Unpowered roller for conveying

A roller and power technology, applied in the field of non-powered rollers, can solve problems such as difficulty in improving work efficiency and inconvenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention is not limited by the following examples, and specific implementation methods can be determined according to the technical solutions of the present invention and actual conditions.

[0020] Below in conjunction with embodiment and accompanying drawing, the present invention will be further described:

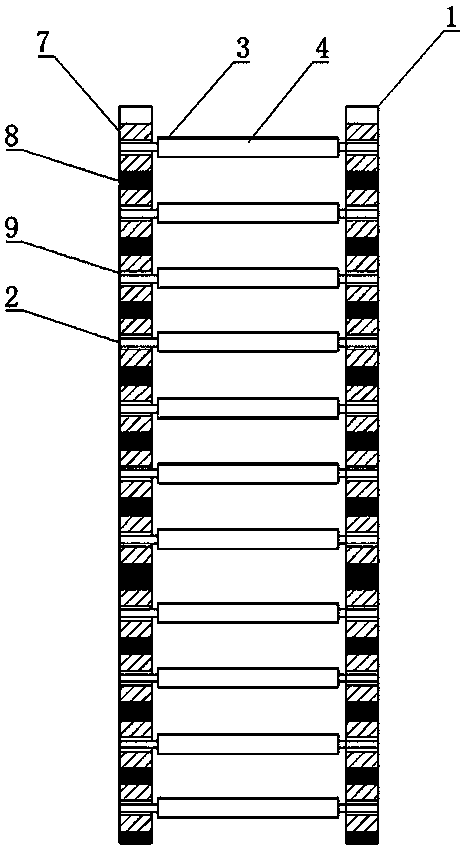

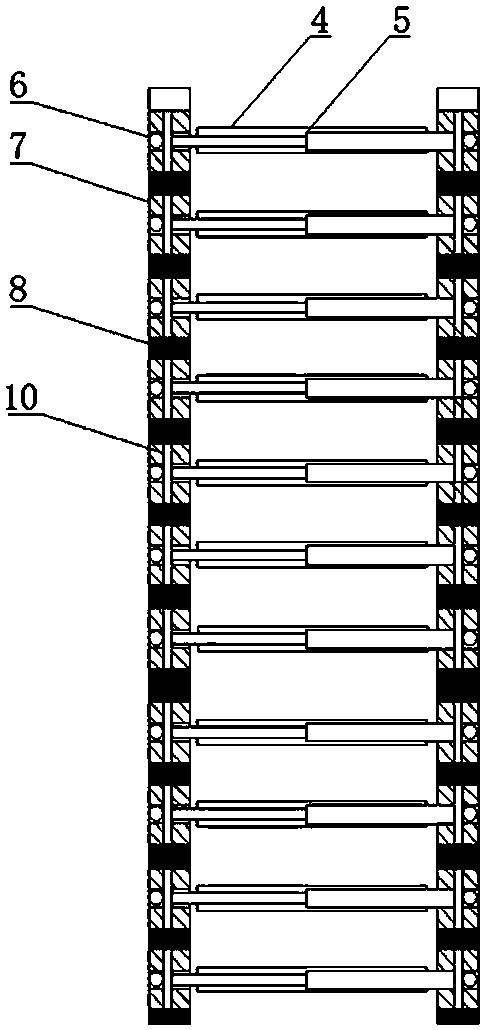

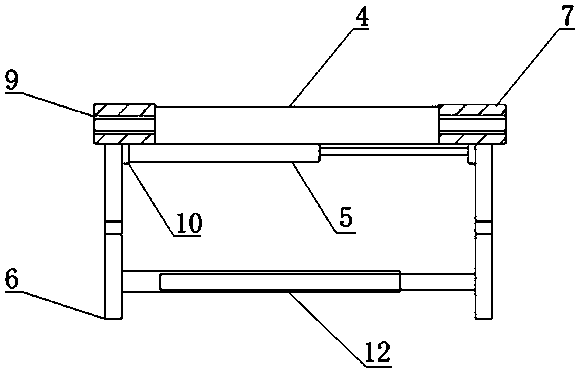

[0021] Such as figure 1 , 2 , 3, 4, 5, 6, 7, 8, a kind of unpowered roller for conveying, including a long arm horizontal frame 1, a rotating shaft 2, a roller 4 with a casing 3, a horizontal hydraulic device 5, a vertical To the hydraulic device 6, the long arm cross frame 1 includes a fixed block 7 and a flexible connection device 8 between the two fixed blocks 7, the fixed block 7 is fixedly connected to the flexible connection device 8, and the two ends of the rotating shaft 2 pass through The bearing 9 is installed on the fixed block 7, and the roller 4 is fixedly installed on the rotating shaft 2. The roller 4 includes a left half roller 41 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com