Integral arched beam connection structure and construction method thereof for upper supporting type steel tied arch bridge

The utility model relates to a tie-rod arch bridge and integral technology, which is applied to the integral arch-beam connection structure of an upper-supported steel tie-rod arch bridge and its construction field. Bridge accident, simplified construction steps, and the effect of less construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The implementation of the present invention will be described in detail below in conjunction with the examples of implementation, but they do not constitute a limitation of the present invention, and are only examples. At the same time, the advantages of the present invention will become clearer and easier to understand.

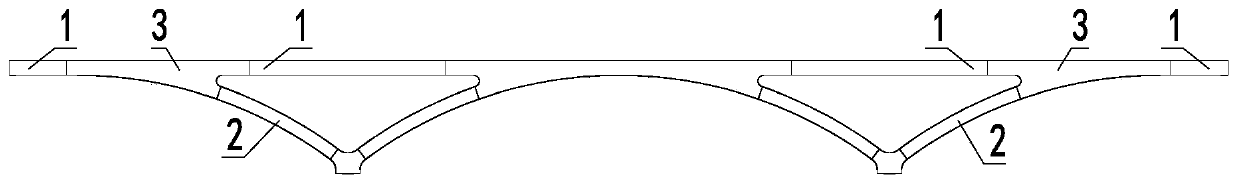

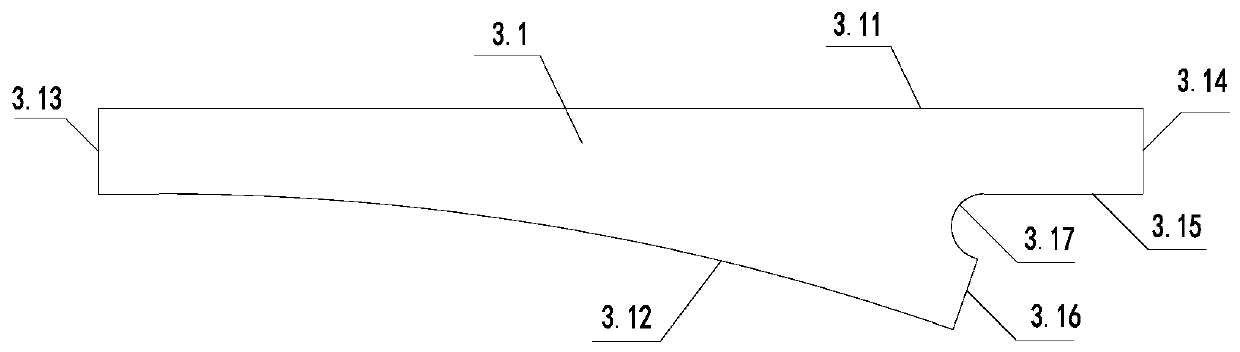

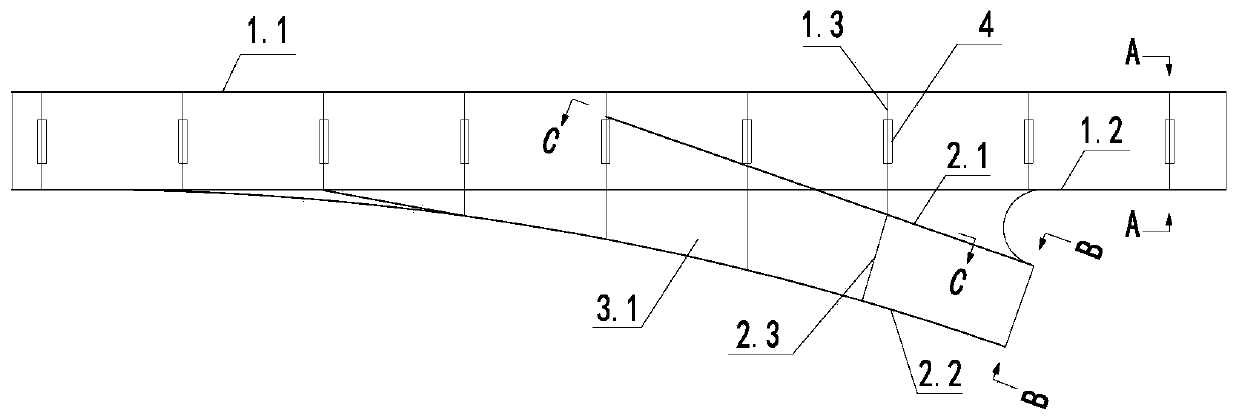

[0033] As shown in the figure, an integral arch-girder connection structure of a steel tie-bar arch bridge is used to connect the main beam 1 and the main arch 2. The main beam 1 includes the main beam top plate 1.1 and the main beam bottom plate 1.2, and the main arch 2 includes The main arch top plate 2.1 and the main arch bottom plate 2.2 include two sets of web assemblies 3 arranged on both sides of the main girder 1 along the bridge direction. Each set of web assemblies 3 includes two integral webs 3.1, and the integral web 3.1 includes transverse Top edge 3.11, curved bottom plate 3.12, first vertical side edge 3.13, second vertical side edge 3....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com