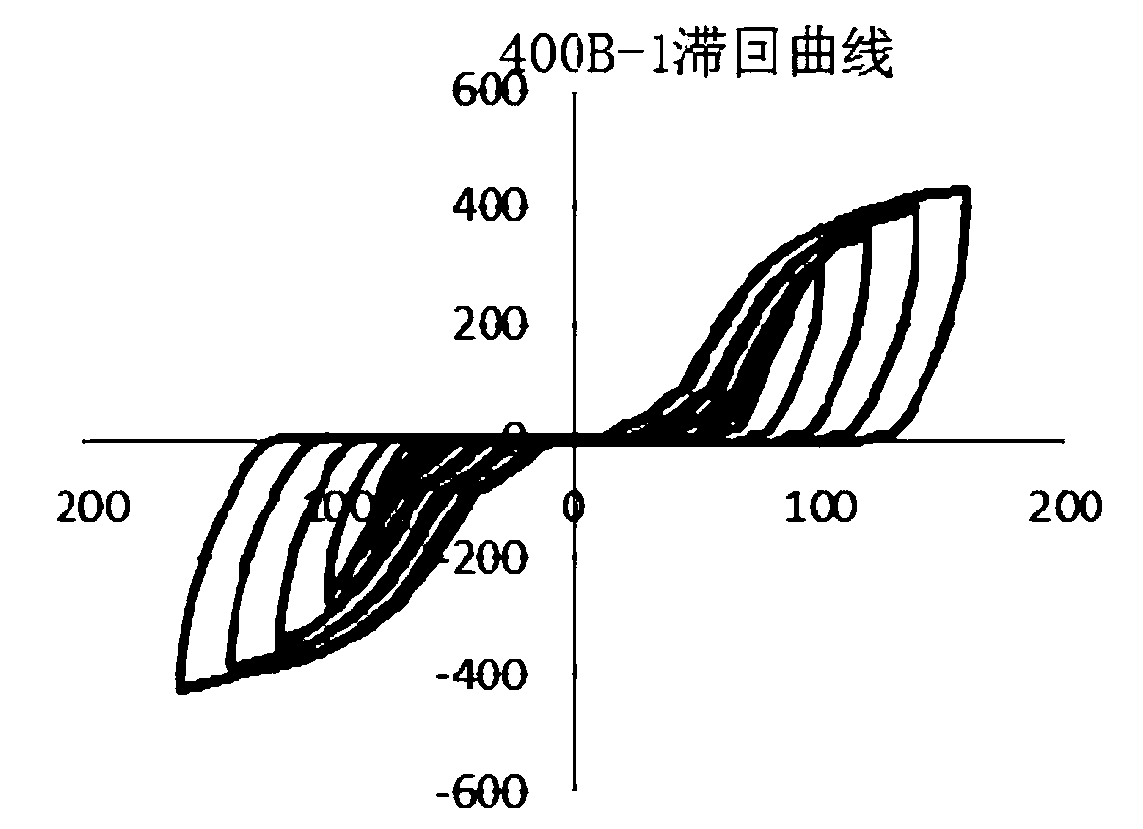

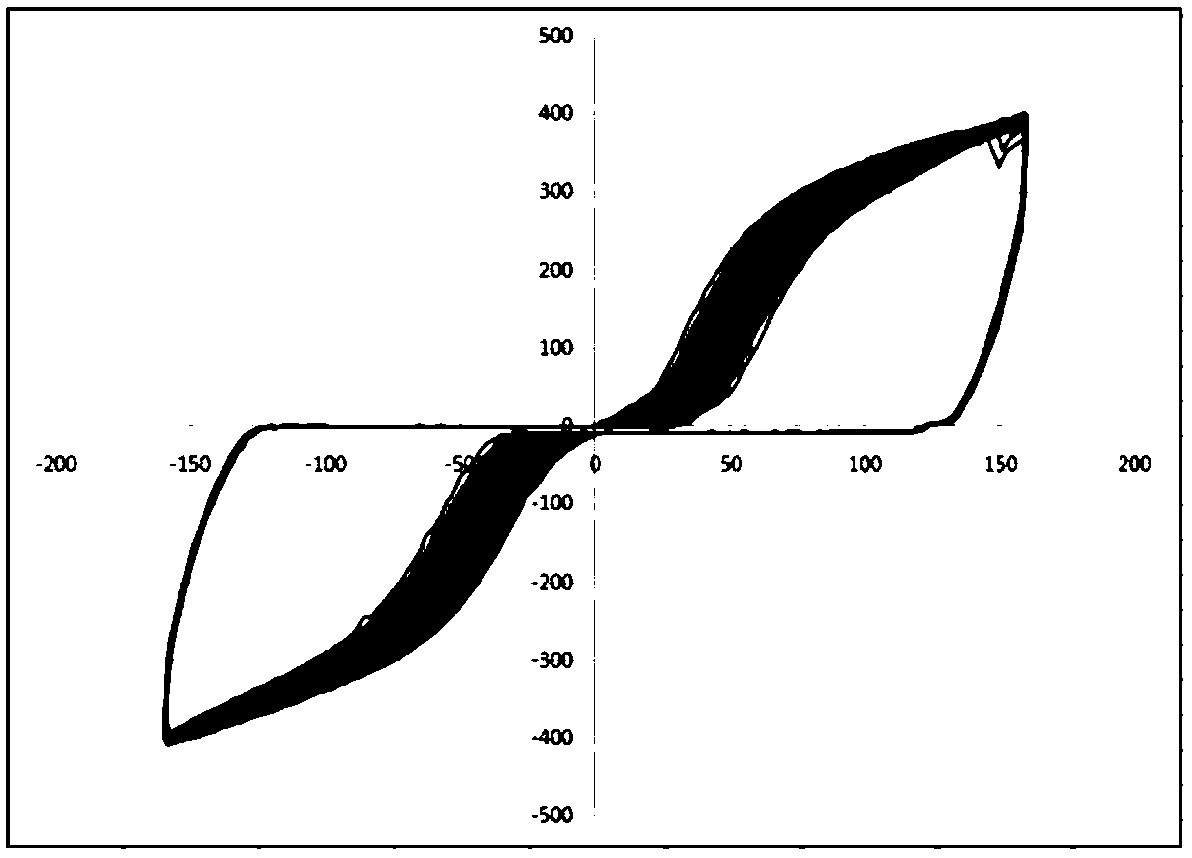

Design and manufacturing method ofsoft steel material with damping anti-seismic device for bridge

ActiveCN108286019AGuaranteed tensile strengthGuaranteed Yield StrengthChemical compositionEnergy absorption

The invention discloses a design and a manufacturing method of a soft steel material with a damping anti-seismic device for a bridge, and relates to a steel formula. The detailed ratio which is designed in a formulaaccording to the mass percentage ratio of a component element of a steel type refers to the claim. The manufacturing method comprises the steps of smelting, continuous casting, round steel rolling, round steel finishing and finished product forging. A low-carbon aluminum killed steel with a specified chemical component range is prepared according to the formula and the manufacturingmethod, and meanwhile, element contents of P and Swhich influence plastic performance are strictly controlled, and the residual element contentsare controlledand thennot only tensile strength and yield strength of the soft steel are guaranteed to be within a certain strength range, but also the specific value of the yield strength and the tensile strength is not greater than 0.72, and a manufactured anti-seismic isolation device is excellent in equivalent damping ratio and low-cycle fatigue performance, so that the use requirements of stress and energy absorption and seismic resistance of a railway bridge comprehensive working condition are met.

