Patents

Literature

94results about How to "Stable force transmission" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

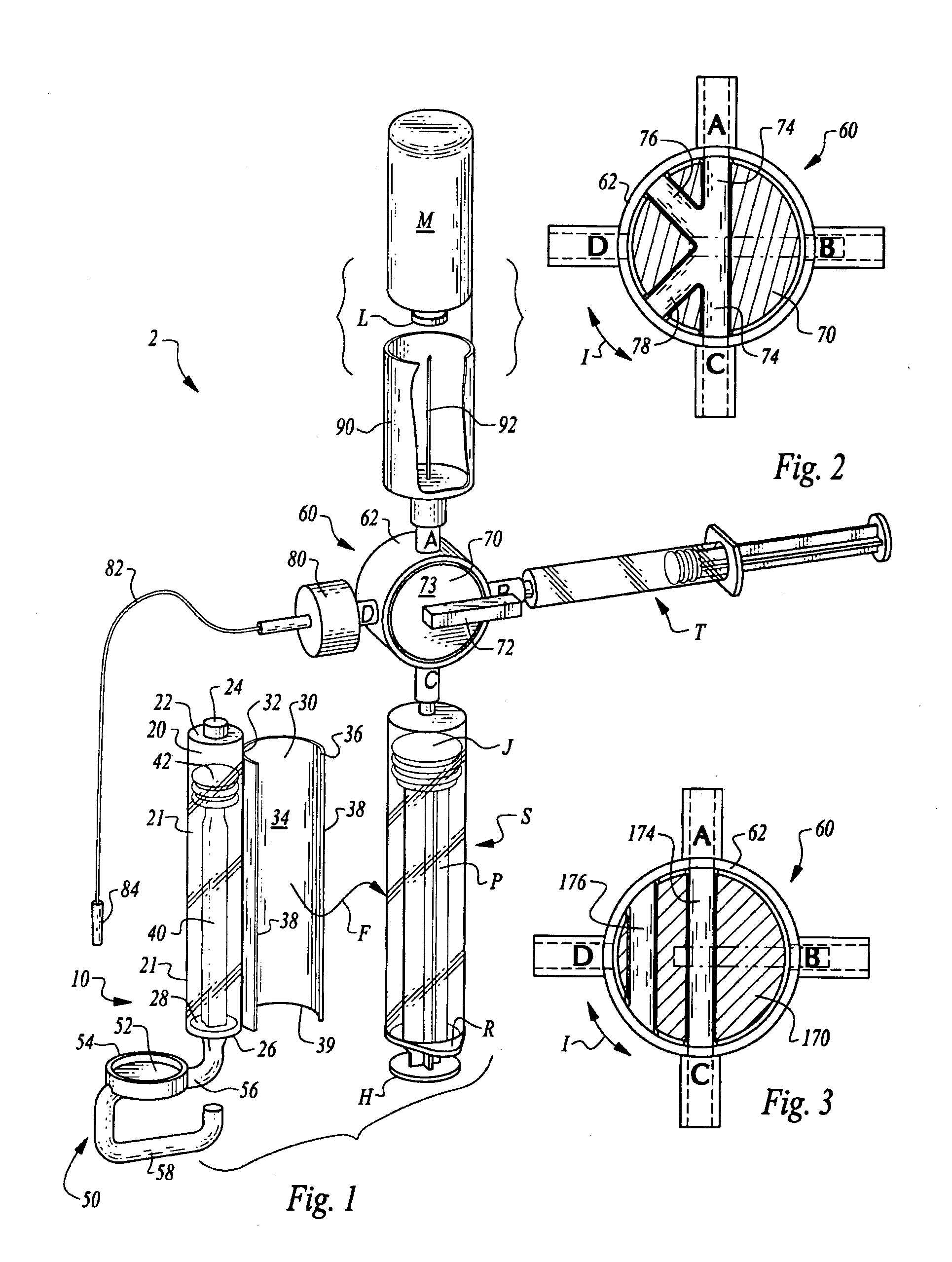

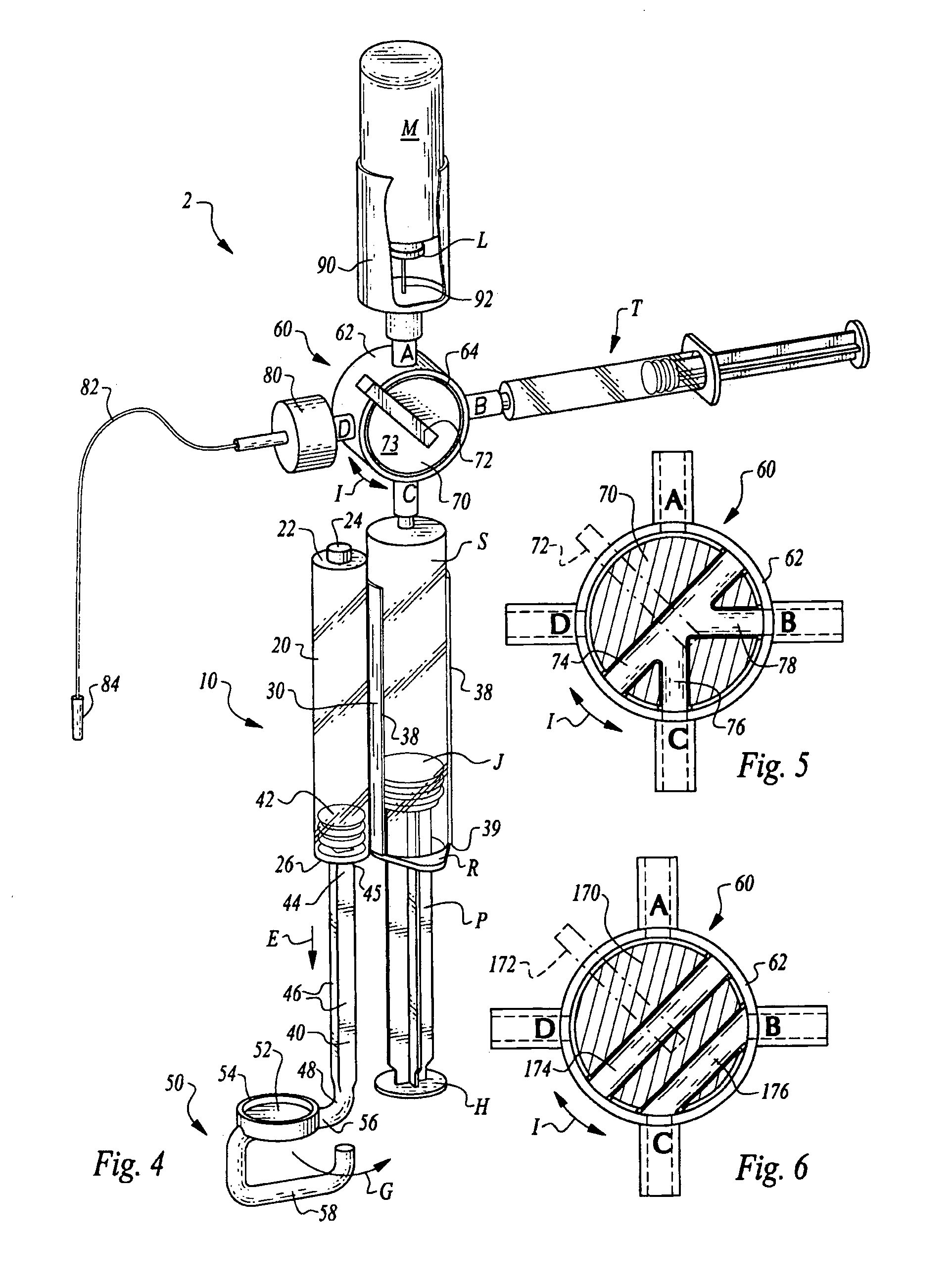

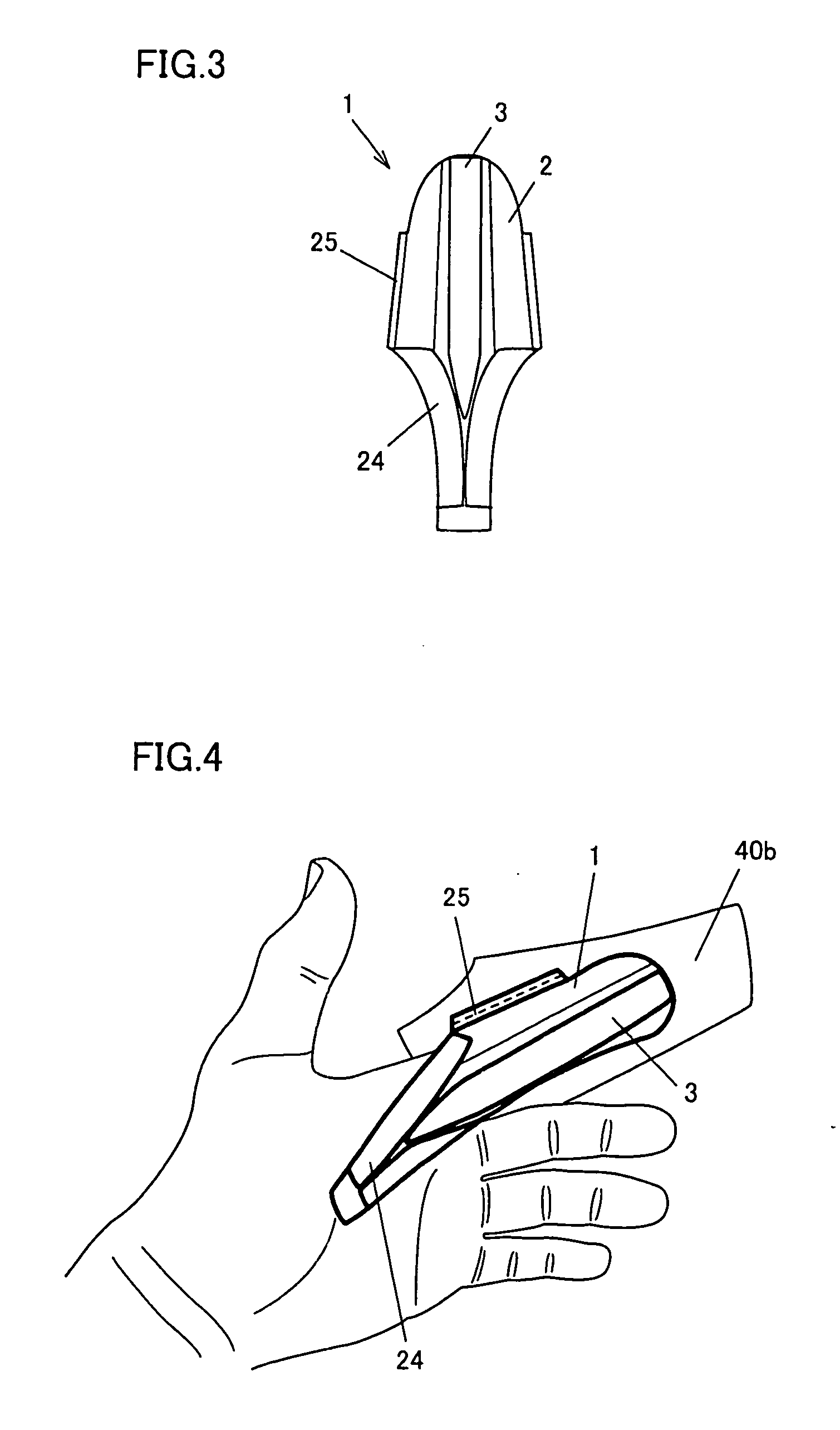

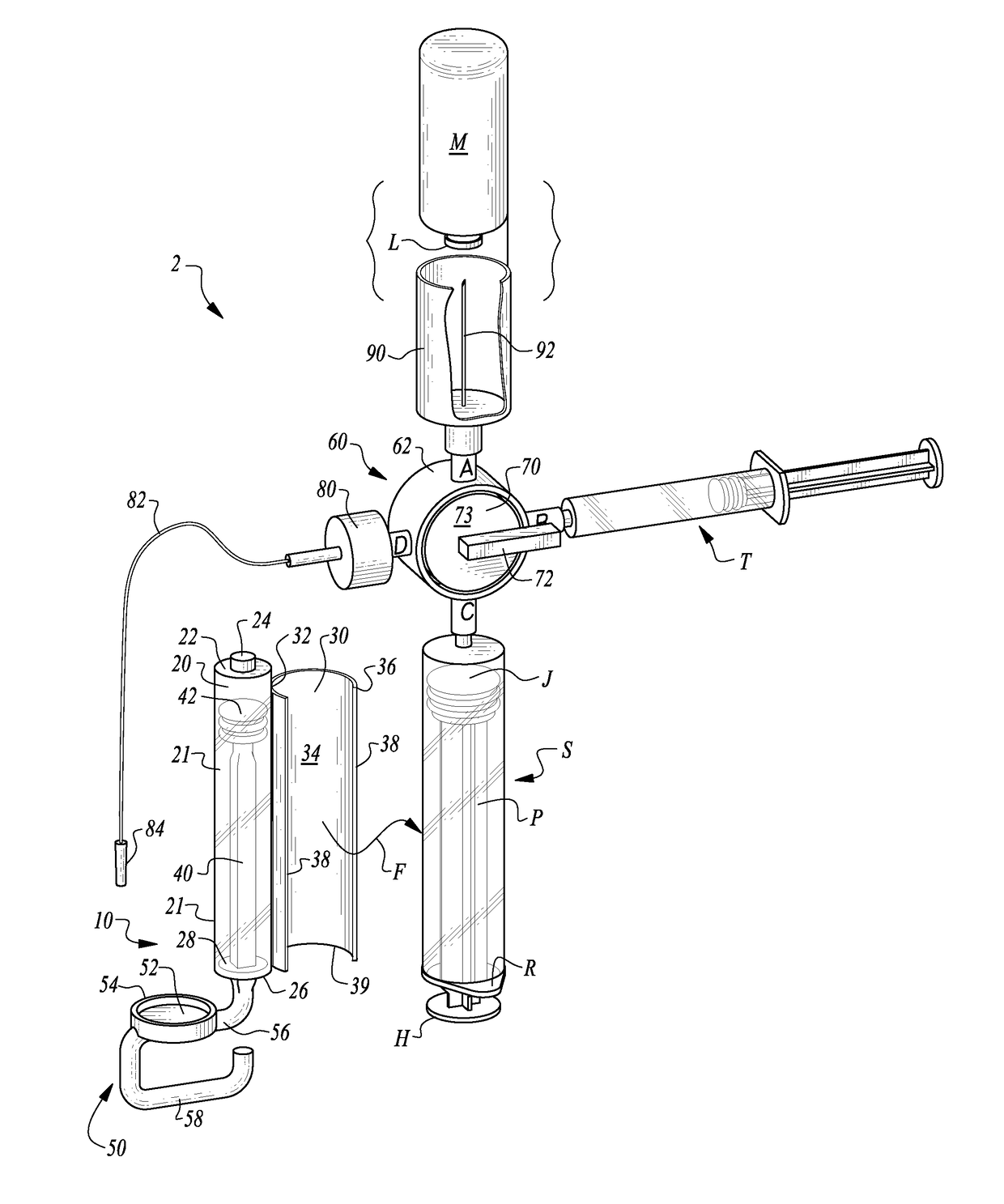

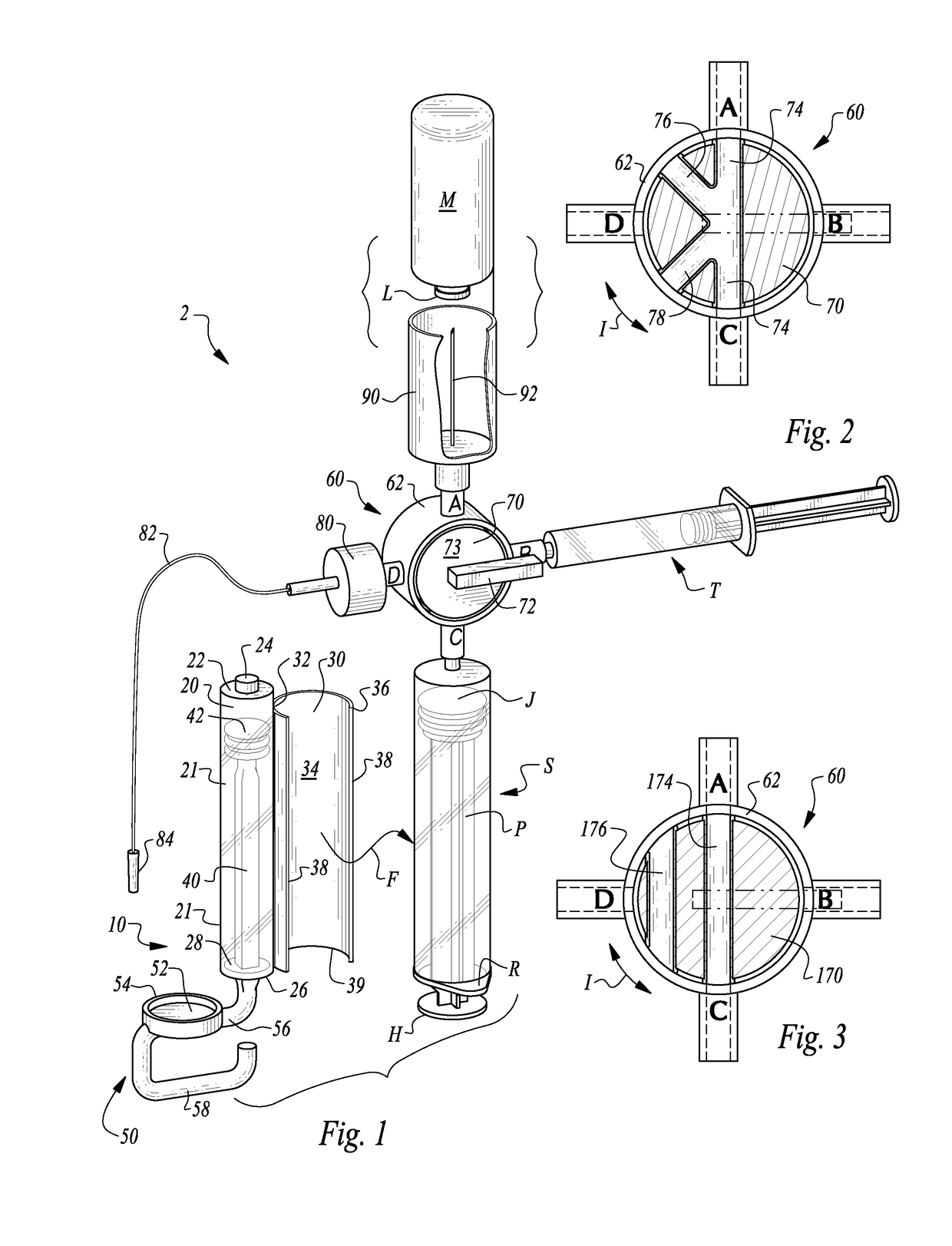

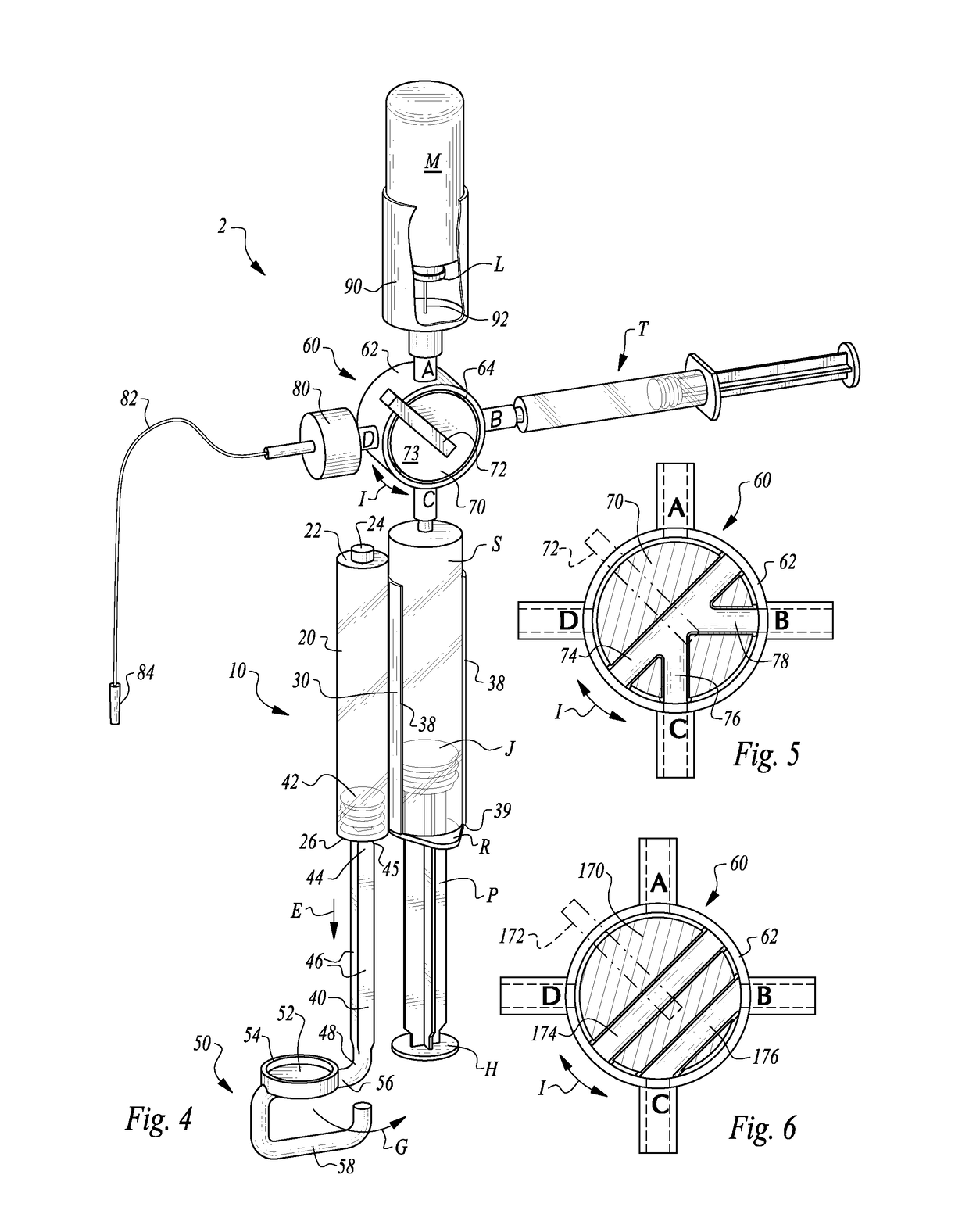

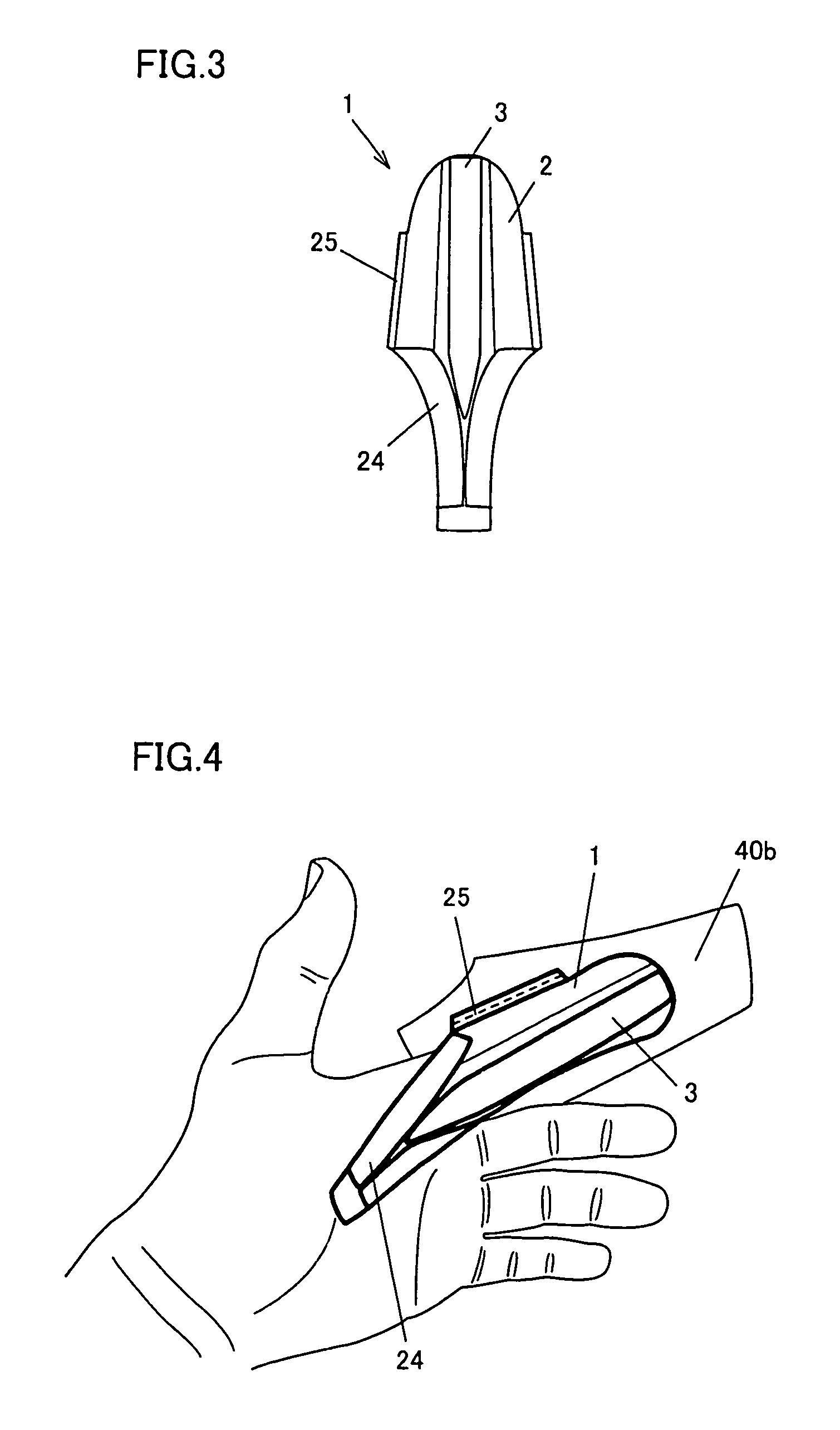

Compact non-electric medicament infuser

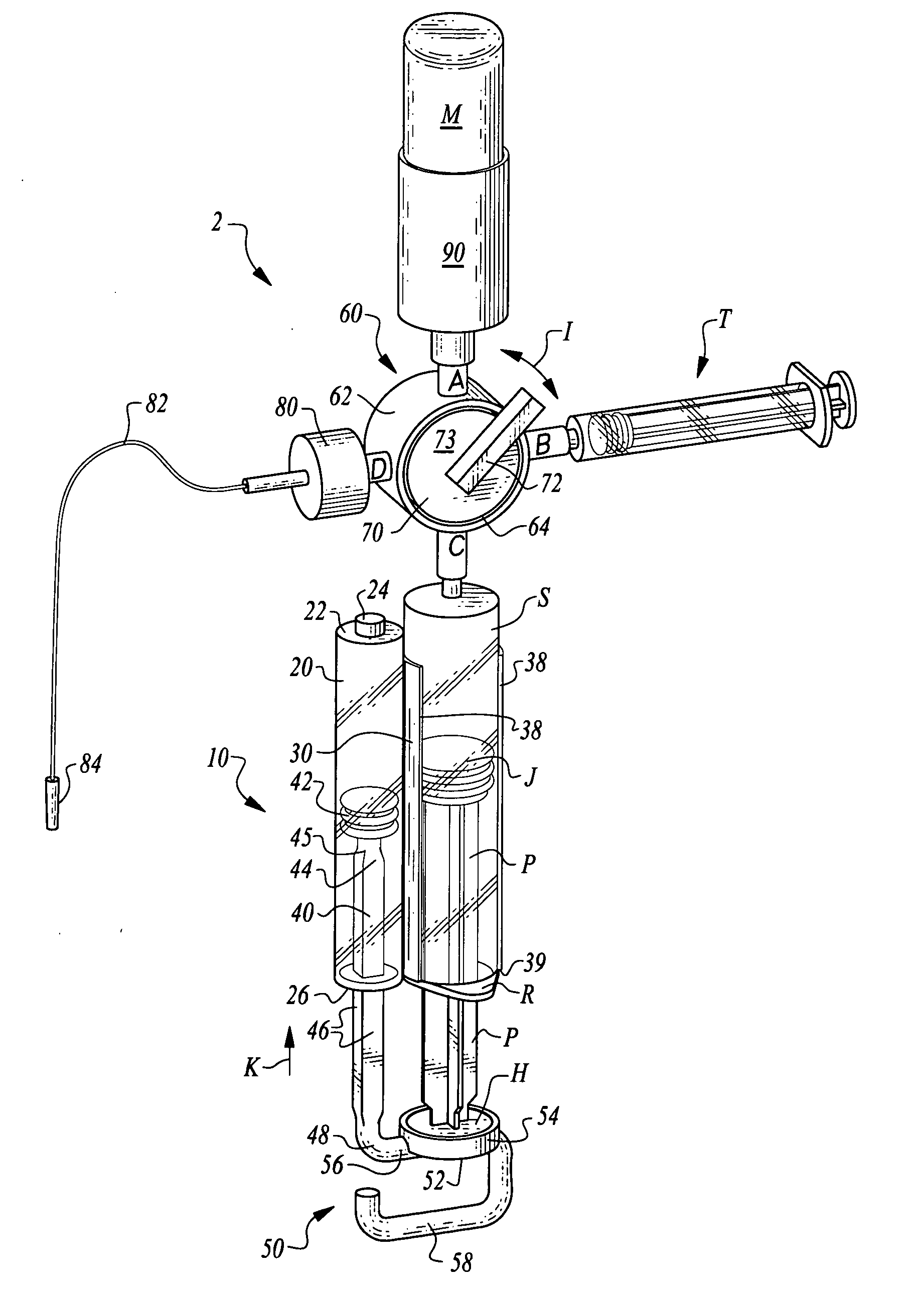

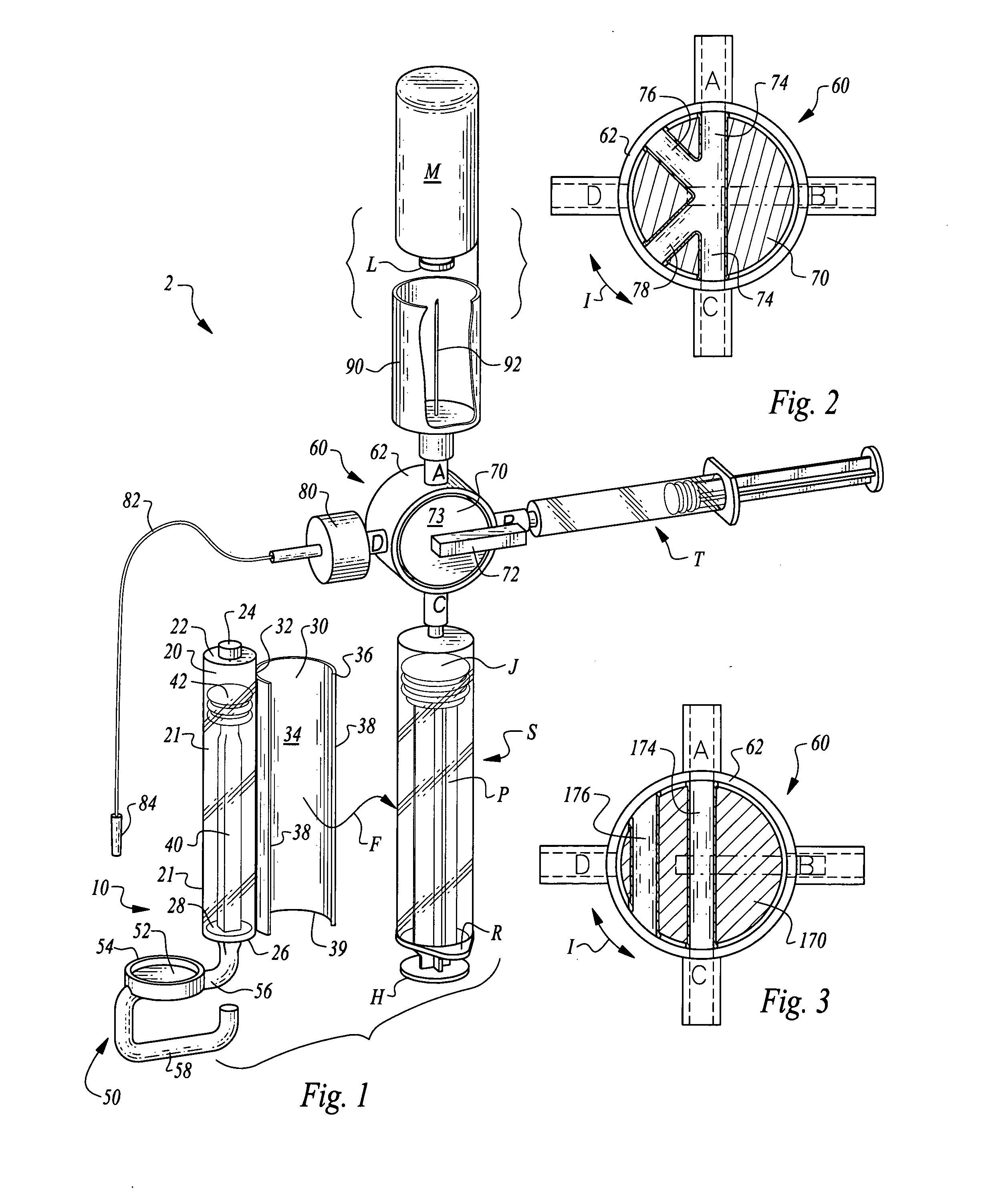

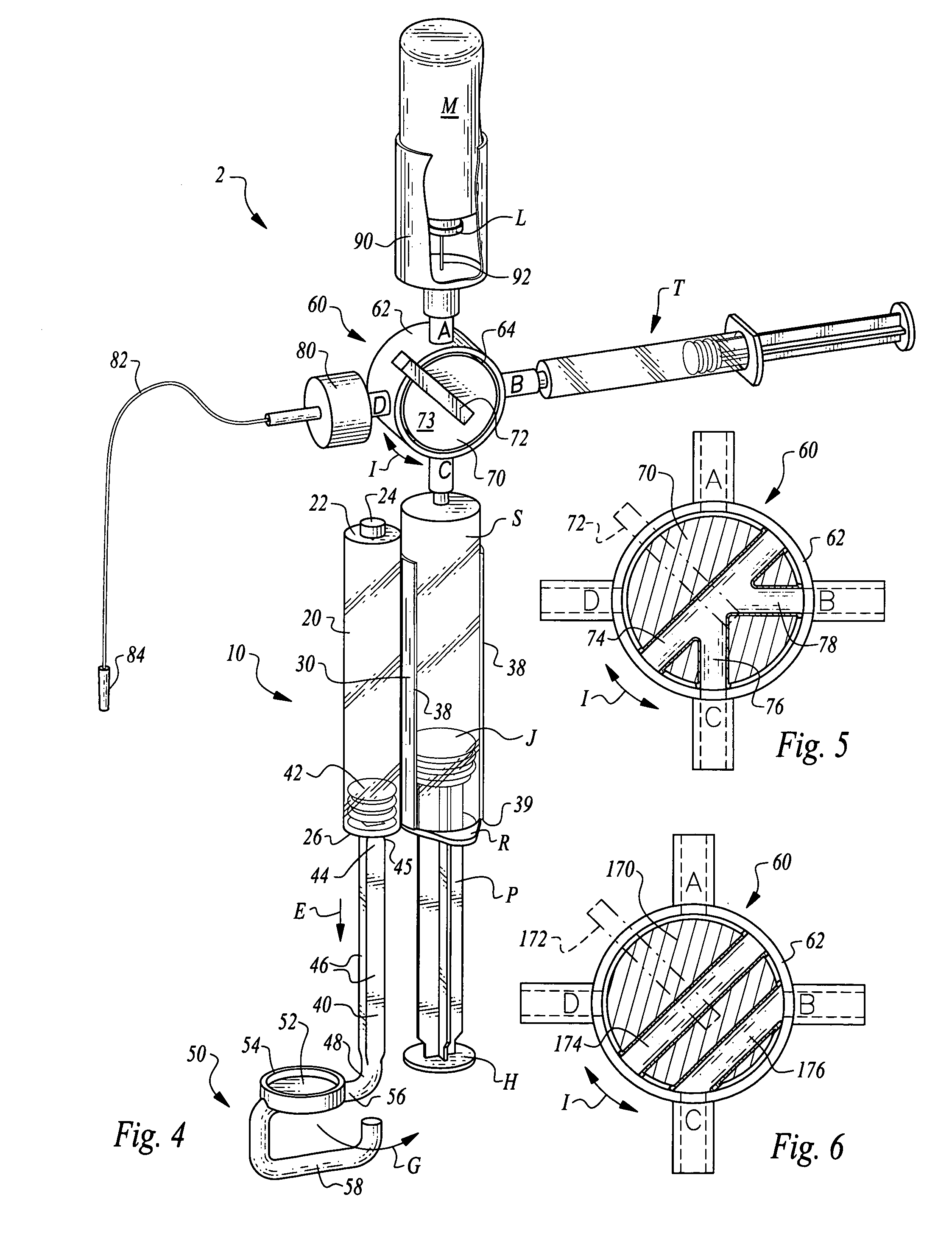

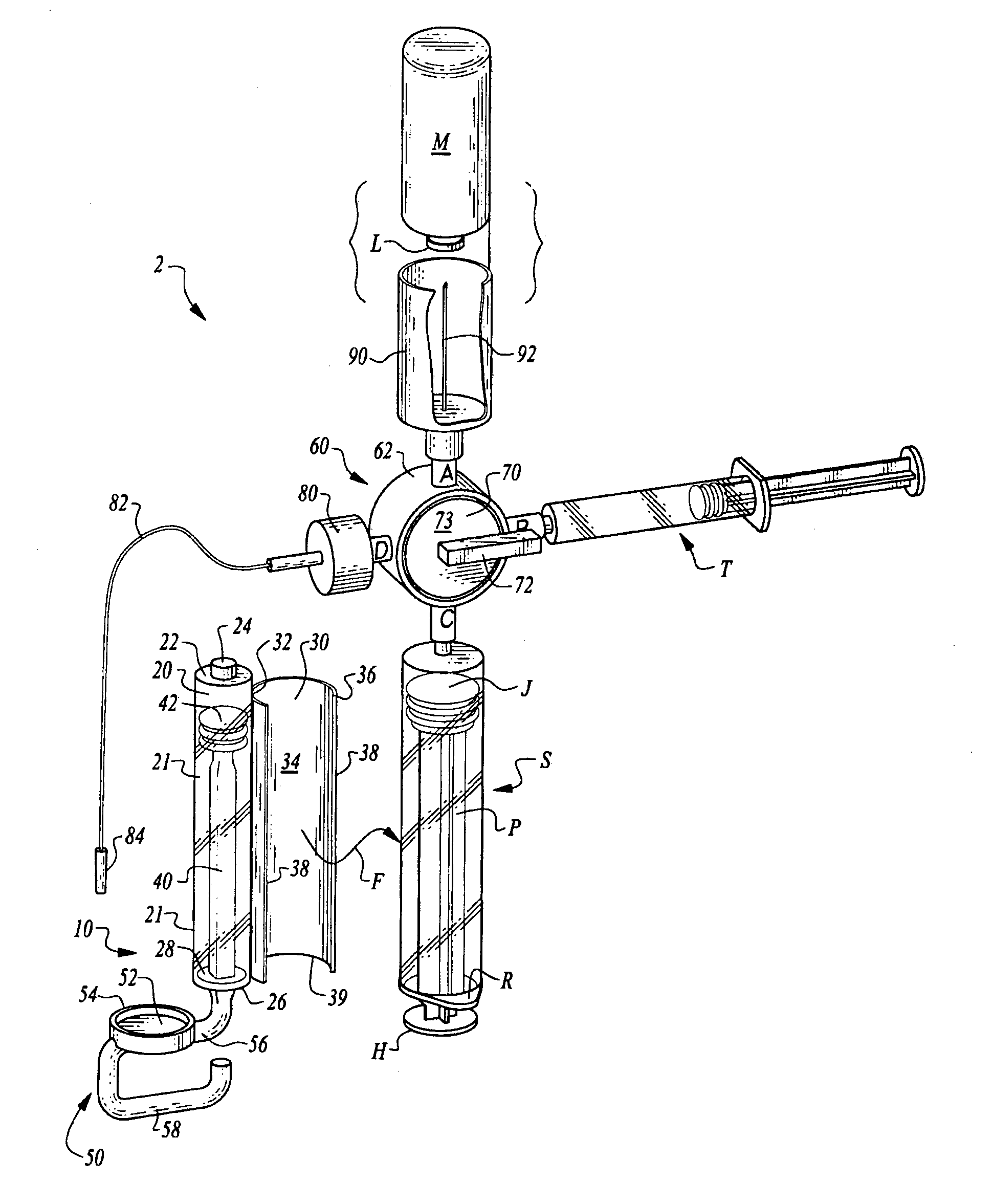

ActiveUS20100305507A1Easily attached to patientStable force transmissionIntravenous devicesSuction devicesMedication injectionDriver/operator

An assembly is provided which includes an infusion device coupled to a standard medication syringe. The medication syringe may be coupled to a stopcock valve having multiple ports and to which syringes, vial adapters, infusion tubing, and multiple other items may be coupled. The infusion device includes a source of power based on a resistance force such as vacuum, spring or gas power. The infusion device converts the resistance based force to usable work in the form of a force applicator. The force applicator includes a driver section on one section of a reciprocating arm and an attachment to the power source on another section of the arm. The driver is pulled outward (excursion) to increase the size of the chamber, creating a force that tends to return the driver back inward, causing incursion. The driver can be attached removably to the syringe plunger to induce the infusion process.

Owner:MONUMEDICAL

Compact non-electric medicament infuser

ActiveUS20140323970A1Easily attached to patientStable force transmissionAutomatic syringesFiltering accessoriesDrug injectionStopcock

An assembly is provided which includes an infusion device coupled to a standard medication syringe. The medication syringe may be coupled to a stopcock valve having multiple ports and to which syringes, vial adapters, infusion tubing, and multiple other items may be coupled. The infusion device includes a source of power based on a resistance force such as vacuum, spring or gas power. The infusion device converts the resistance based force to usable work in the form of a force applicator. The force applicator includes a driver section on one section of a reciprocating arm and an attachment to the power source on another section of the arm. The driver is pulled outward (excursion) to increase the size of the chamber, creating a force that tends to return the driver back inward, causing incursion. The driver can be attached removably to the syringe plunger to induce the infusion process.

