Belt tension meter calibration device

A belt tension and calibration device technology, applied in the direction of measurement device, force/torque/work measuring instrument calibration/test, instrument, etc., can solve the problems of inability to calibrate the tension meter, error, etc., and achieve the effect of reliable connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

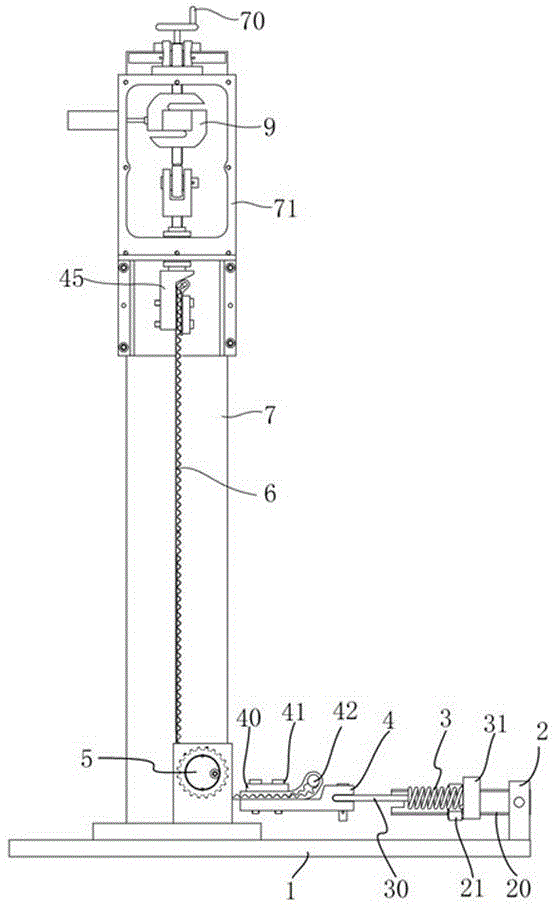

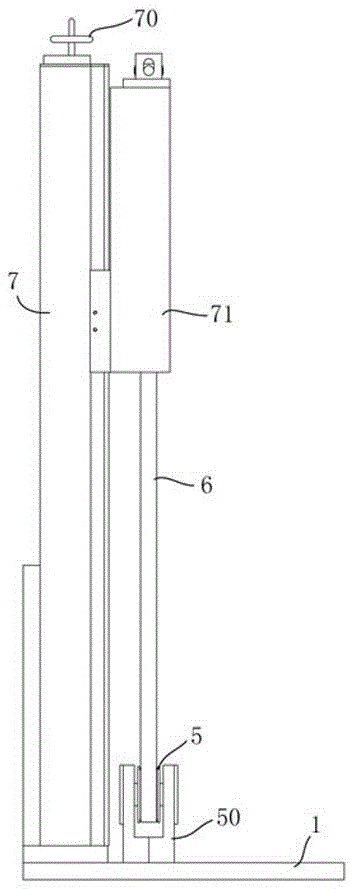

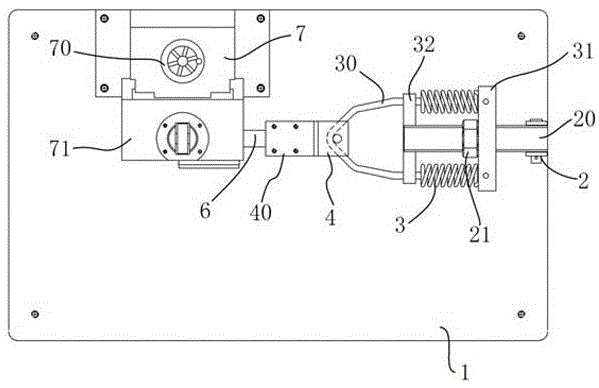

[0015] The embodiment of belt tensiometer calibration device of the present invention: as Figure 1-3 As shown, it includes a base 1 and a belt 6 installed on the base 1 . The base 1 is provided with a tensioning mechanism 7. When the belt 6 is installed on the base 1, the first end of the belt is connected to the base 1 through the buffer spring 3, and the tensioning mechanism 7 pulls the second end of the belt 6 to stretch the belt 6. tight.

[0016] The second end of the belt is connected with the tensioning mechanism 7 through a tension sensor 9 . When the belt 6 is tensioned by the tensioning mechanism, the tension sensor 9 can detect the pulling force of the belt so as to compare with the detection value of the belt tension meter, so as to realize the calibration of the belt tension meter. In this embodiment, the tension mechanism 7 is a screw nut mechanism vertically arranged on the base 1, the screw of the screw nut mechanism is fixed in the vertical direction and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com