Owner:上海衍衡新材料科技有限公司 +2

T-shaped node of steel concrete combined pipe assembled by T-shaped steel and threaded sleeve pipe

PendingCN109944362AImprove connection strengthMeet the forceWallsProtective buildings/sheltersEarthquake resistanceUltimate tensile strength

The invention relates to a T-shaped node of a steel concrete combined pipe assembled by T-shaped steel and threaded sleeve pipe, which comprises a first steel concrete combined pipe and a second steelconcrete combined pipe, wherein an end steel plate is exposed at the rear end part of a second rectangular steel plate structure; an internal threaded sleeve is embedded in the front side of the first steel concrete combined pipe; the front half section of the internal threaded sleeve is in threaded connection with a connecting stud; the back side of the end steel plate is welded with two T-shaped steels. The back side of the web of each T-shaped steel is provided with a wrench operation hole corresponding to an installation hole. The front end of the connecting stud is threaded with a connecting nut in the operation hole of the wrench, the back side surface of the wing plate is pressed on the front side surface of the first steel concrete composite pipe by the connecting nut. The node can greatly improve the connection strength of T-shaped nodes between the two steel concrete combined pipes and ensure the reliability of the connection, combines cast-in-place casting and prefabrication, is convenient for construction, has high construction efficiency, can ensure the construction quality, and completely meets the use requirements of integral stress, energy saving, earthquake resistance and the like of modern assembled buildings.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

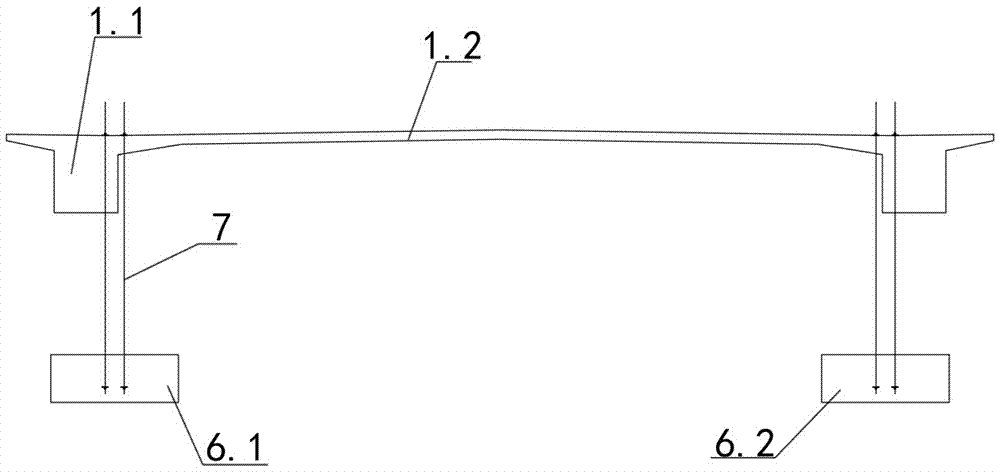

Track beam for suspension type monorail traffic and suspension type monorail traffic bridge

PendingCN112195749AIncrease stiffnessImprove structural strengthBridge structural detailsBridge erection/assemblyTrackwayMonorail

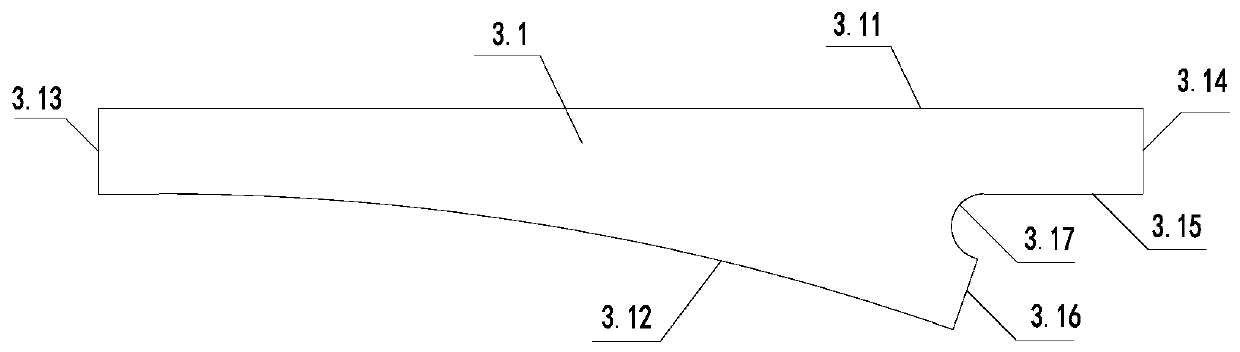

The invention relates to a track beam for suspension type monorail traffic, which comprises a beam top plate, an open type beam bottom plate and a plurality of beam webs; the plate surfaces of the beam webs are parallel to the longitudinal direction of a track, and the upper ends and the lower ends are respectively connected with the beam top plate and the beam bottom plate; the beam webs are distributed on the two transverse sides of a beam bottom plate walking area, and the number of the beam webs on at least one side is not smaller than two so that a side box area can be formed. In addition, the invention further relates to a suspension type monorail traffic bridge which comprises a supporting structure and two sets of track beams, the two sets of track beams are connected through transverse tie beams, and the transverse tie beams are supported on the supporting structure. The side box type section is adopted, closed shear flow can be formed when the side box type section is stressed, the rigidity and structural strength of the track beam are remarkably improved, the driving comfort is greatly improved, and therefore the design span of the suspension type monorail can be increased, and the application range of suspension type monorail traffic is widened.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