Owner:DUNCAN DAVID R

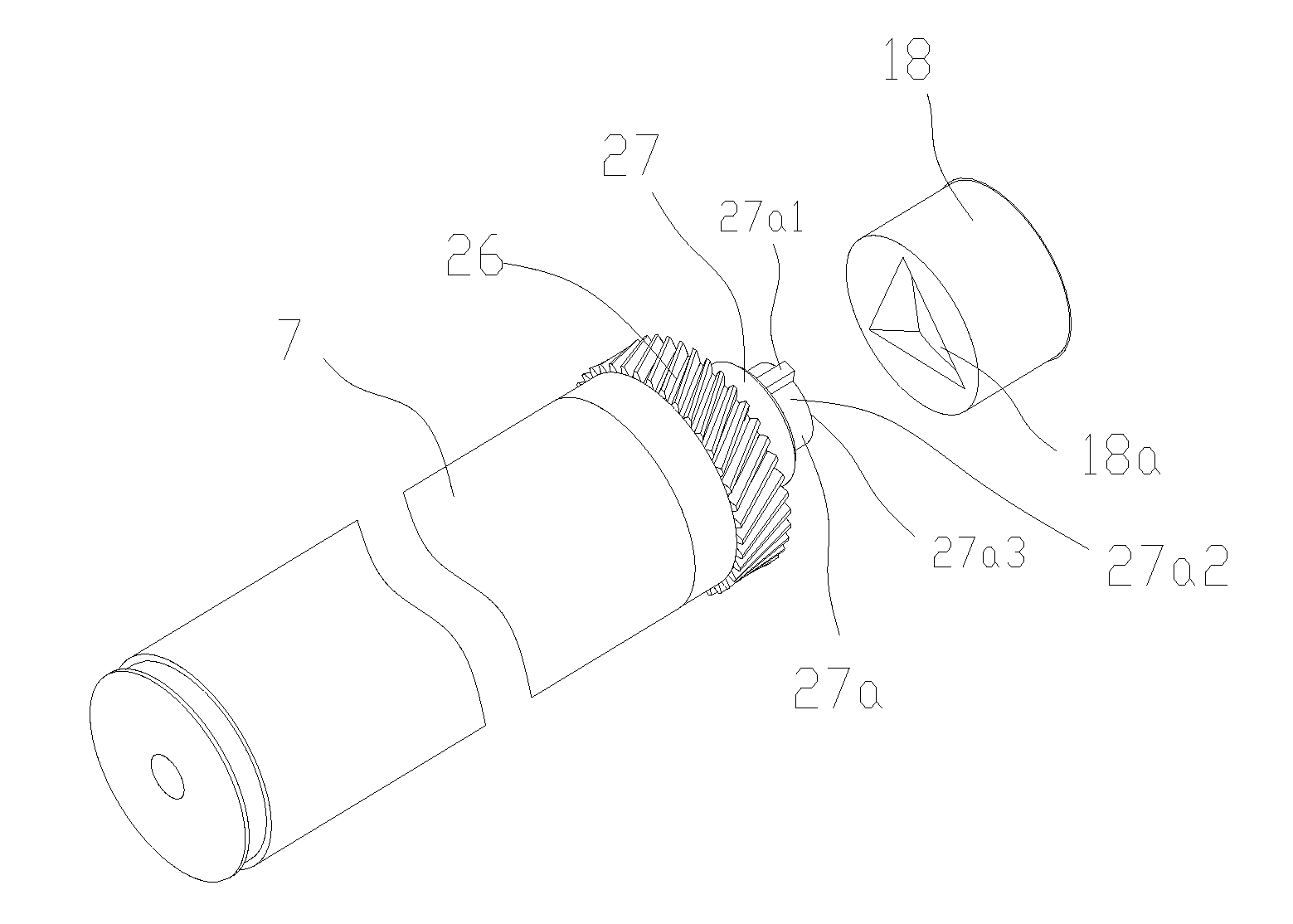

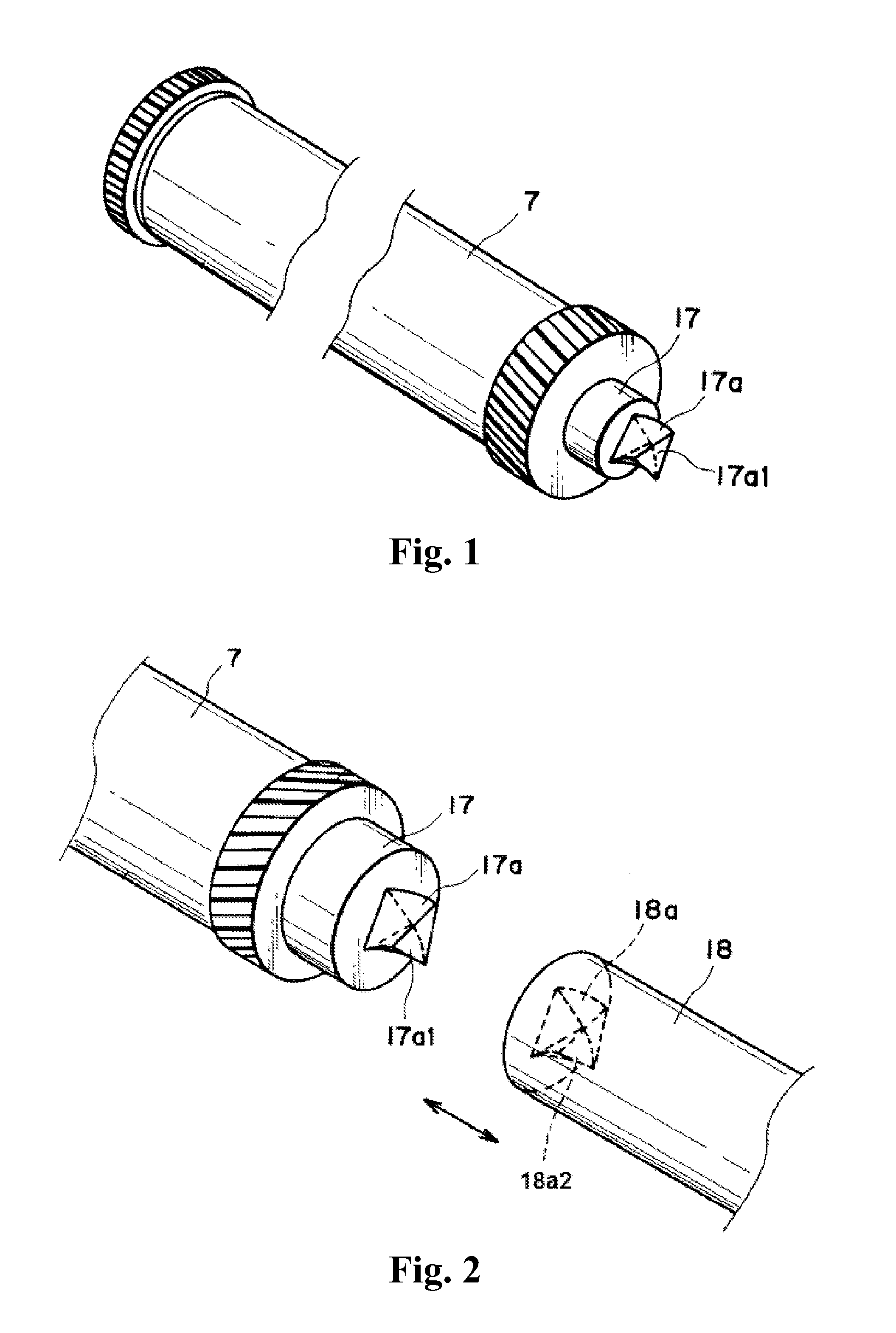

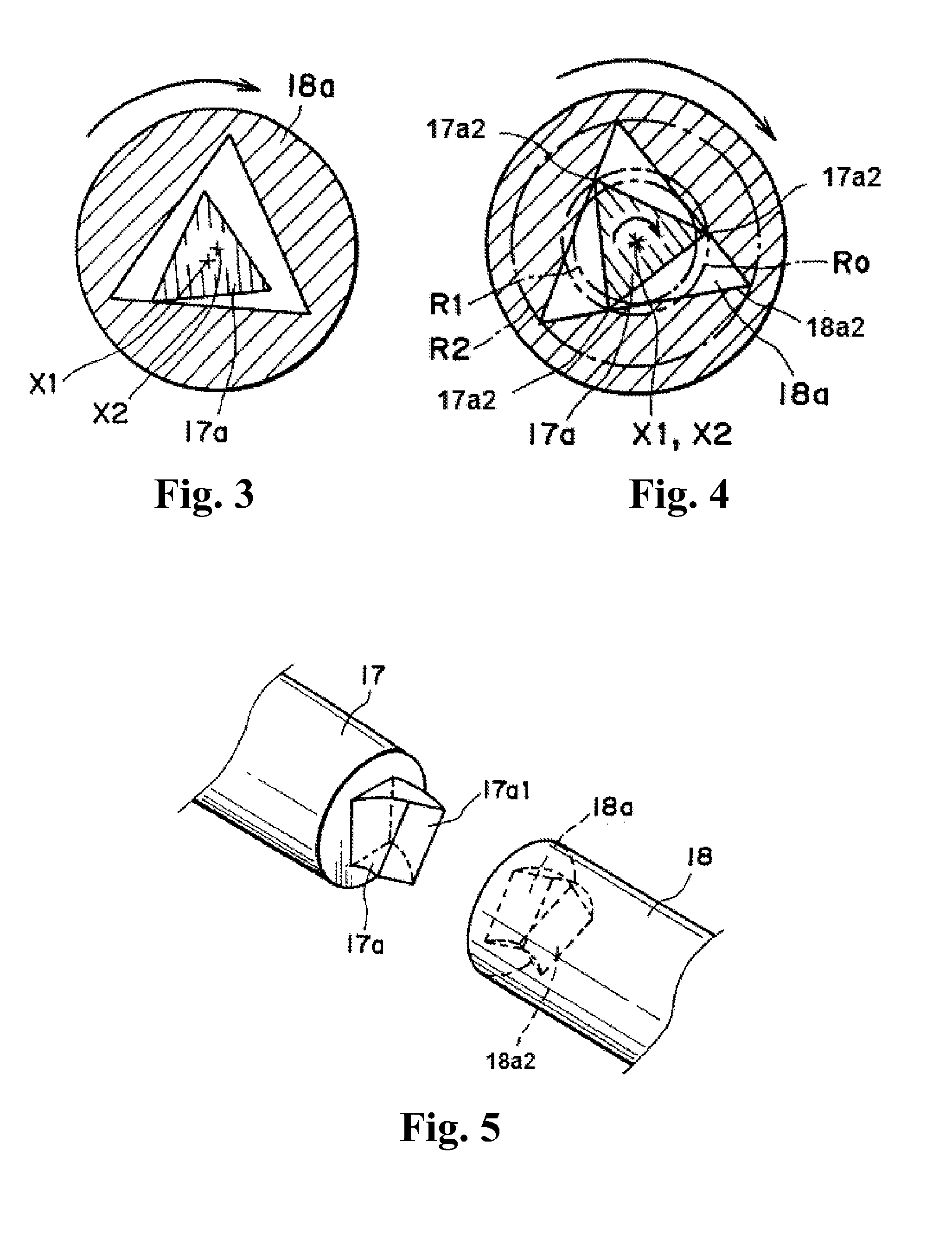

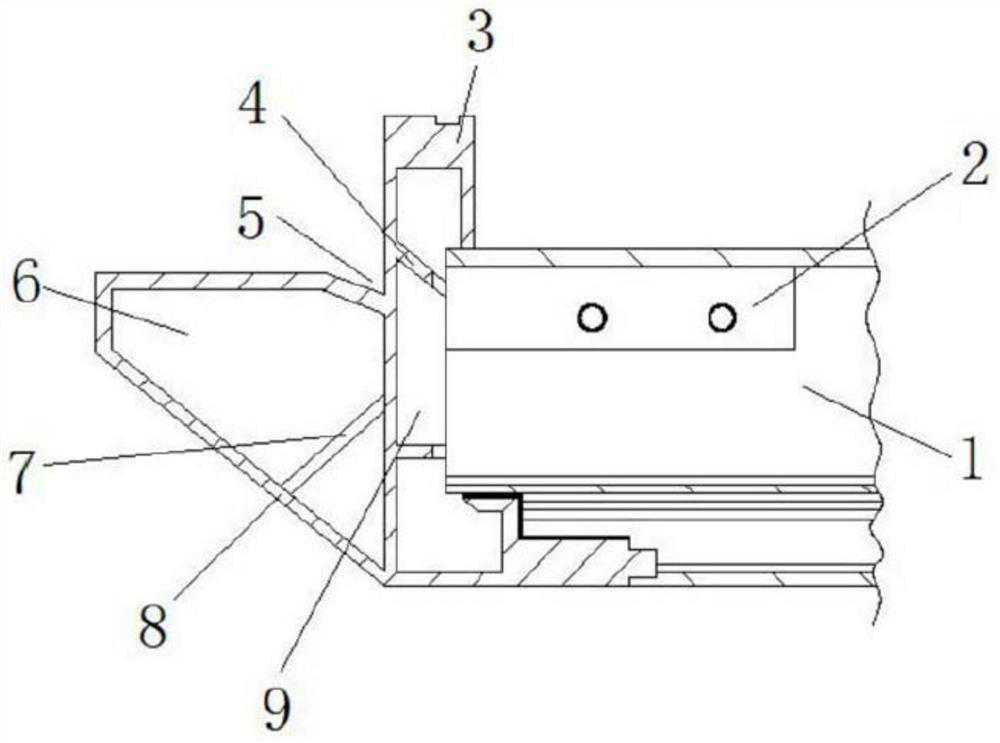

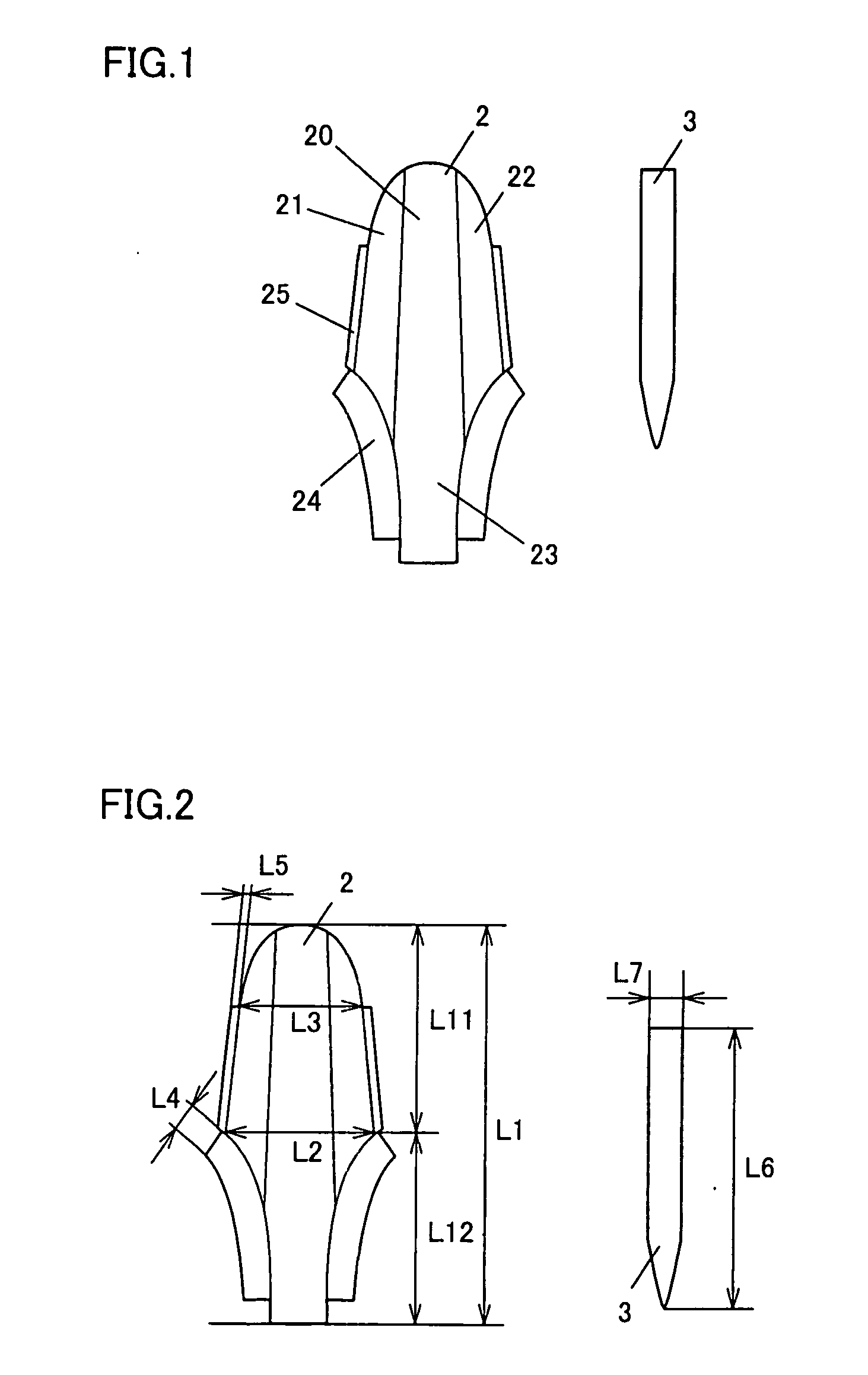

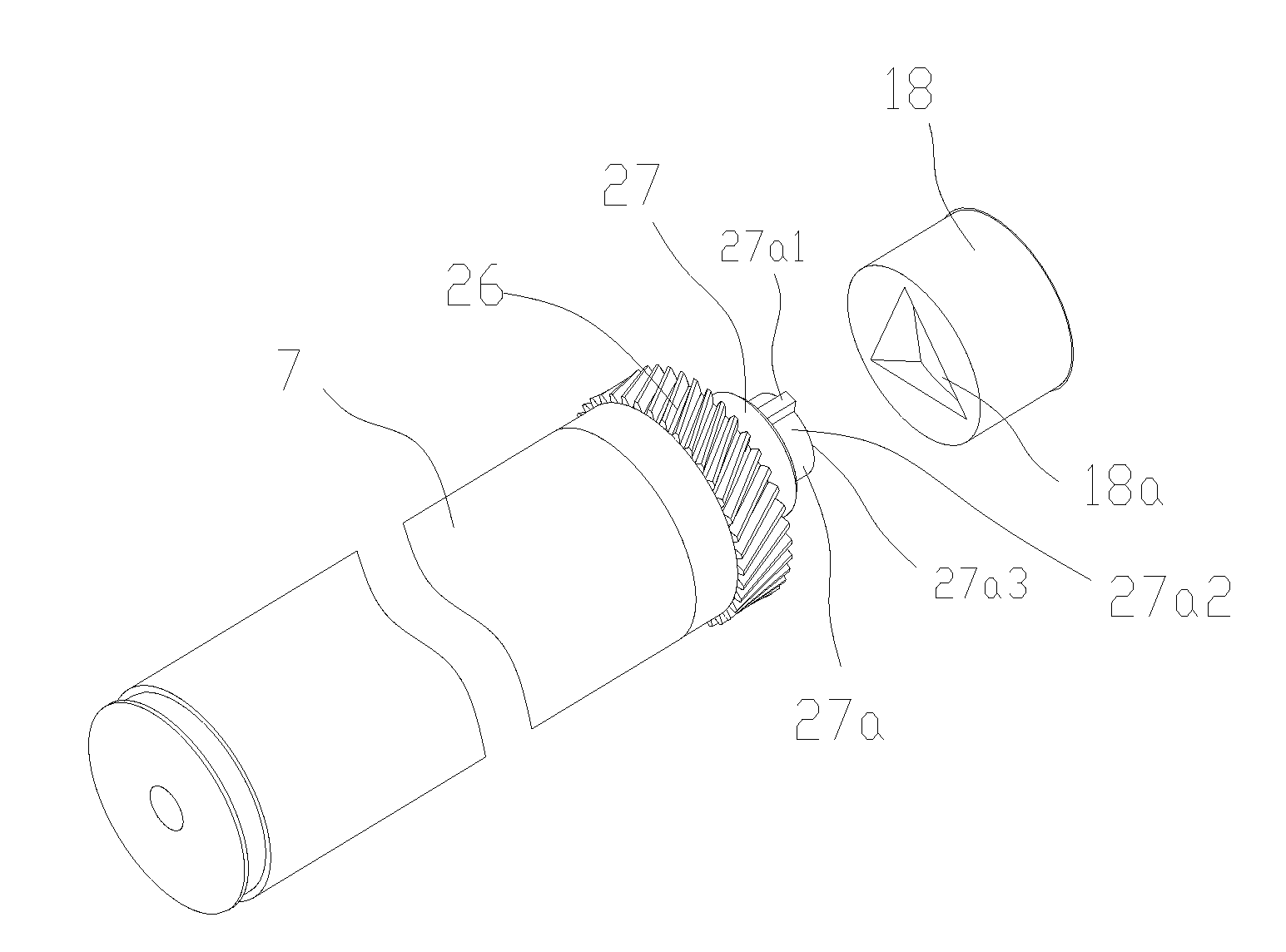

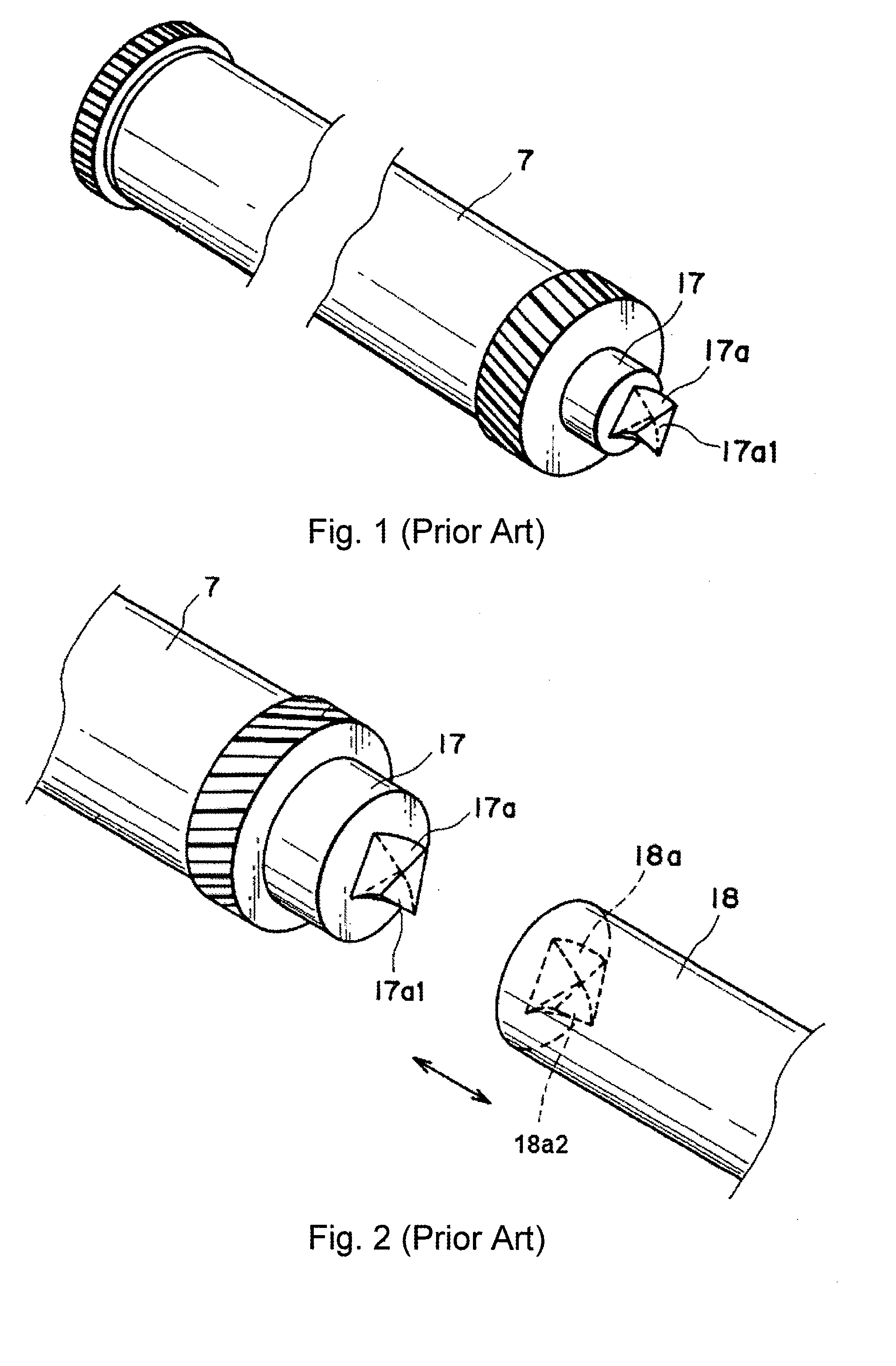

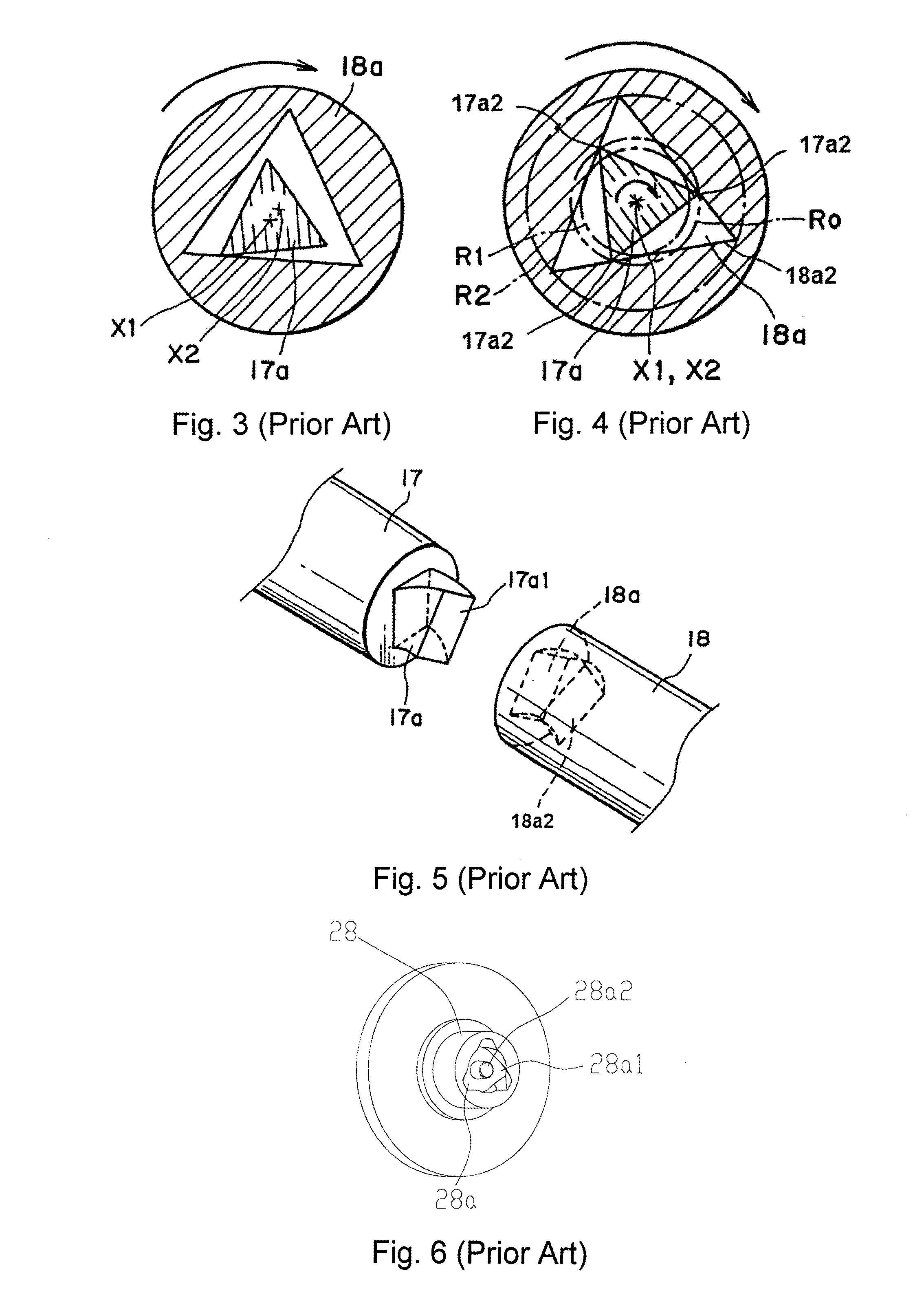

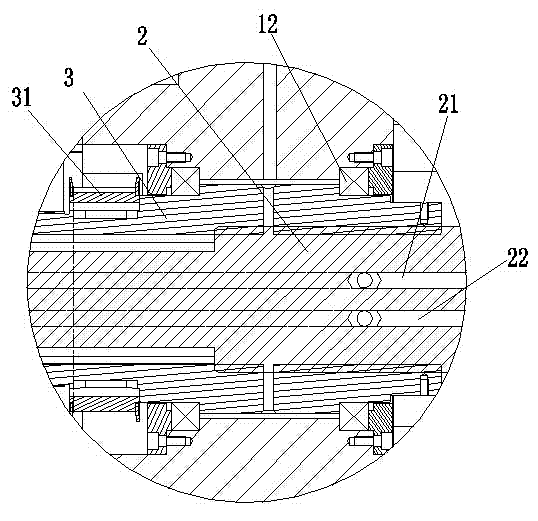

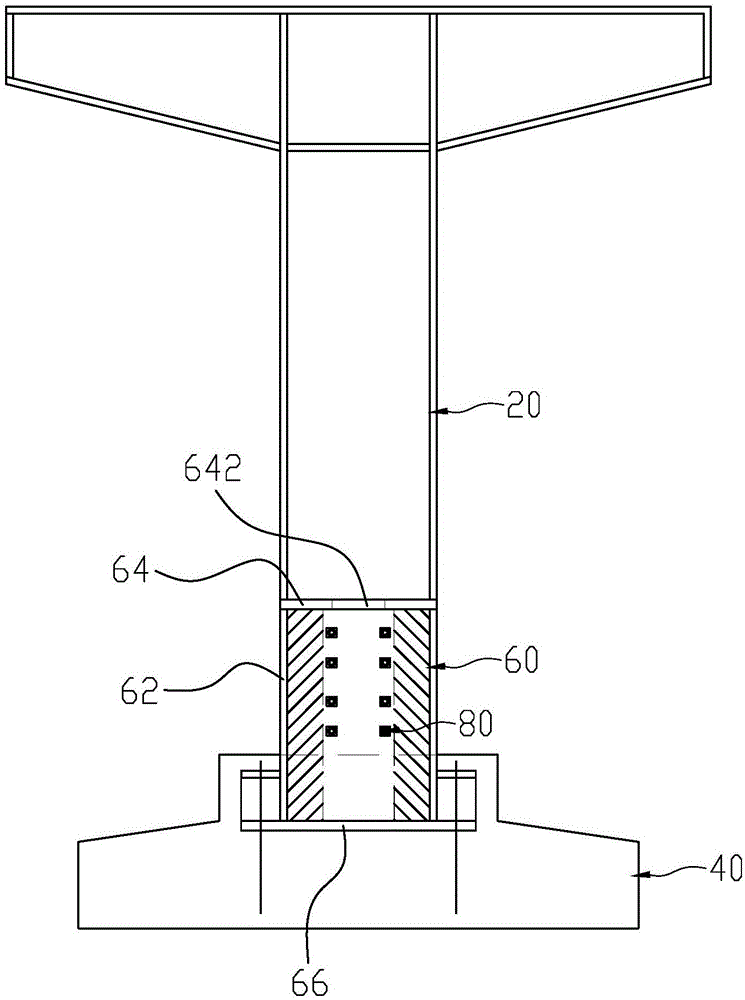

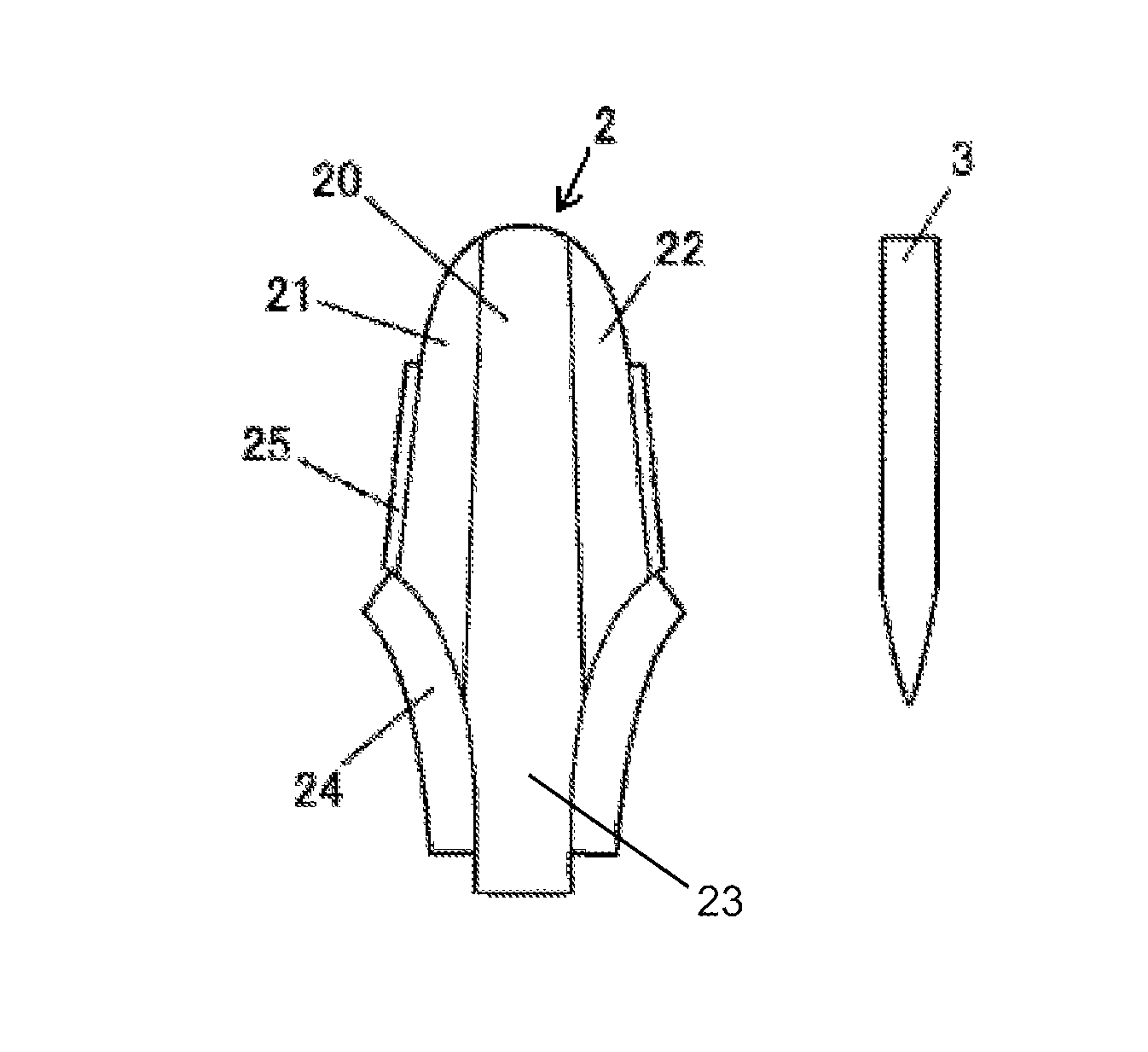

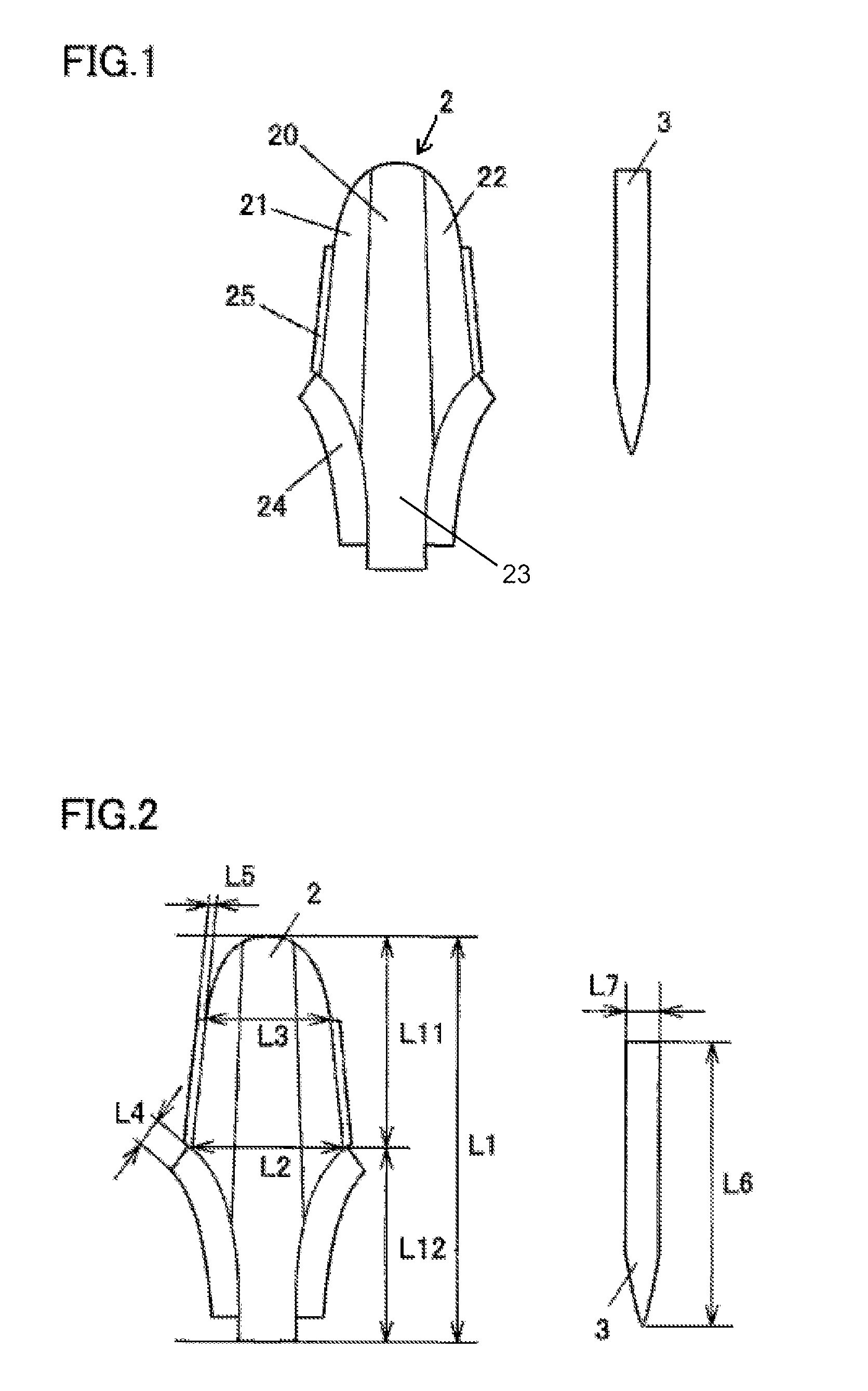

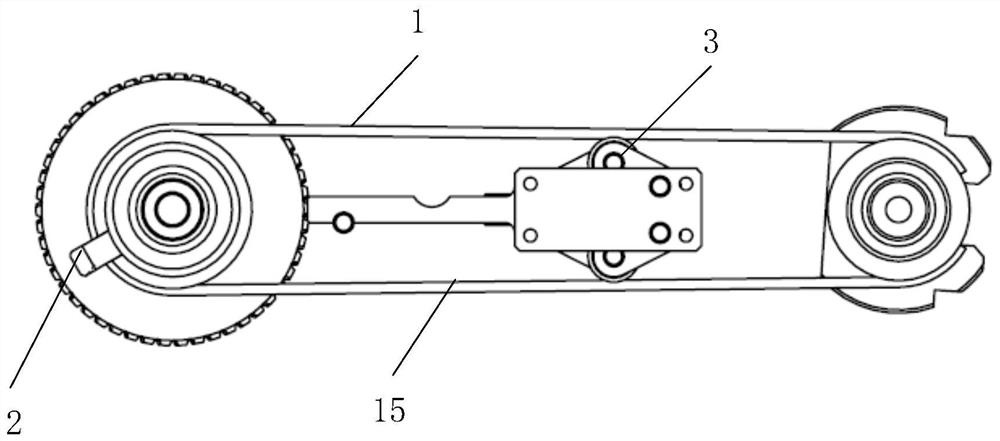

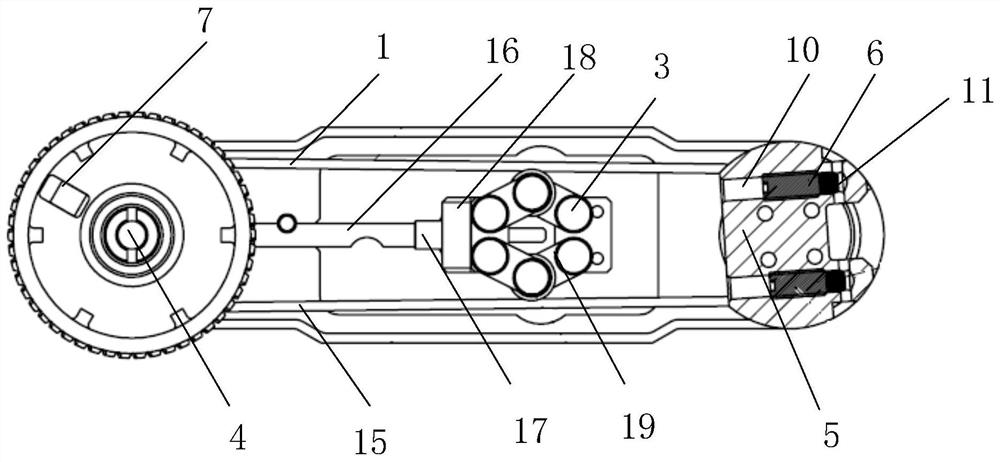

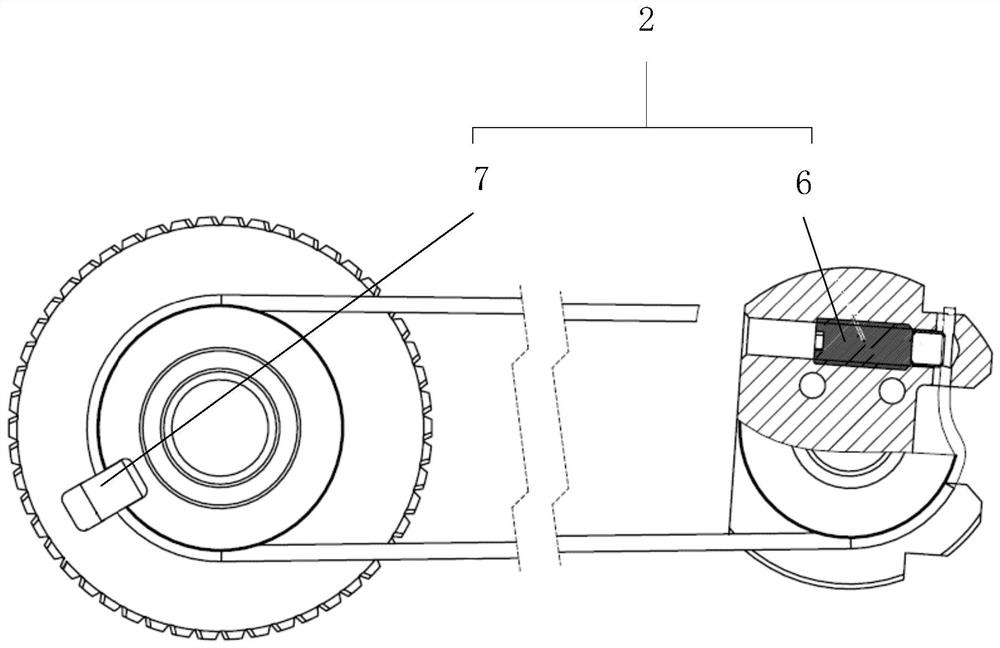

Driving force transmission mechanism and process cartridge containing the same

InactiveUS20130216265A1Reduce wearStressed areaCouplings for rigid shaftsElectrographic process apparatusEngineeringImaging equipment

A driving force transmission mechanism comprising a photosensitive drum driving member, wherein the photosensitive drum driving member is engaged with an image forming apparatus driving member and receives the driving force from the image forming apparatus driving member; the image forming apparatus driving member comprises a triangular groove having a triangular cross-section and driving force transmission portion disposed in three vertex angles of the triangular groove; the photosensitive drum driving member comprises a non-distorting protrusion which is axially extended from the end face of a drum shaft and engaged with the groove on the image forming apparatus driving member; the protrusion has a position-limiting mechanism and a stressed mechanism; a projecting tooth obliquely disposed on said non-distorting protrusion is taken as the stressed mechanism; and each projecting tooth also has a mating surface which is engaged with the driving force transmission component to transmit the driving force.

