Track beam for suspension type monorail traffic and suspension type monorail traffic bridge

A monorail and suspension technology, applied in the field of rail transportation, can solve the problems of restricting the application scope of the suspension monorail, affecting the driving comfort, and low torsional rigidity, so as to meet the problems of force and deformation control, expand the scope of application, Effect of large torsional stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

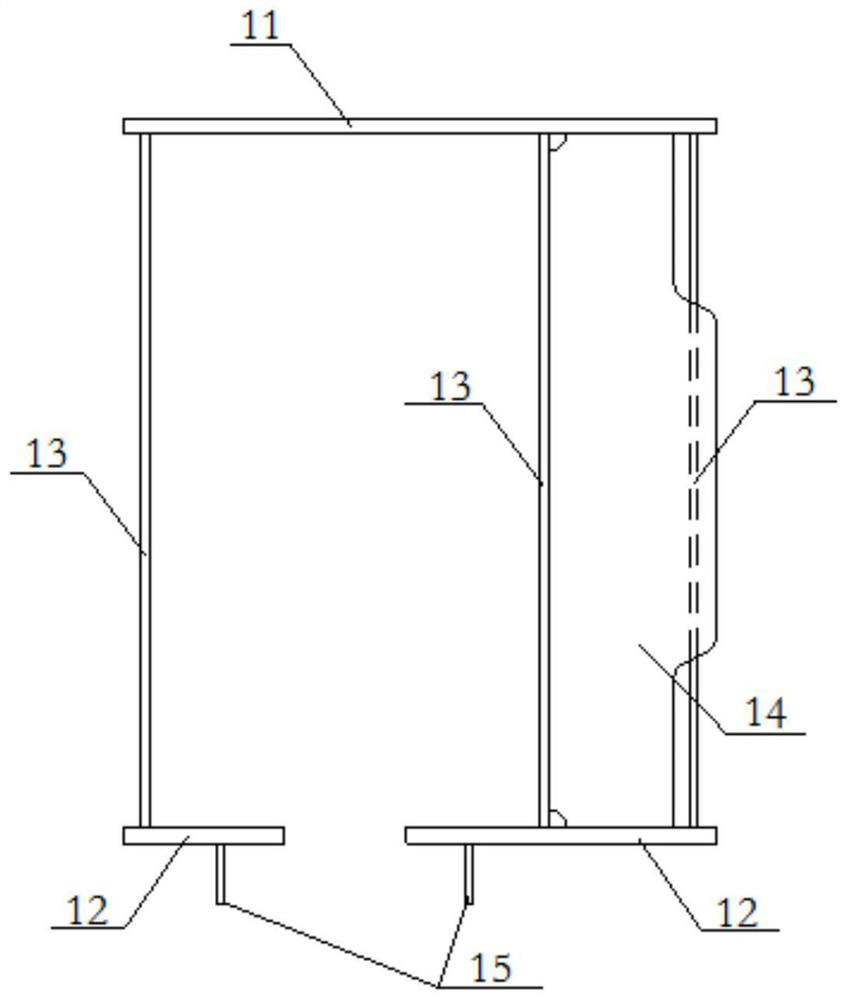

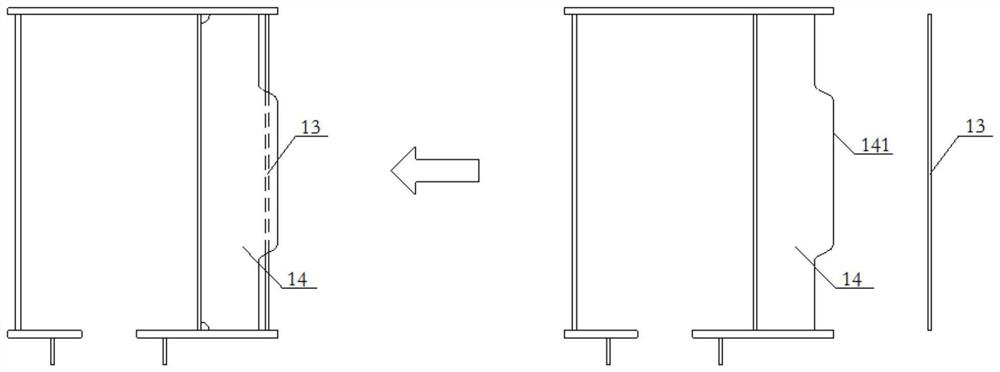

[0025]Such asFigure 1-Figure 4 , The embodiment of the present invention provides a rail beam 1 for suspended monorail transportation, comprising a beam top plate 11, an open beam bottom plate 12, and a plurality of beam webs 13 arranged in parallel and spaced apart. The plate surface of the beam web 13 Parallel to the longitudinal direction of the rail and connected to the beam top plate 11 and the beam bottom plate 12 at the upper and lower ends respectively, the beam webs 13 are distributed on both lateral sides of the running area of the beam bottom plate 12 and at least one of the beam webs 13 The quantity is not less than 2 to form the side box area.