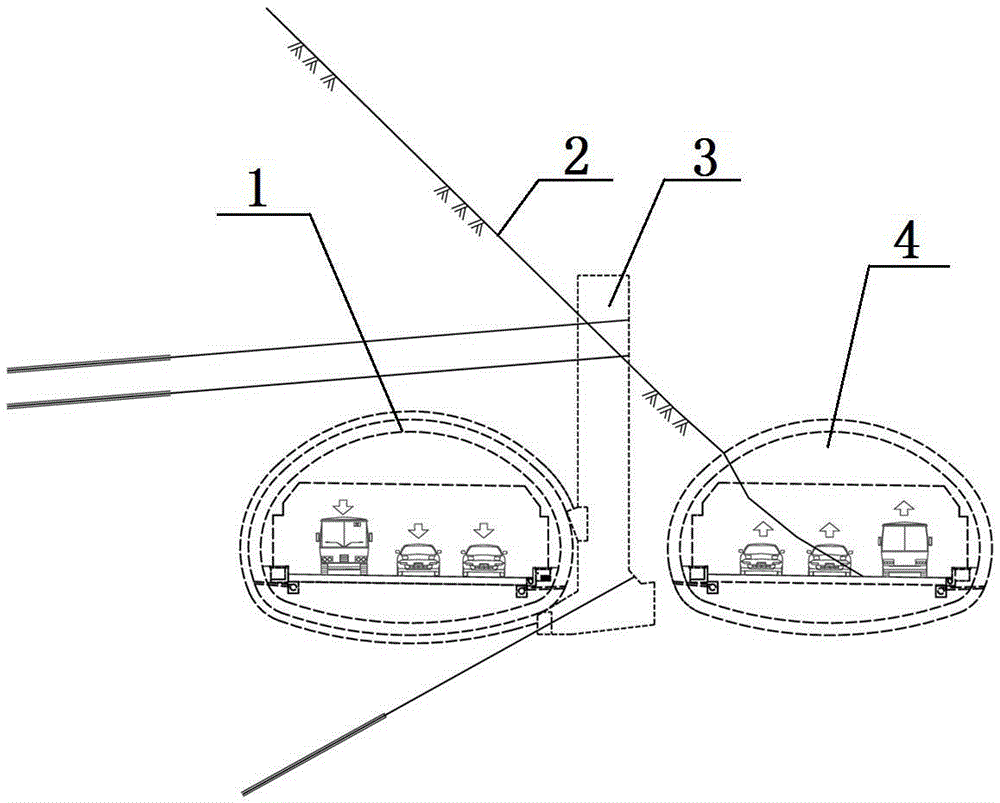

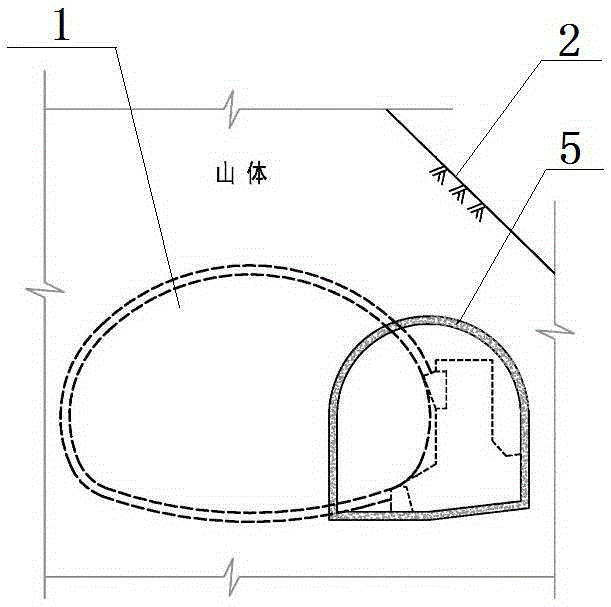

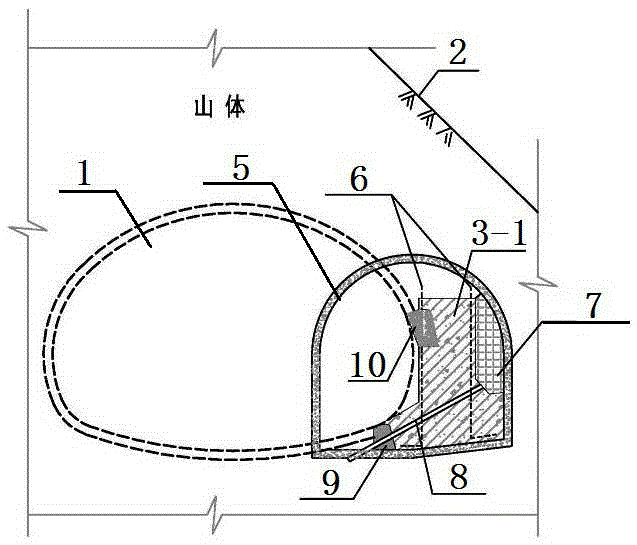

A construction method for a tunnel located at the slope foot of a mountain

ActiveCN103089272BMeet the forceFulfil requirementsUnderground chambersTunnel liningEngineeringSupport point

The invention relates to a method for constructing a tunnel located at a mountain slope toe. The method comprises the following step: firstly, pilot tunnel of an internal tunnel close to one side of a mountain slope toe is finished; a lower portion structure body of a parapet pile is constructed in the pilot tunnel, and a reinforcement cage is constructed by digging hole on the ground of the mountain slope toe, concrete is poured into the reinforcement cage, and the reinforcement cage and the lower portion structure body are combined into the parapet pile; construction of the internal tunnel is finished; soil body outside the parapet pile is dug out, and meanwhile the parapet pile is reinforced; and finally, the external tunnel construction is finished. The method has the advantages that the lower portion structure body of the parapet pile is constructed in the pilot tunnel so that hole digging depth on the ground of the mountain slope can be reduced, and construction risk is reduced; an upper portion horizontal supporting beam is arranged on the parapet pile and can serve as a preliminary bracing supporting point of an internal tunnel master cave arched part, so that one component has functions of two components; and the method is suitable for a tunnel with small interval, engineering construction land is saved, and traffic organization of a tunnel portal is benefited.

Owner:SHANGHAI MUNICIPAL ENG DESIGN INST GRP

A composite construction method for the main girder of a cable-stayed bridge and its counterweight structure system

ActiveCN106917358BSymmetrical satisfactionMeet the forceCable-stayed bridgeBridge erection/assemblyFalseworkComposite construction

The invention provides a combined construction method of a cable-stayed bridge main beam and a counterweight foundation structure system of the construction method. The construction method comprises the following steps: designing a scaffold foundation, designing an excavation slope and step height of a dam at an edge slope region, designing the counterweight structure system of an nth block to a (n+m)th block of a mid-span, excavating the dam, wholly pouring the scaffold foundation and a counterweight foundation, carrying out symmetrical construction on a side-span and the mid-span of a main beam block by block by adopting a construction method for pouring by adopting a symmetrical hanging basket cantilever at two sides, and constructing an nth block to a (n+m)th block of the side-span and the like. The counterweight system provided by the invention comprises the scaffold foundation and the counterweight structure system. A combined construction technology of a main beam front-support-point hanging basket cantilever pouring method and a bracket cast-in-place method is adopted and two technologies are combined together, so that a side-span main beam which cannot meet hanging basket cantilever pouring is constructed; meanwhile, a mid-span main beam and the side-span main beam are symmetrically constructed and a stress state of a cable-stayed bridge is wholly met; a working period is shortened and the construction cost is reduced.

Owner:BEIJING URBAN CONSTR ROAD & BRIDGE GROUP

Threaded sleeve and T-shaped node of short U-shaped steel connection type steel concrete combined pipes

PendingCN109944363AImprove connection strengthMeet the forceWallsProtective buildings/sheltersEarthquake resistanceConnection type

The invention discloses a threaded sleeve and T-shaped node of short U-shaped steel connection type steel concrete combined pipes. The threaded sleeve and the T-shaped node comprise a first steel concrete combined pipe and a second steel concrete combined pipe, wherein the first steel concrete combined pipe and the second steel concrete combined pipe are vertically arranged mutually; an end steelplate is exposed from the rear end of the second steel concrete combined pipe; an internal thread sleeve is embedded in a first concrete layer at the front side of the first steel concrete combined pipe; the front half section of the internal thread sleeve is in threaded connection with a connecting screw rod; the rear side surface of the end steel plate is welded to a U-shaped steel; installationholes are formed in the left side and right side of the U-shaped steel; and the front end of the connecting screw rod penetrates through the installation holes and connects the U-shaped steel integrally. The threaded sleeve and the T-shaped node can greatly improve the connection strength of the T-shaped node between the two steel concrete combined pipes, ensures the reliability of connection, combines a cast-in-place mode and prefabrication, is convenient for construction, has high construction efficiency, ensures the construction quality, and completely meets the use requirements of integral stress, energy saving, earthquake resistance and the like of modern assembly-type buildings.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Integral arched beam connection structure and construction method thereof for upper supporting type steel tied arch bridge

PendingCN110258291AImprove integrityStable force transmissionBridge structural detailsBridge erection/assemblyStructural integrityArch bridge

The invention discloses an integral arched beam connection structure and construction method thereof for an upper supporting type steel tied arch bridge. The connection structure is used for connecting a main beam and a main arch, and comprises two groups of web plate assemblies, wherein the two groups of web plate assemblies are arranged at both sides of the main beam along the bridge direction; each group of web plate assembly comprises two integral web plates, wherein each integral web plate includes a transverse top edge, an arc-shaped bottom plate, a first vertical side edge, a second vertical side edge, a transverse middle edge, an inclined side edge and an arc edge; a main beam top plate is arranged between the two transverse top edges of the two groups of the web plate assemblies, and a main beam bottom plate is arranged between the two transverse middle edges of the two groups of the web plate assemblies, and main beam separation partitions are arranged between the main beam top plate and the main beam bottom plate at intervals; and a main arch top plate is arranged at the top ends of the inclined side edges of the web plate assemblies and perpendicular to the inclined side edges, and the main arch top plate extends upward into the main beam and is fixedly connected with the main bean partition plates. According to the integral arched beam connection structure of the upper supporting type steel tied arch bridge, the main beam and the main arch are connected through integral web plates, thus increasing structural integrity, guaranteeing smooth force transmission of the structure and improving the stability of the structure.