Owner:NINESTAR CORP

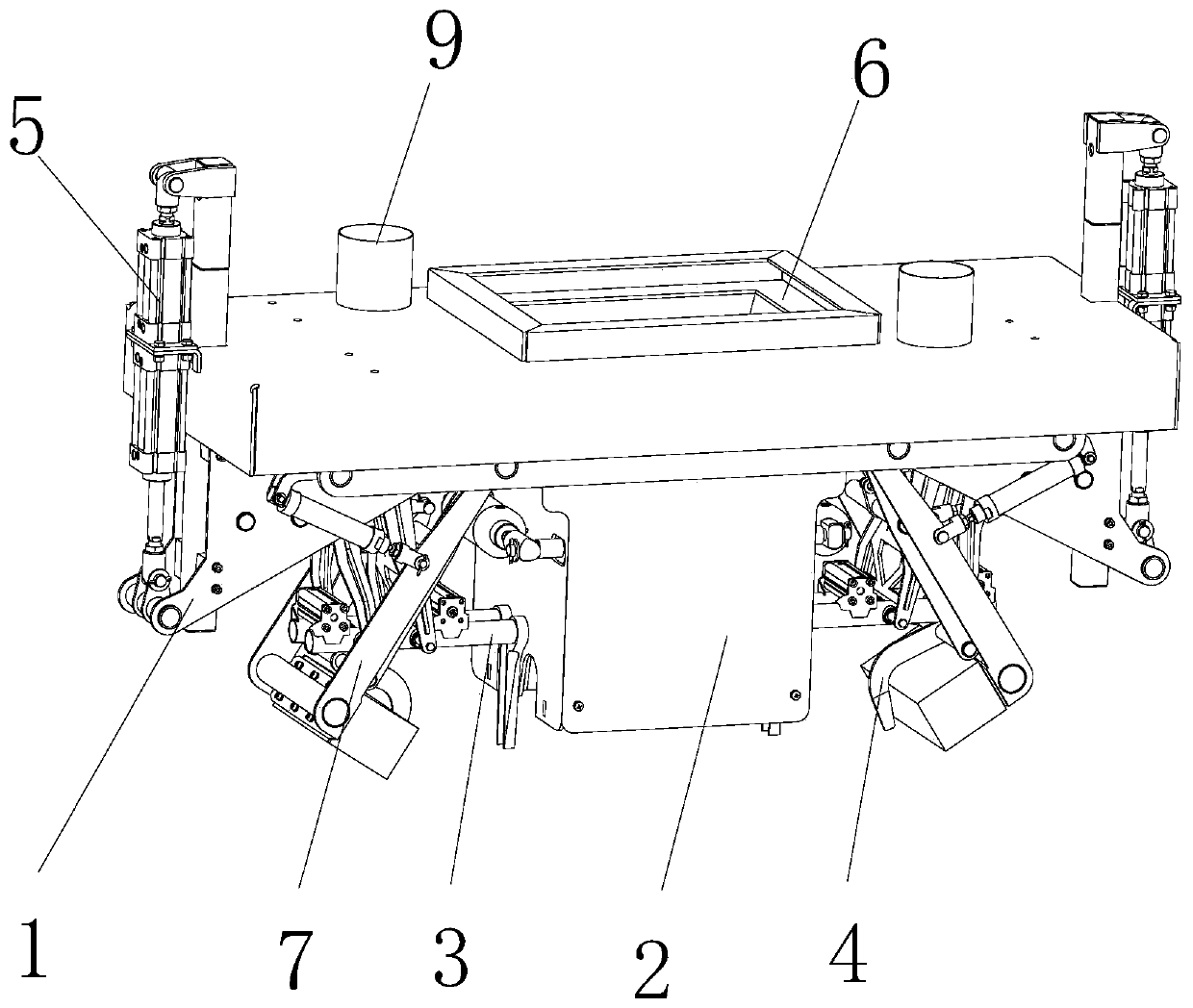

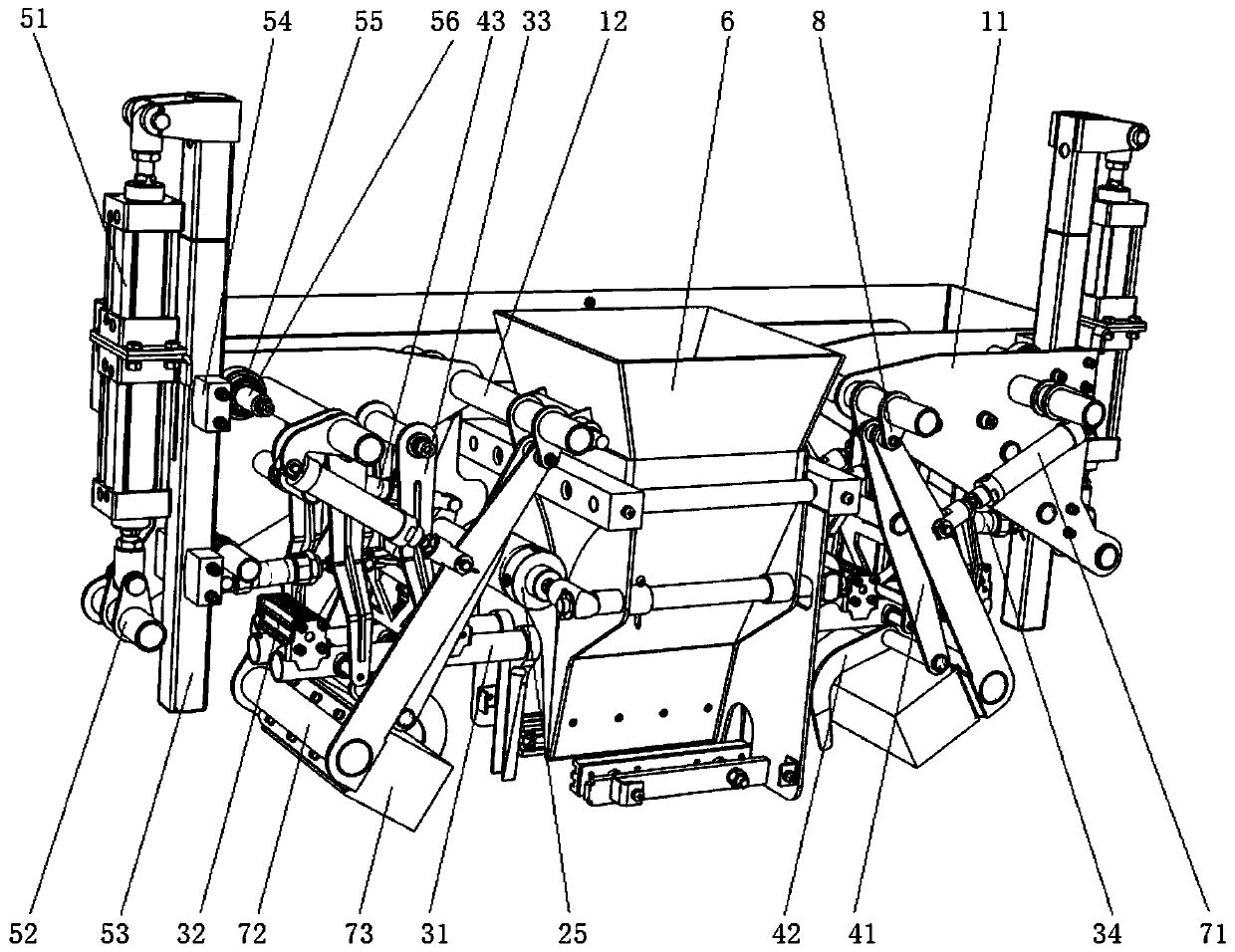

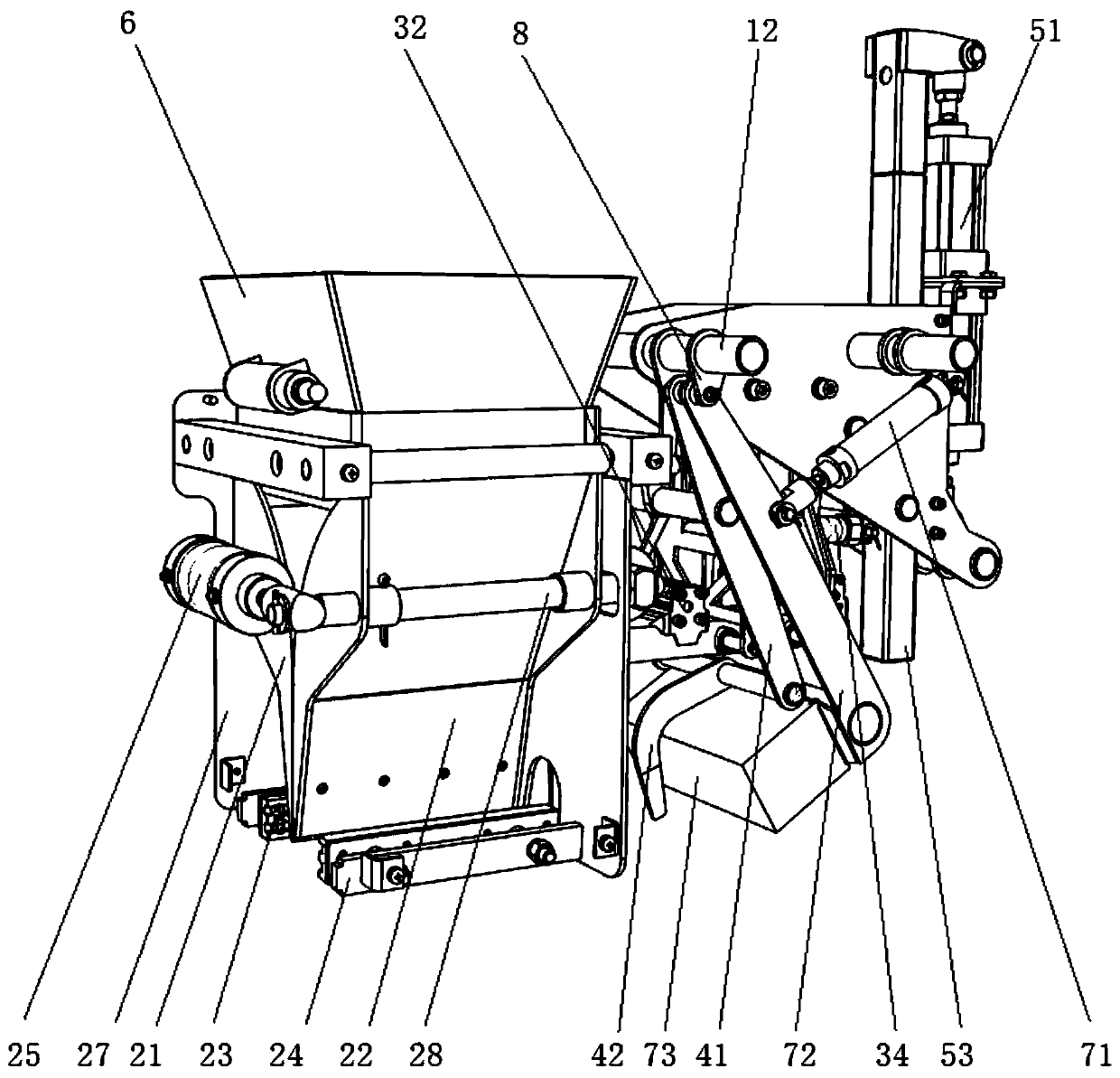

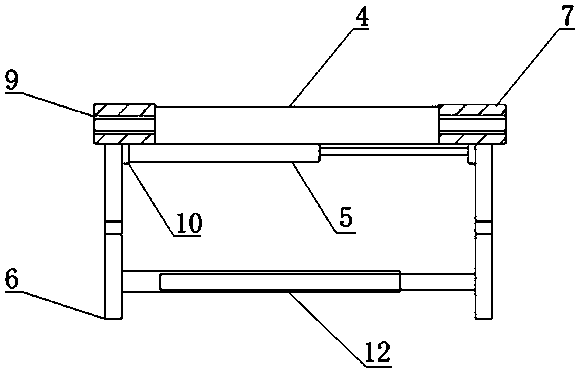

M-type bag forming clamping device

PendingCN109850270AHighly integratedCompact structureSolid materialEngineeringMechanical engineering

The invention provides an M-type bag forming clamping device. The M-type bag forming clamping device solves the problems of complex and large structure, low matching degree and low packaging efficiency of an existing M-type bag clamping device. The M-type bag forming clamping device comprises a mounting frame, a bag clamping assembly, two bag supporting rod assemblies, two M-type bag forming assemblies and two lifting assemblies, wherein the mounting frame is connected with the lifting assemblies; the lifting assemblies are fixedly arranged on a discharging device and used for driving the mounting frame to move up and down; the bag clamping assembly is arranged at a discharging opening of the discharging device; the two bag supporting rod assemblies are arranged on the mounting frame, corresponding to two sides of the discharging device, and used for performing bag supporting action on an M-type bag; each bag supporting rod assembly comprises two bag supporting rods, two bag supportingcylinders, two swing frames and a swing cylinder; the two M-type bag forming assemblies are arranged on the mounting frame, correspondingly arranged on two sides of the discharging device, and used for performing M-type forming recovery action on the M-type bag; each M-type bag forming assembly comprises a forming frame, a forming sheet and a forming cylinder; and the movement area of the formingsheet is in the middle of the bag supporting rod assemblies.

