Railway tunnel bottom structure dynamic force model testing device and method

A technology of bottom structure and dynamic model, which is applied in the direction of measuring device, using stable tension/pressure test material strength, preparation of test samples, etc. Static force and other problems, to achieve the effect of simple structure and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The specific implementation manners of the present invention will be further described below in conjunction with the accompanying drawings and examples.

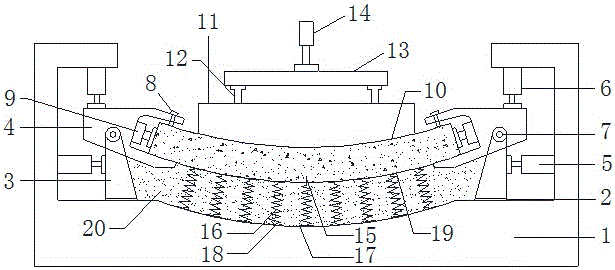

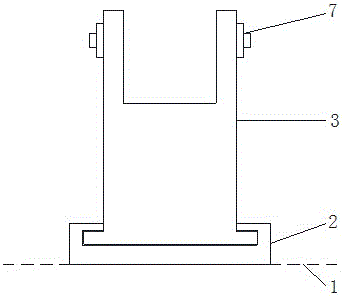

[0027] Such as figure 1 Shown: a dynamic model test device for the bottom structure of a railway tunnel, including a base 1, a basement surrounding rock simulation structure, a tunnel bottom simulation structure, a static loading device and a dynamic loading device;

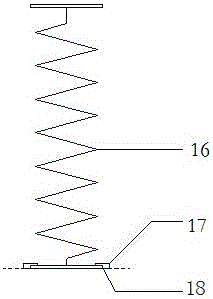

[0028] The surrounding rock simulation structure includes springs 16 and rubber particles 20 for simulating the elastic performance of the surrounding rock and simulating the damping performance of the surrounding rock. The lower end of the spring 16 is fixed on the base 1, and the upper end is fixed on the inverted arch 10. The rubber particles 20 are scattered between the springs 16;

[0029] The simulation structure at the bottom of the tunnel includes an inverted arch 10, a filling layer 11 and a steel rail 12, and the three are fixed sequentially f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com