Owner:湖北省城建设计院股份有限公司

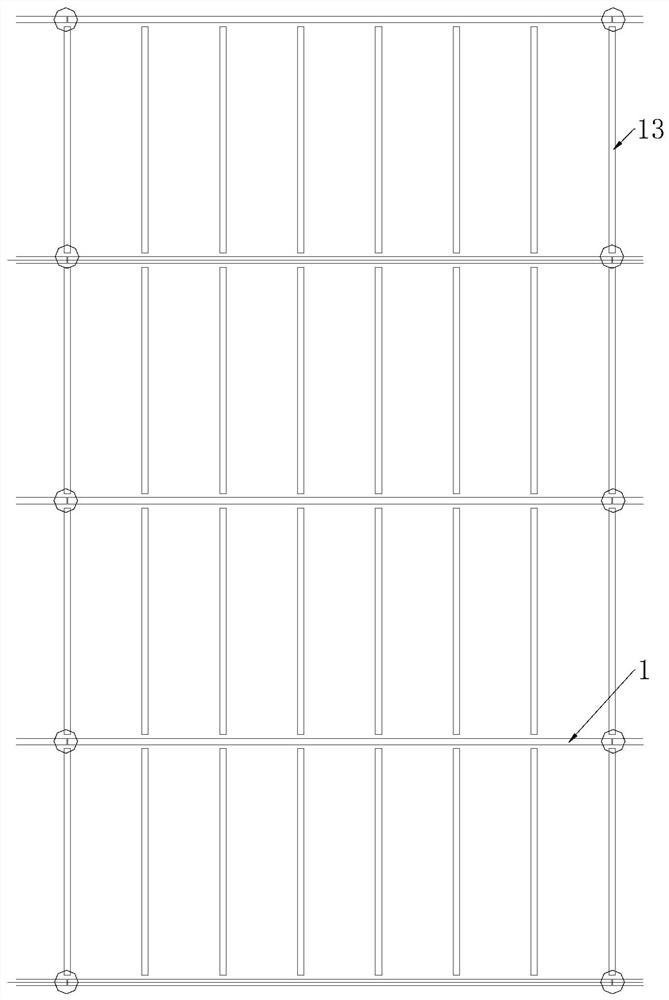

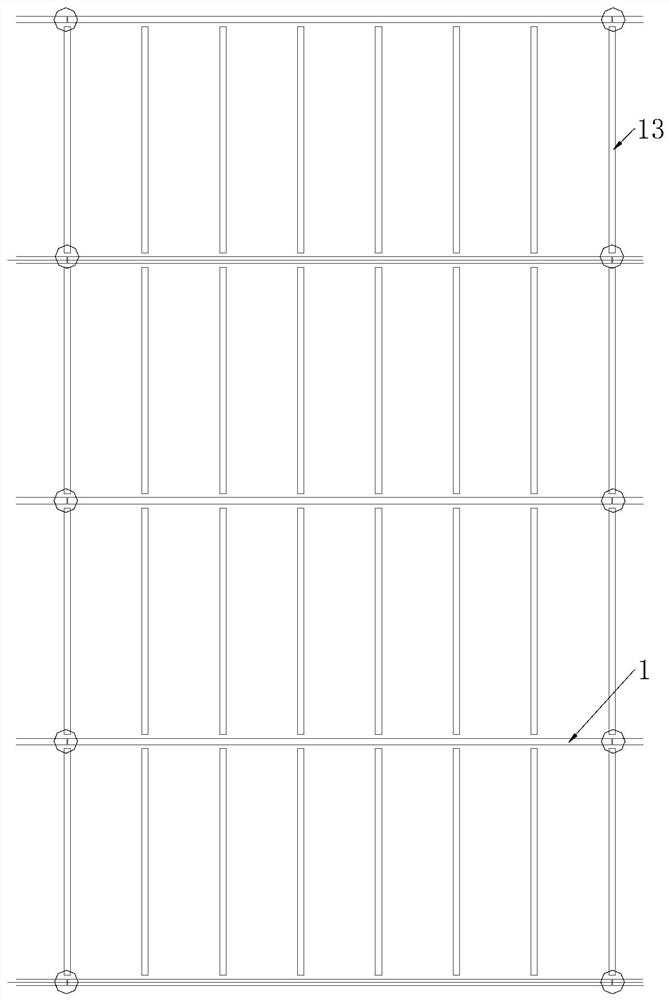

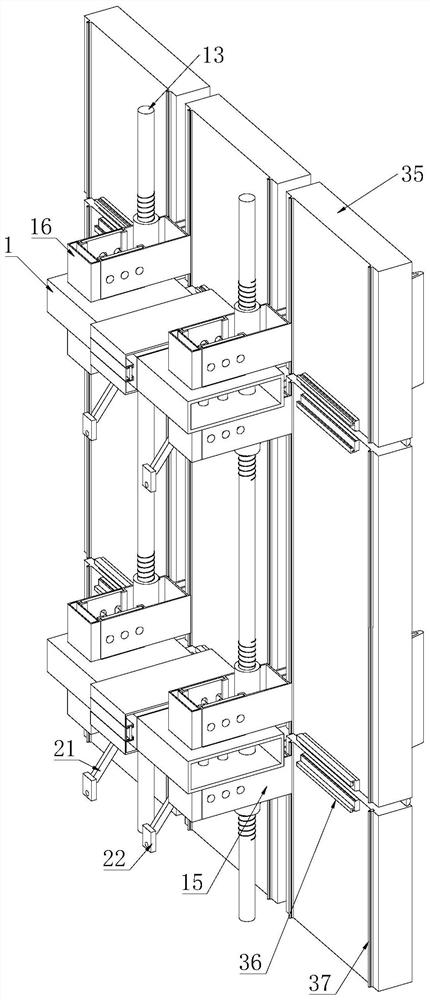

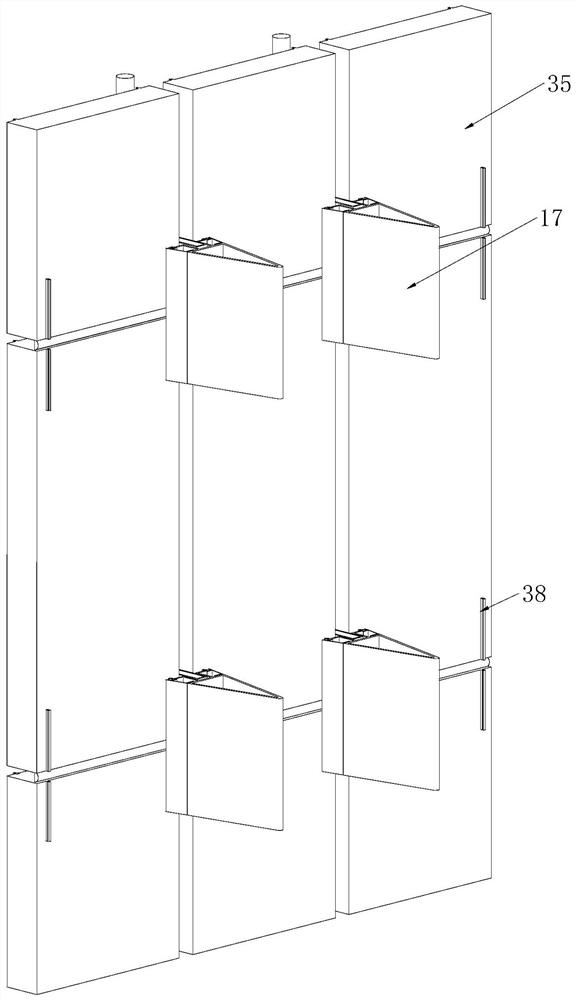

Large-span curtain wall composite structure and installation method thereof

The invention discloses a large-span curtain wall composite structure and an installation method thereof, and belongs to the technical field of large-span curtain wall installation. The large-span curtain wall composite structure comprises steel through large cross beams arranged on a wall body and glass blocks arranged on the steel through large cross beams, pull rod paired holes and a plurality of sets of bolt paired holes are formed in the tops and the bottom sides of the steel through large cross beams at equal intervals, one pull rod paired hole corresponds to one set of bolt paired holes, first machine screw holes are formed in the sides, close to the wall body, of the steel through large cross beams, bent steel plates corresponding