Owner:XIAN MAGNETIC FOREST ELECTROMATIC

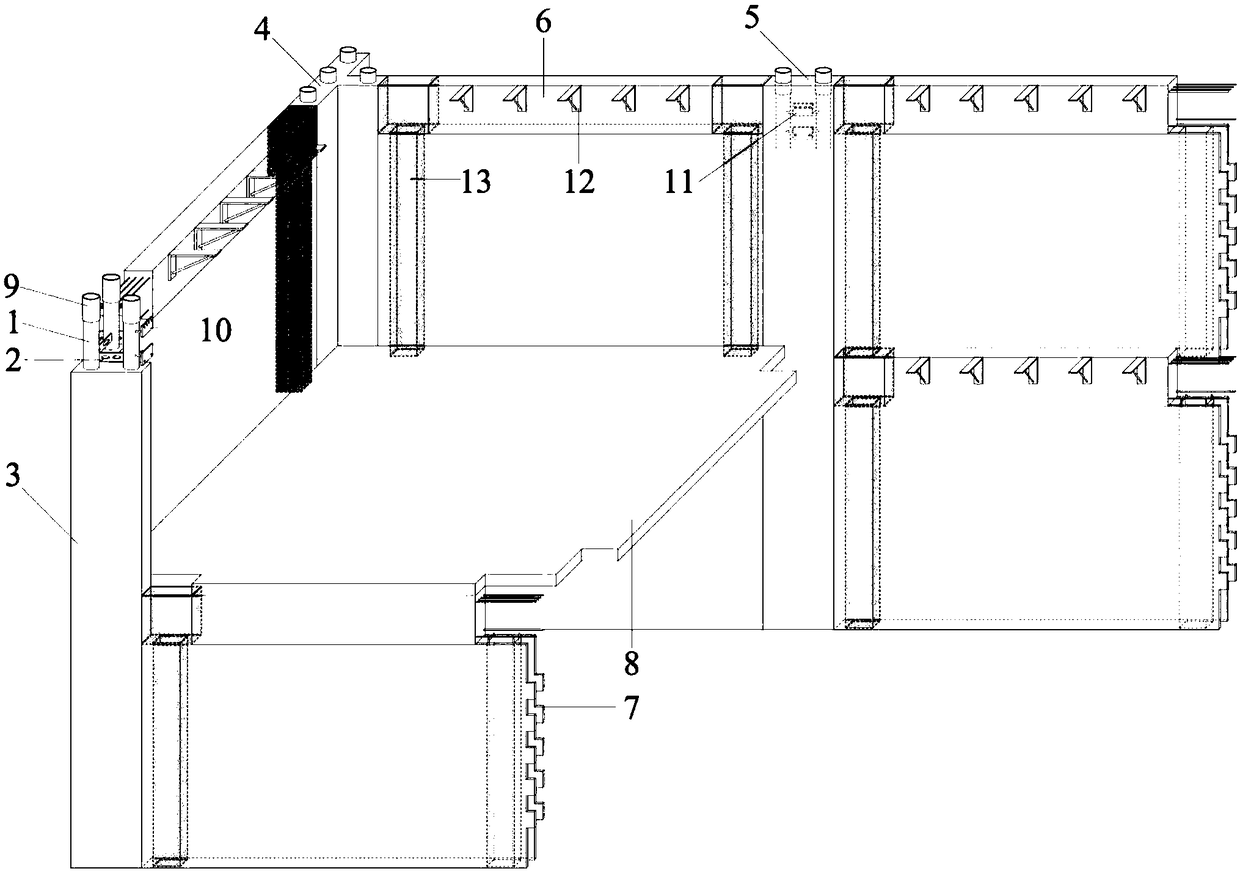

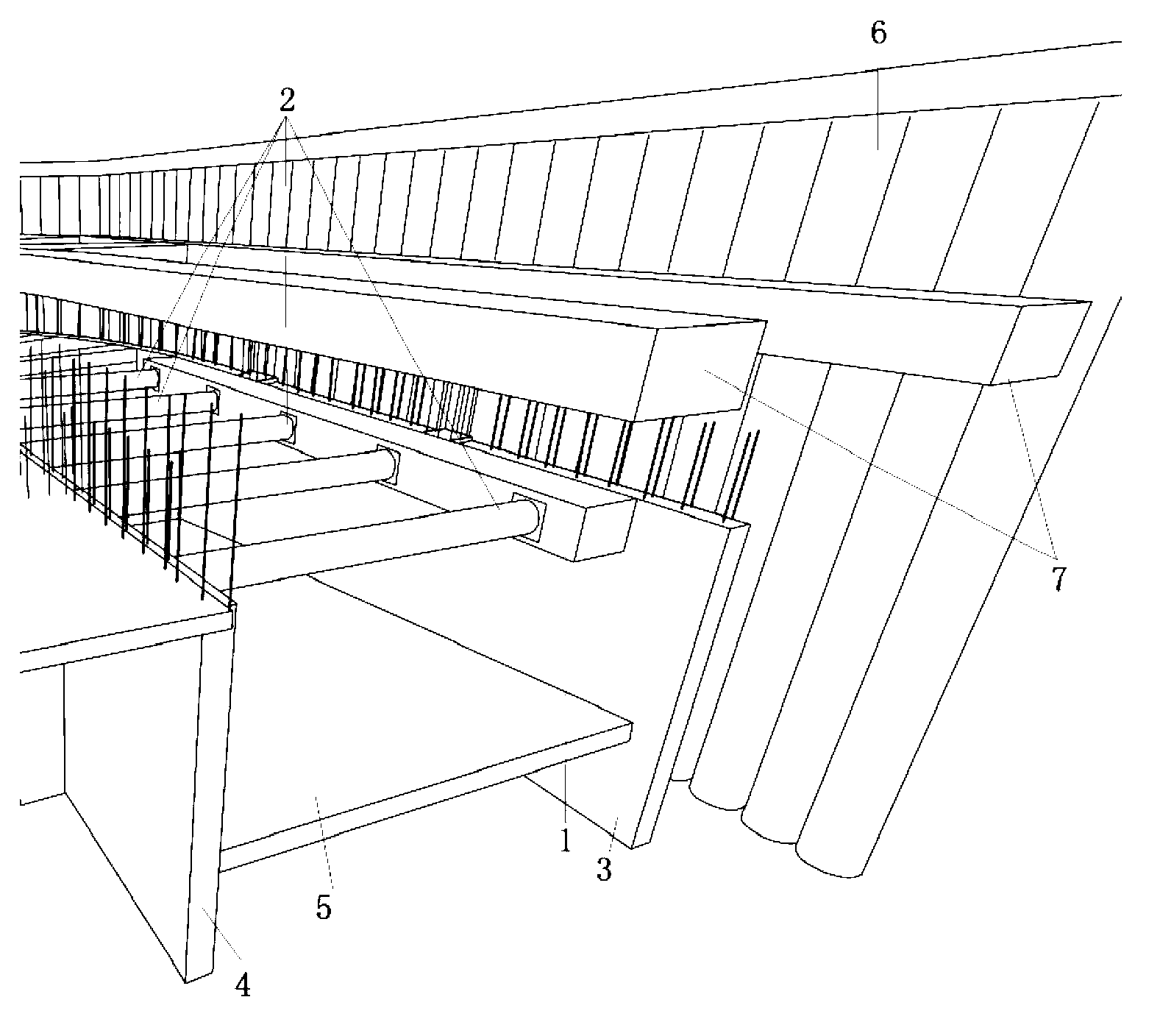

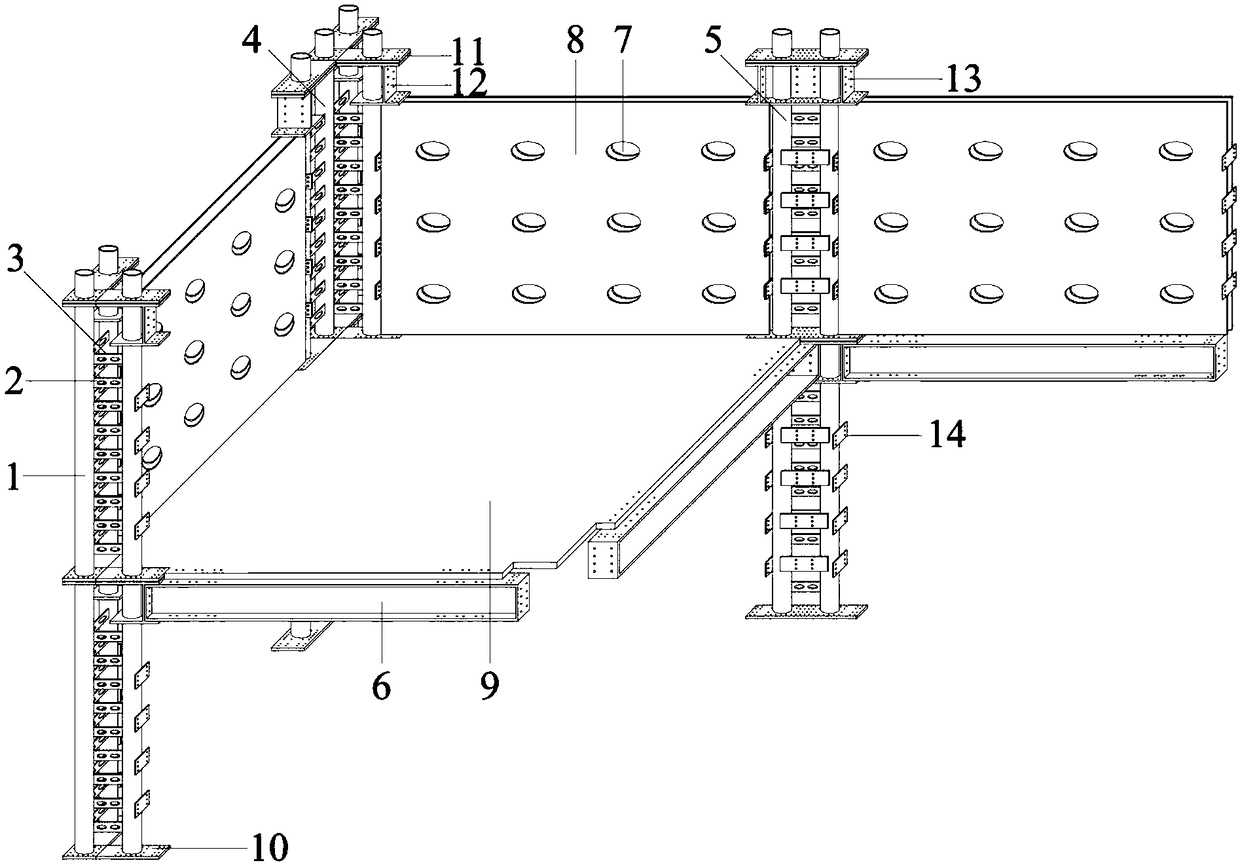

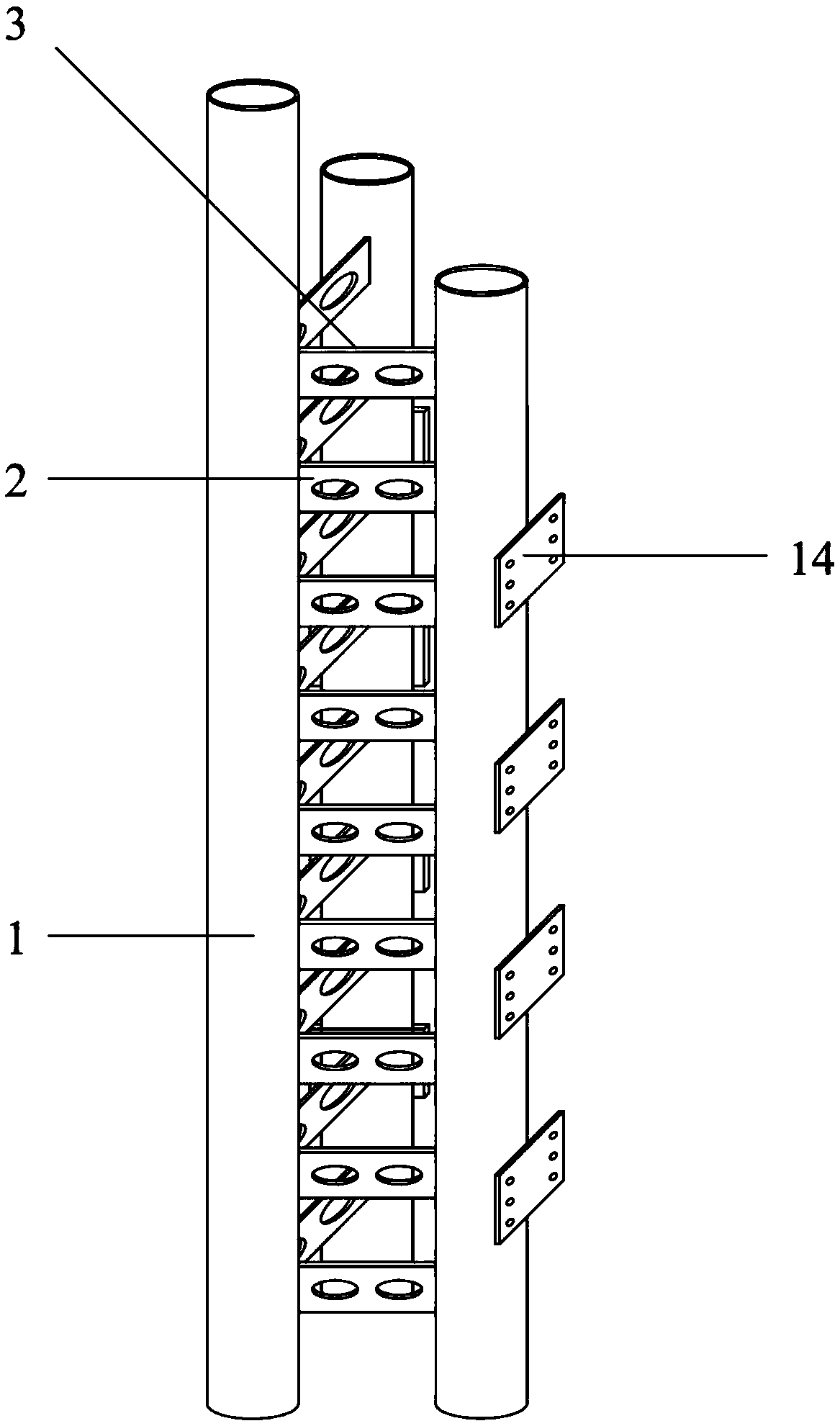

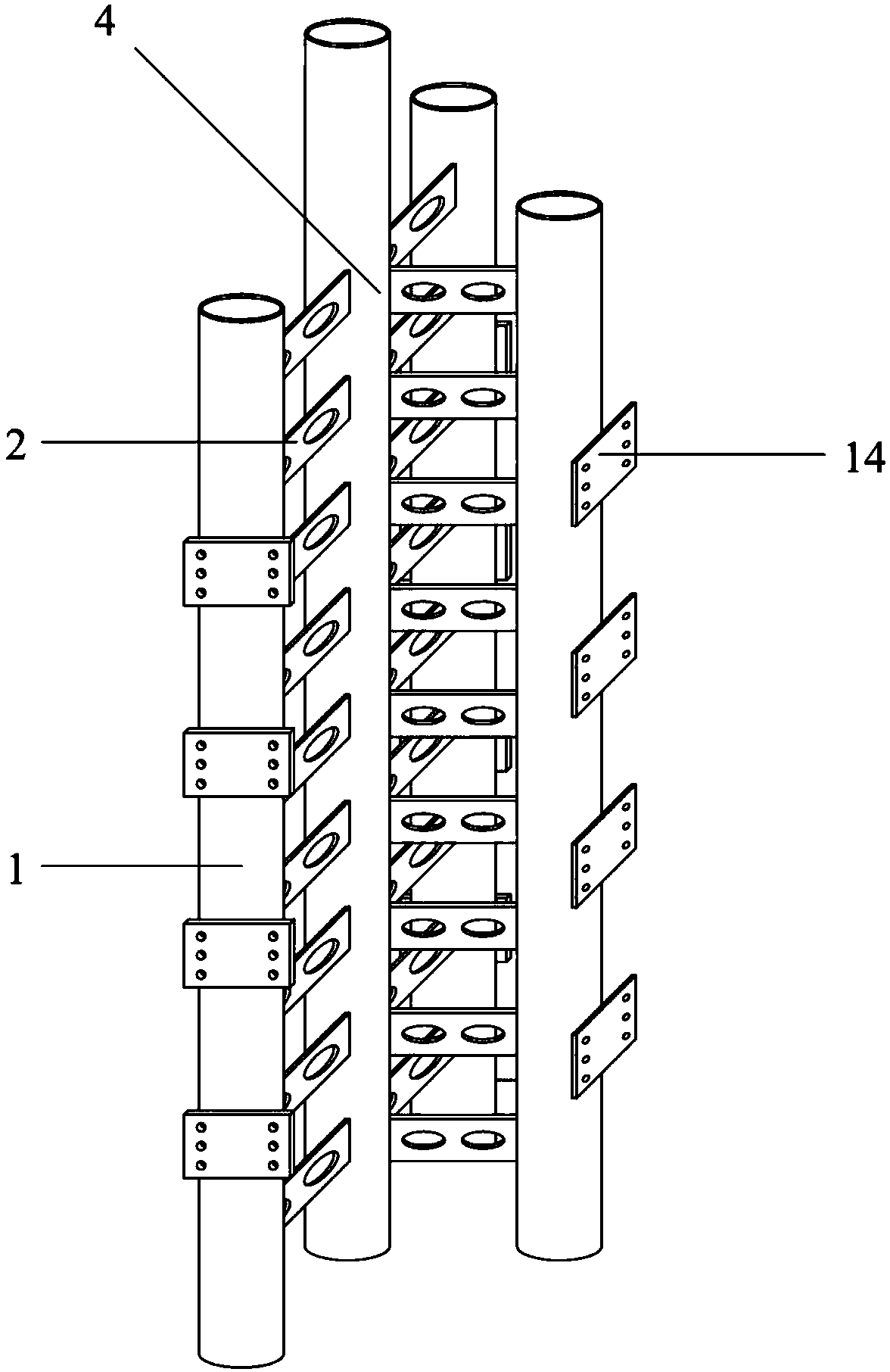

Assembled frame system with concrete filled steel tube branch limb combined special-shaped column and shock absorption wall

ActiveCN109372186AImprove seismic performanceFlexible layoutStrutsWallsEarthquake resistanceReinforced concrete

The invention discloses an assembled frame system with a concrete filled steel tube branch limb combined special-shaped column and a shock absorption wall and belongs to the field of building structure techniques and earthquake resistance and shock absorption of structures. The system primarily comprises a round concrete filled steel tube long column welded steel batten plate, and a prefabricatedcorner column, a prefabricated side column, a prefabricated middle column, a reinforced concrete beam, a steel plate wall, a prefabricated steel floorslab, a column-column connecting sleeve, a column-beam anchoring part, a middle column-beam anchoring part, a beam-plate connecting part, ECC post-cast strips and the like prepared by pouring concrete outside. Upper and lower concrete filled steel tubes are connected through the column-column connecting sleeve, and the column-beam anchoring part, the middle column-beam anchoring part and the round concrete filled steel tube long column are connected and prefabricated through dowels, so that the beam-column node connecting performance is enhanced. The ECC post-cast strips are arranged at two ends of the beam and the wall and are poured up anddown in a penetrating manner, so that the energy consumption ability and the anti-earthquake performance of the structural system are improved. The assembled frame system achieves the functions of hiding column edges and being attractive in building, a project is simple and rapid to construct, the construction efficiency is high, the nodes are connected stably and reliably, and the structural system is good in anti-earthquake performance.

