Slow descending and damping device and slow descending and damping method for toilet

A damping device and slow-down technology, applied in the field of damping devices, can solve problems such as complex structure, poor slow-down effect, poor use effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

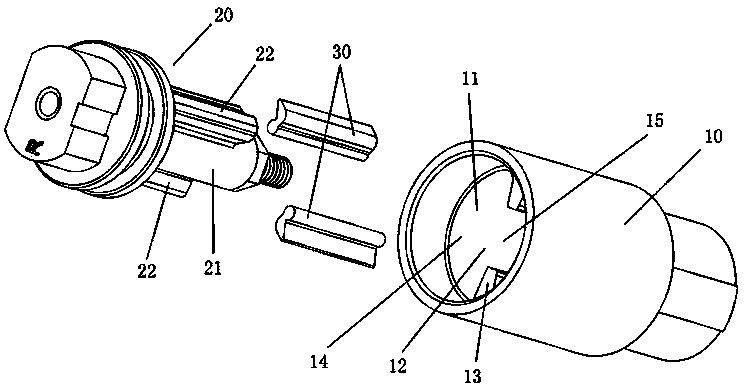

[0054] Such as Figure 1 to 9 As shown, a slow-down damping device for a toilet includes a housing 10, a rotating shaft 20, and a damping control generating unit 30.

[0055] The housing 10 has an inner surface 11 and is surrounded by the inner surface 11 to form a housing cavity 12, and two housing ribs 13 protrude inward from the inner surface 11 of the housing 10.

[0056] The housing cavity 12 of the housing 10 is divided into a first housing cavity 14 and a second housing cavity 15 by means of two housing ribs 13.

[0057] The rotating shaft 20 is rotatably inserted into the housing cavity 12 of the housing 10. The rotating shaft 20 includes a shaft 21 and two connecting units 22, and the two connecting units 22 are fixedly arranged on the outer edge surface of the shaft 21 .

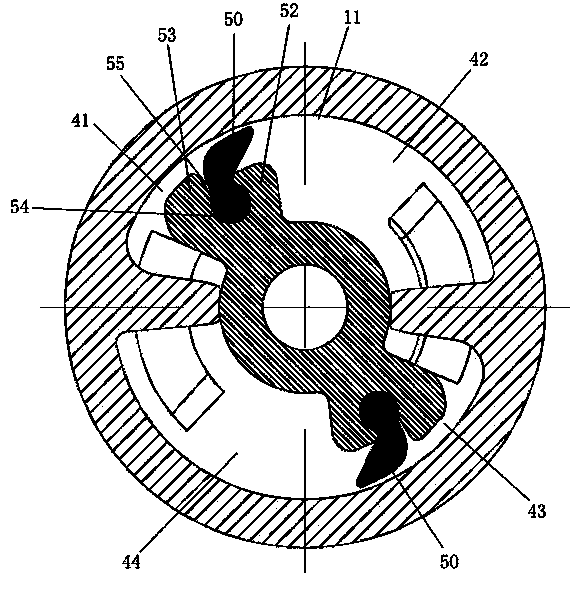

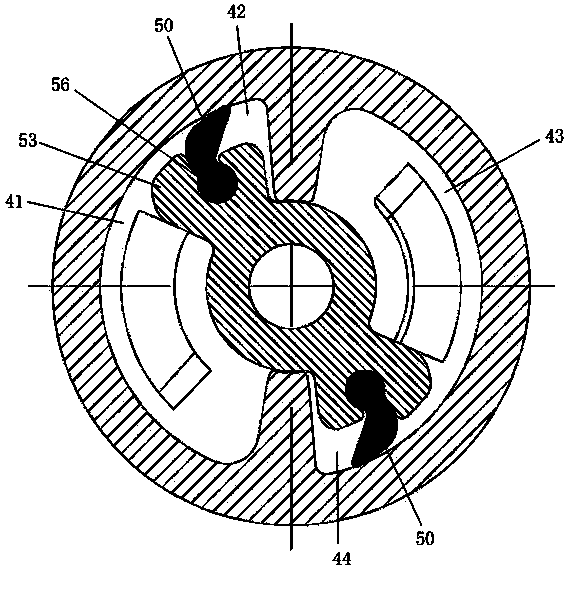

[0058] The damping control generating unit 30 is respectively movably connected to the two connecting units 22, and the first housing cavity 14 is divided into a first opening cavity 41 and a first coverin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com