to the first machine screw holes are arranged on the sides, away from the wall body, of the steel through large cross beams, the first machine screw holes, the bent steel plates, the pull rod paired holes and the bolt holes are distributed alternately, and therefore, stress of a large-span full-height space curtain wall framework can be achieved and met, occupied indoor space of a vertical framework is reduced, the indoor area utilization rate is increased, and the large-span curtain wall composite structure is reasonable in structural stress, convenient and fast to install, good in coordination, good in economical efficiency and good in attractiveness.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

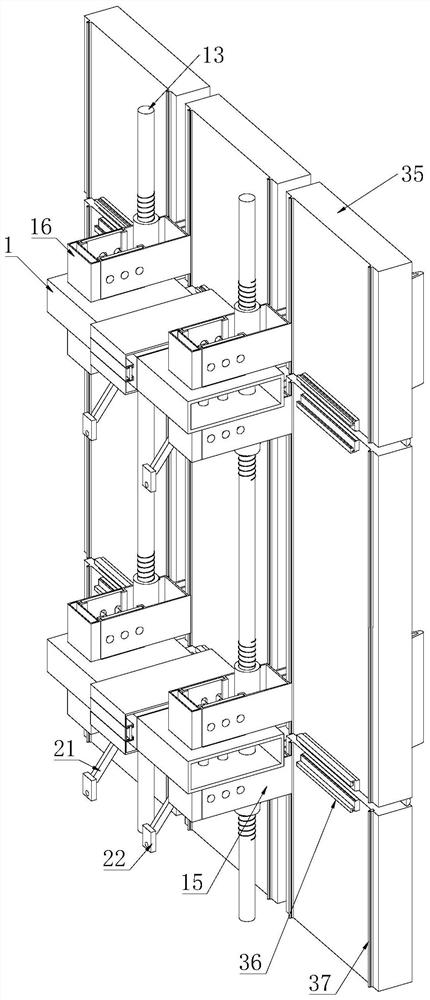

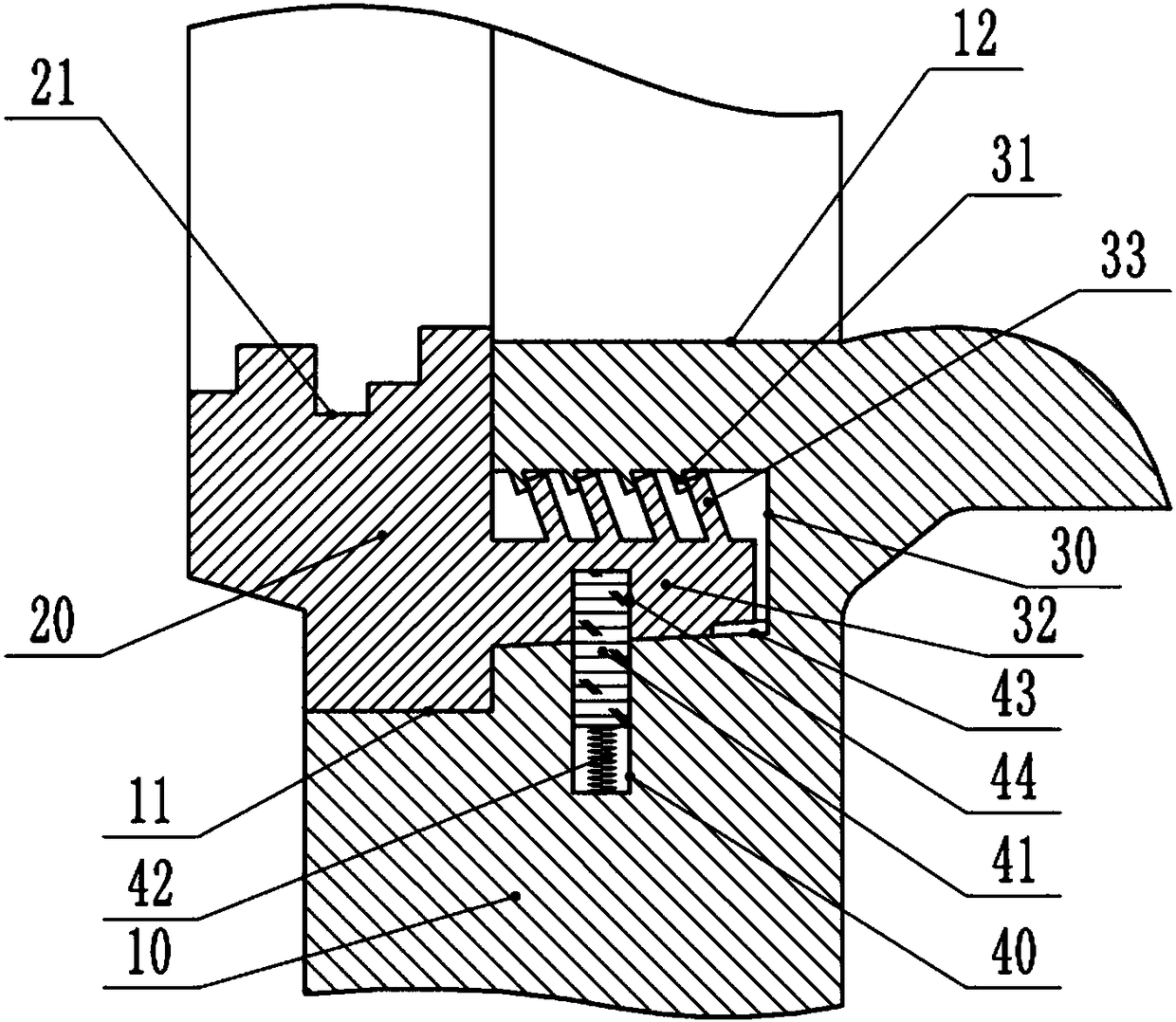

Quick butt joint fine-tuning device for upper layer and lower layer of steel-concrete combined pipes

PendingCN110016971AImprove work efficiencyMeet the forceBuilding constructionsEarthquake resistanceButt joint