Owner:BEIJING UNIV OF TECH

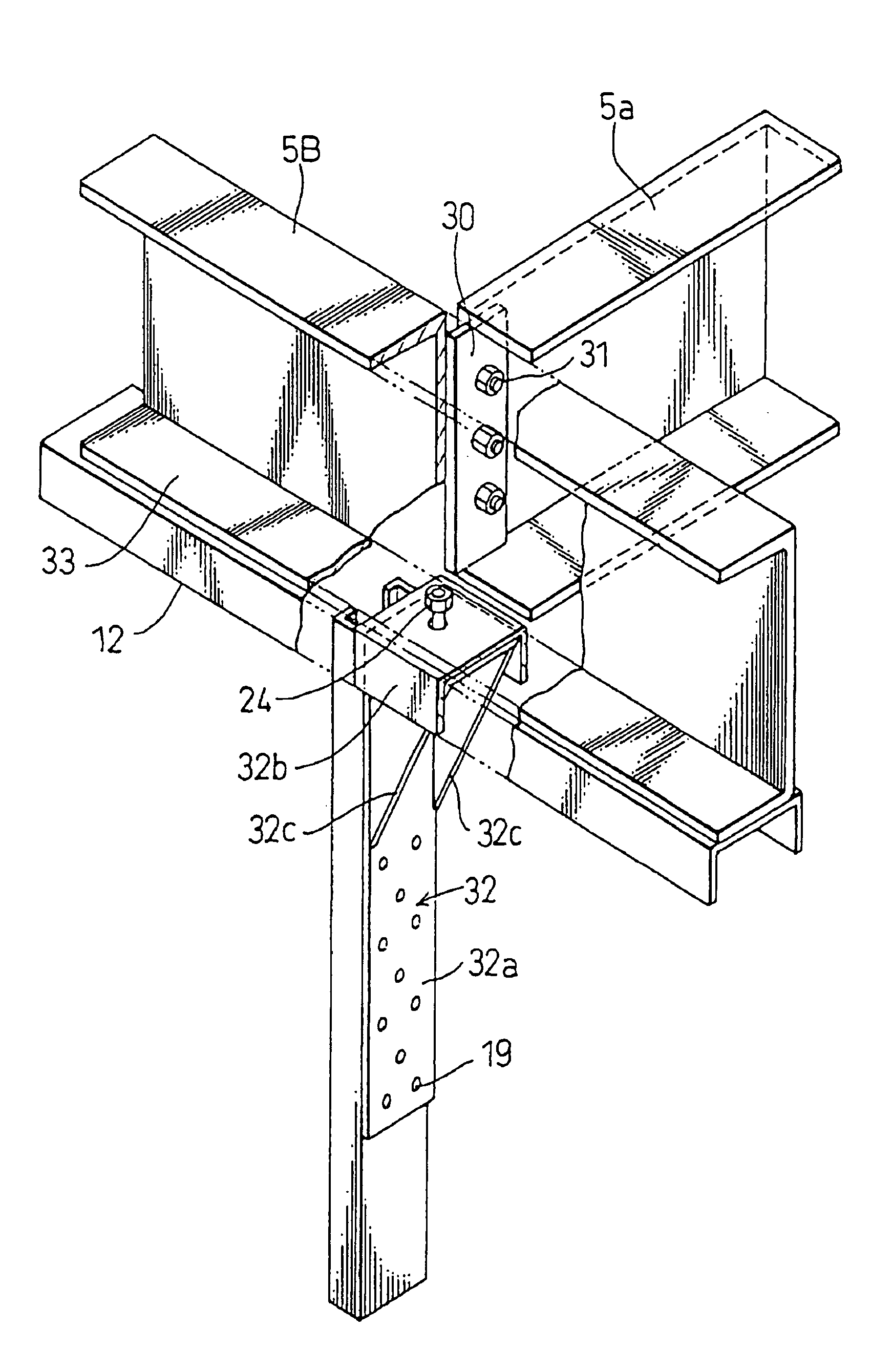

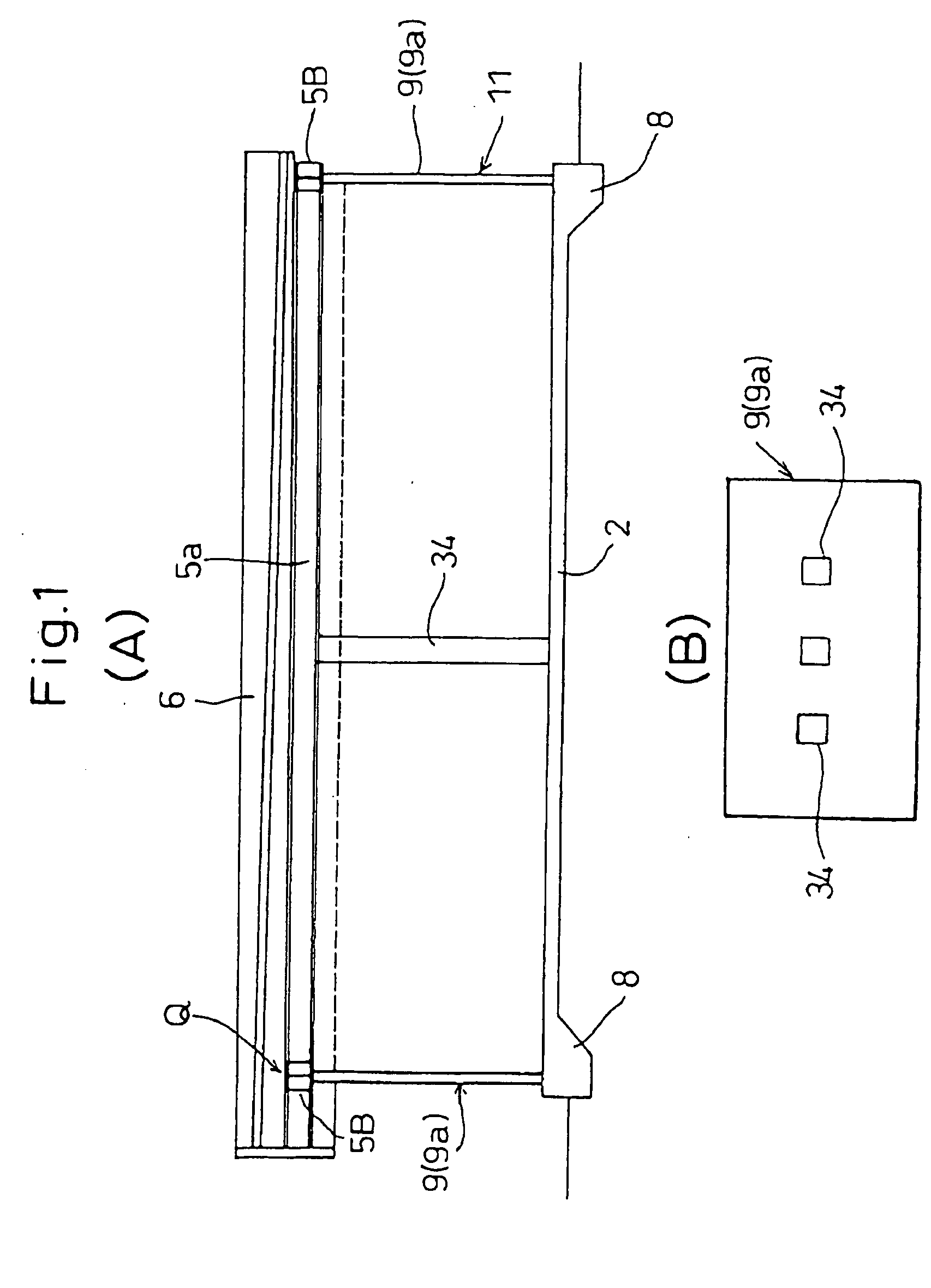

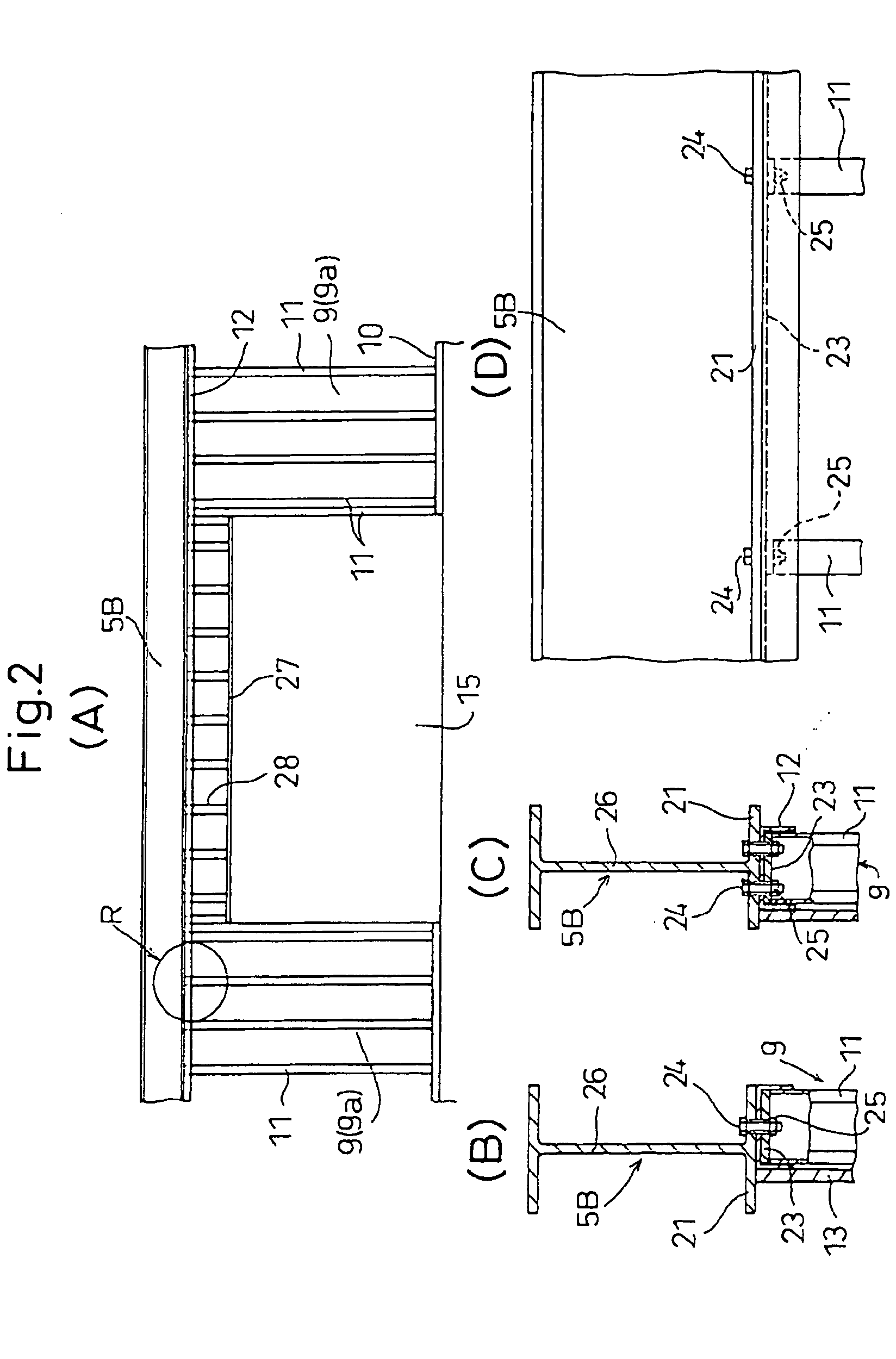

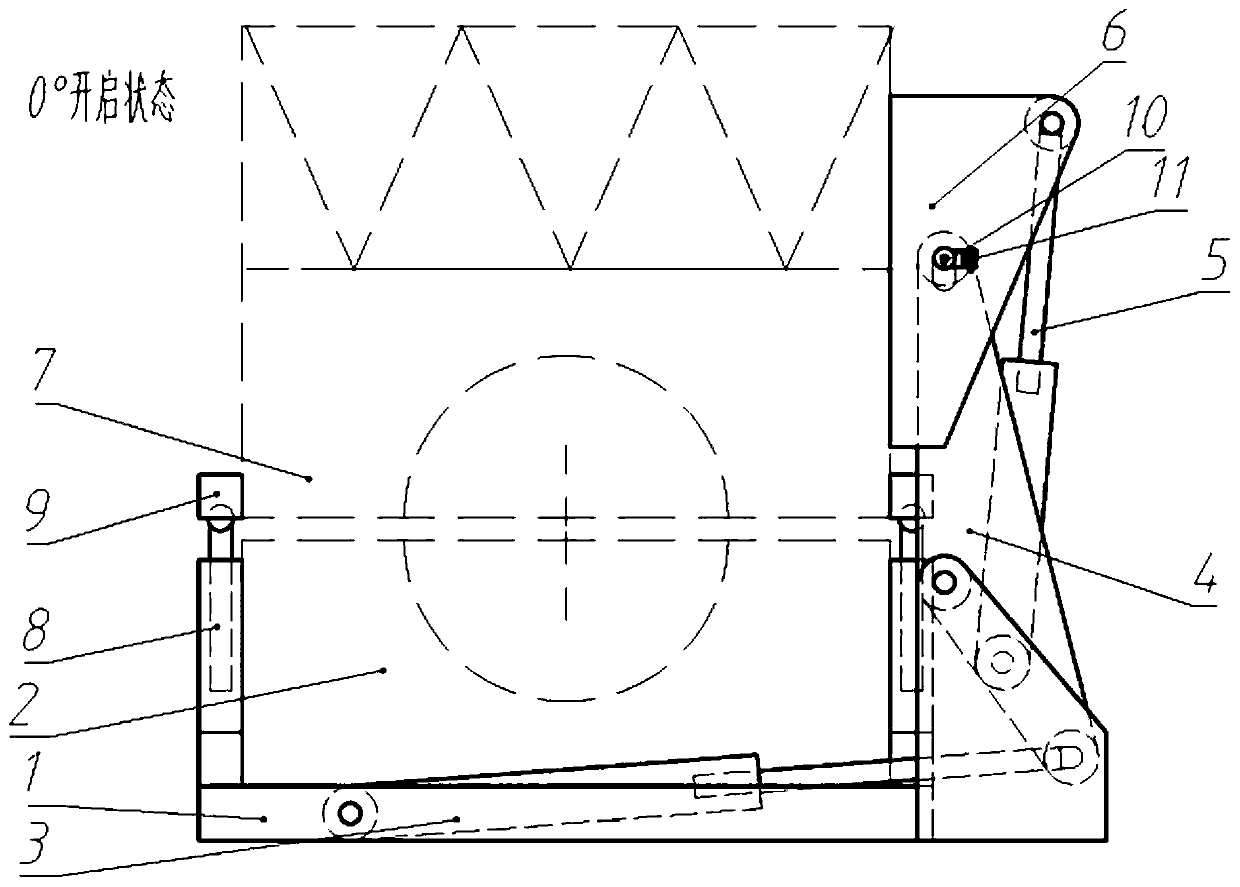

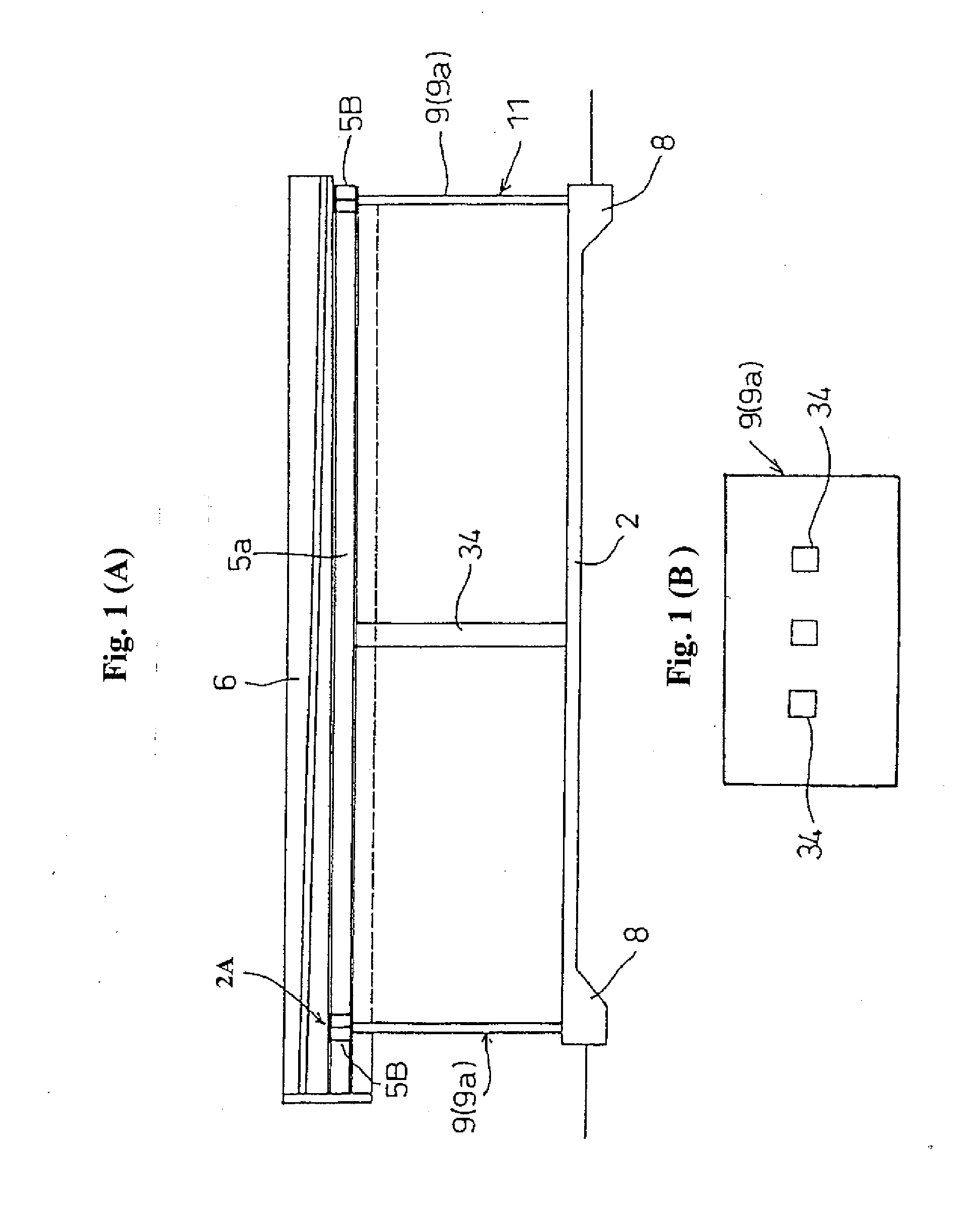

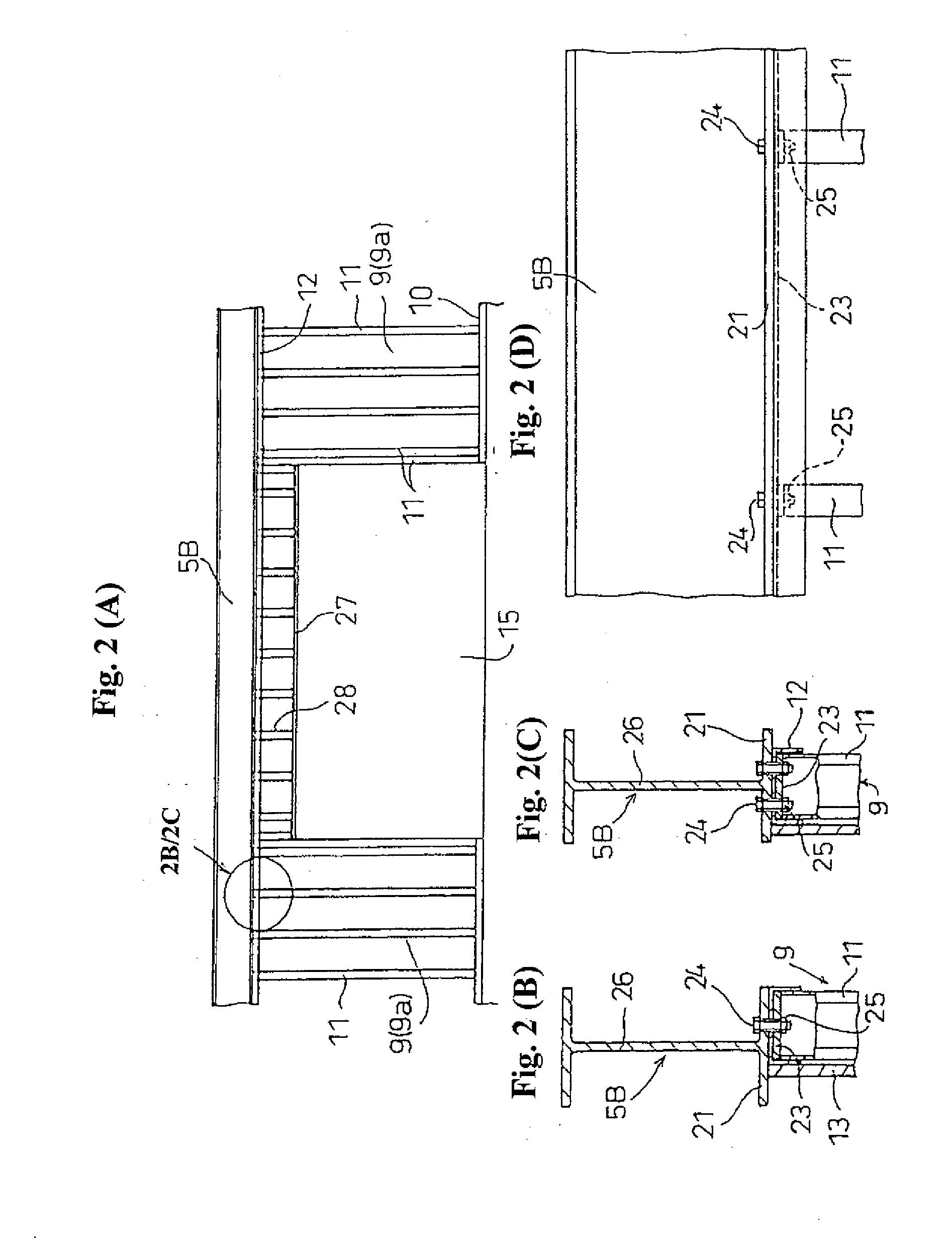

Frame construction for low-rise building

A frame construction for a low rise building. In the construction, a wall frame panel is made of thin light-gauge section steel by bonding together a surface member, a lower frame member, vertical frame members and an upper frame member. Roof or floor support girders are made of heavyweight section steel having H-shape or channel shape. The girders are coupled to frame construction panels by bolts or hold-down fasteners.

Owner:NIPPON STEEL CORP

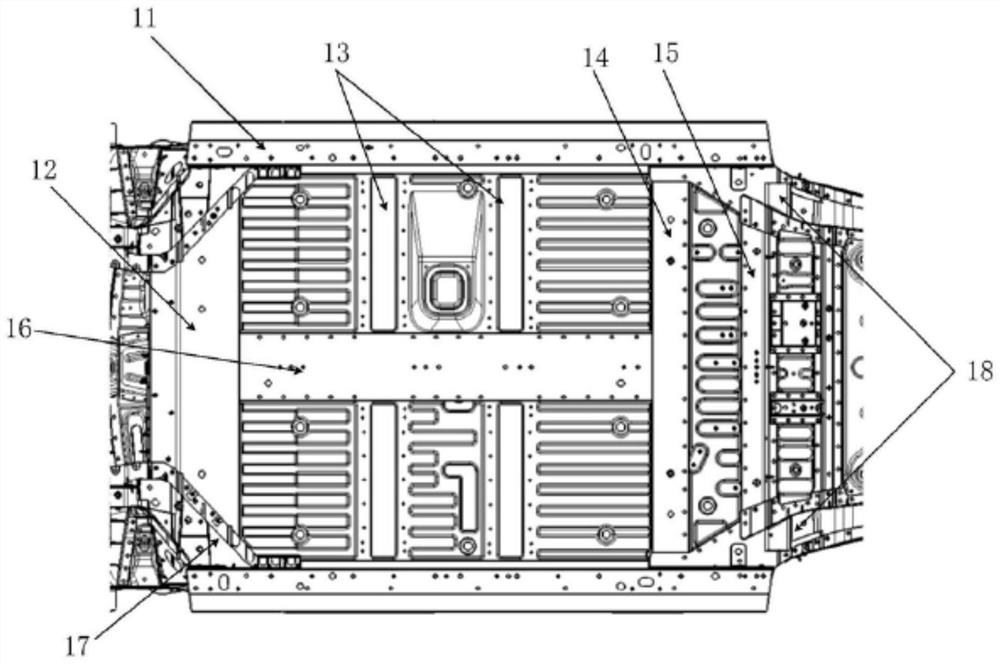

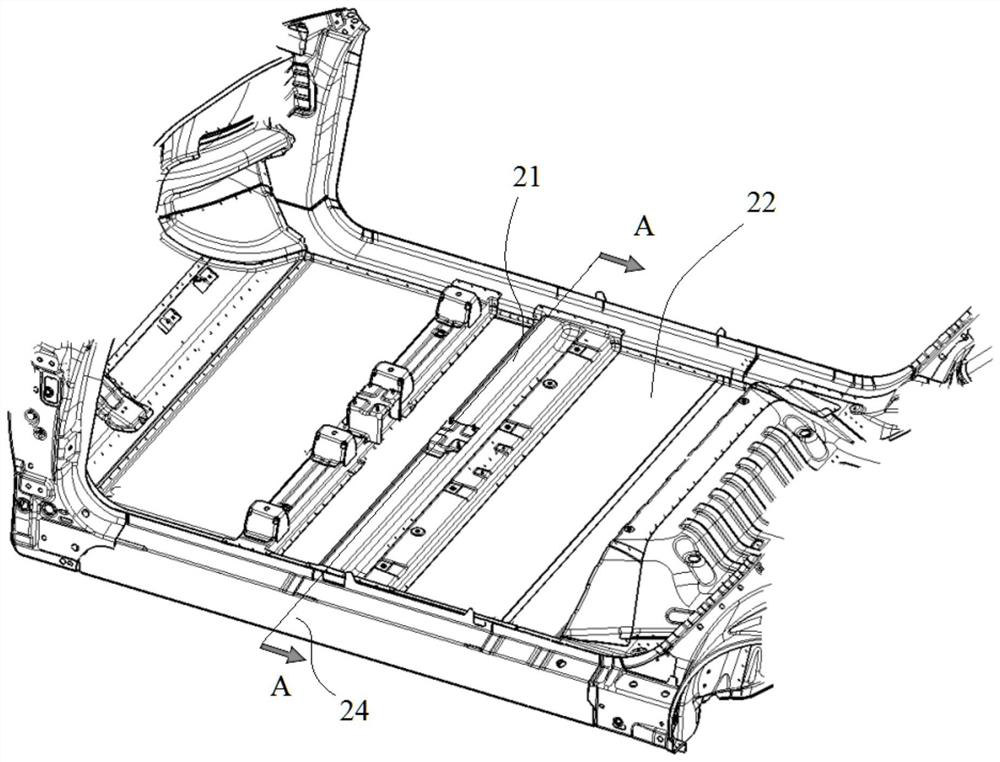

Doorsill longitudinal beam, electric automobile body frame and electric automobile

ActiveCN113602364AStable force transmissionUniform force transmissionElectric propulsion mountingSuperstructure subunitsBattery cellBattery pack

The invention relates to a doorsill longitudinal beam, an electric automobile body frame and an electric automobile. A first extrusion part in the doorsill longitudinal beam horizontally faces a floor cross beam, so that stable and uniform force transmission of side collision or column collision is ensured, the intrusion amount of a battery pack between two side edge beams is reduced, the battery pack does not bear the force transmission requirement of the side column collision at all, force transmission is completely borne by the vehicle body, so that the maximum arrangement space is provided for a battery core body; in addition, due to the fact that an installation gap is formed between the lower portion of a longitudinal beam inner plate and a side edge beam so as to install a pipeline connecting the front portion and the rear portion of the vehicle body, a middle channel can be omitted in the design process, and the riding experience of the whole vehicle is improved.

Owner:VOYAH AUTOMOBILE TECH CO LTD

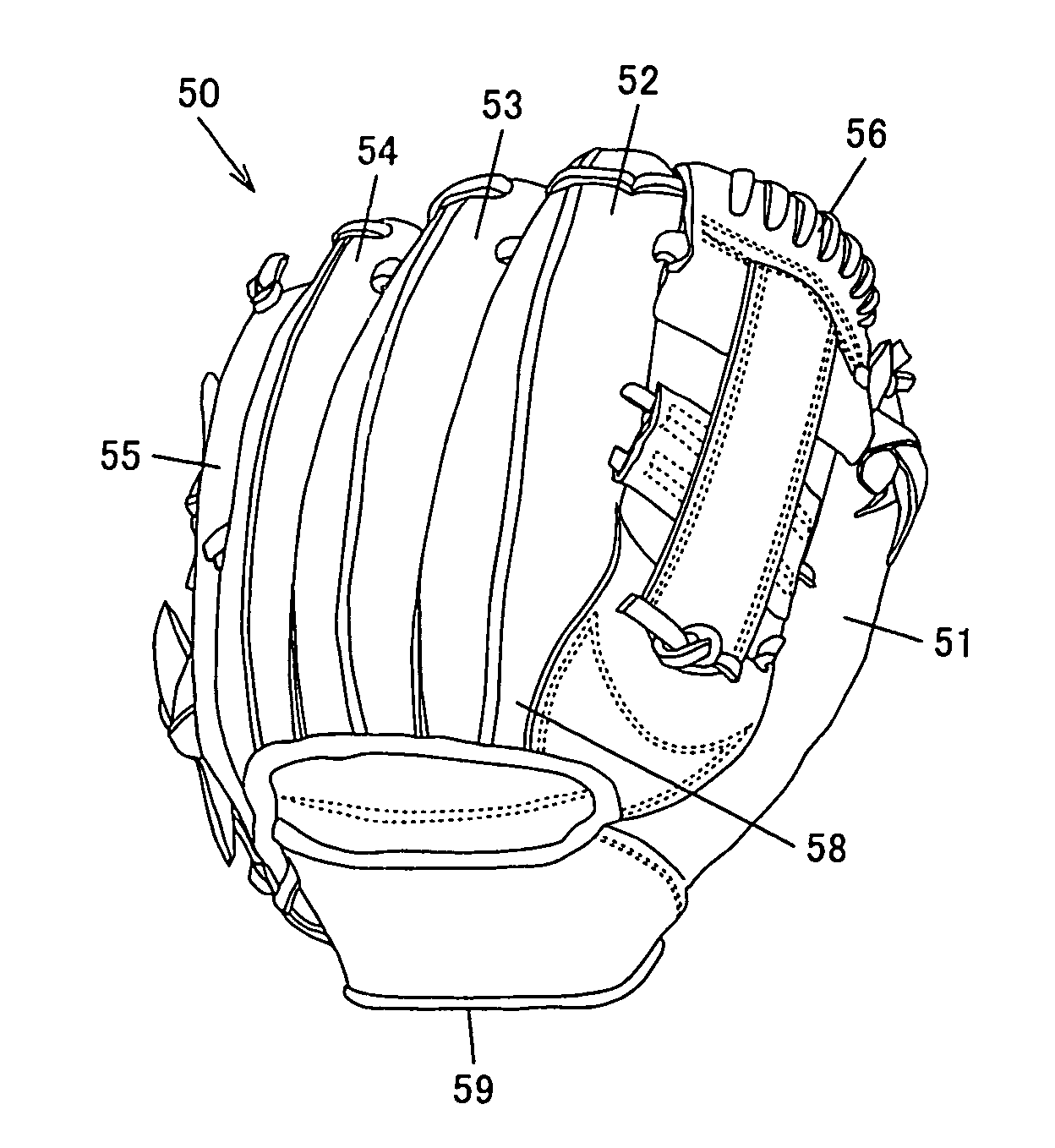

Catching tool for baseball or softball

In a catching tool for baseball or softball, a lining leather including at least a back-side leather and a palm-side leather is inserted into a surface leather including at least a back leather and a ball-receiving leather, and the lining leather has inner-side finger stalls defined by peripheral edges of the back-side leather and the palm-side leather which are sewn together. A finger part stabilizing member is provided along at least a region on right and left sides in a region covering a root part through a fingertip part of a wearer's finger inside the inner-side finger stall. The finger part stabilizing member is provided in at least one of the inner-side finger stalls, which are an inner-side thumb stall, an inner-side forefinger stall, an inner-side middle finger stall, an inner-side fourth finger stall, and an inner-side little finger stall.

Owner:MIZUNO CORPORATION

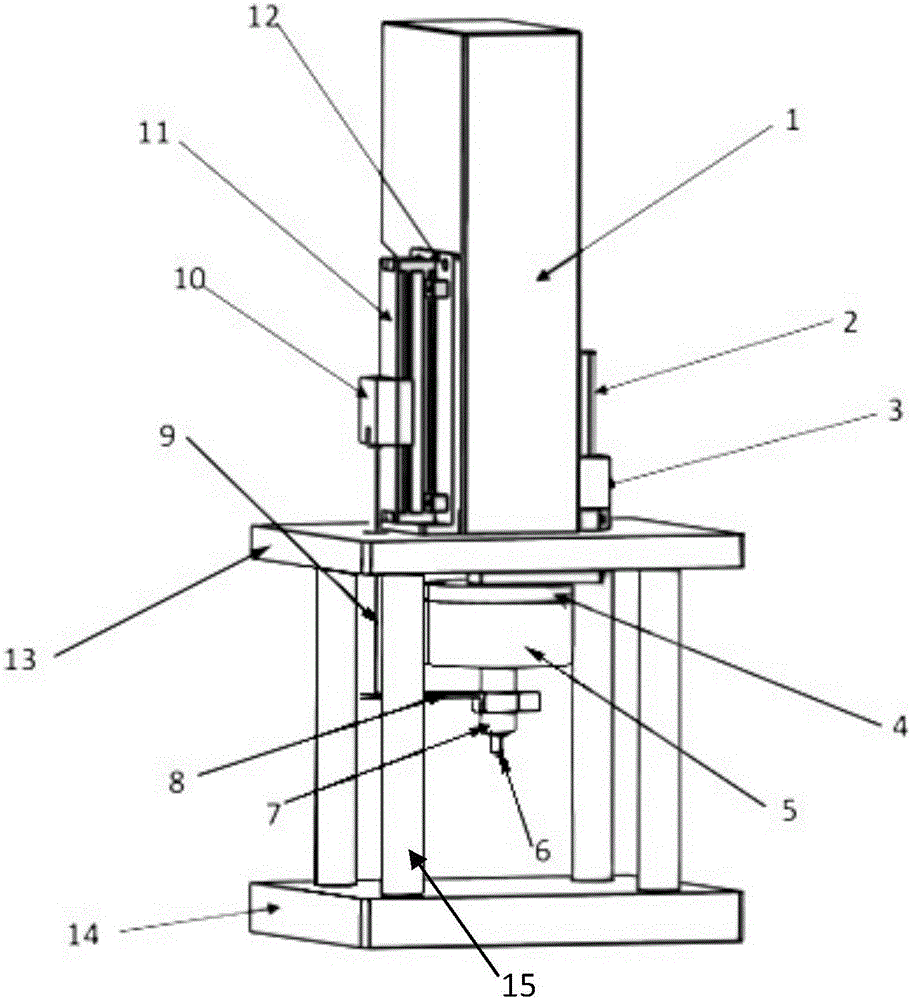

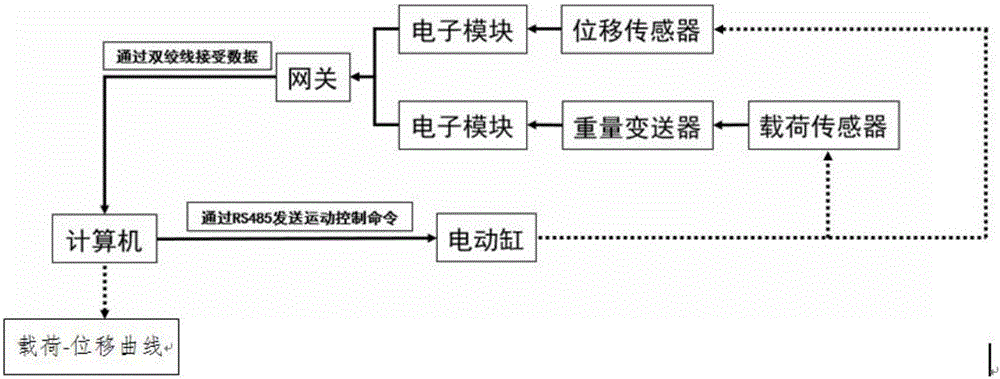

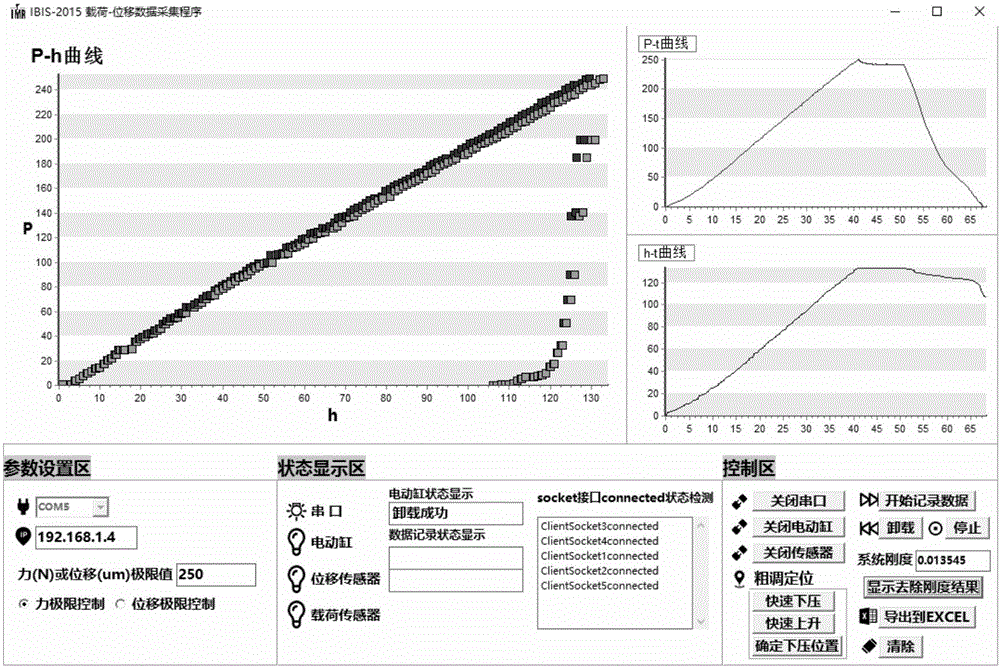

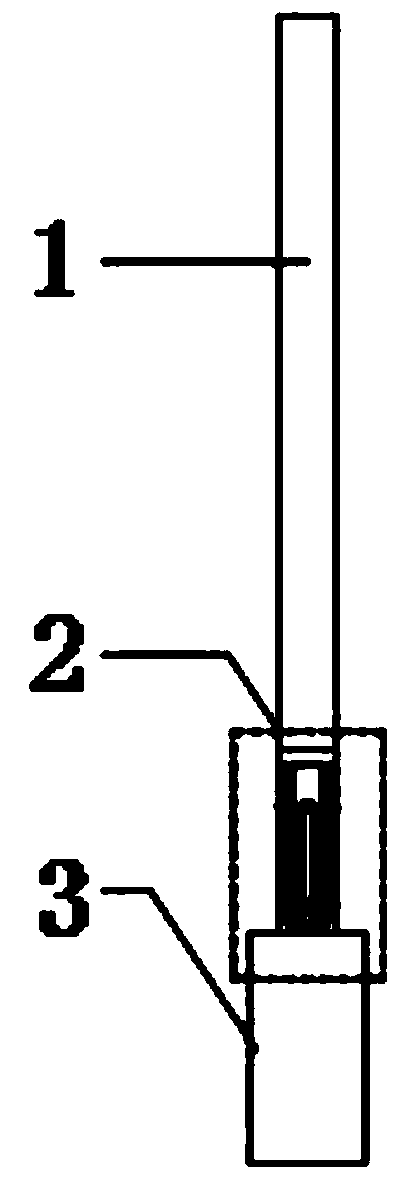

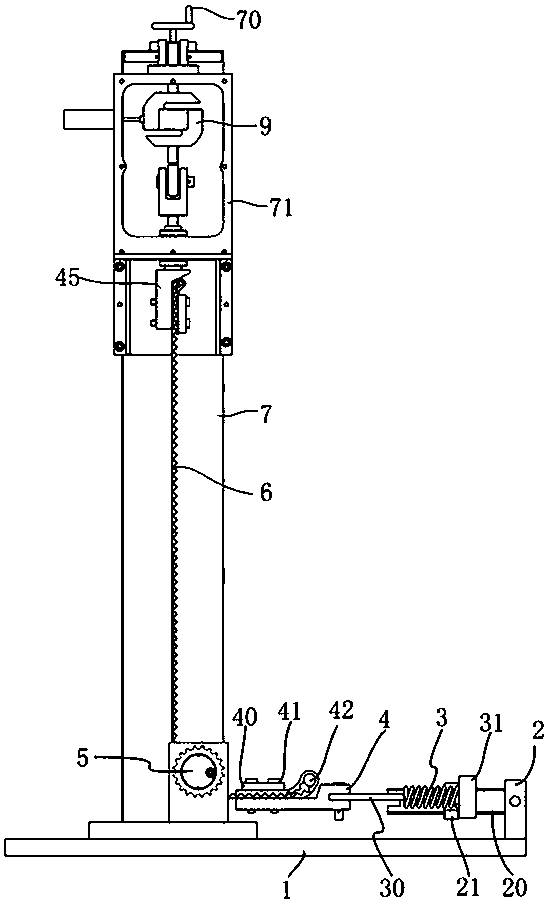

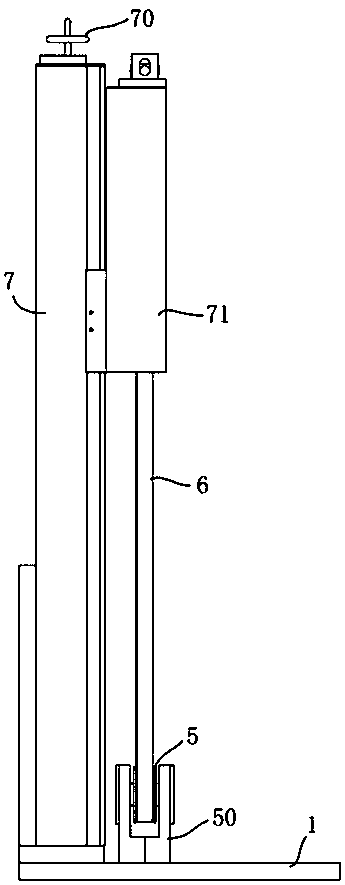

Computer controlled metal material indentation load-displacement data measurement system

