Mounting tool for bolt and nut assembly

A technology for installing tooling and bolts and nuts, which is applied in the field of installing tooling for bolt and nut assemblies, can solve the problems of high labor intensity, difficult to guarantee product quality, poor universality of tooling, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is further described below in conjunction with accompanying drawing:

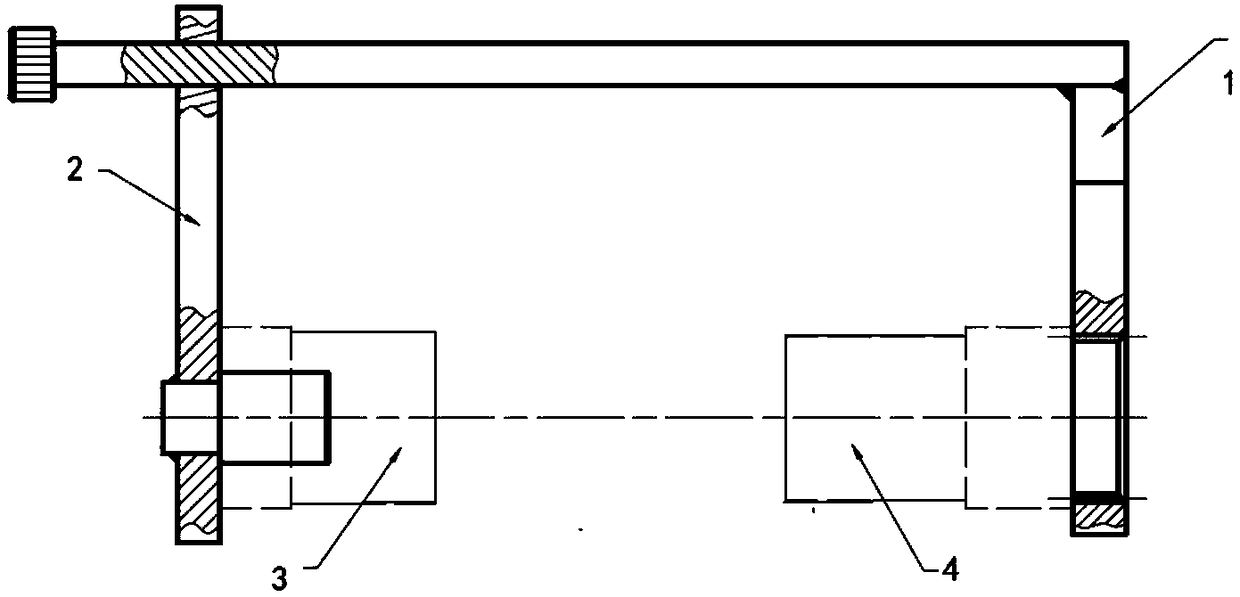

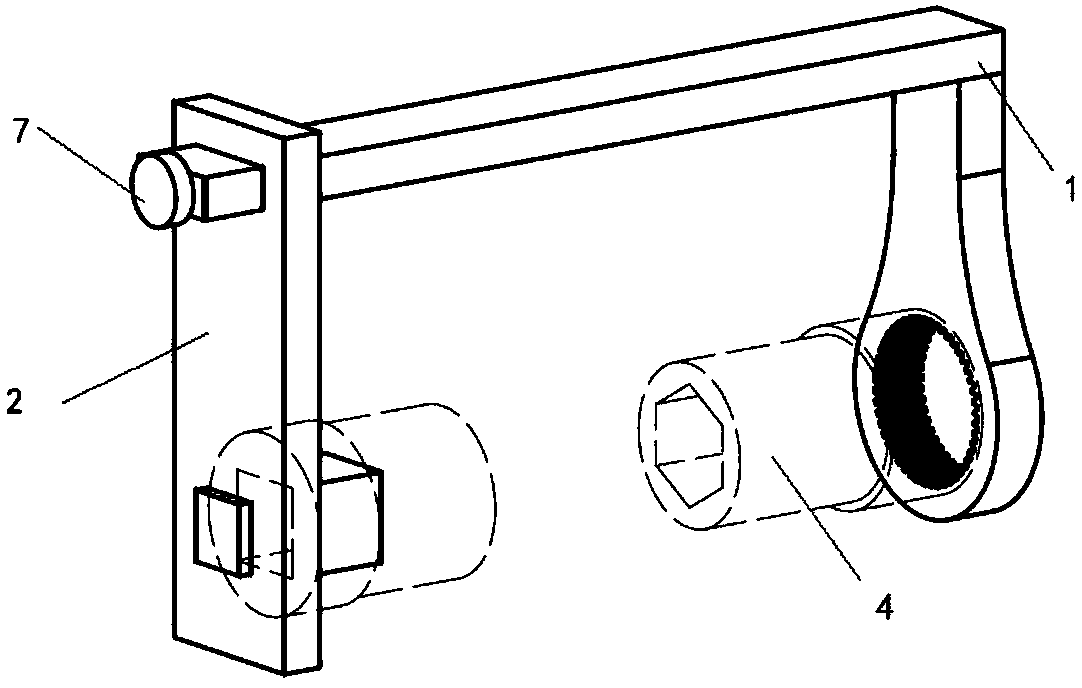

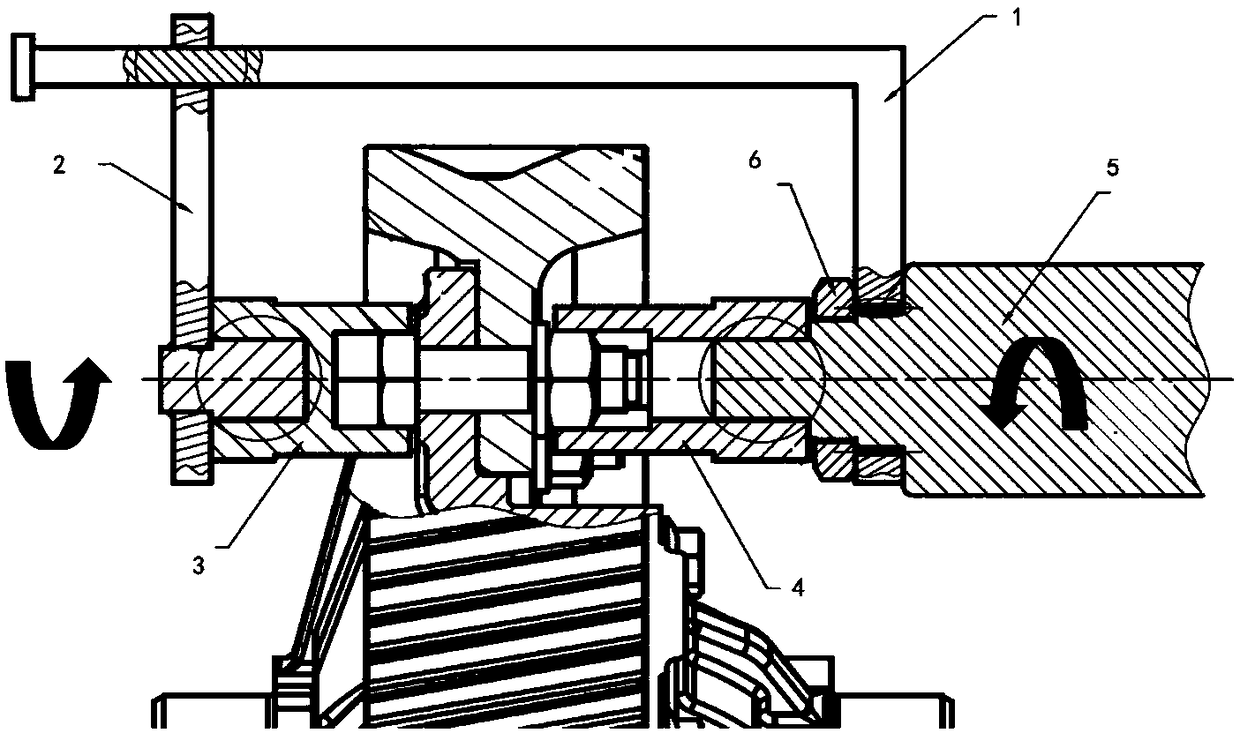

[0025] see Figure 1-Figure 3 , a bolt and nut assembly installation tooling, including L-shaped plate 1, sliding plate 2, bolt sleeve 3 and nut sleeve 4; one end of sliding plate 2 is sleeved on one end of L-shaped plate 1, sliding plate 2 and L The shaped plate 1 forms an inverted concave shape, and the sliding plate 2 can slide on the L-shaped plate 1;

[0026] The other end of the sliding plate 2 is vertically provided with a bolt sleeve 3, and the other end of the L-shaped plate 1 is vertically provided with a nut sleeve 4, and the bolt sleeve 3 and the nut sleeve 4 are arranged oppositely.

[0027] The other end of sliding plate 2 is provided with square hole, and square hole is provided with regular prism, and one end of bolt sleeve 3 is provided with the square hole that matches with regular prism, and bolt sleeve 3 is set on the regular prism; 3 The other end matches ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com