The invention discloses a quick butt joint fine-tuning device for an upper layer and a lower layer of steel-concrete combined pipes. The device comprises an upper rectangular flange and a lower rectangular flange which are horizontally arranged, a plurality of positioning plates are fixedly arranged on the inner wall of a rectangular hole in the upper rectangular flange, the lower side edge of each positioning plate extends into the rectangular hole of the lower rectangular flange, the lower side edge of each positioning plate is fixedly connected with a wedge-shaped clamping plate, the upperend of each wedge-shaped clamping plate is in contact with the lower side face of the lower rectangular flange, and the thickness of the lower side portion of each wedge-shaped clamping plate is smaller than that of the corresponding positioning plate. According to the invention, the butt joint speed between the upper and lower layers of the steel-concrete combined pipes can be greatly improved, atemporary fixing mode of buckles after butt joint is adopted, the upper layer steel-concrete combined pipe does not need to be hoisted all the time in the whole butt joint process of a crane, the operation efficiency of the crane is improved, the perpendicularity between the upper layer steel-concrete combined pipe and the lower layer steel-concrete combined pipe can be finely adjusted, the buttjoint quality and firmness are ensured, and the overall stress, energy conservation, earthquake resistance and other use requirements of modern fabricated buildings are completely met.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Foundation pit steel support and its installation method

ActiveCN111088799BMeet the forceShorten the construction periodExcavationsArchitectural engineeringStructural engineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