InactiveCN105842095ACompact structureHigh precisionInvestigating material hardnessData acquisitionMetallic materials

Belonging to the technical field of material mechanical performance testing, the invention discloses a computer controlled metal material indentation load-displacement data measurement system. The measurement system comprises a mechanical part and an electric control part, the mechanical part is in charge of providing pressure for manufacturing indentations, and the electric control part is responsible for controlling linear motor motion and collecting and processing data. Linear motor motion drives a pressure head to manufacture indentations, a load sensor and a displacement sensor are respectively used for measuring the load applied to the pressure head and the pressure head displacement, and the load and the displacement data are respectively input into a gateway through a two-channel analog input electronic module and an SSI electronic module respectively. By means of an "IBIS2015 load-displacement data acquisition program" developed by programming software Delphi 7, a computer can realize serial communication with the servo linear motor, the displacement sensor and the load sensor through the gateway, thus finishing control of motor motion and acquisition of relevant data.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

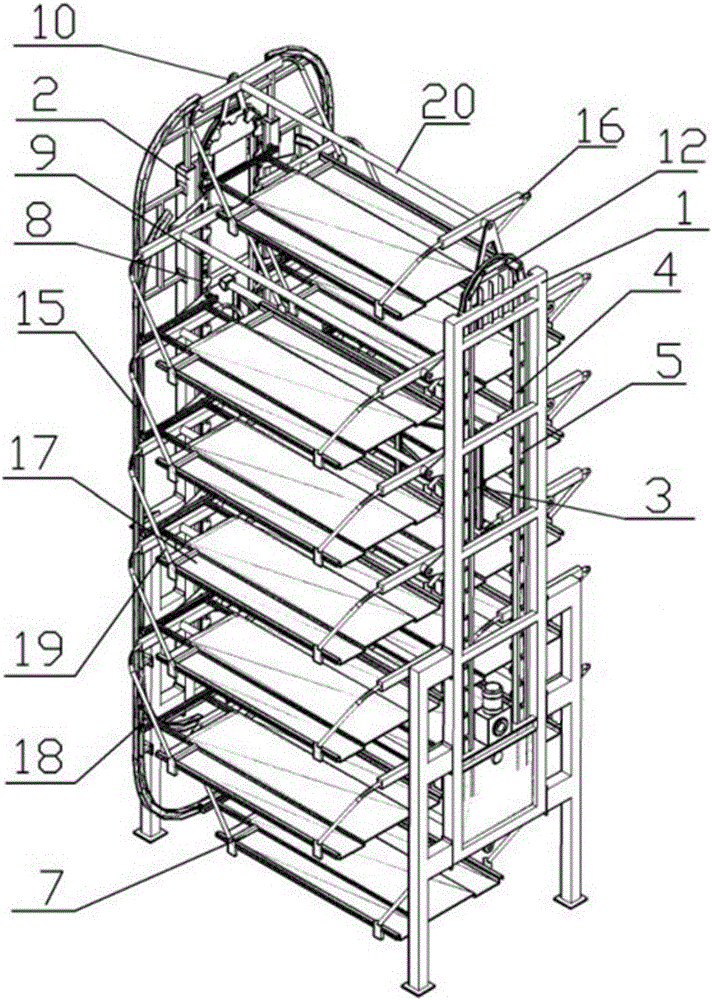

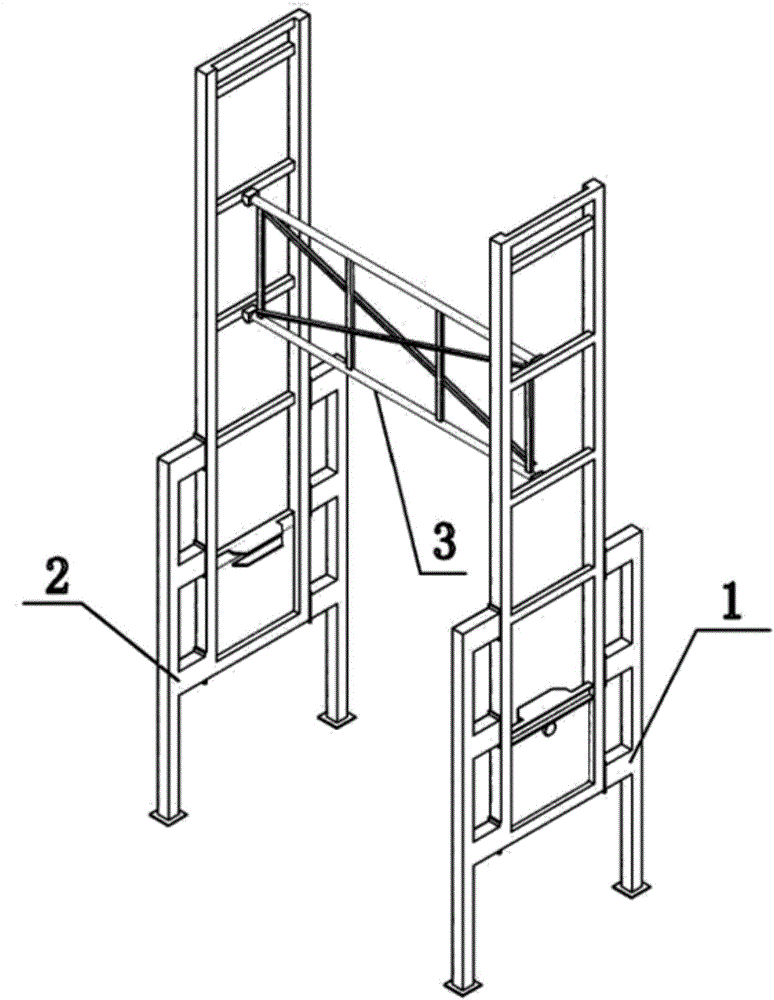

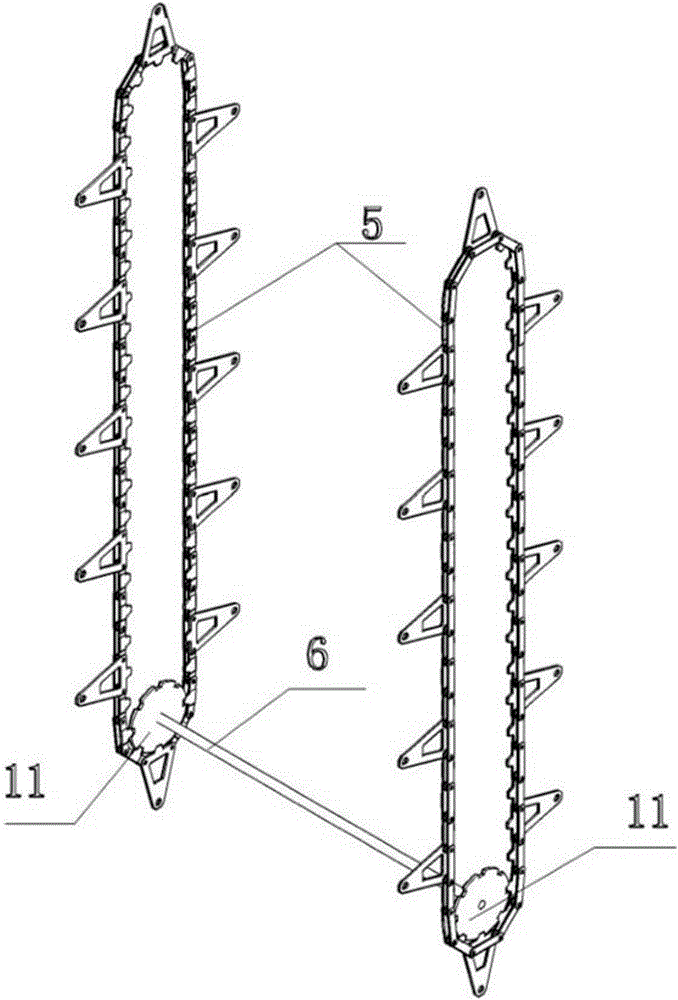

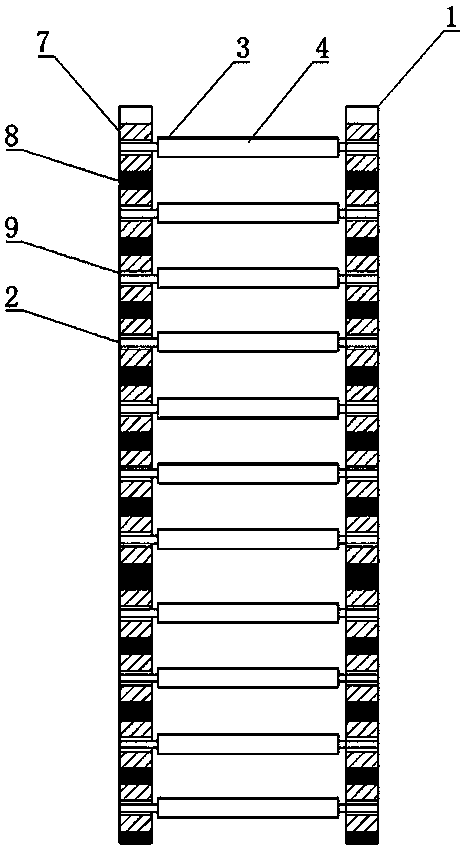

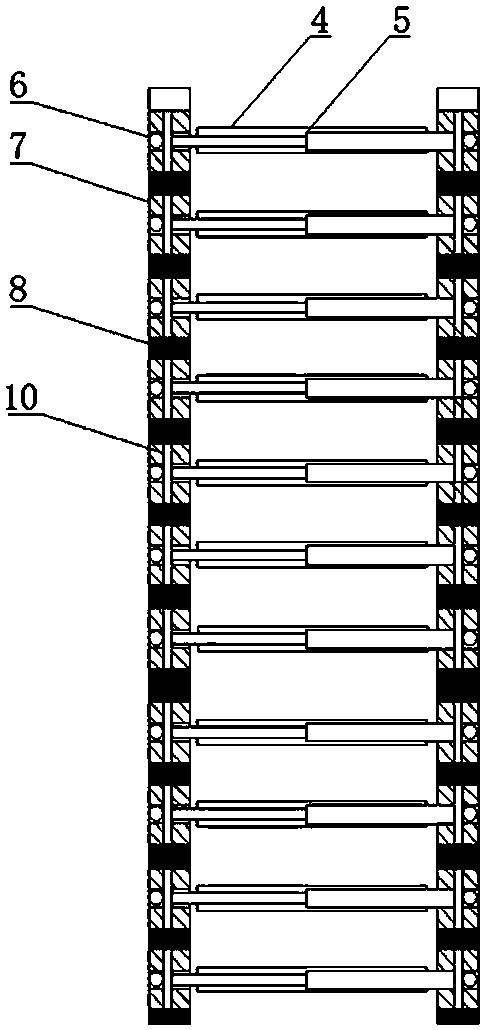

Stereo garage

A stereo garage comprises a driving framework, a guiding framework, a fixed beam, sealed guiding rails, lifting chains, a driving shaft, bearing frameworks, lifting chain sheets and a guiding rail. The driving framework and the guiding framework are of framework structures formed by square steel tubes which are welded; the fixed beam is fixedly connected between the driving framework and the guiding framework and forms a bearing main body with the driving framework and the guiding framework; the sealed guiding rails are respectively arranged in a vertical frame body of the driving framework and a vertical frame body of the guiding framework; the lifting chains are arranged on the sealed guiding rails, the lifting chains can circularly move in the sealed guiding rails and form a lifting system with the sealed guiding rails; the guiding rail is arranged on the outer side of the guiding framework; a plurality of lifting chain sheets are evenly distributed on each lifting chain; a plurality of bearing frameworks are horizontally arranged between two corresponding lifting chains in parallel, and hinge shafts of beams on the two sides of each bearing framework are in hinge connection with corresponding lifting chain sheets. The stereo garage is small in floor area, easy to process, flexible in transmission and low in construction cost.

Owner:朱德海

Driving force transmission mechanism and process cartridge containing the same

InactiveUS8737882B2Reduce wearStressed areaCouplings for rigid shaftsElectrographic process apparatusEngineeringImaging equipment

A driving force transmission mechanism comprising a photosensitive drum driving member, wherein the photosensitive drum driving member is engaged with an image forming apparatus driving member and receives the driving force from the image forming apparatus driving member; the image forming apparatus driving member comprises a triangular groove having a triangular cross-section and driving force transmission portion disposed in three vertex angles of the triangular groove; the photosensitive drum driving member comprises a non-distorting protrusion which is axially extended from the end face of a drum shaft and engaged with the groove on the image forming apparatus driving member; the protrusion has a position-limiting mechanism and a stressed mechanism; a projecting tooth obliquely disposed on said non-distorting protrusion is taken as the stressed mechanism; and each projecting tooth also has a mating surface which is engaged with the driving force transmission component to transmit the driving force.

Owner:NINESTAR CORP

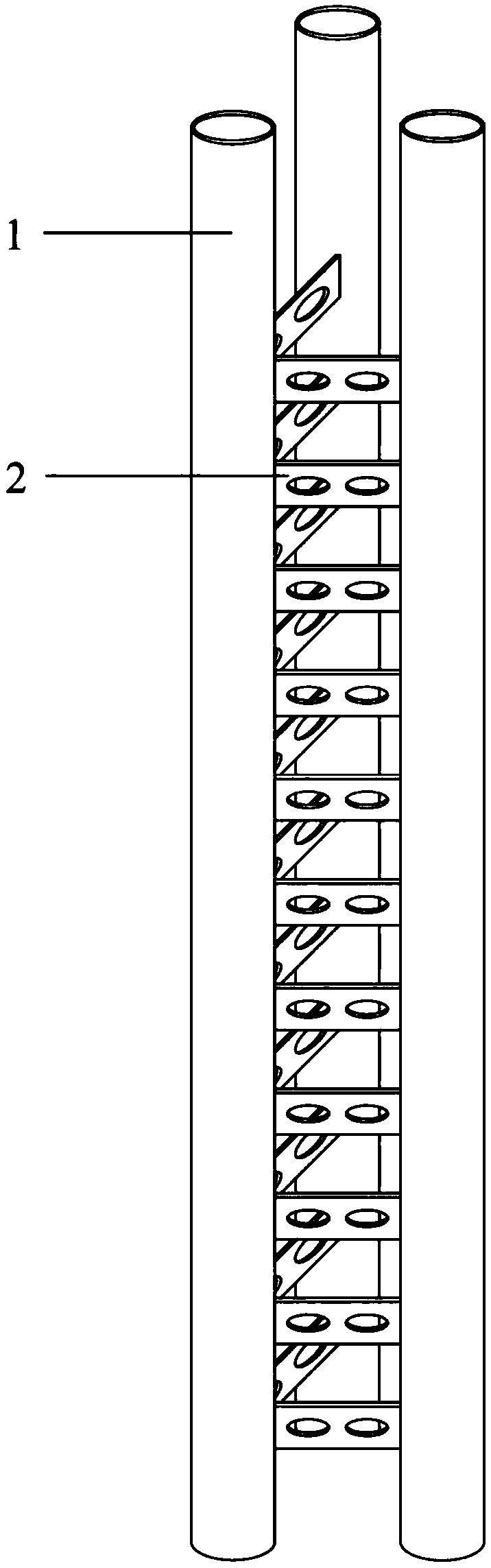

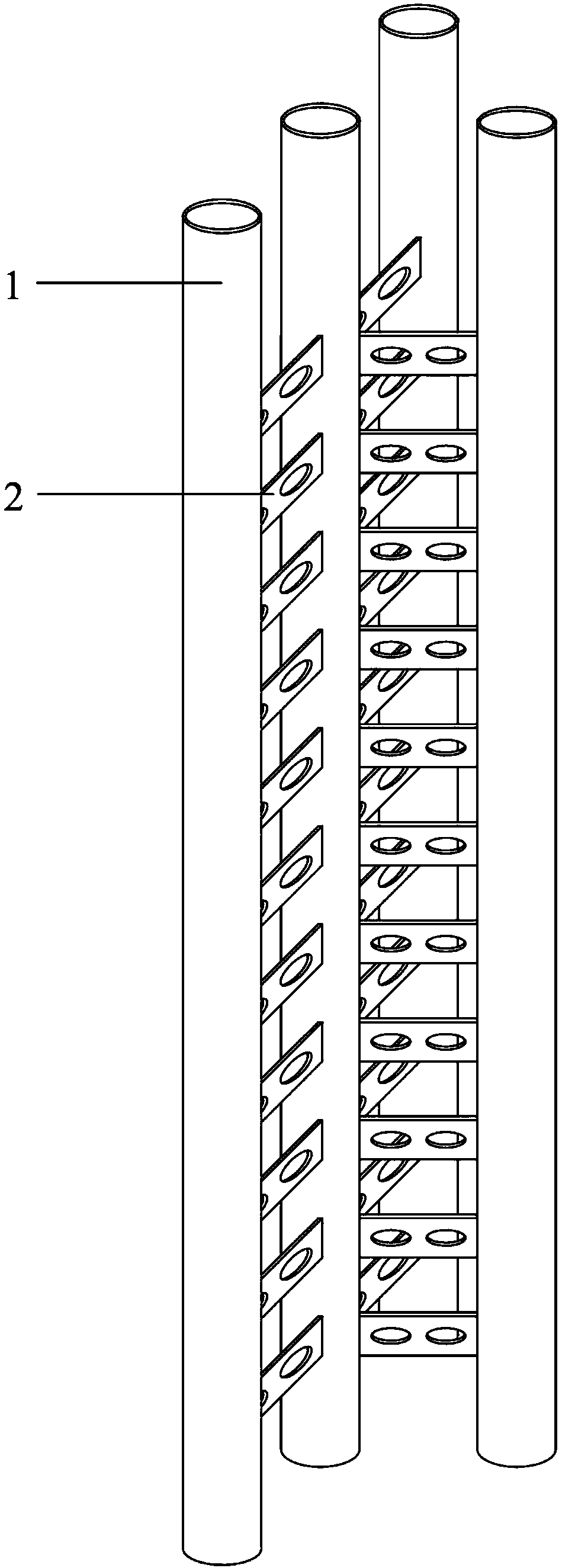

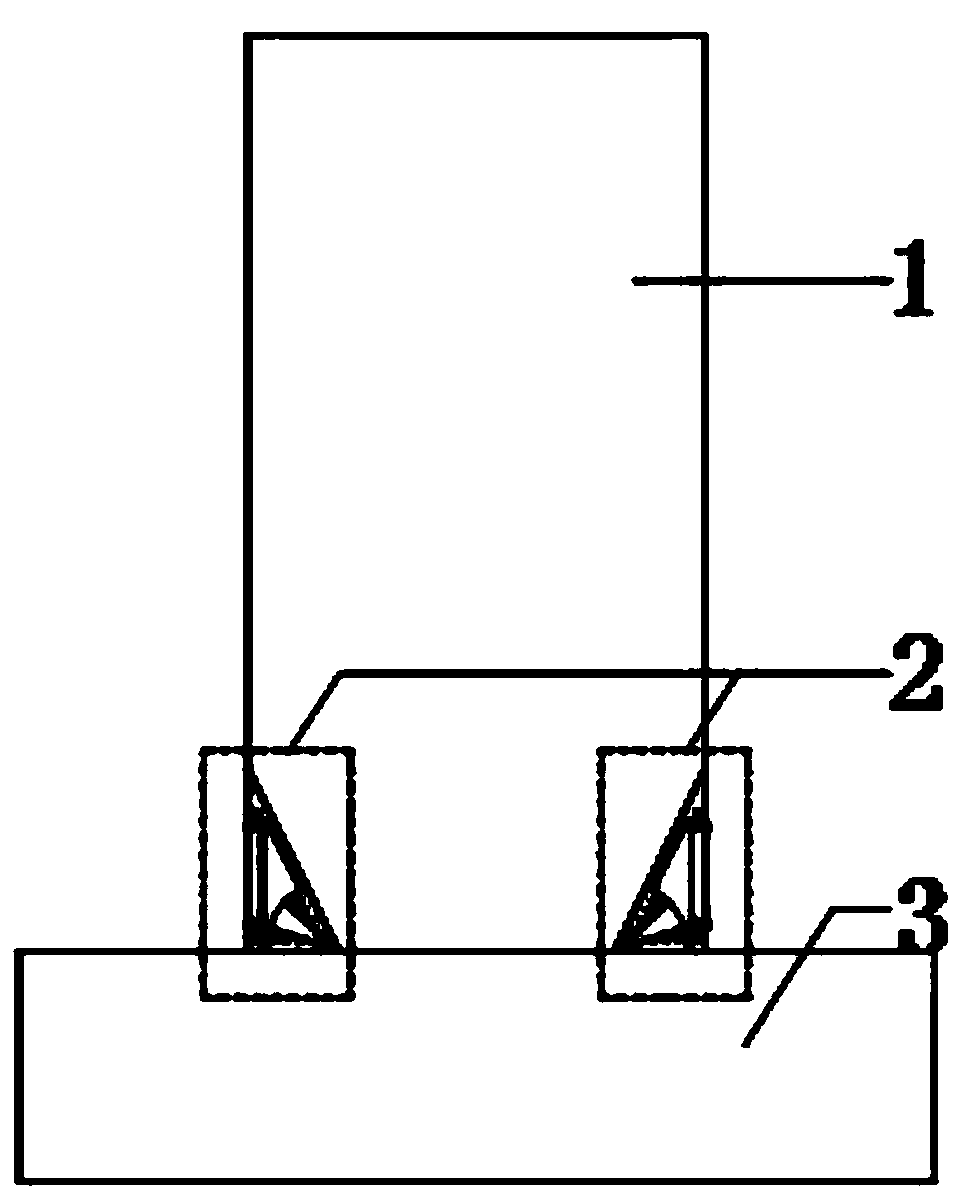

Self-resetting concrete shear wall with built-in shape memory alloys

ActiveCN110005096AAvoid crush damageRealize resetWallsProtective buildings/sheltersReinforced concreteShape-memory alloy

The invention belongs to the technical field of building structures, and relates to a self-resetting concrete shear wall with built-in shape memory alloys. The self-resetting concrete shear wall comprises a reinforced concrete shear wall panel 1 and shape memory alloy (SMA) devices 2. The SMA devices comprise SMA rods and viscoelastic energy dissipation devices. The elastic restoring force generated by the SMA rods drives the wall to return to an initial position when the horizontal load is reduced, and the problem that the wall resetting ability is decreased caused by the loss of prestress during long-term use does not exist. When the wall is laterally deformed, significant restoring force can be produced to drive the wall to reset without the need of excessive deformation, the reset of the wall is realized, the viscoelastic energy dissipation devices convenient to replace can be designed into viscoelastic energy dissipation devices with different damping characteristics according toengineering requirements, wall dynamic characteristics are improved, and the structural performance is optimized.

Owner:BEIJING JIAOTONG UNIV

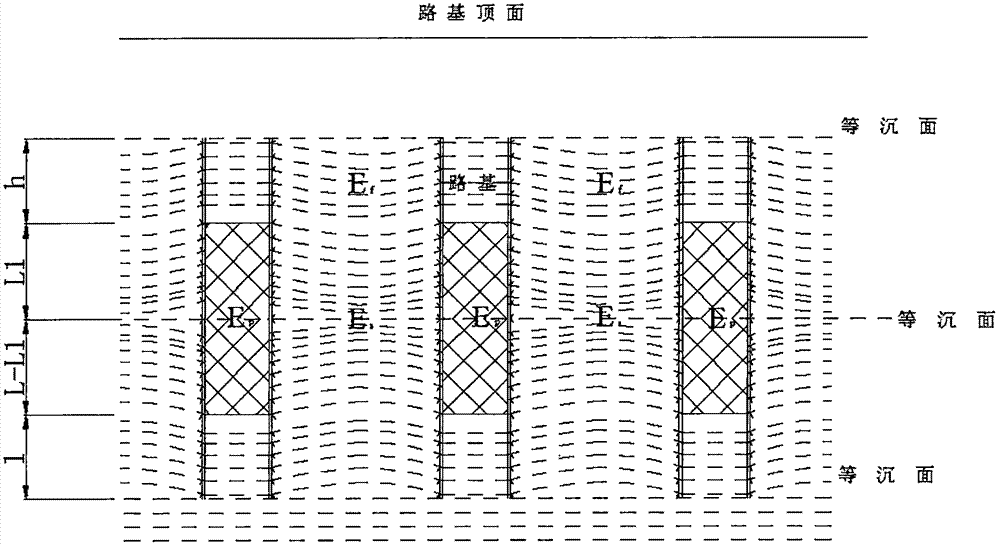

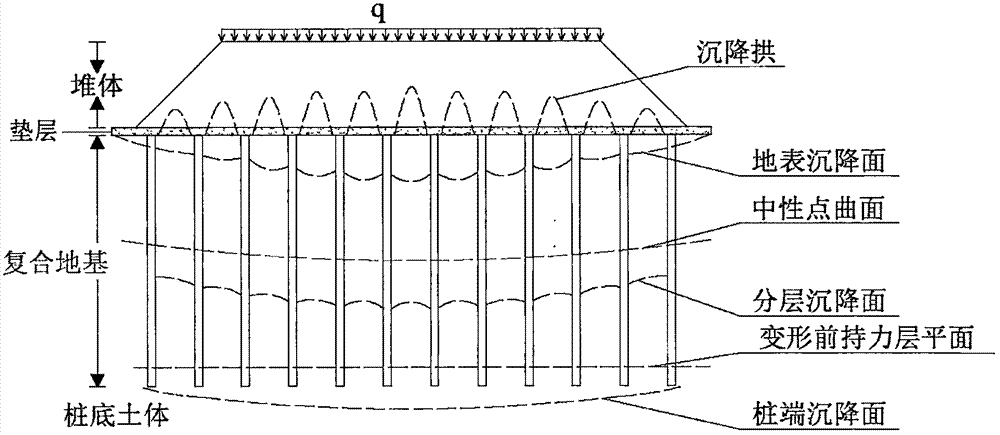

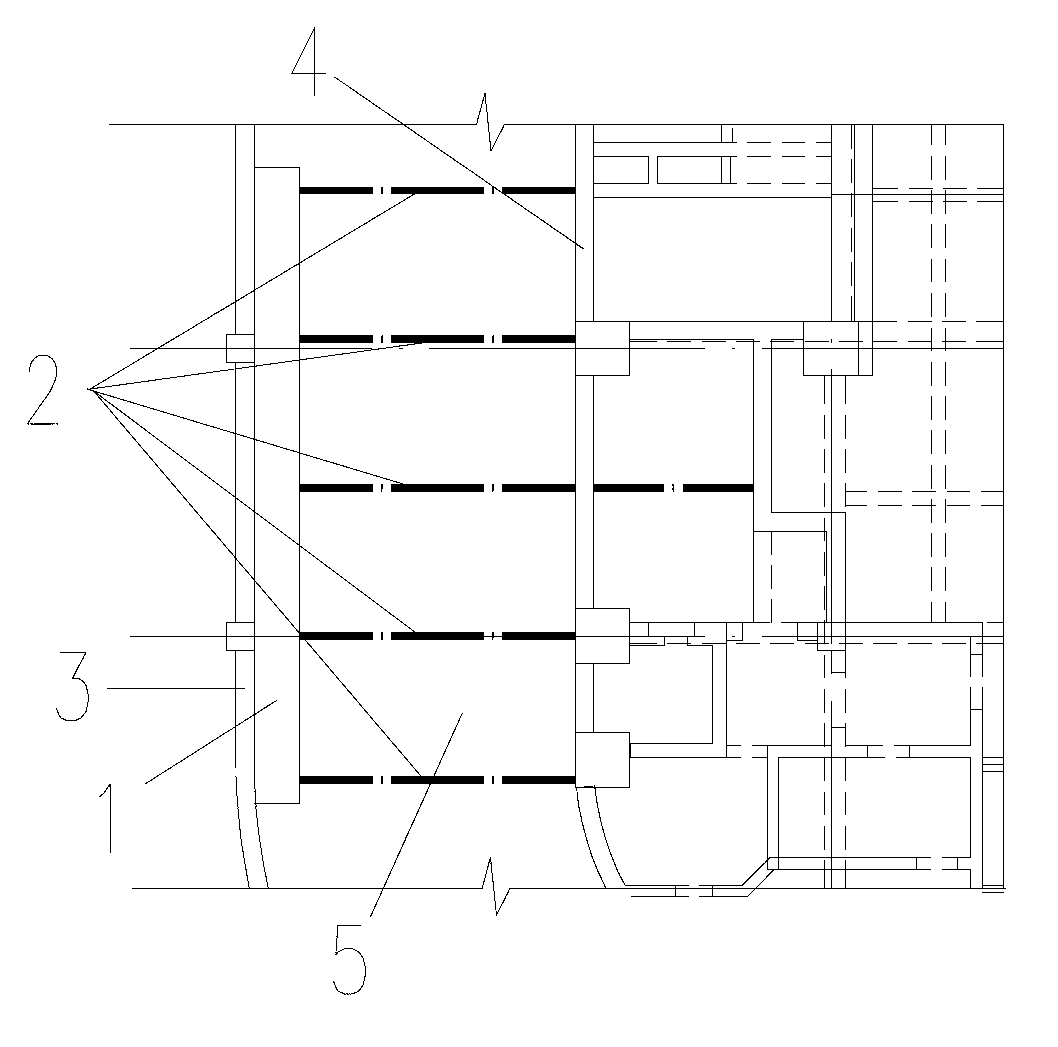

Pile-supported and rigidity-varied reinforced cushion composite foundation and construction method thereof

The invention provides a pile-supported and rigidity-varied reinforced cushion composite foundation and a construction method thereof. The construction method comprises steps as follows: pile body construction of rigid piles is completed in a soft foundation by a pile forming machine, the ground is leveled, a sand and gravel layer which is 150-300 mm thick is laid and is leveled and compacted, then a first geogrid layer is laid, a sand and gravel layer which is 150-300 mm thick is laid on the first geogrid layer and is leveled and compacted, then a second geogrid layer is laid, and a cement stabilized macadam layer which is 150-300 mm thick is laid on the second geogrid layer; finally, road embankment filling is completed. According to the pile-supported and rigidity-varied reinforced cushion composite foundation and the construction method thereof, rigidity of a reinforced cushion is adjusted hierarchically, so that bearing capacity of soil among piles is sufficiently exerted, uneven settlement of a road surface is reduced, and filling limitation at the upper part is broken through. The construction method is suitable for treating foundations of cohesive soil, floury soil, sludge and mucky soil and can be applied to stabilization and treatment of foundations of structures such as earth-filled embankments, flexible surface storage yards, airport runways, oil tanks, grain depots and the like.

Owner:山东省建筑科学研究院有限公司 +1

Construction method for changing steel pipe supports of ramp foundation pit

The invention discloses a construction method for changing steel pipe supports of a ramp foundation pit. The construction method comprises the following steps of: 1, punching a support pile in the periphery of a ramp in a length direction, connecting an inner support system to the inner side of the support pile, then excavating the foundation pit; 2, paving a bottom plate of the ramp in the foundation pit and constructing a ramp inner wall and a ramp outer wall on two sides of the bottom plate of the ramp; 3, constructing a boundary beam on the inner side of the ramp outer wall, sequentially pre-embedding a plurality of pre-embedded steel plates at intervals; 4, connecting additionally-embedded steel plates arranged in one-to-one correspondence with the pre-embedded steel plates to the inner side of the ramp inner wall; 5, connecting a steel pipe support between each pre-embedded steel plate and the corresponding additionally-embedded steel plate; 6, refilling backfill and paving a plain concrete transfer slab band between the support pile and the ramp outer wall; 7, dismantling the inner support system; and 8, pouring concrete of the ramp inner wall and the ramp outer wall, concrete of a ramp top plate beam and concrete of a ramp top plate. By adopting the method, a support changing system is balanced and stable in stress and has enough strength.

Owner:天津住宅集团建设工程总承包有限公司

Frame system comprising prefabricated steel tube concrete combined special-shaped column and energy-consuming steel plate wall

The invention discloses a frame system comprising a prefabricated steel tube concrete combined special-shaped column and an energy-consuming steel plate wall. The system mainly comprises prefabricatedcorner columns, prefabricated side columns and prefabricated middle columns, H-shaped steel beams, the energy-consuming steel plate wall with elliptical holes, prefabricated steel floors, column-column connection flanges, column-column connection rubber pads, column-beam connection parts, middle column-beam connection part, column-wall connection parts and the like, wherein the prefabricated corner columns, prefabricated side columns and prefabricated middle columns are made of circular steel tube concrete columns and steel batten plates; the column-column connection flanges, the column-beamconnection parts, the middle column-beam connection parts and the column-wall connection parts are welded and prefabricated with steel pipes; the structural parts are connected by high-strength bolts.A rubber pad is placed between the upper and lower columns to connect the flanges to enhance the connection. Energy-consuming steel wall and steel slabs open holes to improve the energy consumption and seismic performance of the structural system. The invention realizes full dry construction, no wet operation, simple and quick construction engineering, high construction efficiency, stable and reliable node connection, and good seismic performance of the structural system.