[0026]The above-mentioned opening structure of the beam bottom plate 12 is a conventional technology in the art, and the length direction of the opening groove is parallel to the longitudinal direction of the track, which facilitates the arrangement and operation of bogies, etc.; generally, the left and right sides of the opening...

Embodiment 2

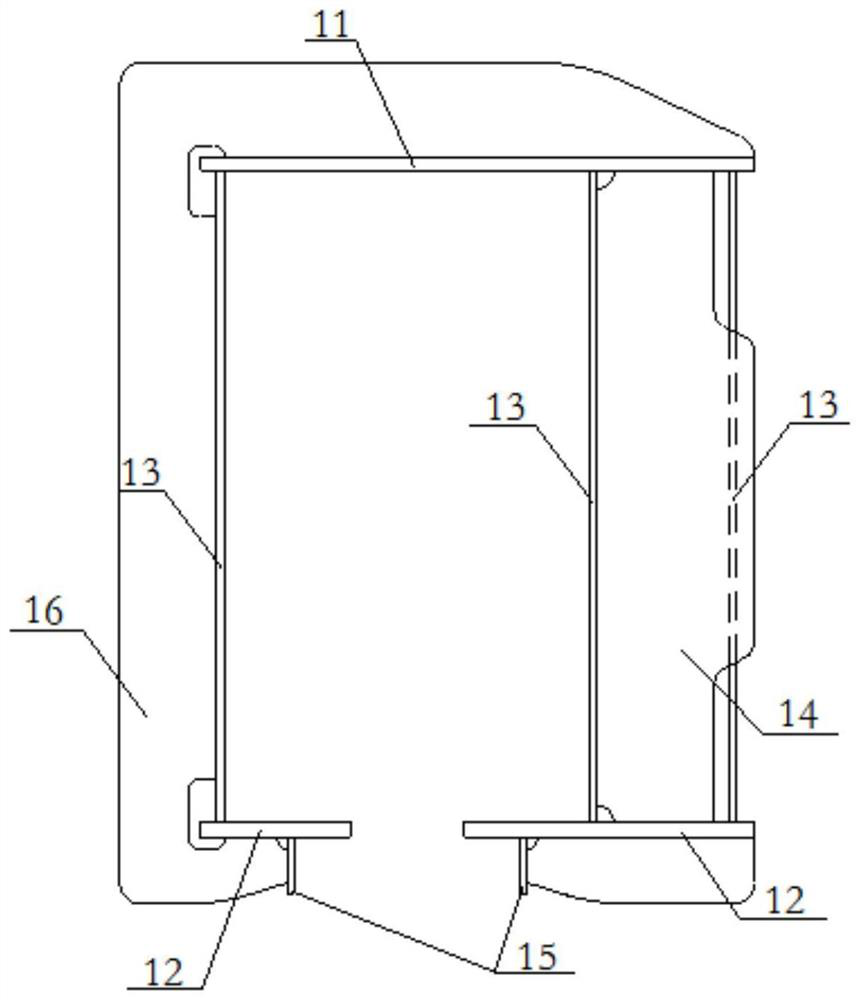

[0035]Such asFigure 5 withFigure 6 , The embodiment of the present invention provides a suspended monorail transportation bridge, including a supporting structure, and also includes two sets of track beams 1 for suspended monorail transportation provided in the first embodiment, and the two sets of track beams 1 pass through the cross beams 2 Connected, the transverse beam 2 is supported on the supporting structure.

[0036]As mentioned above, the track beam 1 has only one side box area and is located on the side of the track beam 1 close to the cross beam 2. The structural strength and rigidity of the corresponding beam section can be achieved by adjusting the width of the side box area; The span and curvature of the track beam 1 and different parts of the track beam 1 can adopt a uniform facade profile. Correspondingly, it can be connected to the cross beam 2 through the above-mentioned side box area, and the force transmission is smooth and the force is reliable.

[0037]As mentioned a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com