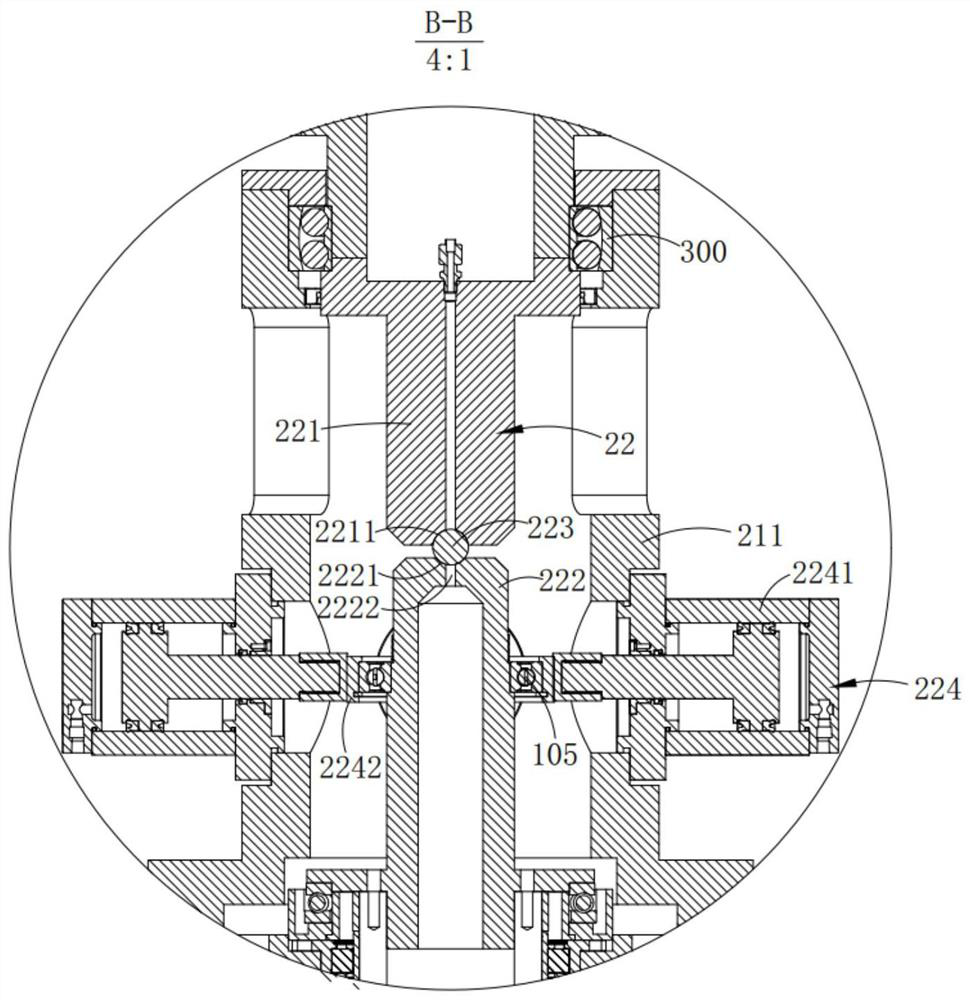

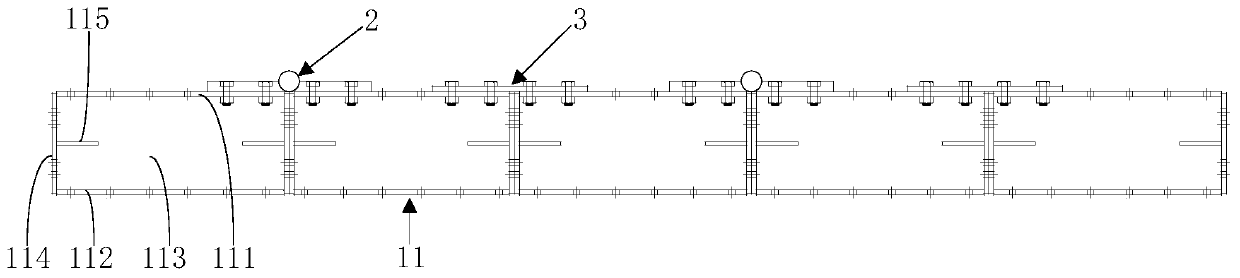

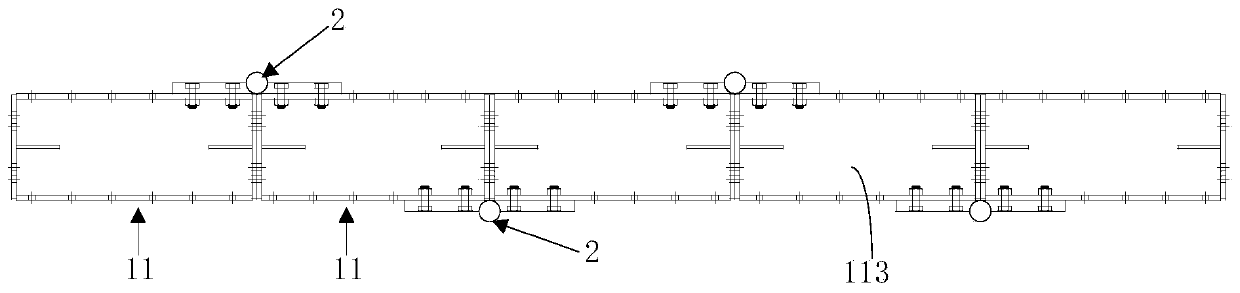

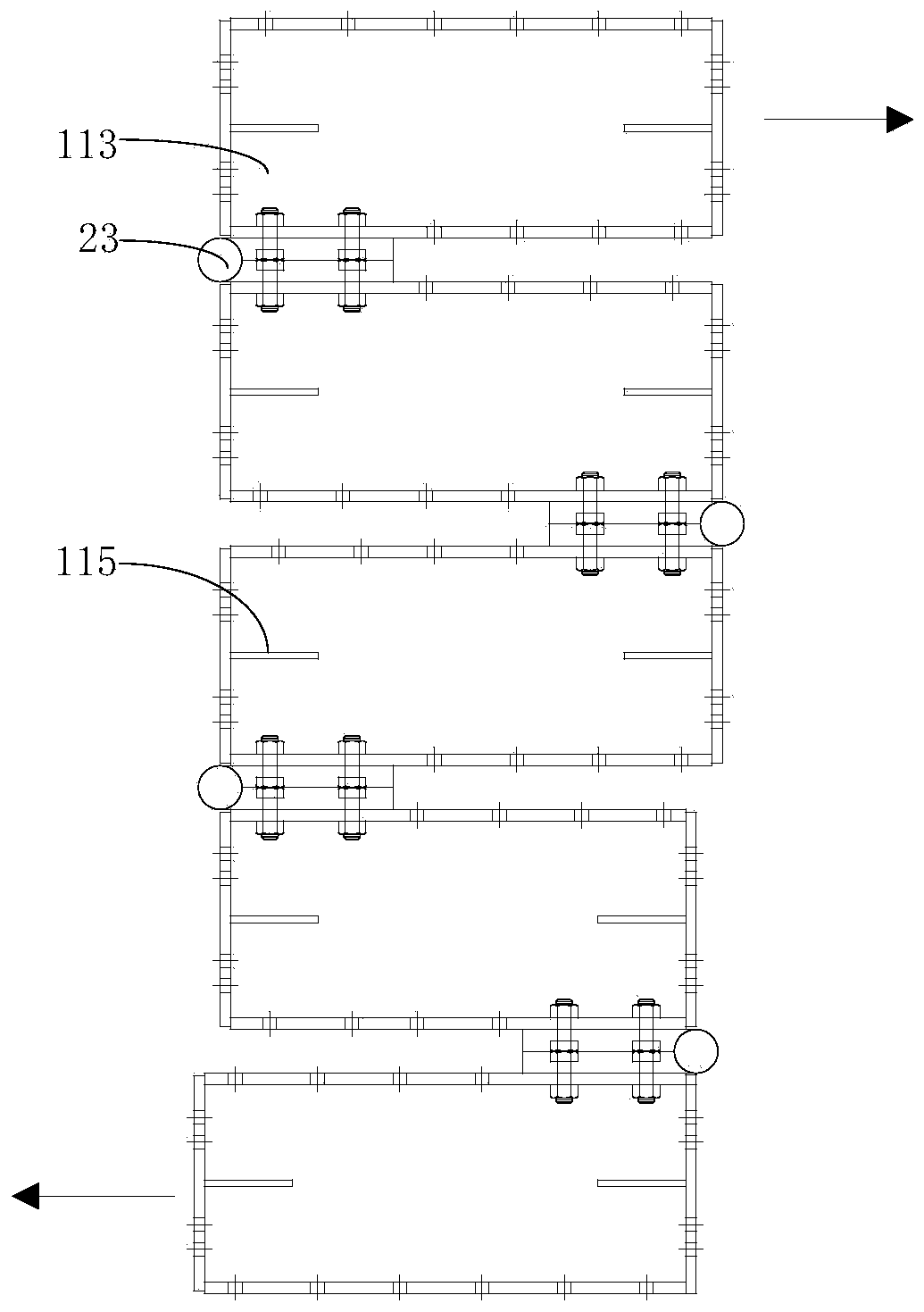

Engine input end shafting bearing testing machine and testing method

PendingCN113532859AImprove test accuracyImprove test efficiencyMachine bearings testingAircraft components testingDrive shaftControl engineering

The invention provides an engine input end shafting bearing testing machine, which comprises a loading system arranged below the top of a rack; a dual-rotor system which is connected with the output end of the loading force of the loading system; an input end bearing test system which is in transmission connection with the rotor power unit, the input end bearing test system comprises: an output bearing seat; and a transmission shaft; the double-rotor system is loaded through the loading system, the double-rotor system is driven to swing, then the rotor power unit is driven to swing, a transmission shaft in transmission connection with the rotor power unit is subjected to the vertical swing action of the rotor power unit, and a sixth test bearing is subjected to radial force and axial force and rotates at a high speed at the same time, the performance test of the sixth test bearing of the input end bearing is completed while the test of the to-be-tested bearing pack is completed, and the device is compact in structure, high in test precision and high in test efficiency.

Owner:中浙高铁轴承有限公司

Foundation pit steel support and installing method thereof

ActiveCN111088799AMeet the forceShorten the construction periodExcavationsArchitectural engineeringStructural engineering

Owner:CHINA CONSTR EIGHT ENG DIV CORP LTD

A large-span curtain wall composite structure and its installation method

The invention discloses a large-span curtain wall composite structure and an installation method thereof, belonging to the technical field of large-span curtain wall installation. The top and bottom sides of the large steel beam are equally spaced with tie rod pairs and multiple sets of bolt pairs, one tie rod pair corresponds to a group of bolt pairs, and the steel through beam is close to one of the walls. The side is provided with a first wire hole, the side of the large steel beam away from the wall is provided with a bending steel plate corresponding to the first wire hole, and the first wire hole and the bending steel plate are opposite to the tie rod. The holes and bolts are alternately distributed to the holes, which can be realized to meet the force of the curtain wall skeleton of the large-span double-height space, reduce the indoor space occupation of the vertical skeleton, and improve the utilization rate of the indoor area. Good coordination, good economy and good aesthetics.