Owner:BEIJING UNIV OF TECH

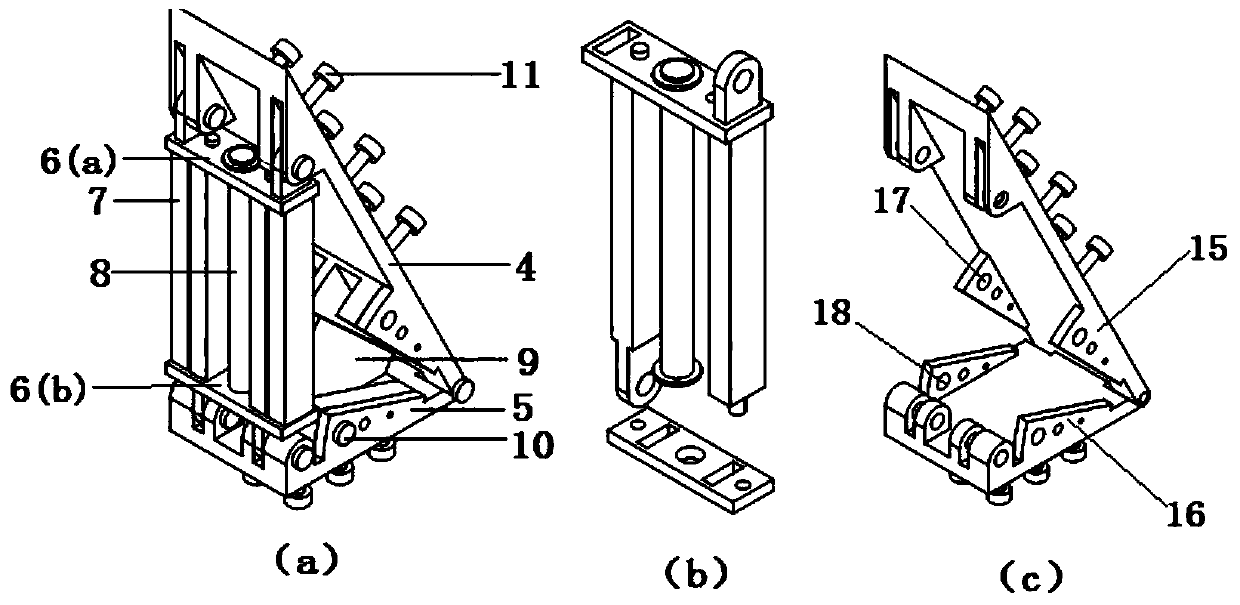

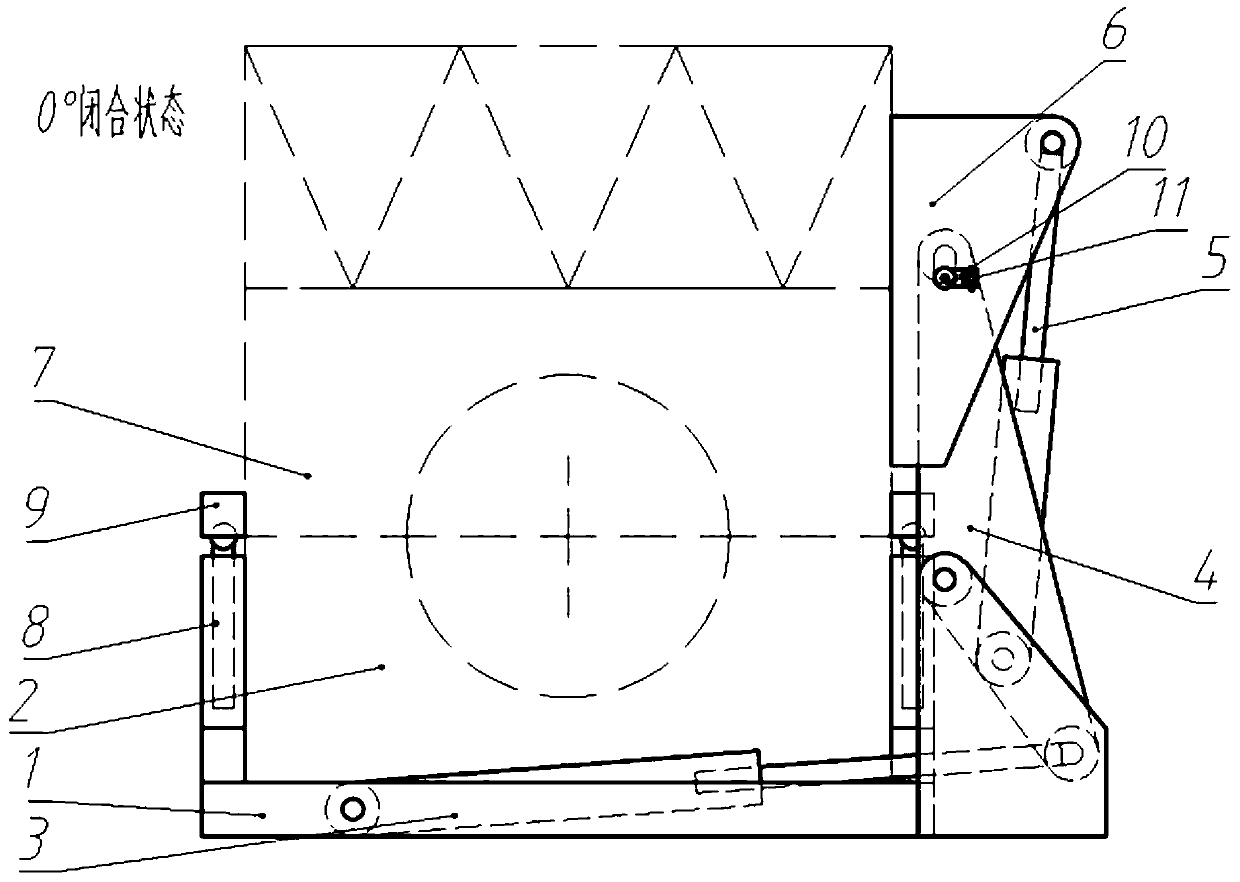

Wind blade automatic turning and mold closing device

ActiveCN110154281ANo loadAvoid volatilityDomestic articlesHydraulic cylinderAgricultural engineering

The invention relates to a wind blade automatic turning and mold closing device. The wind blade automatic turning and mold closing device comprises a base, a lower mold fixedly arranged on the base, and a turnover upper mold movably arranged at the upper part of the lower mold through a turnover mechanism, wherein the turnover mechanism comprises a main hydraulic cylinder, an auxiliary hydraulic cylinder, a main rocker arm, and an auxiliary rocker arm; the main hydraulic cylinder is fixedly arranged on the base; the main rocker arm is rotatably arranged on the base and is connected to the output end of the main hydraulic cylinder in a transmission manner; the auxiliary rocker arm is fixedly arranged on the side of the upper mold; one end of the auxiliary hydraulic cylinder is rotatably arranged on the main rocker arm; the output end of the auxiliary hydraulic cylinder is connected to the auxiliary rocker arm in a transmission manner; a positioning mechanism for positioning the relativeposition of the upper mold and the lower mold is also arranged on the main rocker arm; and a positioning hole matched with the positioning mechanism is also formed in the auxiliary rocker arm. The wind blade automatic turning and mold closing device has high reliability and stable stress and saves space.

Owner:SHANDONG SHUANGYI TECH

Frame construction for low-rise building

A frame construction for a low rise building. In the construction, a wall frame panel is made of thin light-gauge section steel by bonding together a surface member, a lower frame member, vertical frame members and an upper frame member. Roof or floor support girders are made of heavyweight section steel having H-shape or channel shape. The girders are coupled to frame construction panels by bolts or hold-down fasteners.

Owner:NIPPON STEEL CORP

Unpowered roller for conveying

InactiveCN108689075AGuaranteed carrying capacityAvoid breakingSupporting framesRoller-waysLong armLeft half

The invention belongs to the field of conveying devices, and particularly relates to an unpowered roller for conveying. The unpowered roller comprises long arm cross arms, rotary shafts, rollers withsleeves, transverse hydraulic devices and vertical hydraulic devices. The long arm cross arms comprise fixing blocks and flexible connecting devices between the fixing blocks. The two ends of the rotary shafts are mounted on the fixing blocks through bearings, the rollers are fixedly mounted on the rotary shafts, the rollers comprise left half rollers and right half rollers, and the left half rollers and the right half rollers are in penetrating-inserting connection through splines. One ends of the transverse hydraulic devices are fixedly mounted on the lower faces of the fixing blocks throughfixing plates, the other ends of the transverse hydraulic devices are fixedly mounted on the lower faces of the corresponding fixing blocks through fixing plates, and the vertical hydraulic devices are fixedly mounted on the lower faces of the fixing blocks and located on the outer sides of the fixing plates. The lengths of the rollers are adjusted through the transverse hydraulic devices and theconveying height is adjusted through the vertical hydraulic devices, the conveying requirements of workpieces or cargoes of different sizes are met, and the beneficial effects of being high in practicality and high in working efficiency are achieved.

Owner:湖州银轴智能装备有限公司

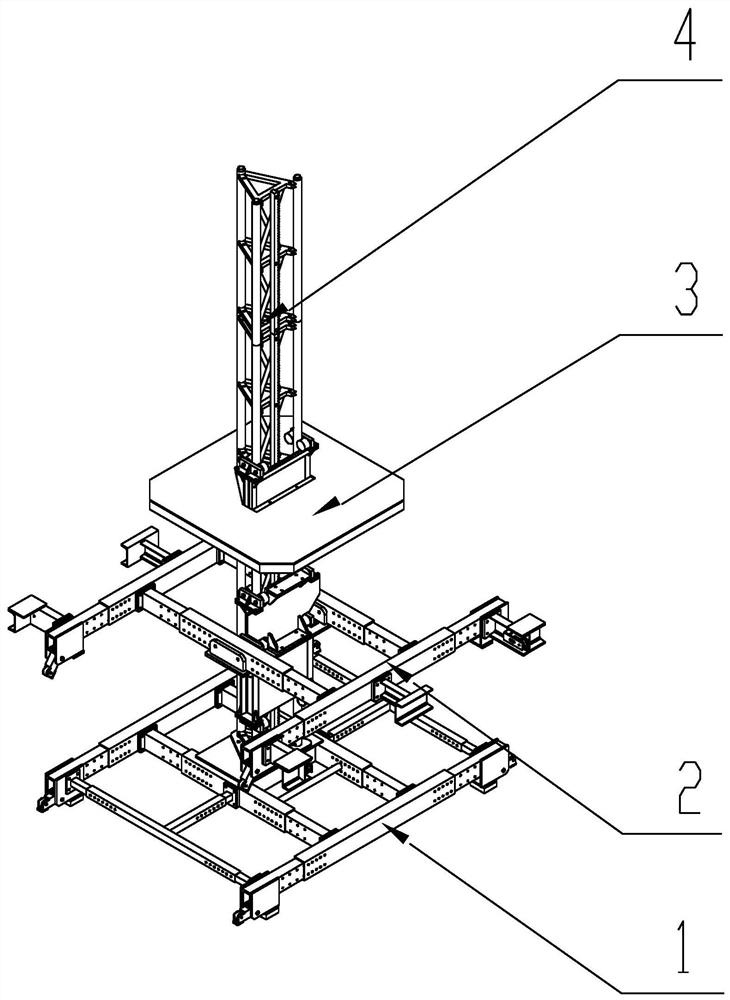

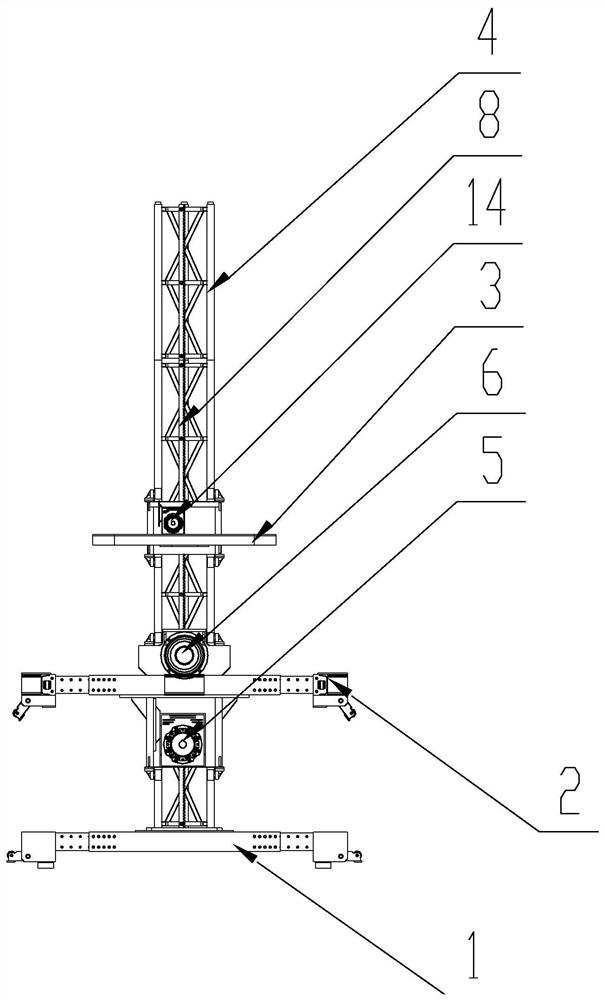

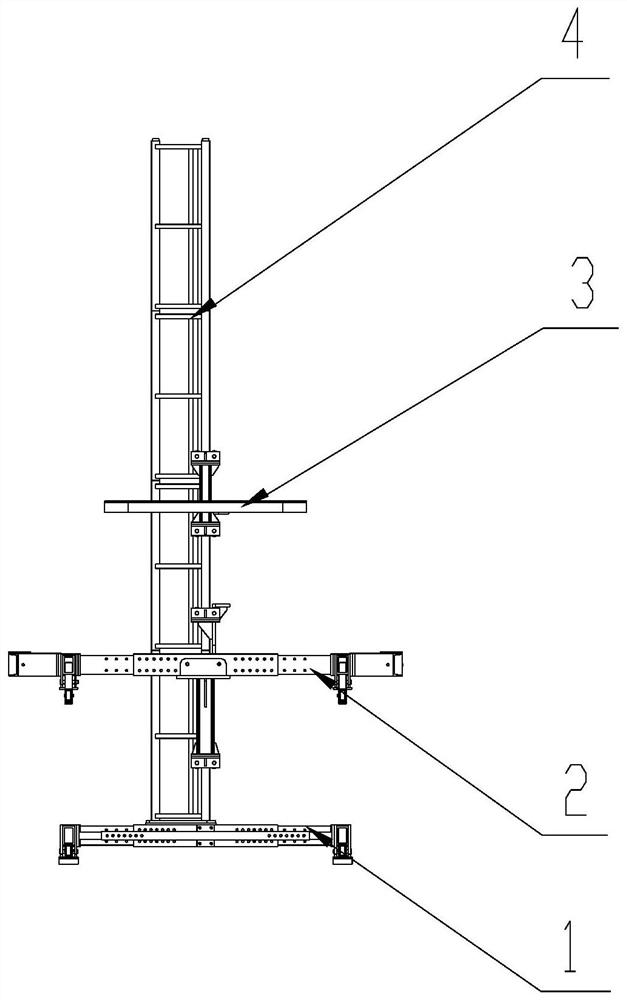

High-rise building climbing pouring system and operation method thereof

PendingCN111877746ASmall amount of deformationStable force transmissionForms/shuttering/falseworksAuxillary members of forms/shuttering/falseworksElectric machineryStructural engineering

The invention provides a high-rise building climbing pouring system and an operation method thereof. The high-rise building climbing pouring system comprises a formwork assembly, a climbing machine assembly, a motor assembly and a positioning box, the formwork assembly is controlled by the motor assembly to be retracted and released, the climbing machine assembly comprises a lower climbing frame,an upper climbing frame, an operation platform and a guide frame, and the formwork assembly is supported at the top of the upper climbing frame. When the climbing machine assembly climbs, the upper climbing frame ascends by a climbing height along the guide frame under the power effect of the motor assembly to form primary climbing installation with the positioning box poured in a foundation pit formwork, and the lower climbing frame is lifted into the positioning box installed through the upper climbing frame in the climbing manner last time along the guide frame under the power effect of themotor assembly, one-time lifting installation is formed, and at the moment, one-time climbing is completed through the high-rise building climbing pouring system. According to the high-rise buildingclimbing pouring system and the operation method thereof, the climbing stability and safety of the climbing machine assembly are guaranteed, the application range is wide, and the green and environment-friendly concept of modern buildings can be met.

Owner:JIANGXI GETO NEW MATERIALS CORP LTD

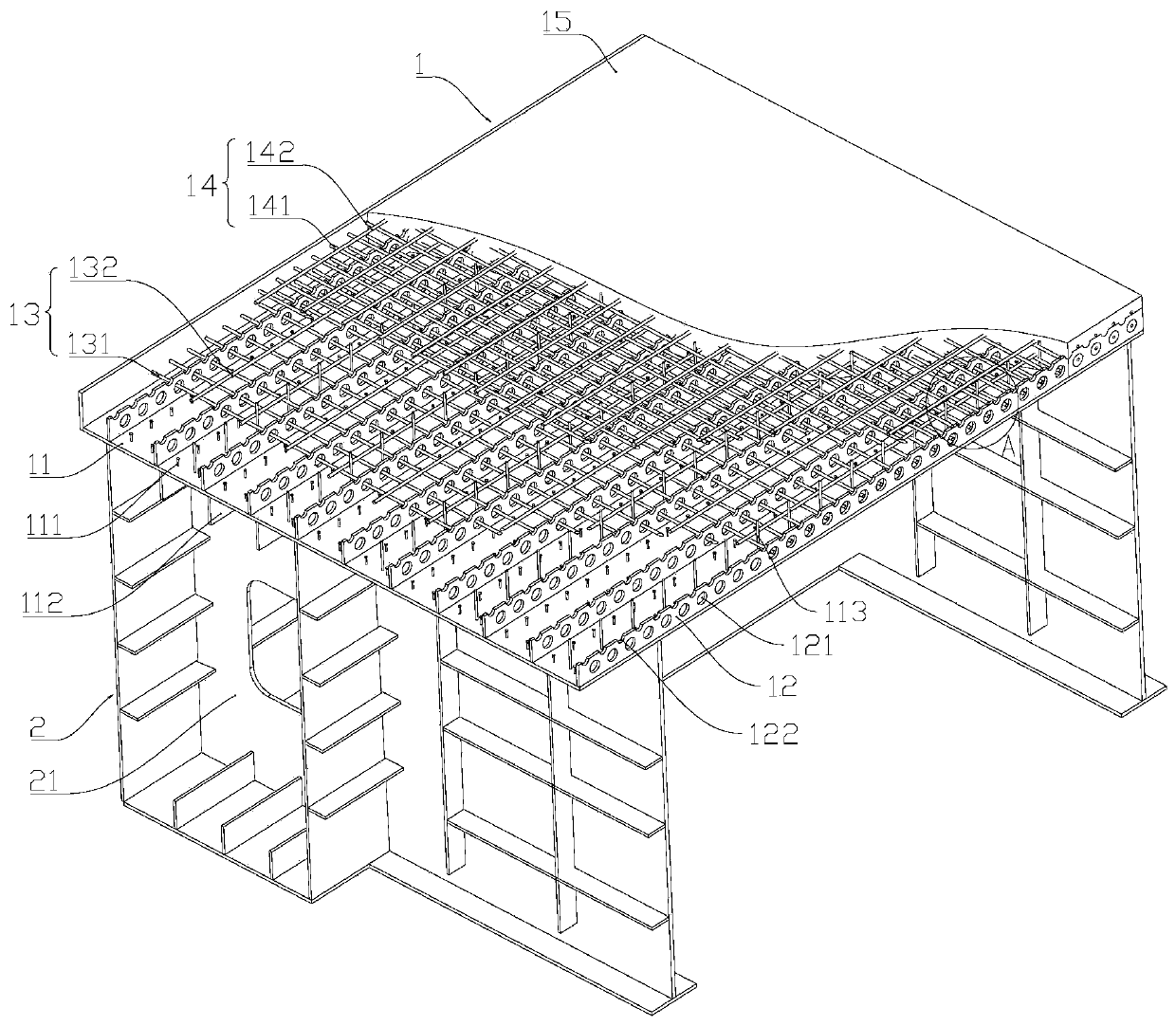

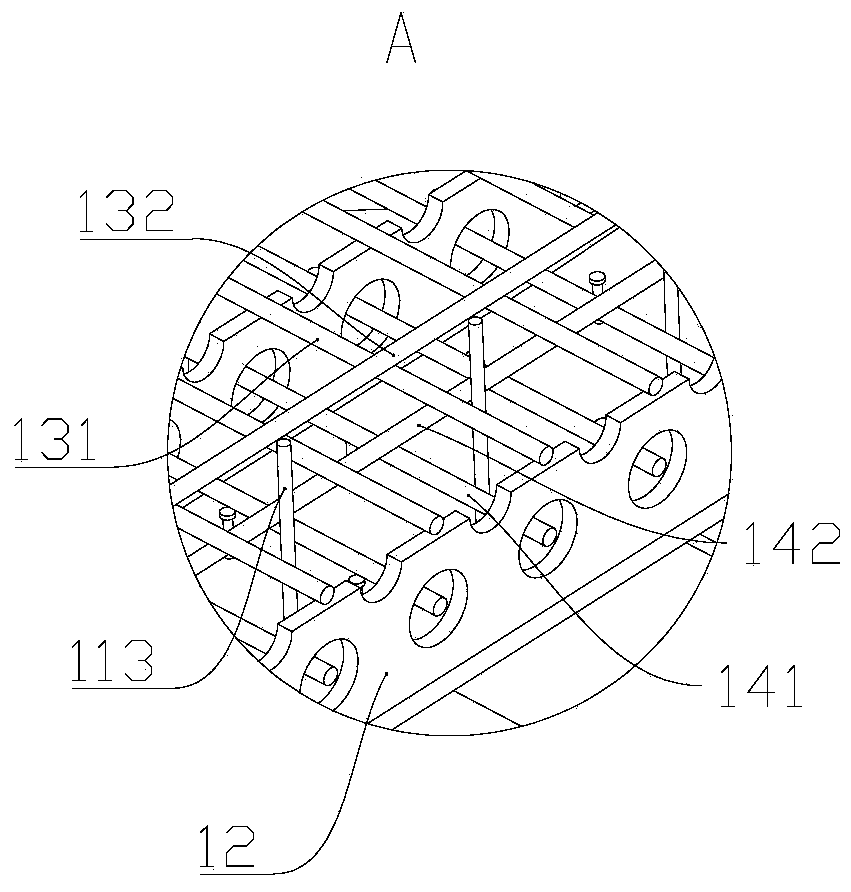

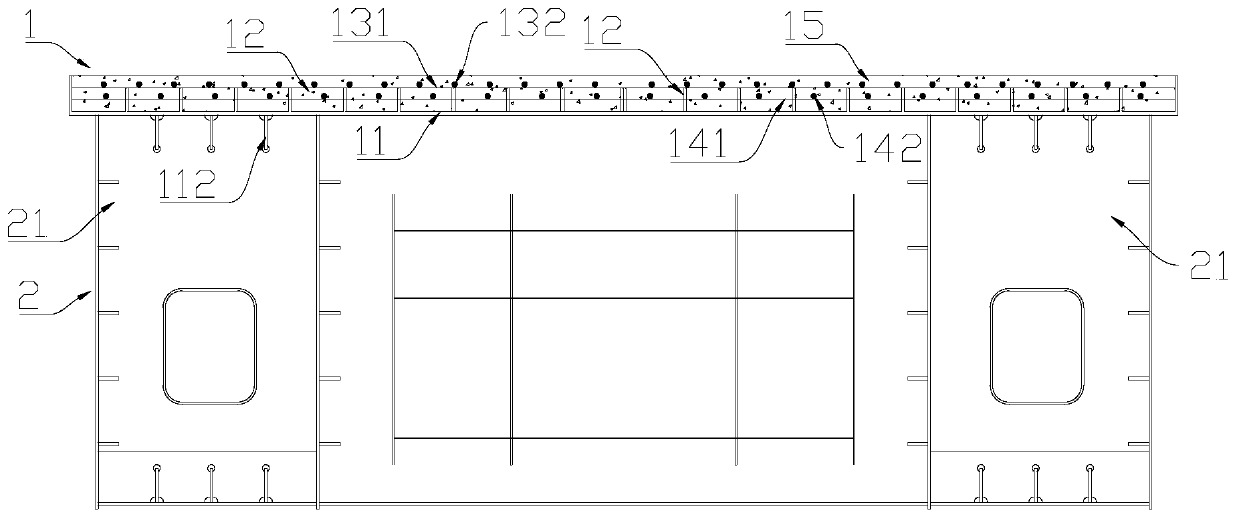

Steel bridge with inverted ribs and orthotropic composite bridge deck

PendingCN110847036AGuaranteed rigidityAvoid concentrated stressBridge structural detailsStress concentrationBridge engineering

The invention discloses a steel bridge with inverted ribs and an orthotropic composite bridge deck, and belongs to the technical field of bridge engineering. The steel bridge with the inverted ribs and the orthotropic composite bridge deck comprises the steel-concrete composite bridge deck and support beams arranged under the steel-concrete composite bridge deck and used for supporting the steel bridge deck; the steel-concrete composite bridge deck comprises a steel bridge deck slab, multiple steel plates with holes, an upper reinforcing mesh, a lower reinforcing mesh and a concrete layer; themultiple steel plates with the holes are arranged on the steel bridge deck slab at intervals; multiple through holes are formed in the steel plates with the holes; multiple rabbets are arranged at the top ends of the steel plates with the holes; multiple columns of shearing-resistant nails are arranged between the adjacent steel plates with the holes; the lower reinforcing mesh penetrates throughthe through holes so as to be arranged in the steel plates with the holes; the upper reinforcing mesh is arranged above the steel plates with the holes; and the concrete layer is arranged on the steel bridge deck slab and is higher than the upper reinforcing mesh. The steel bridge with the inverted ribs and the orthotropic composite bridge deck provided by the invention can effectively solve theproblems such as complexity in construction, fatigue cracks, poor durability and stress concentration commonly existed on a current orthotropic composite bridge deck structure, and the problems such as rapid wear of a pavement layer on a road steel bridge deck and difficulty in maintaining the steel bridge deck of a railway.

Owner:SOUTHWEST JIAOTONG UNIV

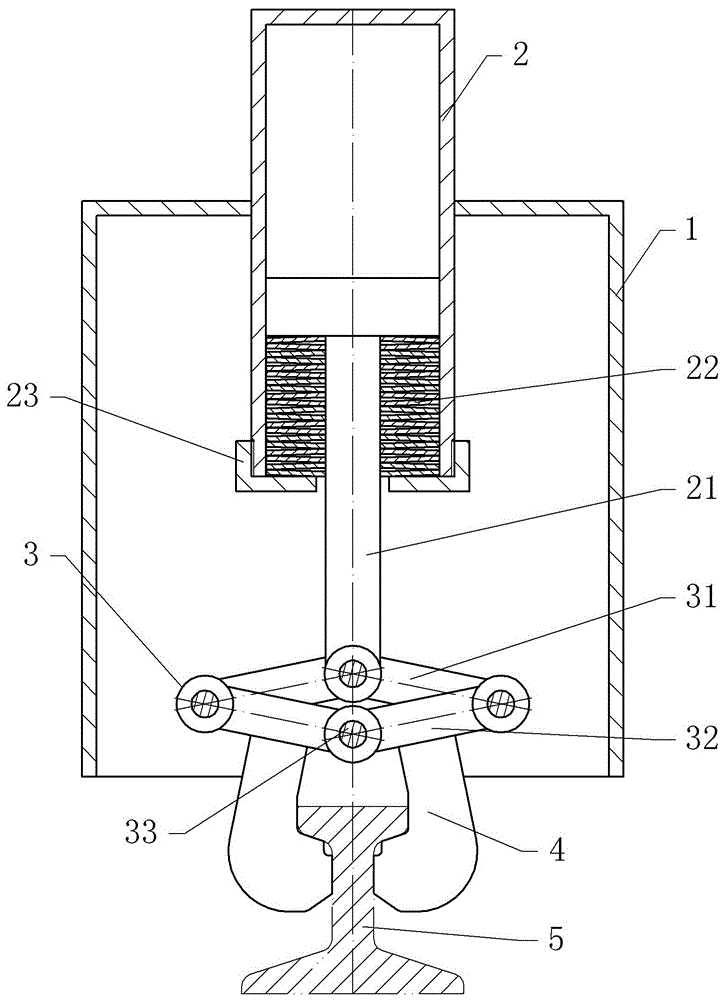

Brake device of roll-dividing machine

InactiveCN106050986AEasy to hideImprove braking effectCombination drum brakesArticle deliveryHydraulic cylinderControl engineering

The invention discloses a brake device of a roll-dividing machine, and relates to the brake device. The brake device of the roll-dividing machine comprises a supporting frame, brake calipers and a hydraulic cylinder, wherein a cylinder body of the hydraulic cylinder is fixed to the supporting frame; the brake calipers are arranged on the left side and the right side of a track; a linkage mechanism is arranged below the hydraulic cylinder; a push rod is fixed to the lower end of a piston of the hydraulic cylinder; the linkage mechanism is composed of a left portion and a right portion which are symmetrical, and the left portion and the right portion each comprise an upper connecting rod and a lower connecting rod of which one ends are hinged together; the other end of each upper connecting rod is hinged to the lower end of the push rod; the other end of each lower connecting rod is hinged through a fixing pin shaft which is fixed to the supporting frame; and the brake calipers are fixed to the middles of the lower connecting rods of the left portion and the right portion correspondingly. In the brake device of the roll-dividing machine, the linkage mechanism is of a multi-connecting-rod hinge structure, so that the structure and force transmission are more stable. The linkage mechanism is a parallelogram mechanism and has a high gain effect, so that the braking effect is improved.

Owner:重庆敏驰塑胶有限公司

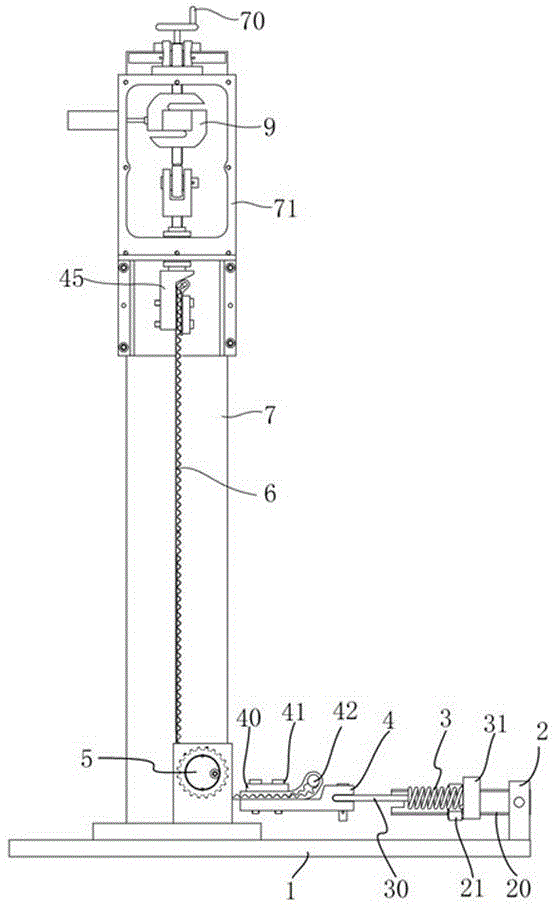

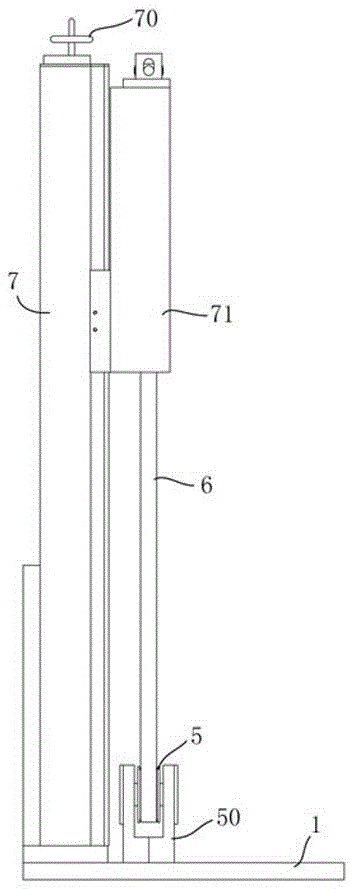

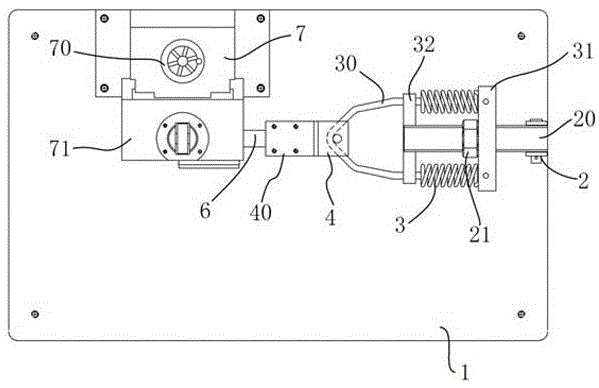

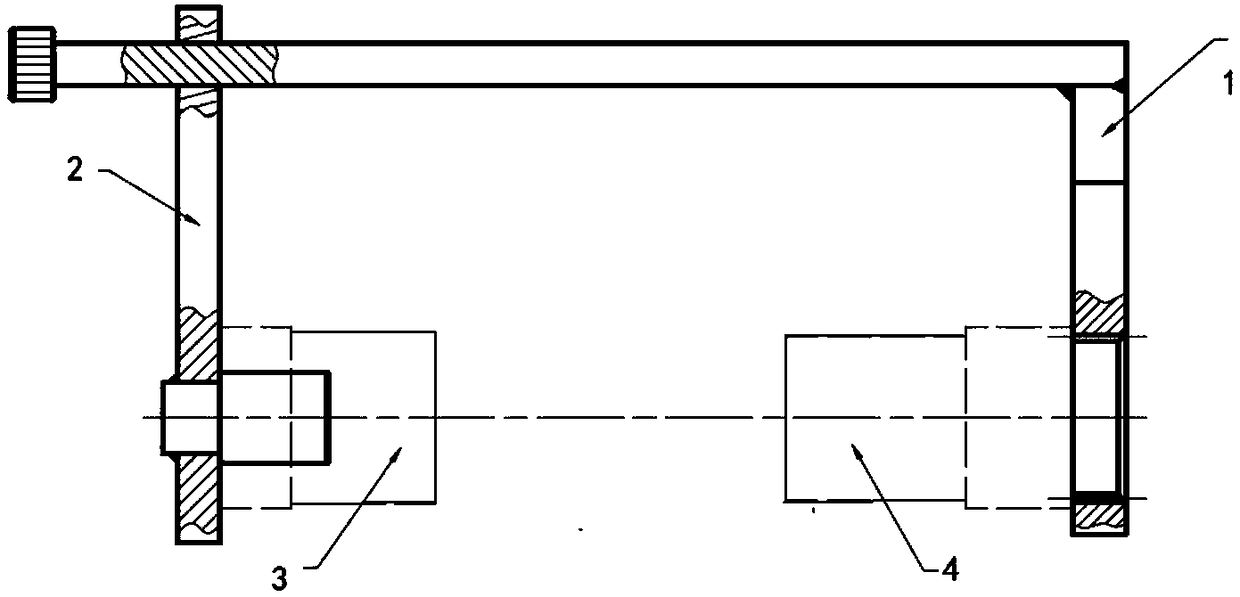

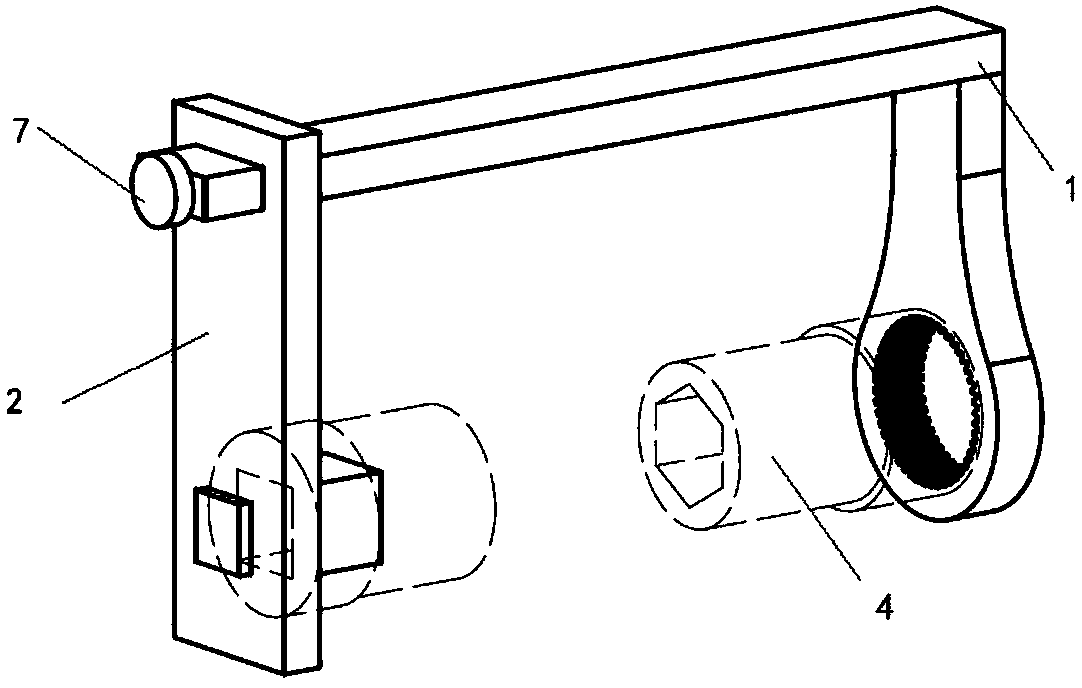

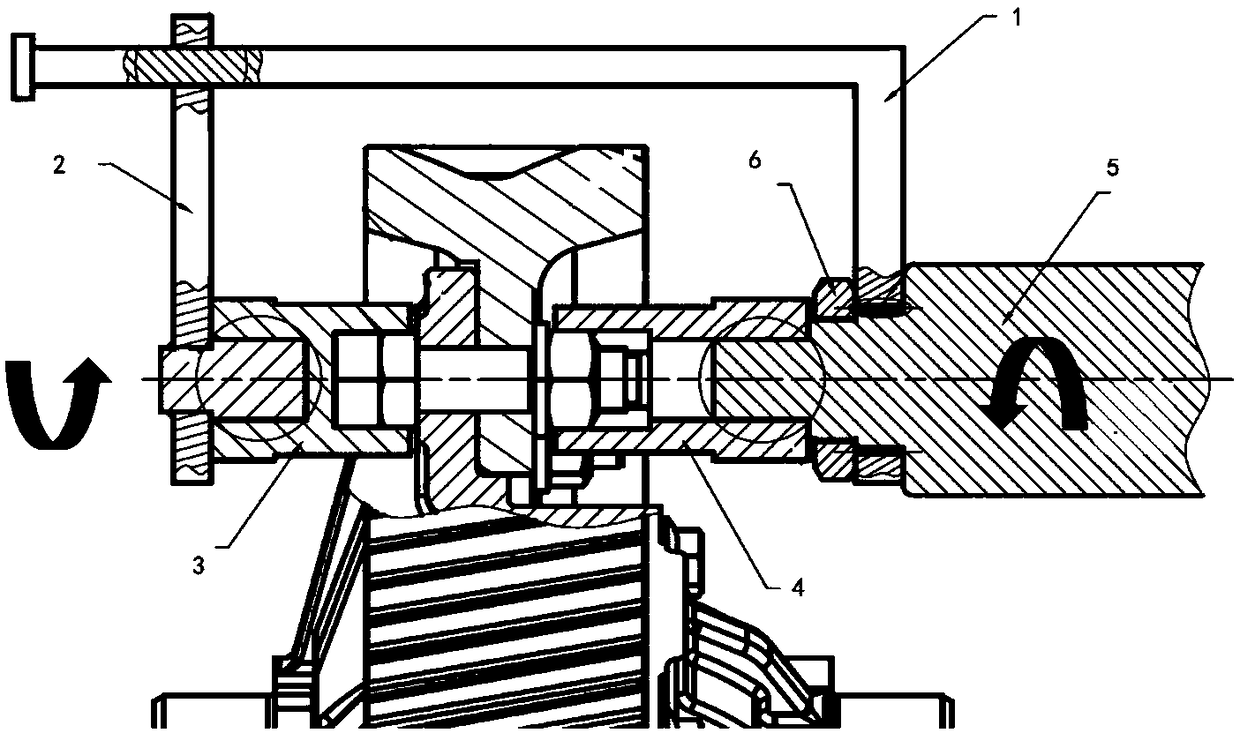

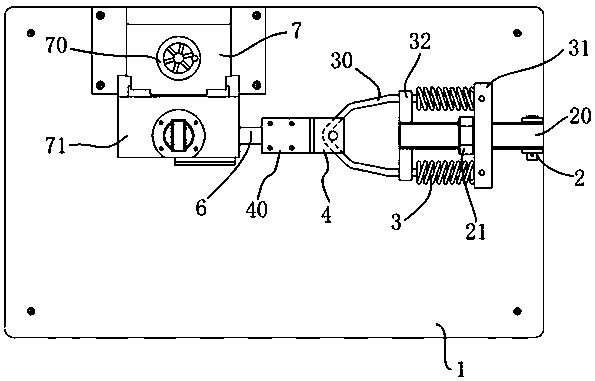

Belt tension meter calibration device

ActiveCN105606302AReliable connectionStable force transmissionForce/torque/work measurement apparatus calibration/testingEngineeringMechanical engineering

The invention provides a belt tension meter calibration device. The belt tension meter calibration device comprises a base and a belt, wherein the first end of the belt is connected on the base by a buffer spring, a tightening mechanism is arranged on the base for driving the second end of the belt to tighten or loose the belt, and the second end of the belt is in transmission connection with the mobile output end of the tightening mechanism by a tension sensor; the first end of the belt is connected with the base by the buffer spring, in this way, the first end of the belt can be displaced under the elastic buffering action of the buffer spring when a tension meter is clamped on the belt and the belt is suffered from lateral pressure applied by the tension meter, and the above displacement can eliminate the extrusion deformation of the belt itself, therefore, the belt tension detection accuracy of the belt tension meter and the calibration precision of the belt tension meter are further improved.

Owner:HENAN PROVINCE INST OF METROLOGY +1

Mounting tool for bolt and nut assembly

PendingCN108312101AReduce labor intensityIncrease productivityWork holdersPower driven toolsEngineeringSlide plate

The invention discloses a mounting tool for a bolt and nut assembly. The mounting tool comprises an L-shaped plate, a sliding plate, bolt sleeves and nut sleeves. One end of the L-shaped plate is sleeved with one end of the sliding plate. The sliding plate and the L-shaped plate form an inverted concave shape, and the sliding plate can slide on the L-shaped plate. The bolt sleeves are vertically arranged at the other end of the sliding plate. The nut sleeves are vertically arranged at the other end of the L-shaped plate. The bolt sleeves and the nut sleeves are oppositely arranged. According to the mounting tool for the bolt and nut assembly, the bolt sleeves are correspondingly arranged at both ends of the tool, the sleeve at one end is fixed, and the sleeve at the other end is connectedwith an electric torque fixing tool, so that the problem that bolts and nuts rotate at the same time in the tightening process is solved, and the fastening requirement is met.

Owner:XIAN FASHITE AUTOMOBILE TRANSMISSION CO LTD

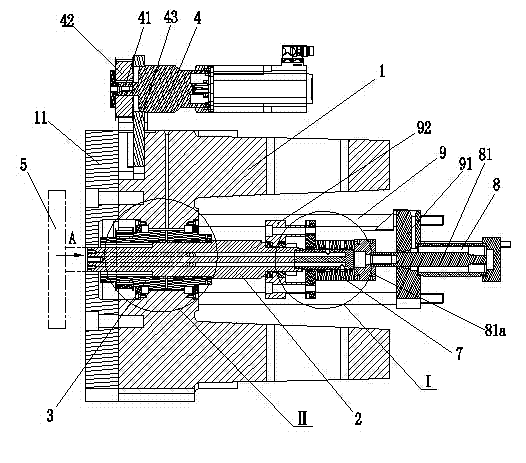

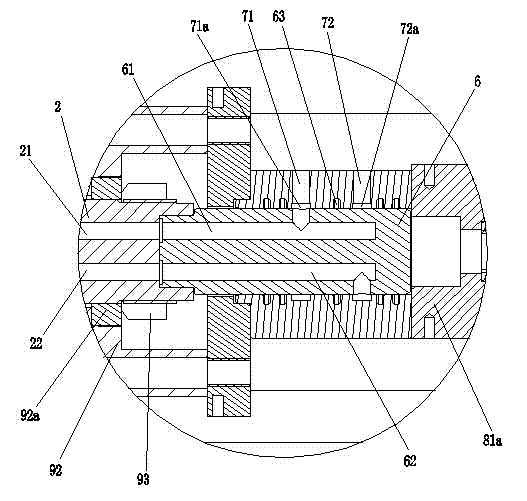

Clamping mechanism of injection molding machine

The invention discloses a clamping mechanism of an injection molding machine. The clamping mechanism comprises a movable wall and a movable wall backing plate covering the movable wall; a linear motion axis and a rotation motion axis in spline fit are arranged in the movable wall; the rotation motion axis is in rotation connection with a servo motor drive; one end of the linear motion axis is in cooperative connection with a mold rotation core, and the other end is in cooperative connection with a rotating shaft connecting rod; a water jacket sleeves outside the rotating shaft connecting rod; the rear end of the water jacket cooperates with an adapter at the front of a demoulding piston rod controlled by a demoulding cylinder group; the water jacket is provided with a water inlet and a water outlet; the water inlet communicates with a water inlet pathway on the linear motion axis through an annular water inlet groove and a water inlet connection hole on the rotating shaft connecting rod; the water outlet communicates with a water outlet pathway on the linear motion axis through an annular water outlet groove and a water outlet connecting hole on the rotating shaft connecting rod; and the water inlet pathway and the water outlet pathway communicate with the rotation core. The invention has the advantages of reasonable and compact structure, good cooling effect and high machining efficiency.

Owner:富强鑫(宁波)机器制造有限公司

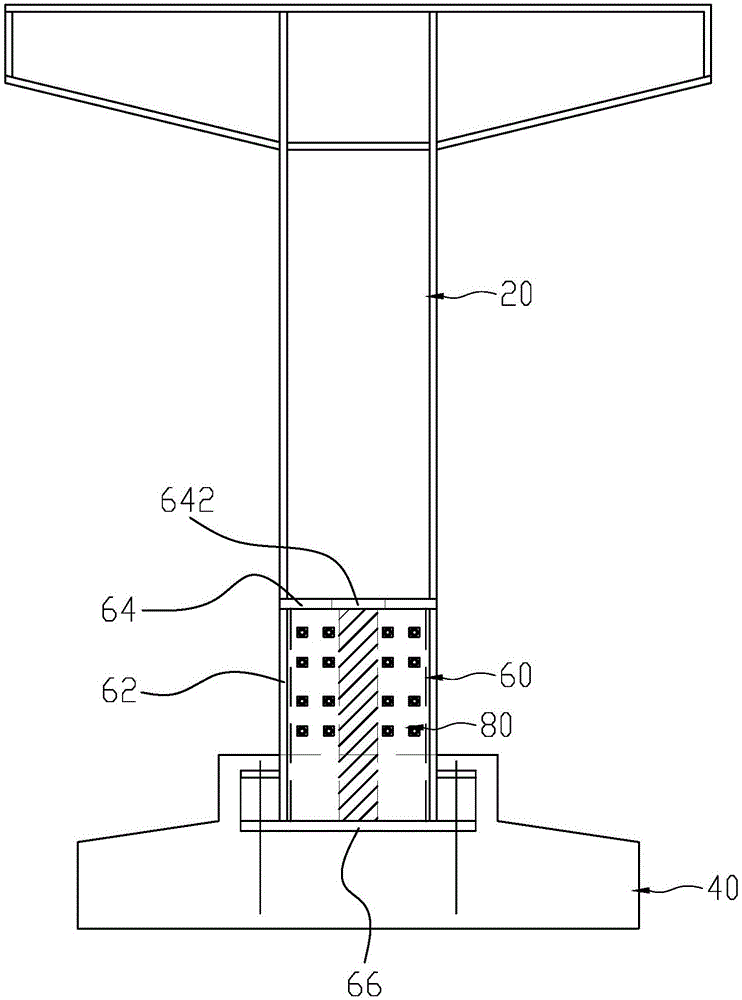

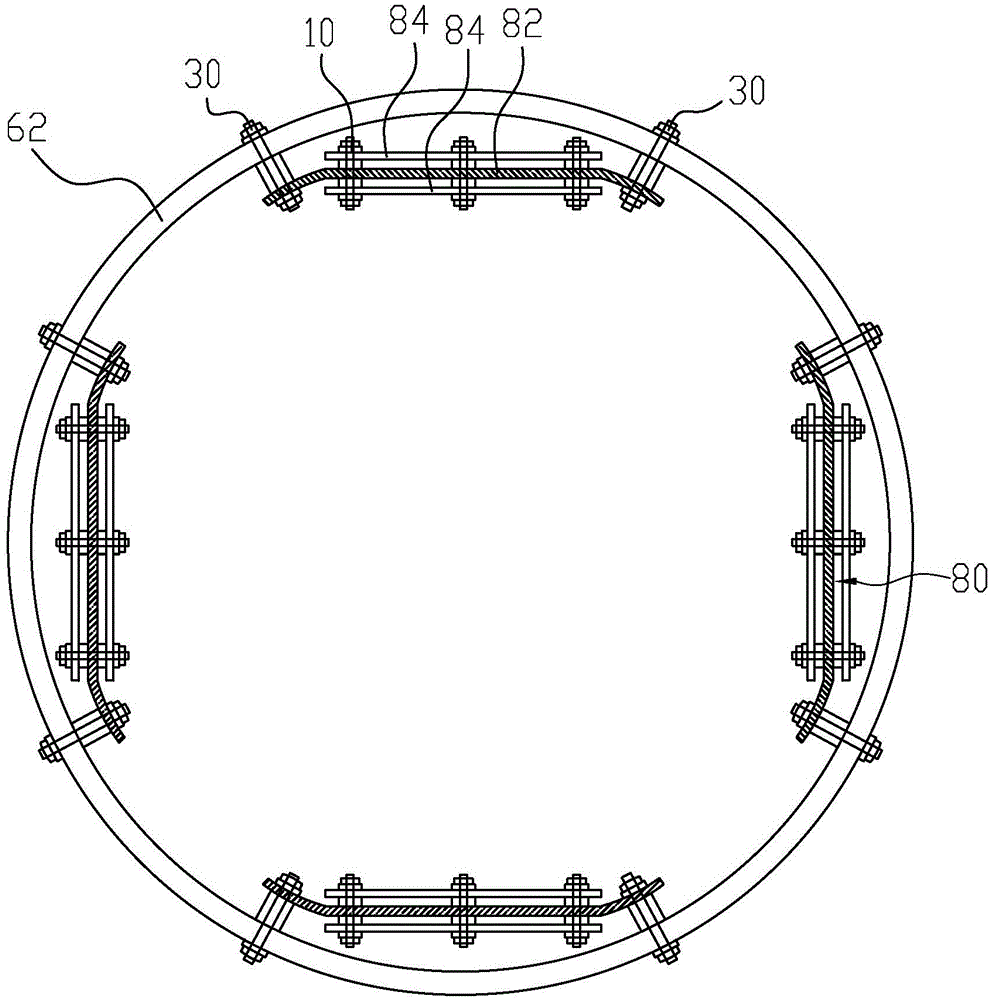

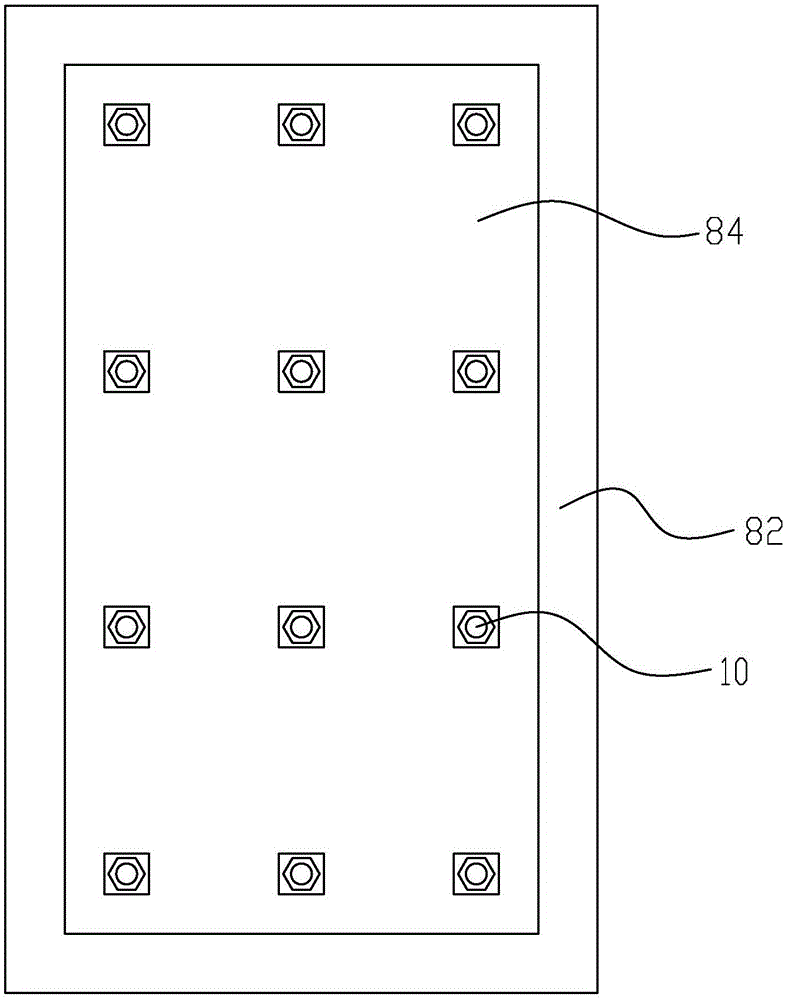

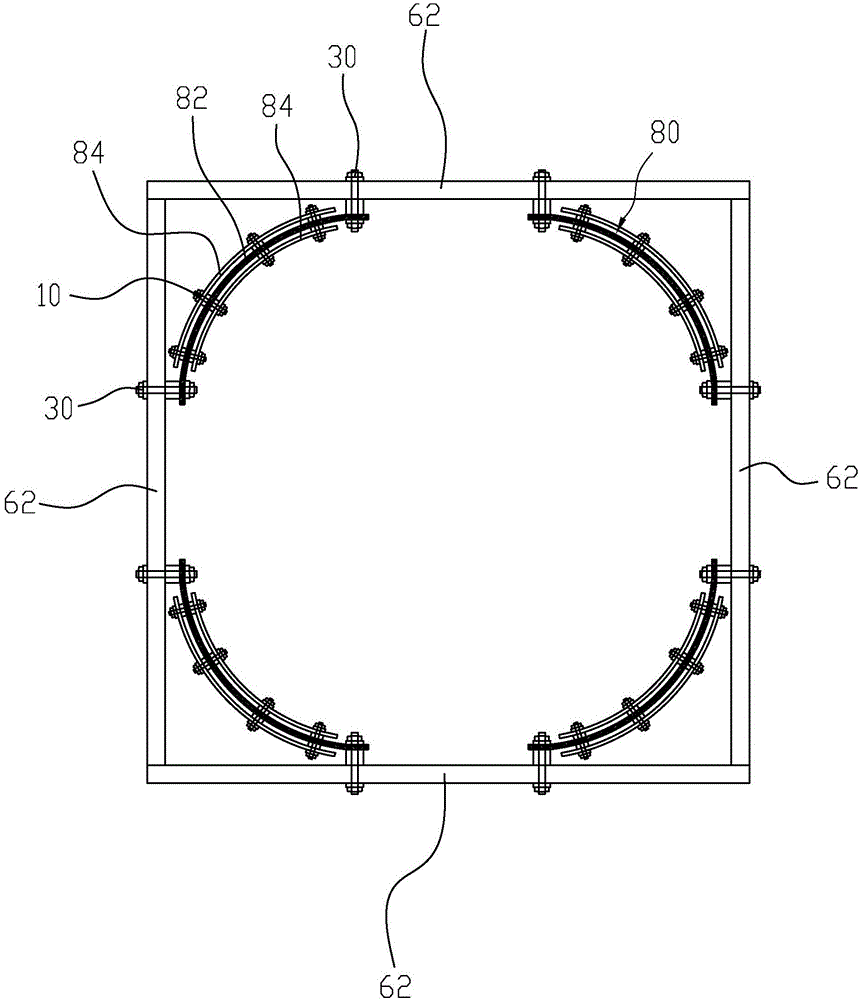

Method for arranging anti-buckling energy dissipation structures at root portion and circular steel tube pier

ActiveCN105019353APrevents bucklingGuaranteed shear compression yield energy dissipationBridge structural detailsBridge materialsSheet steelEngineering

The invention discloses a method for arranging anti-buckling energy dissipation structures at the root portion and a circular steel tube pier. The circular steel tube pier comprises an upper pier, a base and a lower pier which connects the upper pier with the base, the lower pier comprises an outer wall of a cylindrical structure, the outer wall is enclosed by high-strength steel plates, the inner portion of the outer wall is provided with the multiple anti-buckling energy dissipation structures, the anti-buckling energy dissipation structures are arranged in an annular array mode, each anti-buckling energy dissipation structure is composed of three layers of steel plates, the middle layer is an arc-shaped low yield point steel plate, the inner layer and the outer layer are arc-shaped steel shell plates, the arc-shaped steel shell plates and the arc-shaped low yield point steel plate are connected through bolts, and the two sides of the anti-buckling energy dissipation structure are connected with the two high-strength steel plates respectively through high-strength bolts. By means of the arc-shaped steel shell plates, the arc-shaped low yield point steel plate can be prevented from out-of-plane flexural buckling, the shear compression yield energy dissipation of the arc-shaped low yield point steel plate is guaranteed, and therefore the ductility, energy-dissipating capacity and seismic performance of the circular steel tube pier are improved.

Owner:HUAQIAO UNIVERSITY

Compact non-electric medicament infuser

ActiveUS9895487B2Stable force transmissionEasily attached to patientAutomatic syringesFiltering accessoriesMedication injectionVIAL ADAPTER

Owner:DUNCAN DAVID R

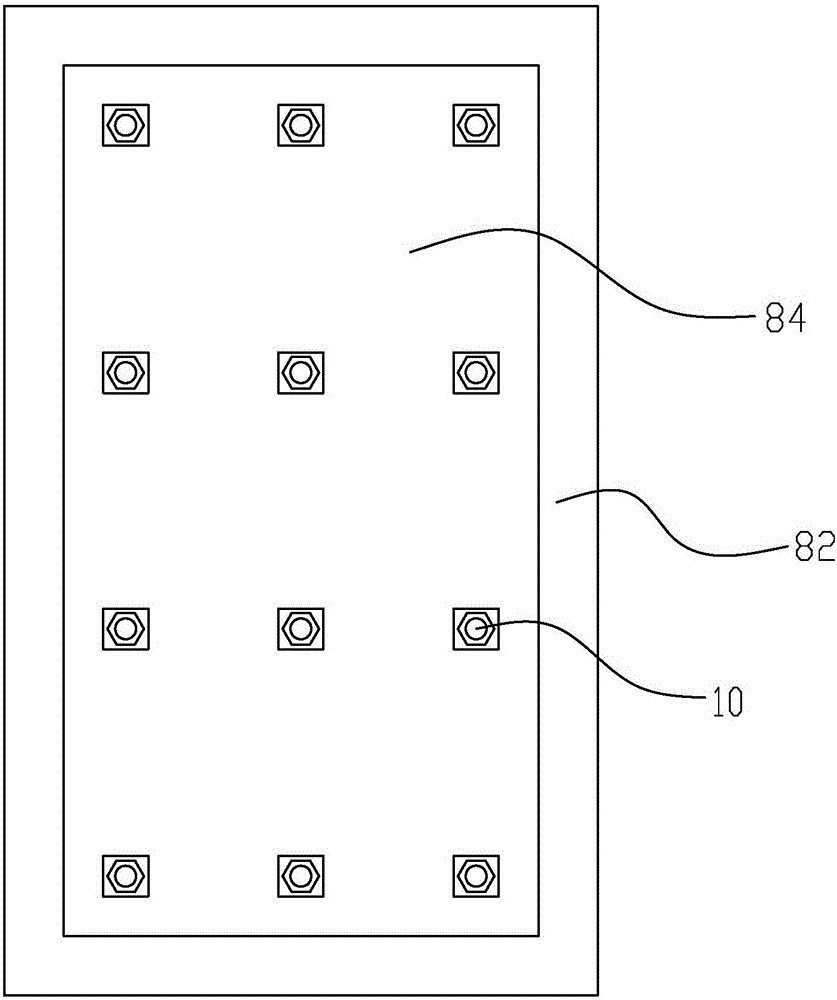

Method for arranging anti-buckling energy dissipation structures at root portion and box steel pier

ActiveCN105019352AQuick Repair Seismic AbilityGuarantee unimpededBridge structural detailsSheet steelHigh intensity

The invention discloses a method for arranging anti-buckling energy dissipation structures at the root portion and a box steel pier. The box steel pier comprises an upper pier, a base and a lower pier which connects the upper pier with the base, the lower pier comprises a square outer wall of a cylindrical structure, the outer wall is enclosed by four high-strength steel plates, the inner portion of the outer wall is provided with the anti-buckling energy dissipation structures between the two high-strength steel plates (namely at the four corners of the lower pier) which are connected perpendicularly, each anti-buckling energy dissipation structure is composed of three layers of steel plates, the middle layer is an arc-shaped low yield point steel plate, the inner layer and the outer layer are arc-shaped steel shell plates, the arc-shaped steel shell plates and the arc-shaped low yield point steel plate are connected through bolts, and the two sides of the anti-buckling energy dissipation structure are connected with the two high-strength steel plates respectively through high-strength bolts. By means of the arc-shaped steel shell plates, the arc-shaped low yield point steel plate can be prevented from out-of-plane flexural buckling, the shear compression yield energy dissipation of the arc-shaped low yield point steel plate is guaranteed, and therefore the ductility, energy-dissipating capacity and seismic performance of the box steel pier are improved.

Owner:HUAQIAO UNIVERSITY +1

Catching tool for baseball or softball

Owner:MIZUNO CORPORATION

Rope transmission mechanism and rope transmission mechanism of manipulator

ActiveCN113043259AIncrease the selected diameterEasy maintenanceProgramme-controlled manipulatorEngineeringWire rope

The invention provides a rope transmission mechanism. The rope transmission mechanism comprises a steel wire rope, a connecting device and a tensioning device, wherein the steel wire rope is sequentially wound on a driving wheel and a driven wheel in a certain direction and forms a steel wire ring; the driving wheel pulls the driven wheel to rotate through the steel wire rope; the connecting device comprises a driving wheel connecting device and driven wheel connecting devices; the driving wheel connecting device is arranged on the driving wheel and connects the driving wheel and the steel wire rope; the driven wheel connecting devices are arranged on the driven wheel and connect the driven wheel and the steel wire rope; and the tensioning device is arranged between the driving wheel and the driven wheel and connected with the steel wire rope and is used for tensioning the steel wire rope. According to the single-rope transmission in the embodiment of the invention, on the premise of a narrow installation space, the space utilization rate is increased, and the selected diameter of the rope is increased, so that the transmission rigidity is improved. The continuous tensioning mechanism is convenient to adjust, the upper section and the lower section of the steel wire rope are effectively and synchronously tensioned, and movement coordination and force transmission stability are guaranteed.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Belt Tension Meter Calibration Device

ActiveCN105606302BStable force transmissionForce/torque/work measurement apparatus calibration/testingPull forceEngineering

The invention provides a belt tension meter calibration device, which includes a base and a belt. The first end of the belt is connected to the base through a buffer spring, and the base is also provided with a tensioner for pulling the second end of the belt to tension or loosen the belt. mechanism, the second end of the belt is connected in drive with the moving output end of the tensioning mechanism through a tension sensor. The first end of the belt is connected to the base through the buffer spring, so when the tension gauge is stuck on the belt and the belt is subjected to the lateral pressure of the tension gauge, the first end of the belt will have a certain displacement under the elastic buffering effect of the buffer spring , this part of the displacement eliminates the extrusion deformation of the belt itself, which further improves the accuracy of the belt tension detected by the tension gauge, thereby improving the calibration accuracy of the belt tension gauge.

Owner:HENAN PROVINCE INST OF METROLOGY +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com