Owner:SHENZHEN GRANDLAND DECORATION GROUP

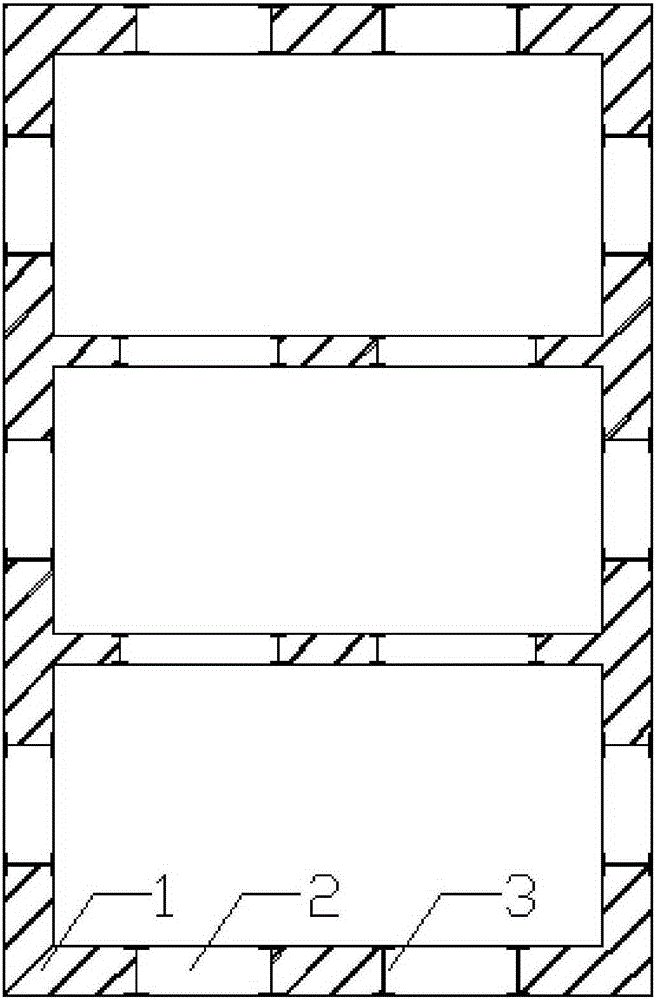

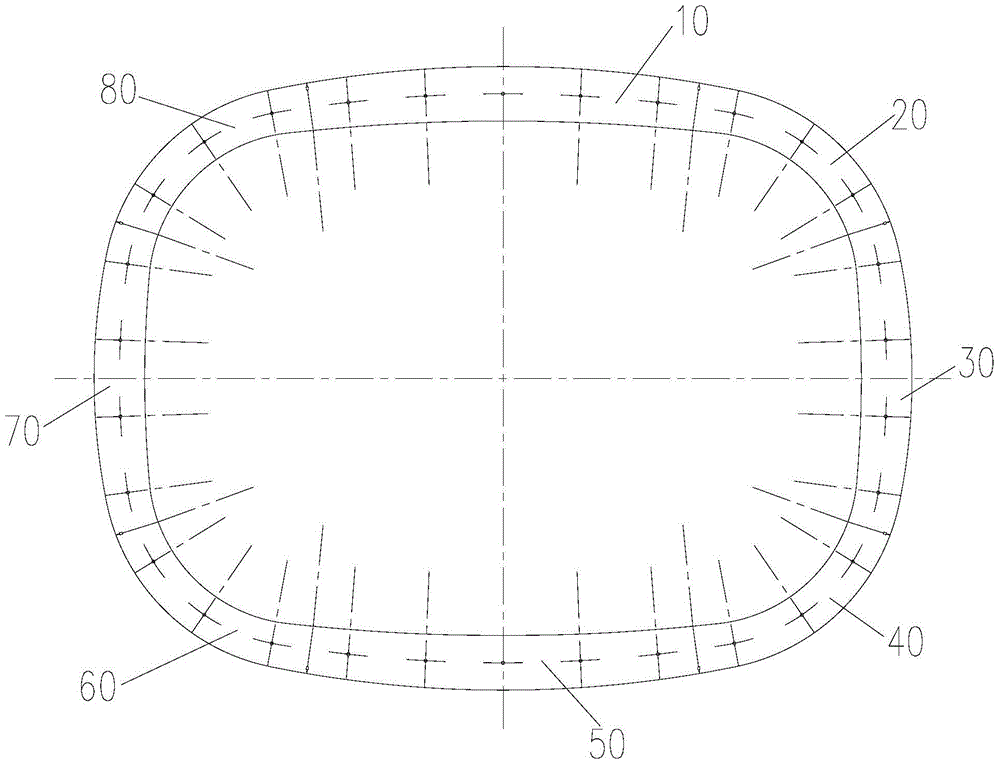

Circumferential block structure of prefabricated rectangular shield tunnel lining

ActiveCN104405408BImprove the forceMeet the forceUnderground chambersTunnel liningEngineeringMechanical engineering

The invention discloses an annular partitioning structure of an assembled type rectangular shield tunnel lining. The annular partitioning structure consists of a top inverted arch partitioning block, a first corner part partitioning block, a first side wall partitioning block, a second corner part partitioning block, a bottom inverted arch partitioning block, a third corner part partitioning block, a second side wall partitioning block and a fourth corner part partitioning block which are connected in series in sequence in the annular direction, wherein the fourth corner part partitioning block is also connected with the top inverted arch partitioning block to integrally form a closed ring in a surrounding manner; splicing joints between the adjacent partitioning blocks are positioned at positions, which are lower in stress, on the lining. The splicing joints of all the partitioning blocks are positioned at positions, which are lower in stress, on the lining, so that stress on the partitioning blocks can be easily met; correspondingly, the partitioning blocks at the regions, which are higher in stress, on the lining are continuously arranged, so that the stress performance of the lining is effectively guaranteed; therefore the annular partitioning structure of the lining can better adapt to the stress characteristic of a rectangular shield tunnel, and the water resistance and the waterproofing capacity of the tunnel are effectively improved.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

Clamping-ring-type front driving axle housing assembly

PendingCN108357301AReduce processing difficulty and production costGood performanceAxle unitsRolling resistance optimizationAutomotive engineering

The invention belongs to the technical field of pick-up front driving axle housings, and particularly discloses a clamping-ring-type front driving axle housing assembly. The clamping-ring-type front driving axle housing assembly comprises a front driving axle housing and a clamping ring, and a clamping spring groove is machined in the clamping ring; an inner hole is formed in the front driving axle housing, an axle hole coaxial to the inner hole is formed in one end of the front driving axle housing, and one end of the outer part of the clamping ring is pressed into the axle hole through pressure. Compared with the prior art, the front driving axle housing assembly is low in machining difficulty, low in production cost and wide in applicability.

Owner:CHONGQING CAFF AUTOMOTIVE BRAKING & STEERING SYST

Measuring structure of shaft rotating speed of ship propeller under internal and external pressure

The invention relates to the field of marine propulsion, in particular to a measuring structure of the shaft rotating speed of a ship propeller under internal and external pressure. The measuring structure of the shaft rotating speed of the ship propeller under internal and external pressure comprises a closed cavity and a main shaft, wherein the closed cavity is composed of a bearing support andinternally provided with an annular contact type rotating speed sensor; and the main shaft penetrates through the annular contact type rotating speed sensor in a clearance fit mode, the main shaft isfurther connected with a set of bearing cavities, the bearing cavitiescompriseshaft sleeves, lip type seal rings, and bearings, O type seal ringsarearranged between the shaft sleeves and the main shaft,shaft couplings are furtherarranged at both ends of the main shaft, and a mechanical seal is connected with each inner sides of the shaft couplings. According to the measuring structure of the shaftrotating speed of the ship propeller under internal and external pressure,the measuring structure of the shaft rotating speedadopts the sealing designs of the mechanical seal, the O type seal, and the lip type seal and thus can bear bothpositivehydraulic pressure and negative hydraulic pressure, and the force and waterproof rating performance requirements of the high-precision rotating speed sensor are met.

Owner:708TH RES INST OF CSSC

T-shaped node of steel concrete combined pipe assembled by long channel steel and threaded sleeve

PendingCN109944364AImprove connection strengthMeet the forceWallsProtective buildings/sheltersEarthquake resistanceUltimate tensile strength

The invention relates to a T-shaped node of a steel concrete combined pipe assembled by long channel steel and a threaded sleeve, which comprises a first steel concrete combined pipe and a second steel concrete combined pipe, wherein the rear end part of a second rectangular steel plate structure exposes an end steel plate; an internal threaded sleeve is embedded in the front side of the first steel concrete combined pipe; the front half section of the internal threaded sleeve is in threaded connection with a connecting screw rod; the rear side surface of the end steel plate is welded with thelong channel steel; the left side and right side of the long channel steel are provided with transparent mounting holes respectively, the mounting holes and the internal threaded sleeve are in one-to-one correspondence, the front end of a connecting screw rod passes through the mounting holes and is threaded with a connecting nut, the connecting nut presses the rear side of the channel steel on the front side surface of the first steel concrete combined pipe. According to the invention, the node can greatly improve the connection strength of T-shaped nodes between the two steel concrete combined pipes and ensure the reliability of connection, combines cast-in-place casting and prefabrication, is convenient for construction, has high construction efficiency, can ensure the construction quality, and completely meets the use requirements of integral stress, energy saving, earthquake resistance and the like of modern assembled buildings.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

T-shaped node of steel concrete combined pipe with high shear strength

PendingCN109944361AAvoid unbalanced force damageGuaranteed reliabilityWallsProtective buildings/sheltersEarthquake resistanceSheet steel

The invention relates to a T-shaped node of a steel concrete combined pipe with high shear strength, which comprises a first steel concrete combined pipe and a second steel concrete combined pipe, wherein an end steel plate is exposed at the rear end portion of a second rectangular steel plate structure; an internal threaded sleeve is embedded in the front side of the first steel concrete combinedpipe; the front half section of the internal threaded sleeve is in threaded connection with a connecting stud; the rear side of the end steel plate is welded with a vertically arranged grooved steelplate; the left side plate of the grooved steel plate and the rear side of the right side plate are welded with a connecting plate; a plurality of anti-shear rod pieces are arranged in the grooved steel plate and are connected to the first steel truss combined pipe; the anti-shear rod pieces are evenly arranged in the vertical direction and are located between the left and right internal threadedsleeve. The T-shaped node of the steel concrete combined pipe with high shear strength can greatly improve the connection strength of T-shaped node between the two steel concrete combined pipes and ensure the reliability of connection; cast-in-place casting and prefabrication are combined, construction is convenient, construction efficiency is high, thereby ensuring the construction quality, and completely meeting the use requirements of integral stress, energy saving, earthquake resistance and the like of modern assembled buildings.

Owner:HENAN LYUJIAN BUILDING TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com